Worm Gearbox

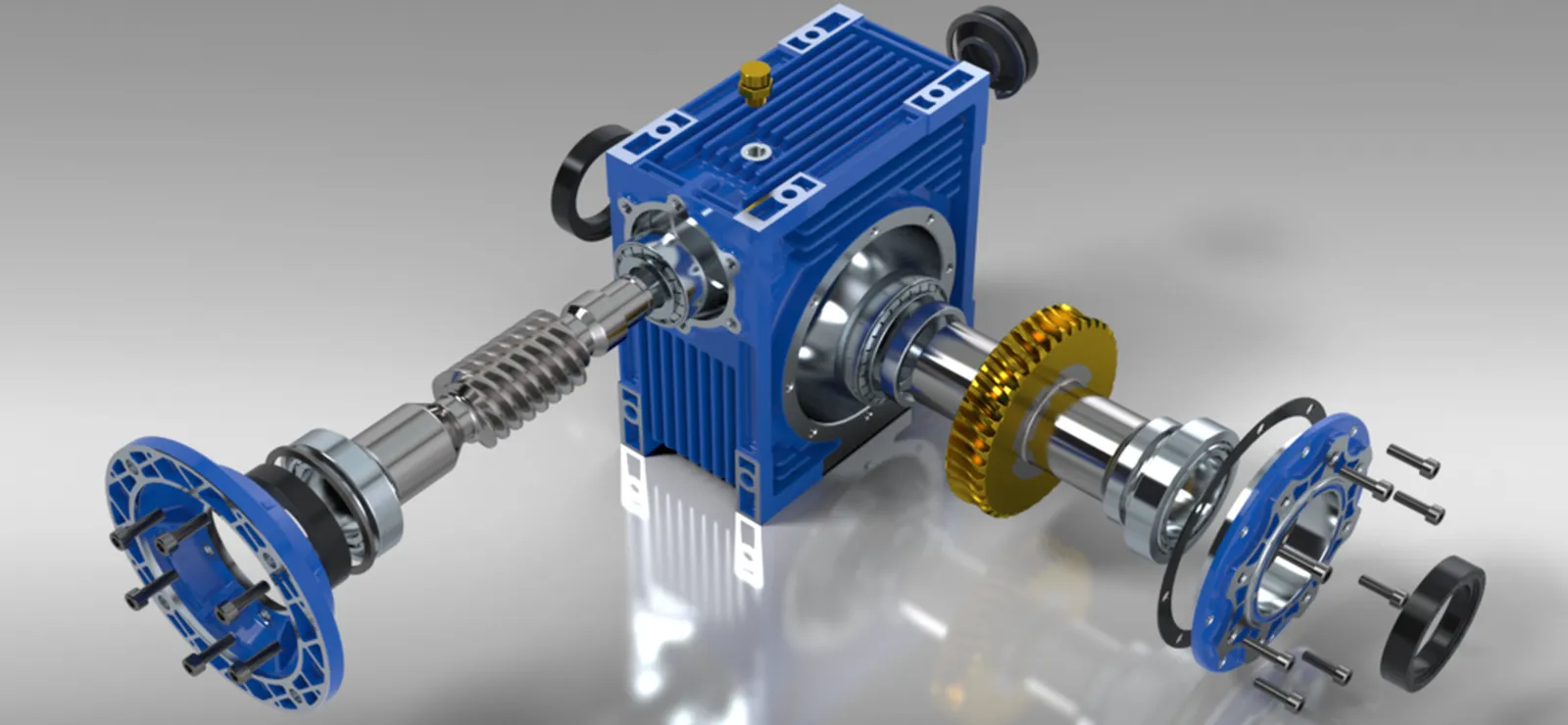

A worm gearbox, also known as a worm gear reducer or worm drive gearbox. That is a type of mechanical power transmission device. That enables the transfer of rotational motion. And power between two non-intersecting shafts at right angles to each other. It consists of two primary components: the worm gear and the worm wheel. The working principle of a worm gearbox is based on the interaction between two key components: the worm gear and the worm wheel.

Worm Gearbox Types

The VF series worm gear reducer is lightweight, ideal for compact applications. The JDLB series high precision low backlash worm gearbox offers low backlash for servo-driven systems, ensuring accuracy in robotics and automation. Each type balances torque, speed, and durability for diverse industrial needs.

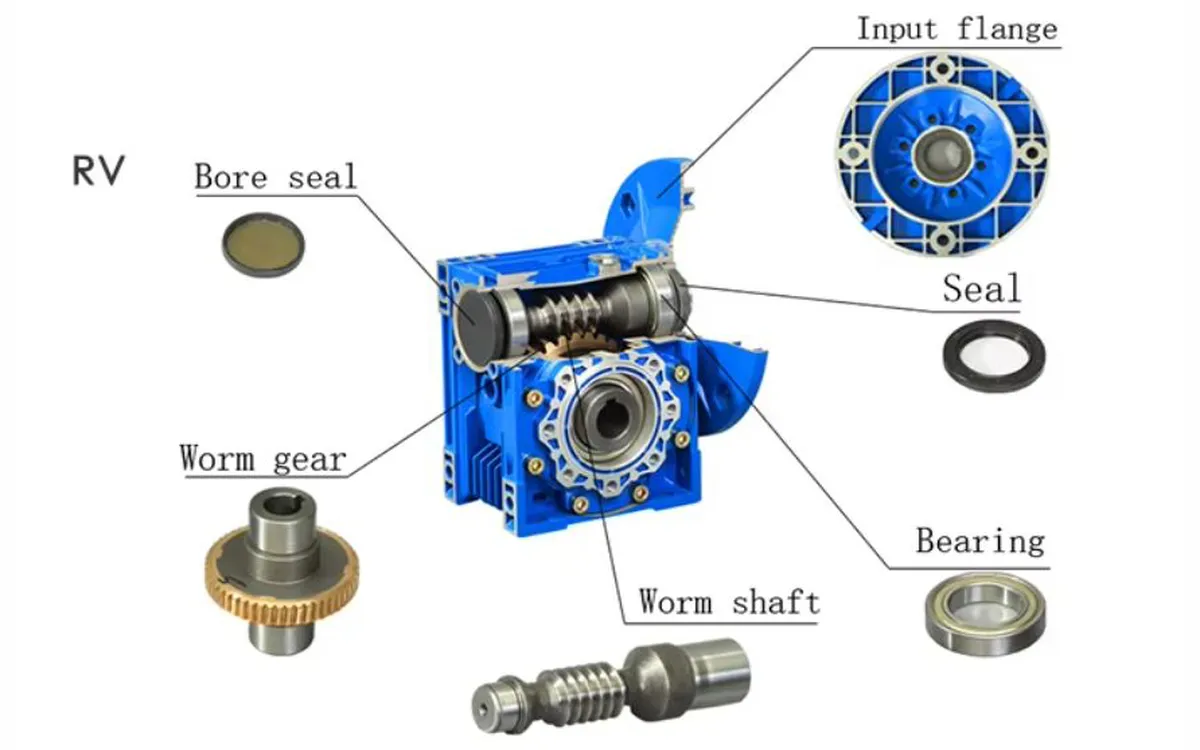

RV Series Worm Gearbox

WP Series Worm Gearbox

SWL Series Screw Jack

UDL Series Stepless Speed Variator

JDLB Series High Precision Worm Gearbox

VF Series Worm Gear Reducer

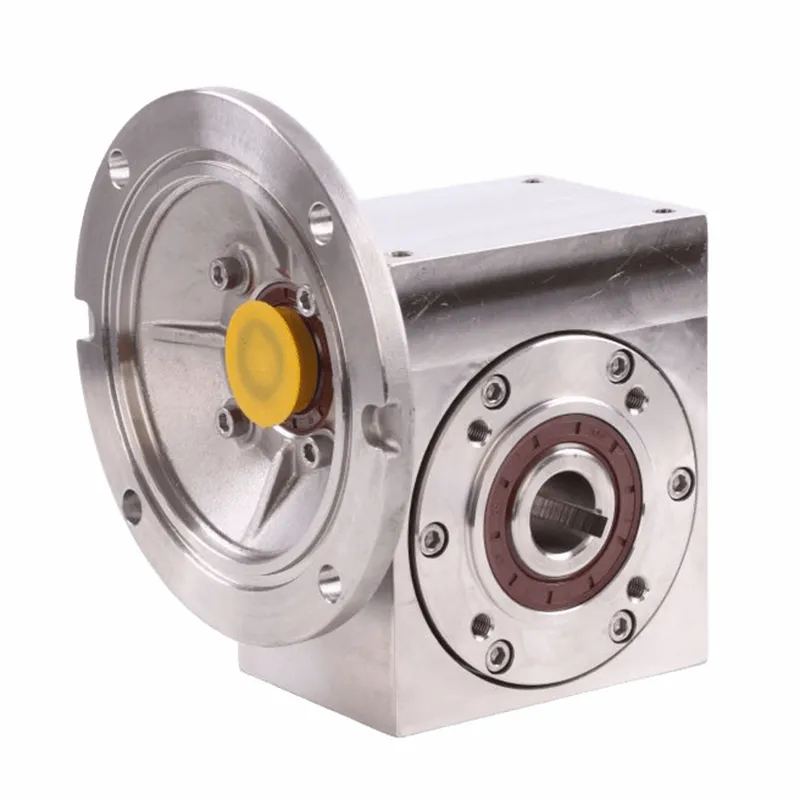

Stainless Steel Worm Gear Reducer

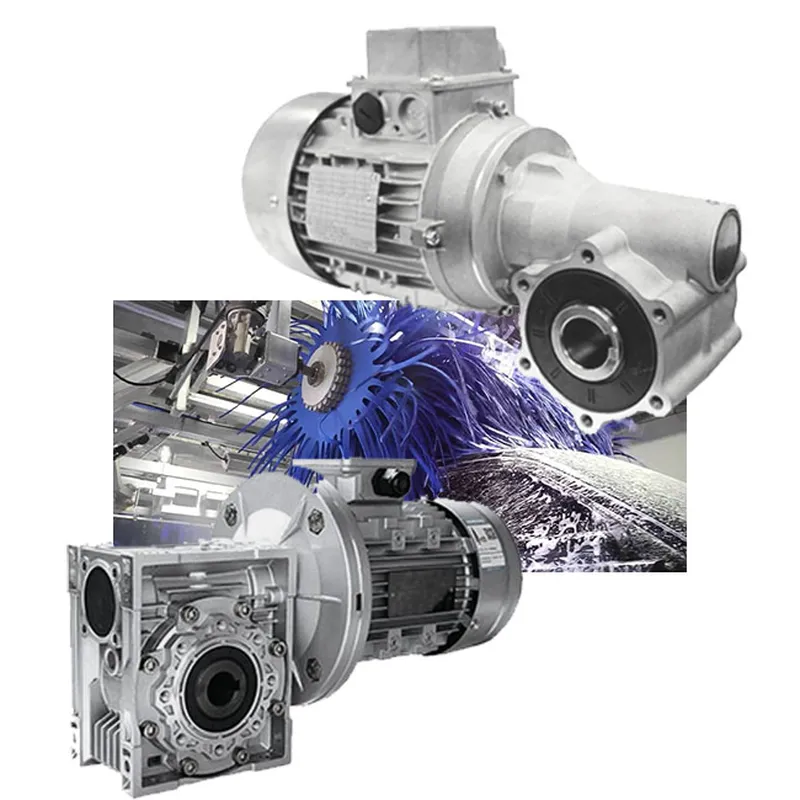

Worm Gearbox for Different Applications

Greenhouse Gear Motor for Automatic Sunshade System

Worm Gearbox for Automatic Car Washing Machine

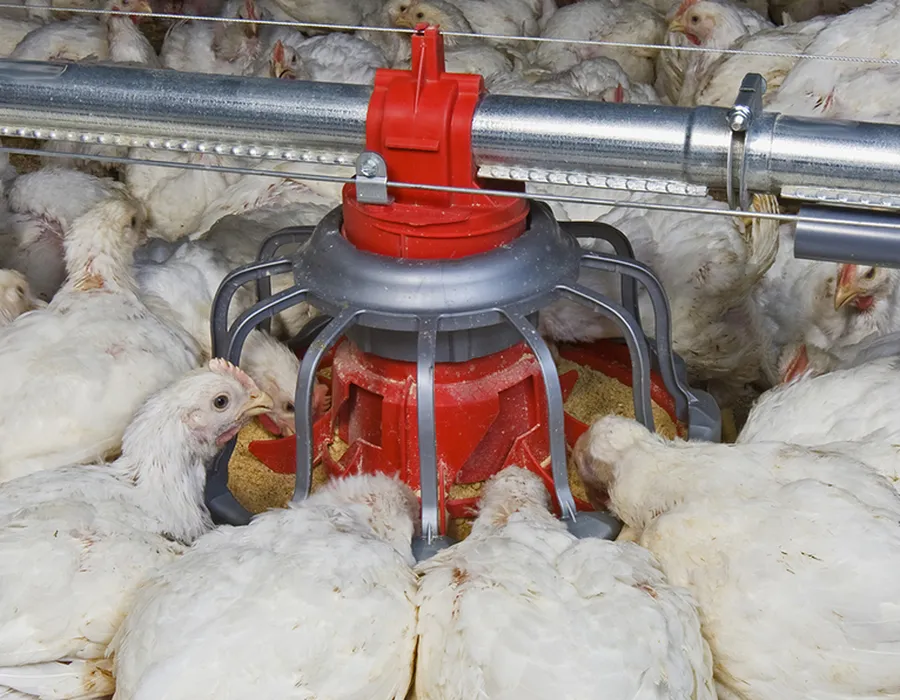

Worm Gearbox for Poultry Feeding System

What is a Worm Gear Reducer?

Worm gear reducer is referred to by several names, like worm gearbox, worm reduction gearbox, and worm drive gearbox. Its internal transmission structure is a worm gear system that consists of a worm and worm wheel; the worm drives the worm wheel. The whole structure of the worm gearbox is mainly composed of the worm and worm wheel, shaft, bearing, housing, and other accessories. Its function is to reduce the speed, increase the output torque, and change the direction of the output torque.

WP series and RV series are two common types of worm gearboxes, as well as our main products since our establishment. They are precision-engineered and manufactured, also rigorously tested before leaving our factory. Choose CMN Transmission to get a reliable and durable worm gearbox for your application and business.

Worm Drive Gearbox Features

(1) High Torque Output:

Worm gearboxes are specifically designed to deliver high torque output, making them ideal for applications that require the movement of heavy loads. Their efficient torque multiplication allows them to handle demanding industrial tasks effortlessly.

(2) Compact Design:

One of the standout features of worm gearboxes is their compact size. Despite being small, they can deliver significant power, making them suitable for applications where space is limited without compromising performance.

(3) Smooth and Quiet Operation:

Due to the sliding action between the worm gear and worm wheel, these gearboxes operate with minimal vibration and noise. This makes them ideal for environments like hospitals, offices, or residential areas where quiet operation is critical.

(4) Self-locking Capability:

Certain worm gearbox configurations exhibit self-locking properties, meaning the system prevents reverse motion. This adds an essential safety feature, particularly in applications like lifts, hoists, and conveyors, where back-driving could lead to accidents.

(5) Durability and Longevity:

Worm gearboxes are constructed to withstand high loads and continuous operation. Their robust design ensures a long service life, reducing the need for frequent replacements and minimizing maintenance costs in industrial environments.

(6) Versatility in Applications:

These gearboxes are widely used across various industries, including automotive, agriculture, food processing, and robotics. Their adaptability to different operational requirements ensures they remain a popular choice for diverse mechanical systems.

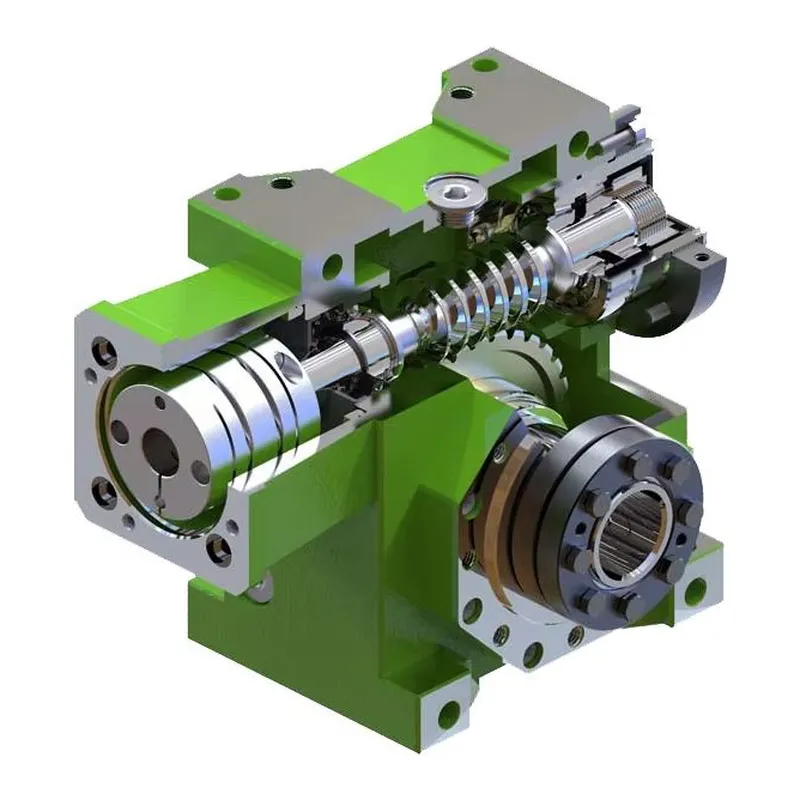

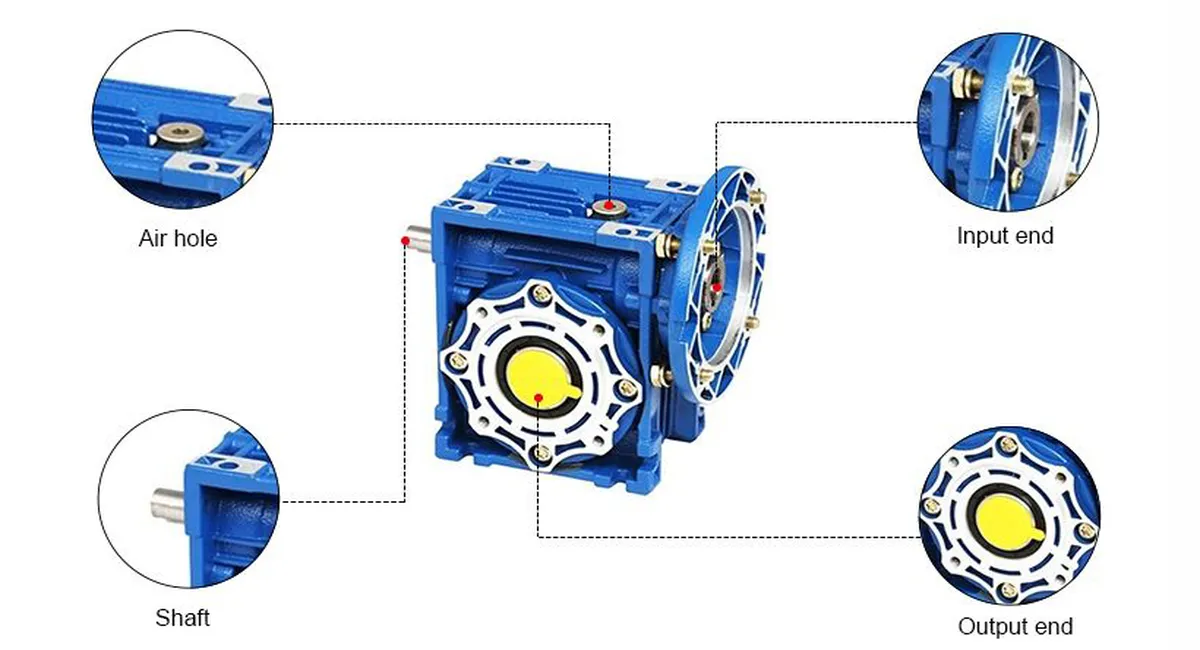

Aluminum Worm Gearbox Parts

Worm Gear

The primary driving component is the worm gear. It is a threaded screw-like rod with a helical shape, resembling a spiral or a screw thread. The worm gear is typically mounted on one of the shafts and connected to the input source of rotation.

Worm Wheel

The worm wheel is the driven component and is usually mounted on the second shaft. which positioned at a right angle to the worm gear. The worm wheel is a cylindrical gear with teeth that mesh with the threads of the worm gear. This interaction enables the transfer of motion and torque from the worm gear to the worm wheel.

Housing

The worm gear and worm wheel enclosed within a housing or gearbox casing. The housing provides protection, support, and proper alignment for the internal components. It designed to withstand the forces and stresses generated during operation.

Bearings

Bearings are crucial components that support the shafts on which the worm gear and worm wheel mounted. These bearings reduce friction and allow for smooth rotation of the shafts.

Seals

Seals used to prevent the ingress of contaminants such as dust and moisture into the gearbox. They help maintain the lubrication and protect the internal components.

Lubrication System

To ensure smooth operation and reduce wear and friction. worm gearboxes are typically equipped with a lubrication system. This system provides the necessary lubricant to the gear meshing surfaces.

Input and Output Shafts

The input shaft connected to the worm gear, and the output shaft connected to the worm wheel. These shafts extend beyond the gearbox housing. and provide the means to transmit power to and from the gearbox.

Mounting Flanges

Worm gearboxes often have mounting flanges or brackets. That allow them to be securely attached to the machinery or equipment they are serving.

Adjustment Mechanisms

Some worm gearboxes may include adjustment mechanisms to control backlash. which is the amount of free play or clearance between the worm gear and worm wheel teeth. Adjustments made to optimize the gearbox’s performance.

Bearing Caps and Covers

These components used to secure the bearings. and provide additional protection to the internal components.

How Does a Worm Gear Reducer Work?

Worm Wheel Gearbox Applications

- Conveyor Systems

Worm gearboxes are essential in conveyor systems used in industries like manufacturing, food processing, and logistics. They ensure precise speed control, efficient power transmission, and the ability to handle heavy loads, enabling smooth and reliable conveyor belt operations. - Automotive Steering Systems

In automotive steering mechanisms, worm drive gearboxes provide the necessary reduction in speed and increase in torque. This makes steering easier and more efficient, delivering precise control and stability for drivers under various road and speed conditions. - Lifting and Hoisting Equipment

Worm reducer gearboxes are extensively used in cranes, elevators, and winches due to their ability to handle high torque and ensure safe, accurate lifting and lowering of heavy loads in construction and industrial applications. - Material Handling Equipment

In machinery like forklifts and pallet jacks, worm gearboxes provide the power and control needed to move, lift, and place heavy materials efficiently. Their compact design allows seamless integration into these systems. - Robotics and Automation

Robotics and automated systems utilize worm gear reducers to precisely control the movement of robotic arms and components. Their high torque output and smooth operation are crucial for tasks requiring accuracy and reliability.

- Mining and Construction Equipment

Heavy machinery like excavators, bulldozers, and rock crushers rely on heavy duty worm gearboxes to power various functions. They control the movement of tracks, arms, and other components, ensuring durability and efficiency in challenging environments. - Agricultural Machinery

Worm reduction gearboxes play a vital role in agricultural equipment like tractors, plows, and harvesters. They control the rotation and movement of tools, enabling efficient plowing, planting, and harvesting in demanding farming conditions. - Packaging Machinery

Worm gear speed reducers are integral to packaging equipment such as filling, labeling, and capping machines. They control the precise movement and alignment of containers and components, ensuring accuracy, efficiency, and consistency in packaging operations. - Solar Tracking Systems

Worm gearboxes are used in solar tracking systems to adjust the angle of solar panels, ensuring they follow the sun’s movement throughout the day. This maximizes solar energy capture and improves system efficiency. - Marine and Boating

In marine applications, industrial worm gearboxes are used in boat winches and anchor windlasses. They provide the power and control needed for lifting and lowering anchors or adjusting sails in challenging marine conditions.

Conveyor Systems

Automotive Steering Systems

Lifting and Hoisting Equipment

Material Handling Equipment

Packaging Machinery

Agricultural Machinery

Robotics and Automation

Mining and Construction

Marine and Boating

Custom Worm Gear Gearbox

As a leading worm gearbox manufacturer and supplier, we specialize in delivering high-quality, custom worm gearbox solutions tailored to the specific demands of a wide range of industries. Our worm gear reducers are renowned for their reliability, precision, and efficiency, making them ideal for applications requiring accurate speed and torque control. Commonly utilized in manufacturing, robotics, conveyor systems, packaging machinery, and agricultural equipment, our gearboxes ensure optimal performance. Contact us today for a customized solution and personalized quotation!

Our Customer Reviews

“We’ve been using aluminum worm gearboxes in our food processing line for over a year, and their performance has been outstanding. They’re compact, efficient, and corrosion-resistant, perfect for our industry. We’re impressed with the durability and reliability they offer!”

-Italian Customer

-German Customer

“These right angle worm gearboxes have proven to be exceptional in our robotics applications. The precision and smooth operation are exactly what we needed for our robotic arms. Customer service was excellent, and the technical support ensured a seamless integration process.”

-Korean Customer

-American Customer

-British Customer

-Canadian Customer:

“Operating in agriculture, we need gearboxes that can withstand heat and dust. These aluminum worm gearboxes have delivered exceptional performance. Their lightweight design makes installation easy, and they’ve been reliable even in our toughest working environments.”

-Australian Customer

“We use these worm gearboxes in our conveyor systems for coffee production. They provide excellent speed reduction and consistent performance, even with heavy loads. Their long lifespan and efficiency have greatly improved our operational productivity and reduced downtime.”

-Brazilian Customer

-Russian Customer