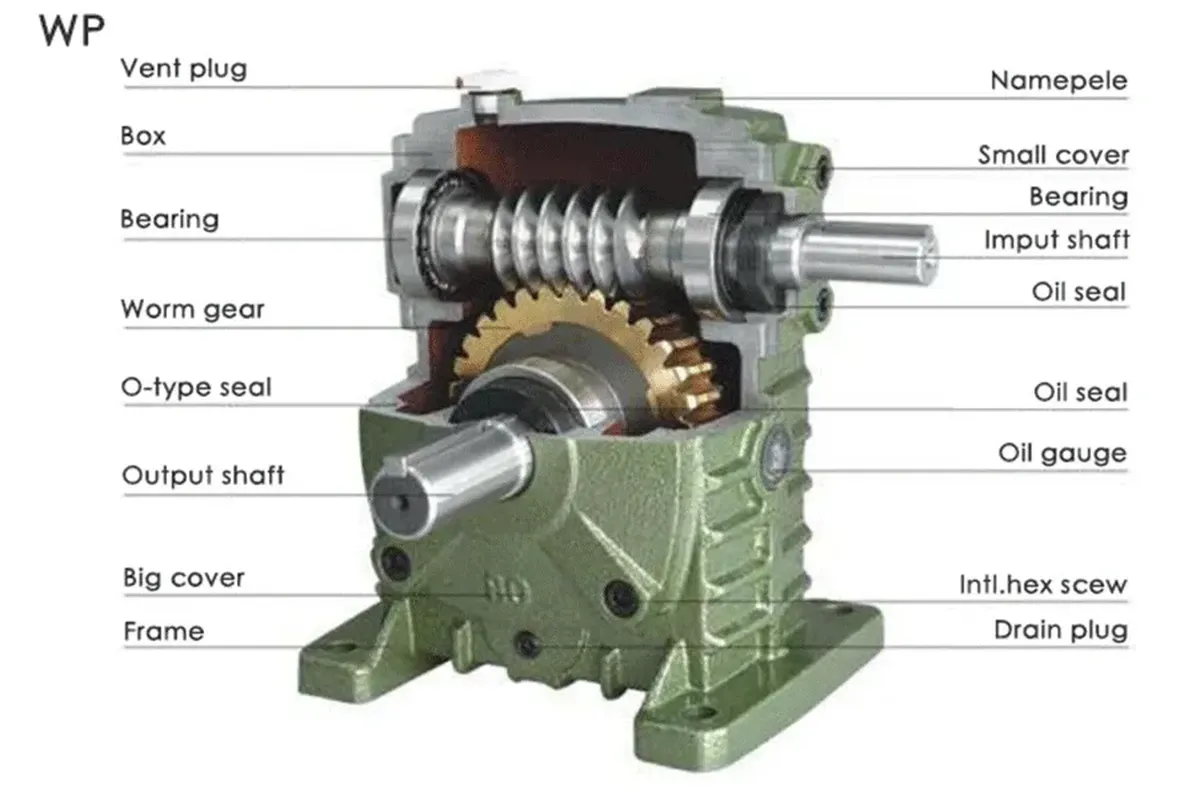

WP Series Worm Gearbox

The WP series worm gearbox is a common type of worm gearbox. It has a compact structure, stable transmission, low vibration and noise, a large reduction ratio, wide versatility, and can be used with various mechanical equipment. It has a self-locking function under certain conditions, so the braking device can be saved for some mechanical equipment with braking requirements, and its input shaft can rotate forward and reverse. WP series worm gear reducers are widely used in the reduction and transmission of various mechanical equipment such as plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction and so on.

Single Speed Worm Gear Reducer Models

Double Speed Worm Gear Reducer Models

Universal Speed Worm Gear Reducer Models

What is a WP Series Worm Gearbox?

The basic structure of the WP worm gear reducer is mainly composed of transmission parts, worm gear, worm shaft, bearing, housing, and other accessories. The housing of the WP series worm reducer gearbox is made of cast iron, which has strong rigidity, large bearing capacity, and is not easy to deform. The worm is made of 45# high-quality steel through heat treatment, and the worm gear is made of tin bronze, which has good wear resistance, especially in load capacity. And bearings, oil seals, and other accessories are all from well-known brands at home and abroad.

WP Series Worm Gear Reducer Parts

- Worm Gear

The worm gear is made of tin bronze, known for its excellent wear resistance and high load capacity. It plays a crucial role in transmitting motion from the worm shaft to the output shaft, ensuring smooth torque conversion and reliability under heavy loads. - Worm Shaft

The worm shaft is constructed from 45# high-quality steel and is heat-treated to enhance its strength and durability. Its helical design meshes seamlessly with the worm gear, delivering precise speed reduction and efficient power transmission with minimal friction. - Housing

The housing is made from rugged cast iron, providing exceptional rigidity and resistance to deformation. This sturdy structure protects internal components, ensures long-term reliability, and supports heavy loads while also aiding in heat dissipation to maintain optimal operating conditions. - Bearings

Premium bearings are used to support the worm shaft and worm gear, ensuring smooth rotational movement and reducing wear and tear. These bearings can handle both radial and axial loads, enhancing the gearbox’s overall performance and operational lifespan.

Oil Seals

High-quality oil seals are used to prevent lubricant leakage and protect internal components from dust, dirt, and moisture. The seals are critical in maintaining the gearbox’s efficiency, minimizing contamination, and ensuring consistent performance over extended periods.Input Shaft

The input shaft is designed to connect the motor or other power sources to the gearbox. It ensures that rotational energy is effectively transferred to the worm shaft for speed reduction while maintaining alignment and smooth operation.Output Shaft

The output shaft delivers the reduced speed and increased torque to the connected machinery. It is precision-engineered to handle heavy loads and integrates easily with couplings, pulleys, or other equipment for seamless power transfer.Lubrication System

The lubrication system ensures that all moving parts operate efficiently by minimizing friction and heat generation. Proper lubrication reduces wear, extends the lifespan of internal components, and maintains consistent performance under varying operating conditions.

WP Series Worm Reducer Gearbox Features

1. Compact and Durable Design

The WP series worm reducer gearbox features a compact structure, making it ideal for installations with limited space. Its housing is constructed from high-strength cast iron, providing excellent rigidity, durability, and resistance to deformation under heavy loads and demanding operating conditions.

2. High Reduction Ratio

This worm gear speed reducer offers a large reduction ratio in a single stage, making it suitable for applications requiring significant speed reduction and high torque output. The efficient design ensures smooth and precise power transmission, making it highly effective for diverse industrial uses.

3. Stable Transmission with Low Noise

The worm gear mechanism provides stable transmission with minimal vibration and noise. This feature makes the WP series worm gear gearbox ideal for environments where quiet operation is critical, such as food processing, packaging, and other noise-sensitive industries.

4. Self-Locking Function

Under specific conditions, the WP worm gear reducer has a self-locking capability, preventing reverse motion. This eliminates the need for additional braking devices in certain applications, enhancing safety and reducing costs for machinery requiring controlled stopping or holding positions.

5. Versatile Compatibility

The WP series worm drive gearbox is highly versatile and can be paired with various types of mechanical equipment. Its adaptability allows it to be used across industries such as mining, metallurgy, lifting, plastics, chemical processing, and construction, meeting diverse operational needs.

6. Heat Resistance and Wear Durability

The worm shaft is made of heat-treated 45# steel, while the worm gear is crafted from wear-resistant tin bronze. These materials ensure high heat resistance, excellent load capacity, and extended durability, even under continuous heavy-duty operation or harsh working environments.

WP Worm Drive Gearbox Applications

- Mining and Quarrying Equipment

WP worm drive gearboxes are widely used in mining and quarrying machinery such as conveyors, crushers, and screening equipment. Their high torque output, durability, and ability to handle heavy loads make them ideal for the demanding conditions of these industries. - Material Handling and Lifting Systems

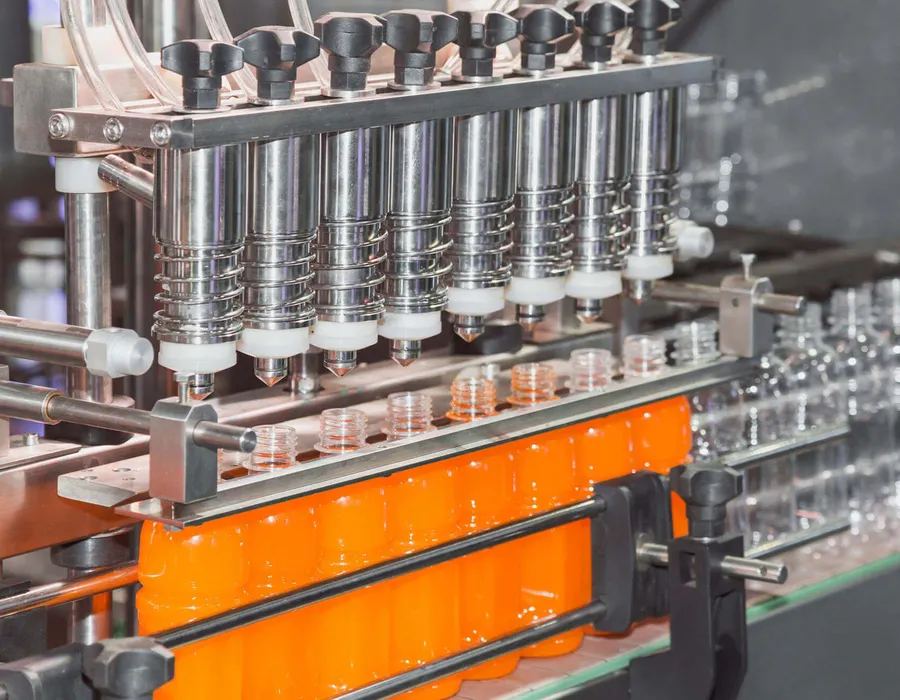

In material handling equipment like hoists, cranes, and elevators, WP worm reducer gearboxes ensure safe and efficient operation. Their self-locking capability prevents reverse motion, while the compact design and high reduction ratio allow for precise speed control and stable performance. - Food Processing and Packaging Machinery

WP worm drive reduction gearboxes are commonly found in food processing and packaging systems, including mixers, conveyors, and filling machines. Their low noise levels, smooth operation, and corrosion-resistant housing make them suitable for hygienic and noise-sensitive environments in the food industry. - Plastic and Rubber Machinery

These worm reduction gearboxes are integral to plastic and rubber processing equipment such as extruders, injection molding machines, and cutting systems. Their ability to deliver precise speed reduction and torque control ensures the accuracy and efficiency required in manufacturing processes. - Chemical and Construction Industries

WP worm gear reducer gearboxes are used in chemical mixers, agitators, and construction machinery like concrete mixers and compactors. Their robust construction, resistance to harsh environments, and reliable torque output make them suitable for handling demanding applications in these sectors. - Textile and Printing Machines

In textile and printing machinery, WP worm gear speed reducers enable smooth and accurate speed control for processes like weaving, knitting, and printing. Their stable transmission and ability to reduce vibrations help maintain product quality and ensure consistent machine performance.

Mining and Quarrying Industry

Conveyor Equipment

Food and Beverage Industry

Plastic and Rubber Machinery

Chemical Industry

Construction Industry

Textile Industry

Metallurgy Industry