Zinc Die-Cast Bevel Gears Ratio 1:1 Straight-Tooth System

Zinc die-cast bevel gears with a 1:1 ratio and straight-tooth system are mechanical components used to transmit torque between intersecting shafts at a 90-degree angle. The straight-tooth design features linear teeth, providing simplicity and efficiency in low-speed, low-load applications. These bevel gears are often used in machinery requiring precise motion transfer, like small-scale automation or instrumentation.

Zinc die-cast bevel gears with a 1:1 ratio and straight-tooth system are mechanical components used to transmit torque between intersecting shafts at a 90-degree angle. Made from zinc alloy (typically ZnAl4Cu1), these gears offer a cost-effective, lightweight alternative to steel or iron gears, with good strength but limited suitability for continuous operation due to material properties. The 1:1 ratio means both gears have the same number of teeth, ensuring equal rotational speed without torque multiplication. The straight-tooth design features linear teeth, providing simplicity and efficiency in low-speed, low-load applications. These gears are often used in machinery requiring precise motion transfer, like small-scale automation or instrumentation.

Zinc Die-Cast Bevel Gear Ratio 1:1

|  |

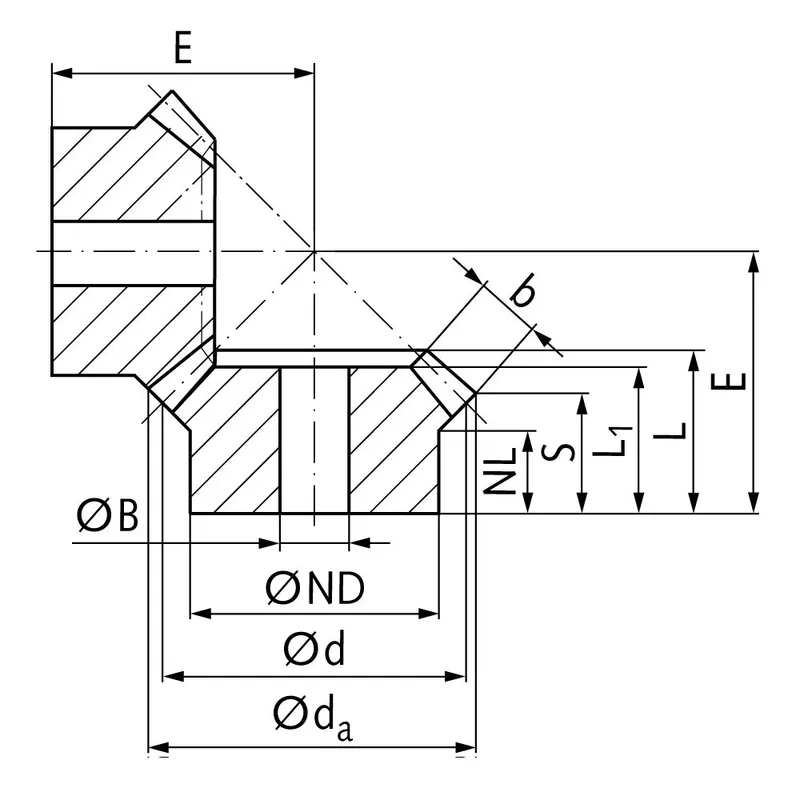

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH9 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 16 | 17,5 | 16 | 12 | 7,5 | 13,0 | 13,0 | 10,5 | 4,5 | 6 | 17,9 | 14 | 7 |

| 1,5 | 16 | 26,0 | 24 | 19 | 10,7 | 17,0 | 18,6 | 14,5 | 6,9 | 8 | 25,5 | 46 | 27 |

| 2 | 16 | 34,6 | 32 | 23 | 10 | 19,2 | 21,3 | 15,1 | 9,6 | 10 | 30,0 | 110 | 52 |

| 2,5 | 16 | 43,3 | 40 | 26 | 12 | 23,0 | 25,5 | 17,6 | 12,3 | 12 | 36,2 | 230 | 88 |

| 3 | 16 | 52,3 | 48 | 30 | 13 | 26,0 | 29,3 | 20,6 | 14,0 | 14 | 42,5 | 380 | 146 |

| 3,5 | 16 | 61,4 | 56 | 34 | 14 | 29,2 | 33,2 | 23,2 | 15,5 | 16 | 49,4 | 580 | 228 |

- In the torque calculation of zinc-die-cast bevel gears only the root strength was considered.

- Due to the material properties these gears are only to a limited extend suitable for continuous operation.

Zinc Die-Cast Bevel Gear Production Process

The production of zinc die-cast bevel gears involves a precise, multi-step process optimized for creating durable, cost-effective components with straight-tooth designs and 1:1 ratios for intersecting shaft applications.

- Alloy Preparation: The process begins with selecting a zinc alloy, typically ZnAl4Cu1 (Zamak 5), known for its strength, ductility, and castability. Raw zinc is melted in a furnace at approximately 420–450°C, ensuring a homogeneous molten alloy. Impurities are skimmed, and the alloy is tested for composition to meet mechanical requirements.

- Mold Design and Fabrication: High-precision steel molds, or dies, are crafted to form the gear’s geometry, including straight teeth and bevel angles. These molds are designed using CAD software to ensure accurate tooth profiles and 90-degree shaft alignment. The dies are polished and coated to enhance durability and facilitate part release.

- Die-Casting Process: The molten zinc alloy is injected into the mold under high pressure (up to 20,000 psi) using a die-casting machine. This ensures the alloy fills intricate tooth details. The process is rapid, with cycle times of 10–30 seconds, allowing high production rates. Cooling occurs within the mold, solidifying the gear in seconds.

- Ejection and Trimming: Once solidified, the gear is ejected from the mold. Excess material, or flash, is removed via automated trimming or vibratory deburring to achieve precise dimensions.

- Post-Processing: Gears undergo surface treatments like polishing or plating (e.g., nickel or zinc coating) to enhance corrosion resistance. Teeth may be machined for tighter tolerances, though zinc’s castability often minimizes this need.

- Quality Control: Each gear is inspected for dimensional accuracy, tooth profile fidelity, and surface defects using tools like CMM (Coordinate Measuring Machines) and hardness testers. Gears are tested for torque capacity, ensuring suitability for low-load, low-speed applications up to 100°C.

Zinc Die-Cast Bevel Gear Purpose

- Automotive Industry

Zinc die-cast bevel gears are widely used in automotive applications such as transmission systems, steering mechanisms, and differential drives. Their lightweight design, corrosion resistance, and high strength make them suitable for enduring continuous mechanical stress and environmental exposure. - Industrial Machinery

In industrial machines, these gears are crucial components for power transmission in conveyor belts, mixers, and pumps. Their precise 1:1 ratio and durability ensure efficient motion transfer, even under heavy loads, while maintaining operational reliability. - Home Appliances

Zinc die-cast bevel gears are commonly used in home appliances like blenders, washing machines, and vacuum cleaners. Their smooth operation and resistance to wear allow for quiet, long-lasting functionality in devices subjected to regular and intensive use. - Robotics and Automation

These gears play a vital role in robotics and automated systems, where precise motion control is essential. Their ability to transmit power at right angles, combined with their compact size and durability, ensures efficient performance in complex robotic movements. - Aerospace and Defense

In aerospace and defense applications, zinc die-cast bevel gears are used in control systems and navigation mechanisms. Their lightweight nature and ability to withstand harsh environments make them ideal for maintaining functionality in extreme conditions. - Medical Equipment

Medical devices, such as imaging machines and surgical robots, rely on zinc die-cast bevel gears for precision and reliability. Their corrosion resistance and consistent performance under sterilization processes ensure they meet the stringent standards of medical applications.

|  |

| Bevel Gear for Automotive Industry | Bevel Gear for Robotics Industry |

|  |

| Bevel Gear for Aerospace Industry | Bevel Gear for Medical Industry |

Bevel Gear Vs Miter Gear

Miter gears are a type of bevel gear with teeth that intersect at a 90-degree angle. They are designed to transmit motion and power between two shafts that are perpendicular to each other. Miter gears are commonly used in a wide range of mechanical applications, including industrial machinery, automotive systems, and precision instruments.

The teeth of miter gears are cut at a 45-degree angle to the axis of rotation, allowing them to mesh together smoothly and efficiently. This unique tooth geometry enables miter gears to change the direction of rotation while maintaining a constant velocity ratio between the input and output shafts.

Advantages of Miter Gears

Compact Design

Due to their perpendicular arrangement, miter gears allow for a more space-efficient power transmission system compared to other gear types.

High Efficiency

The precise meshing of the gear teeth ensures smooth and efficient transfer of motion and torque between the intersecting shafts. This high efficiency translates to reduced energy consumption and improved overall system performance.

Versatility

Miter gears are highly versatile and can be used in a wide range of applications across various industries. They are suitable for both low and high-speed applications, as well as for transmitting light to moderate loads.

Disadvantages of Miter Gears

Limited Load Capacity

Compared to other types of bevel gears, such as spiral bevel gears, miter gears have a relatively limited load capacity. The point contact between the gear teeth results in higher stress concentrations, which can lead to premature wear and reduced gear life under heavy loads.

Backlash

Miter gears are prone to backlash, which refers to the clearance between the mating gear teeth. Backlash can cause positioning errors, vibrations, and noise in the gear system.

Alignment Sensitivity

Any misalignment between the intersecting shafts can lead to increased wear, vibration, and reduced gear life.

Bevel gears are a type of mechanical gear that features conically-shaped teeth, allowing them to transmit power between intersecting shafts at various angles. Unlike miter gears, which are limited to 90-degree angles, bevel gears offer greater flexibility in shaft orientation. These gears find extensive use in a wide range of machinery and applications where power transmission between non-parallel shafts is required.

Bevel gears come in different configurations, including straight bevel gears, spiral bevel gears, and hypoid bevel gears.

- Straight bevel gears have teeth that are cut straight across the cone surface, while spiral bevel gears feature curved teeth for smoother and quieter operation.

- Hypoid bevel gears, a variation of spiral bevel gears, have an offset pinion axis for increased torque capacity and reduced noise.

Advantages of Bevel Gears

Versatile Shaft Angles

One of the primary advantages of bevel gears is their ability to transmit power between shafts at various angles, not just limited to 90 degrees like miter gears.

Smooth and Quiet Operation

Spiral bevel gears and hypoid bevel gears offer smoother and quieter operation compared to straight bevel gears. The curved teeth of spiral bevel gears provide a more gradual engagement, reducing vibration and noise.

High Torque Capacity

Bevel gears, particularly hypoid bevel gears, are capable of transmitting high torque loads. The offset pinion axis in hypoid gears allows for larger tooth contact areas, increasing their load-carrying capacity.

Compact Design

Bevel gears enable compact designs by allowing power transmission between intersecting shafts in a smaller space compared to other gear configurations.

Disadvantages of Bevel Gears

Complex Manufacturing

The manufacturing process for bevel gears, especially spiral and hypoid bevel gears, is more complex and costly compared to other gear types.

Higher Friction and Heat Generation

Due to the sliding action between the teeth, bevel gears are subject to higher friction compared to spur or helical gears.

Potential for Backlash

Bevel gears may experience backlash, which is the clearance or play between mating gear teeth. Backlash can result in reduced positional accuracy and increased wear, particularly in applications requiring precise positioning or low-speed operation.

Limited Speed Ratios

While bevel gears offer versatility in shaft angles, they are limited in terms of achievable speed ratios compared to other gear types like worm gears.

Key Differences Between Miter Gears and Bevel Gears

While both miter gears and bevel gears are used to transmit power between intersecting shafts, they have distinct differences in design, functionality, and mechanical advantage.

Design

Miter gears are a specific type of bevel gear designed to operate with shafts at a 90-degree angle.

In contrast, bevel gears can be designed for any angle between 0 and 180 degrees, providing greater flexibility in shaft positioning.

Functional

Miter gears are typically used in applications requiring a 90-degree change in direction of motion or power transmission. They are commonly found in hand tools, automotive differentials, and industrial machinery.

Bevel gears, on the other hand, offer more versatility in terms of shaft angles and are used in a wider range of applications, such as automotive drivetrains, aircraft control systems, and power transmission in various machines.

Mechanical Advantage

Miter gears generally have a 1:1 gear ratio, meaning they do not provide any mechanical advantage in terms of speed or torque.

Bevel gears, however, can be designed with different gear ratios, allowing for speed reduction or torque multiplication, depending on the application requirements.

Load Requirements

The load capacity of miter gears and bevel gears varies based on factors such as material, surface hardness, and tooth profile. Generally, bevel gears can handle higher loads compared to miter gears due to their ability to distribute stress more evenly along the tooth surface.

Space Constraints

Miter gears are more compact and require less space for their installation, making them suitable for applications with limited space. Bevel gears, while more versatile in terms of shaft angles, may require more space to accommodate their larger size and angular positioning.

Additional information

| Edited by | Yjx |

|---|