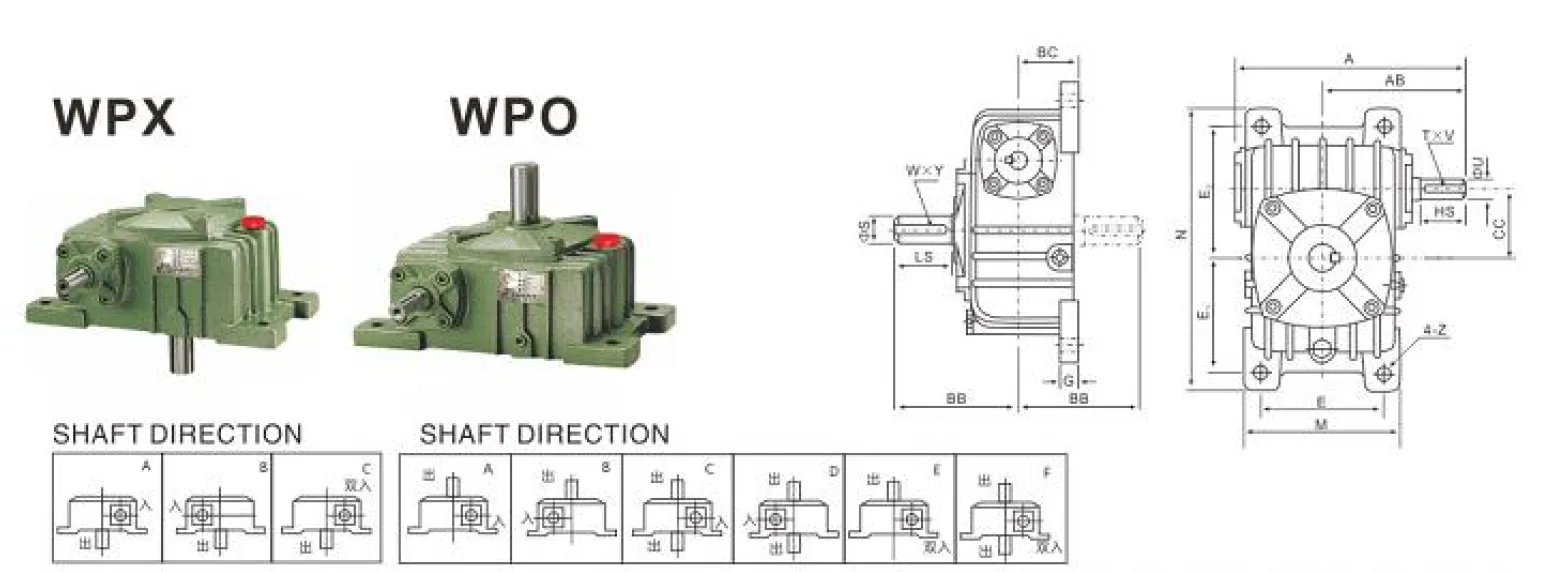

WPX Worm Gear Reducers/Worm Gearbox

The WPX worm gear reducer, also known as the WPX worm gearbox, is a horizontally mounted worm reduction gearbox designed for efficient power transmission and speed reduction in mechanical systems. It is characterized by its compact design, robust construction, and reliable performance. The key feature of the WPX worm gear speed reducer is its output shaft oriented downwards, which makes it particularly suitable for applications requiring vertical force transfer or where space constraints demand such an arrangement. The WPX worm drive gearbox is widely used in industries such as mining, construction, plastics, metallurgy, and chemical processing.

The WPX worm gear reducer, also known as the WPX worm gearbox, is a horizontally mounted worm reduction gearbox designed for efficient power transmission and speed reduction in mechanical systems. It is characterized by its compact design, robust construction, and reliable performance. The key feature of the WPX worm gear speed reducer is its output shaft oriented downwards, which makes it particularly suitable for applications requiring vertical force transfer or where space constraints demand such an arrangement.

The gearbox operates using a worm and gear mechanism, where a screw-shaped worm meshes with a helical gear to achieve high torque output and significant speed reduction in a single stage. The WPX worm drive gearbox is widely used in industries such as mining, construction, plastics, metallurgy, and chemical processing due to its ability to handle heavy loads with minimal maintenance. Its design ensures smooth operation, low noise, and extended service life, making it suitable for both continuous and intermittent applications. Additionally, the WPX worm gearbox is available in various sizes and ratios to cater to diverse mechanical requirements, offering flexibility and reliability across industrial sectors.

WPX Worm Gear Reducer Specifications

| Product Name: | WPX Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPX |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.12kW~15kW |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

WPX Worm Gearbox Dimensions

| Model | Ratio | A | AB | BB | CC | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 74 | 40 | 94 | 184 | 70 | 74 | 86 | 10 | 10 |

| 50 | 175 | 108 | 97 | 50 | 116 | 220 | 90 | 93 | 102 | 15 | 12 | |

| 60 | 198 | 120 | 112 | 60 | 126 | 260 | 100 | 105 | 120 | 20 | 12 | |

| 70 | 231 | 140 | 131 | 70 | 156 | 295 | 120 | 120 | 135 | 20 | 15 | |

| 80 | 261 | 160 | 142 | 80 | 175 | 325 | 140 | 130 | 150 | 20 | 15 | |

| 100 | 322 | 190 | 169 | 100 | 224 | 375 | 190 | 155 | 180 | 25 | 15 | |

| 120 | 371 | 219 | 190 | 120 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 135 | 422 | 249 | 210 | 135 | 306 | 495 | 250 | 210 | 235 | 30 | 18 | |

| 147 | 438 | 256 | 210 | 147 | 302 | 558 | 250 | 230 | 278 | 32 | 18 | |

| 155 | 497 | 295 | 252 | 155 | 350 | 590 | 290 | 245 | 295 | 35 | 21 | |

| 175 | 534 | 314 | 255 | 175 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 200 | 580 | 342 | 319 | 200 | 440 | 710 | 370 | 290 | 360 | 40 | 24 | |

| 250 | 705 | 420 | 385 | 250 | 510 | 860 | 440 | 350 | 440 | 45 | 28 |

| Input shaft | Output shaft | Weight | Oil quantity | ||||

|---|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) | (L) |

| 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 5 | 0.36 |

| 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 6 | 0.50 |

| 40 | 15 | 5×3 | 50 | 22 | 7×4 | 10 | 0.60 |

| 40 | 18 | 5×3 | 60 | 28 | 7×4 | 15 | 1.00 |

| 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 20 | 1.50 |

| 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 35 | 2.00 |

| 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 50 | 4.20 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 75 | 6.50 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 96 | 6.50 |

| 85 | 40 | 12×5 | 110 | 60 | 18×7 | 115 | 9.30 |

| 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 140 | 10.5 |

| 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 200 | 12.7 |

| 110 | 60 | 18×7 | 155 | 90 | 25×9 | 340 | 23.0 |

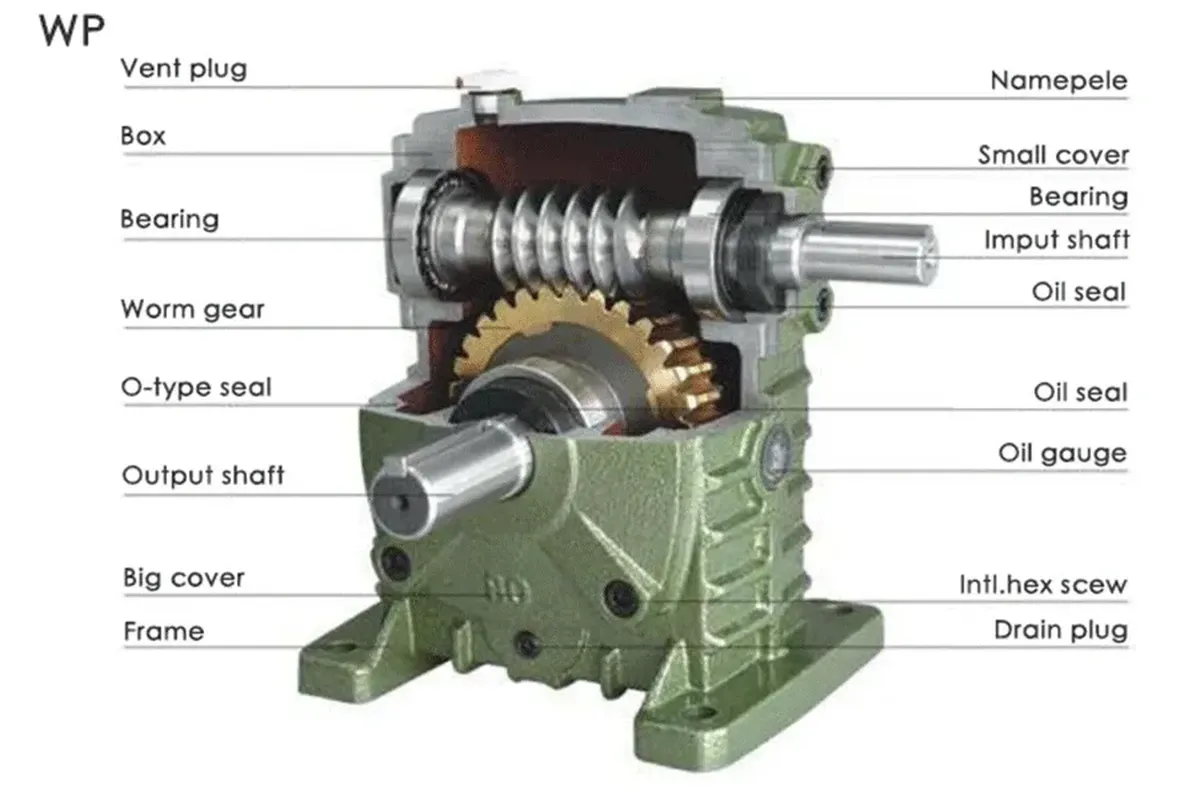

WPX Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPX Worm Gear Reducer Parts

- Worm Shaft

The worm shaft is a precision-engineered screw-like component that drives the gear mechanism. Made from high-strength alloy steel, it ensures efficient torque transmission and durability. Its helical threads engage smoothly with the worm gear, minimizing friction and wear during operation. - Worm Gear

The worm gear is a wheel-like component made from wear-resistant bronze or similar materials. It meshes with the worm shaft to achieve speed reduction and torque multiplication. Its design ensures high load-carrying capacity and smooth motion transfer for prolonged operational life. - Housing (Gearbox Casing)

The housing encases and protects internal components from external contaminants such as dust, moisture, and debris. Typically made of cast iron or aluminum, it provides structural integrity and heat dissipation, ensuring the gearbox remains durable even under heavy-duty operations. - Oil Seals

Oil seals are critical for maintaining lubrication within the gearbox and preventing leakage of gear oil. They also act as barriers against dirt and contaminants, ensuring smooth operation and reducing the risk of premature wear on the internal parts. - Bearings

Bearings support the rotation of the worm shaft and worm gear, reducing friction and ensuring smooth motion. High-quality bearings enhance the gearbox's efficiency and longevity by minimizing wear, even under continuous or high-load operations. - Output Shaft

The output shaft is the component that transfers reduced speed and amplified torque to the connected machinery. Positioned vertically downward in WPX worm gearboxes, it is built to withstand heavy loads and ensure precise power delivery during operation. - Cooling Fins

Cooling fins are integrated into the gearbox housing to dissipate heat generated during operation. By enhancing air circulation, they help maintain optimal operating temperatures, preventing overheating and extending the gearbox's lifespan even in high-performance applications.

WPX Worm Reduction Gearbox Applications

- Conveyor Systems

WPX worm reduction gearboxes drive conveyor belts in industries like mining and manufacturing. Their high torque and precise speed reduction ensure smooth material transport. The downward output shaft suits specific conveyor layouts, enhancing efficiency in handling bulk goods or assembly line processes with minimal maintenance. - Mixing Equipment

In chemical and food processing, worm reducer gearboxes power mixers and agitators. Their robust construction handles high-viscosity materials, delivering consistent torque. The compact design fits into tight spaces, while the downward shaft ensures optimal alignment for efficient mixing in industrial blending applications. - Packaging Machinery

WPX worm gear reducers are integral to packaging machines, such as fillers and sealers. They provide reliable speed control for precise operations. The downward output shaft allows seamless integration into compact packaging lines, ensuring consistent performance in high-speed, automated packaging processes across various industries. - Material Handling Equipment

In cranes and hoists, worm gear speed reducers offer high torque for lifting heavy loads. Their durable cast iron housing withstands harsh conditions. The downward shaft configuration simplifies integration into lifting mechanisms, ensuring safe and efficient material handling in warehouses and construction sites. - Textile Machinery

WPX worm gearboxes drive looms and spinning machines in textile production. Their smooth torque delivery ensures consistent operation under varying loads. The compact, horizontally mounted design fits seamlessly into textile equipment, providing reliable speed reduction for precise fabric manufacturing processes with minimal downtime. - Plastics Processing

In extrusion and molding machines, worm drive gearboxes deliver the high torque needed for processing plastics. Their sturdy design resists wear from continuous operation. The downward output shaft aligns with extruder configurations, ensuring efficient power transmission for producing high-quality plastic products in industrial settings.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Construction Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Plastic and Rubber Machinery |

Choose the Right WPX Worm Gearbox for Your Needs

- Determine Load Requirements: Assess the torque and load demands of your application. WPX worm gearboxes offer ratios from 10:1 to 60:1 and power from 0.18kW to 15kW. Match the gearbox size, such as WPX40 or WPX250, to your equipment’s load to ensure efficient power transmission and longevity.

- Evaluate Speed Reduction Needs: Identify the required output speed for your machinery. Worm drive gearboxes provide precise speed reduction through their worm and wheel design. Choose a model with the appropriate gear ratio to achieve the desired output speed for applications like conveyors or mixers.

- Consider Mounting Configuration: Ensure the gearbox’s horizontal mounting and downward output shaft align with your equipment’s layout. WPX models support foot or flange mounting, offering flexibility for integration into systems like packaging machines or material handling equipment, ensuring seamless installation and operation.

- Check Environmental Conditions: Evaluate the operating environment for factors like dust, moisture, or temperature extremes. WPX worm drive reduction gearboxes feature robust cast iron housing and effective seals to withstand harsh conditions, making them suitable for industries like mining or chemical processing with minimal maintenance needs.

- Verify Motor Compatibility: Confirm the input flange or shaft matches your motor specifications. Worm reducer gearboxes accommodate various motor sizes and types, ensuring secure and aligned connections. This compatibility is crucial for applications in textile or plastics machinery, where precise motor integration enhances performance.

- Assess Maintenance Requirements: Consider the gearbox’s lubrication and maintenance needs for long-term reliability. WPX models use synthetic or mineral oil to minimize wear and heat. Select a gearbox with accessible maintenance points to reduce downtime in high-demand applications like food processing or material handling.

Additional information

| Edited by | Yjx |

|---|