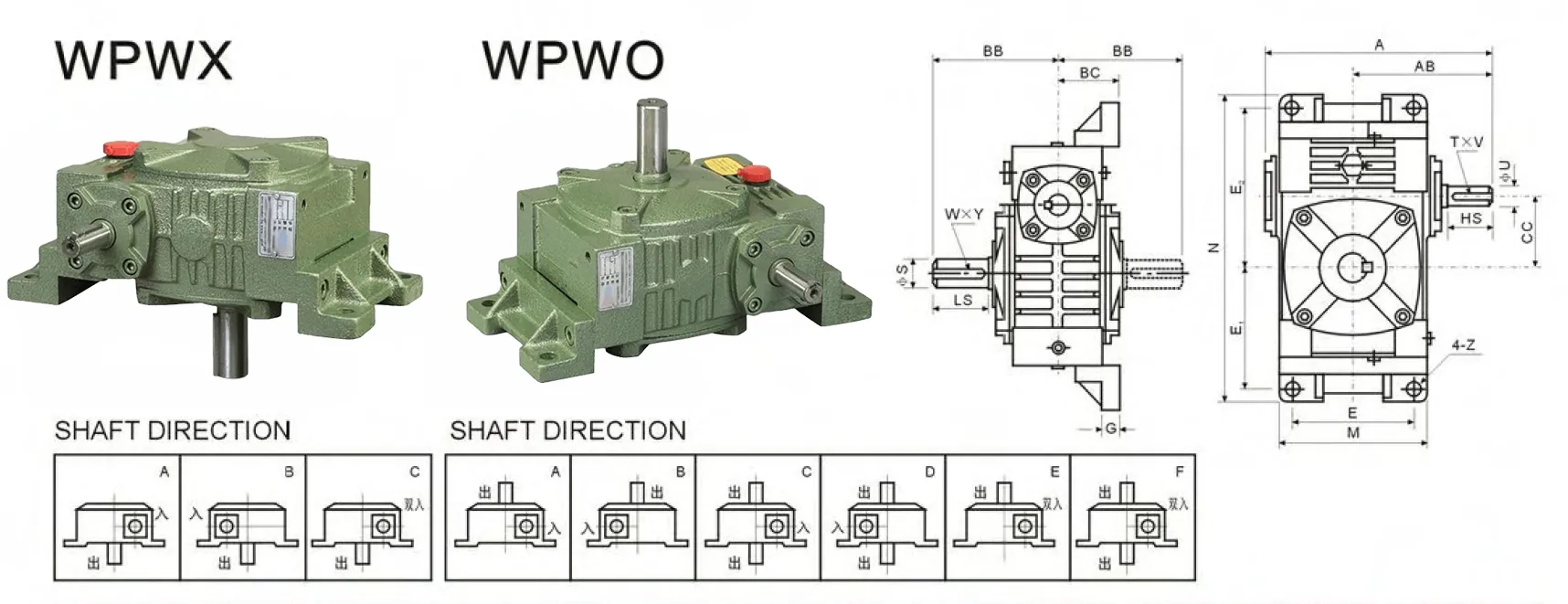

WPWX Worm Gear Reducers/Worm Gearbox

WPWX worm gear reducers, also known as worm gearboxes, are highly efficient speed reducers designed for compact spaces and demanding applications. These devices consist of a worm (a screw-like gear) that meshes with a worm wheel, typically crafted from bronze, to transmit torque smoothly and efficiently. Enclosed in a durable cast iron housing, WPWX models are engineered for long-lasting performance and reliability. A distinguishing feature of the WPWX worm gearbox is its vertically downward output shaft, which offers versatility for various installation configurations, making it adaptable to diverse machinery setups.

WPWX worm gear reducers, also known as worm gearboxes, are highly efficient speed reducers designed for compact spaces and demanding applications. These devices consist of a worm (a screw-like gear) that meshes with a worm wheel, typically crafted from bronze, to transmit torque smoothly and efficiently. Enclosed in a durable cast iron housing, WPWX models are engineered for long-lasting performance and reliability. A distinguishing feature of the WPWX worm gearbox is its vertically downward output shaft, which offers versatility for various installation configurations, making it adaptable to diverse machinery setups.

These worm reducer gearboxes are capable of achieving high gear ratios, ranging from 10:1 to 60:1, enabling significant reductions in speed while amplifying torque output. This makes them ideal for low-horsepower applications across industries such as plastics, metallurgy, and mining. Their compact structure ensures they occupy minimal space, while their low noise and vibration levels enhance operational comfort. Additionally, under specific conditions, WPWX worm gear speed reducers exhibit a self-locking property, which eliminates the need for external braking systems, enhancing safety.

WPWX Worm Gear Reducer Specifications

| Type: | WPWX Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWX Worm Gearbox Dimensions

| Model | Ratio | A | AB | BB | BC | CC | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 74 | 45 | 40 | 95 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 175 | 108 | 97 | 50 | 50 | 111 | 226 | 90 | 90 | 110 | 14 | 12 | |

| 60 | 198 | 120 | 112 | 55 | 60 | 127 | 257 | 100 | 102 | 129 | 15 | 12 | |

| 70 | 231 | 140 | 131 | 65 | 70 | 152 | 305 | 120 | 120 | 155 | 20 | 15 | |

| 80 | 261 | 160 | 142 | 70 | 80 | 174 | 350 | 140 | 140 | 180 | 20 | 15 | |

| 100 | 322 | 190 | 169 | 90 | 100 | 224 | 410 | 190 | 165 | 215 | 22 | 15 | |

| 120 | 371 | 219 | 190 | 100 | 120 | 264 | 494 | 220 | 195 | 255 | 25 | 18 | |

| 135 | 422 | 249 | 210 | 110 | 135 | 304 | 559 | 260 | 230 | 285 | 30 | 18 | |

| 155 | 497 | 295 | 252 | 140 | 155 | 345 | 605 | 290 | 250 | 305 | 35 | 21 | |

| 175 | 534 | 314 | 255 | 150 | 175 | 374 | 675 | 320 | 273 | 348 | 40 | 21 | |

| 200 | 580 | 342 | 319 | 175 | 200 | 424 | 749 | 370 | 305 | 390 | 40 | 24 | |

| 250 | 705 | 420 | 385 | 200 | 250 | 510 | 920 | 440 | 375 | 475 | 45 | 28 |

| Input shaft | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 5 |

| 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 8 |

| 40 | 15 | 5×3 | 50 | 22 | 7×4 | 11 |

| 40 | 18 | 5×3 | 60 | 28 | 7×4 | 15.5 |

| 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 24 |

| 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 38 |

| 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 56 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 84 |

| 85 | 40 | 12×5.5 | 110 | 60 | 18×7 | 129 |

| 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 157 |

| 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 224 |

| 110 | 60 | 18×7 | 155 | 90 | 25×9 | 374 |

WPWX Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWX Worm Drive Gearbox Advantages

- High Torque Output and Efficiency

WPWX worm drive gearboxes deliver exceptional torque multiplication through high gear ratios, typically ranging from 10:1 to 60:1. This allows for significant speed reduction, making them ideal for applications requiring powerful torque in compact machinery, such as conveyors or mixers. - Compact and Space-Saving Design

The worm gear speed reducers feature a vertically downward output shaft, enabling flexible installation in tight spaces. Its compact structure optimizes space without compromising performance, making it suitable for industries like plastics or packaging where equipment footprint is critical. - Self-Locking Capability

Under specific conditions, the WPWX worm reducer gearboxes offer self-locking, preventing back-driving without additional braking systems. This enhances safety and reliability in applications like hoists or elevators, where unintended movement could pose risks, ensuring operational stability and reduced maintenance. - Low Noise and Vibration

The worm and worm wheel design, often with a bronze wheel and steel worm, ensures smooth operation with minimal noise and vibration. This makes worm and wheel gearboxes ideal for environments requiring quiet performance, such as food processing or precision manufacturing. - Durability and Robust Construction

Encased in a cast iron housing, WPWX worm gear reducers are built for longevity and resistance to wear. Their sturdy design withstands harsh industrial conditions, such as those in metallurgy or mining, ensuring reliable performance with minimal maintenance over time. - Versatile Applications Across Industries

Worm reduction gearboxes are adaptable to diverse sectors, including textiles, chemicals, and agriculture. Their ability to handle varying loads and speeds, combined with easy maintenance, makes them a cost-effective solution for machinery requiring precise motion control and consistent performance.

WPWX Worm Gear Reducer Uses

- Plastics Industry

In the plastics industry, WPWX worm gear reducers are used in machinery like extruders and injection molding equipment. Their ability to deliver high torque with low noise ensures consistent, precise operation, which is critical for manufacturing high-quality plastic products efficiently. - Metallurgy Industry

The metallurgy sector benefits from worm gear gearboxes in equipment like furnaces, continuous casting machines, and rolling mills. Their robust construction and high torque output enable them to handle heavy loads and harsh environments, ensuring reliable performance in metal processing applications. - Mining Industry

WPWX worm gear speed reducers are essential in mining operations, powering conveyors, crushers, and hoists. Their compact design and ability to withstand heavy-duty loads make them ideal for space-constrained setups and the demanding conditions often encountered in mining environments. - Food Processing Industry

In food processing, these worm reducer gearboxes are used in mixers, conveyors, and packaging machines. Their quiet operation, durability, and ability to provide smooth torque transmission ensure hygienic and efficient processing, meeting the industry's stringent performance and cleanliness requirements. - Textile Industry

Textile machinery like spinning, weaving, and dyeing equipment relies on worm gearbox reducers for precise speed control and torque transmission. Their compact design and low noise levels make them suitable for continuous operation in environments requiring precision and efficiency. - Material Handling Industry

WPWX worm reduction gearboxes are extensively used in material handling systems such as conveyors, elevators, and automated storage systems. Their self-locking feature, high torque output, and mounting versatility ensure safe and efficient transport of goods in warehouses and factories.

|  |

| Worm Gearbox for Metallurgy Industry | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Food and Beverage Industry |

WPWX Worm Gear Speed Reducer Components

- Worm: The worm is a screw-like gear, typically made of hardened steel, which engages with the worm wheel to transmit power. Its precise threading ensures smooth and efficient torque transfer, critical for achieving high gear ratios in worm gear speed reducers.

- Worm Wheel: Constructed from bronze or similar materials, the worm wheel meshes with the worm to reduce speed and increase torque. Its durable design ensures long-term performance, minimizing wear even under high loads, making it essential for reliable operation in industrial applications.

- Housing: The cast iron housing encases all internal components, providing structural integrity and protection. Its robust construction resists impacts and harsh environments, ensuring durability in industries like mining or metallurgy, while also facilitating heat dissipation to maintain optimal operating temperatures.

- Output Shaft: The vertically downward output shaft in worm gear reducers delivers the final torque to the driven equipment. Its sturdy design supports heavy loads, and its configuration allows flexible mounting, making it adaptable for various applications like conveyors or mixers.

- Input Shaft: The input shaft receives power from the motor, transferring it to the worm. Precision-engineered for alignment, it ensures efficient energy transmission. Its robust build withstands continuous operation, critical for maintaining consistent performance in high-demand industrial environments.

- Bearings: High-quality bearings support the worm and shafts, reducing friction and ensuring smooth rotation. They enhance the worm drive reduction gearbox’s efficiency and longevity by minimizing wear, crucial for maintaining performance in applications requiring continuous operation, such as textile or chemical processing.

- Seals: Oil seals prevent lubricant leakage and protect internal components from dust and contaminants. Their robust design ensures reliable operation in harsh environments, extending the worm gear reducer gearbox’s lifespan and reducing maintenance needs in industries like agriculture or plastics manufacturing.

Additional information

| Edited by | Yjx |

|---|