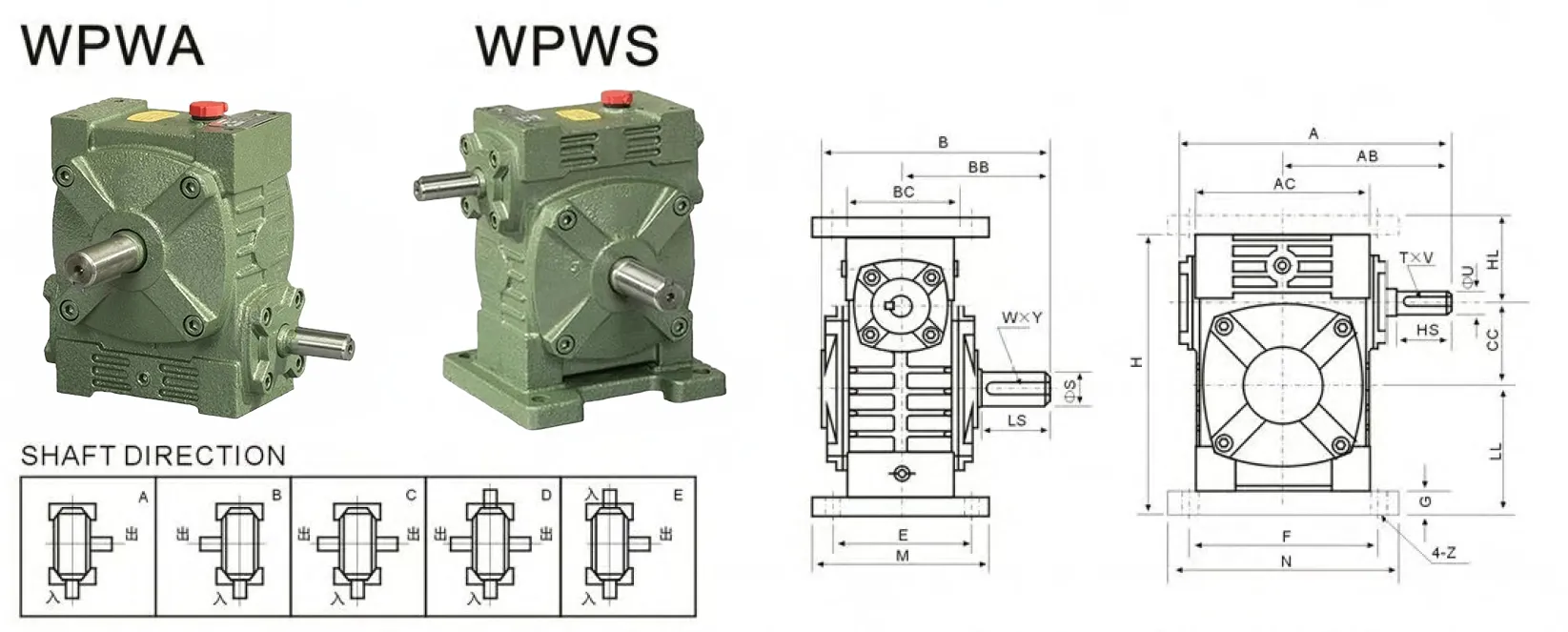

WPWS Worm Gear Reducers/Worm Gearbox

WPWS worm gear reducers, commonly referred to as worm gearboxes, are specialized speed reducers designed for efficient power transmission in compact spaces. These devices utilize a worm (a screw-like gear) meshing with a worm wheel, enabling a right-angle drive that converts high-speed, low-torque input into low-speed, high-torque output. The WPWS series, a variant of the WP series worm gearbox, features a robust cast iron housing for durability, with worm gears crafted from wear-resistant tin bronze and a steel worm for enhanced strength.

WPWS worm gear reducers, commonly referred to as worm gearboxes, are specialized speed reducers designed for efficient power transmission in compact spaces. These devices utilize a worm (a screw-like gear) meshing with a worm wheel, enabling a right-angle drive that converts high-speed, low-torque input into low-speed, high-torque output. The WPWS series, a variant of the WP series worm gearbox, features a robust cast iron housing for durability, with worm gears crafted from wear-resistant tin bronze and a steel worm for enhanced strength. Offering gear ratios from 5:1 to 60:1, and up to 10,000:1 with double reduction, these gearboxes are versatile for various applications, including conveyors, lifts, and industrial machinery.

Key features of WPWS worm gear speed reducers include low noise levels, minimal vibration, and self-locking capabilities at higher ratios (typically 50:1 to 60:1). The self-locking function prevents back-driving in certain conditions, enhancing safety and reliability. The WPWS worm drive gearbox is characterized by its upper input shaft configuration, allowing flexible mounting options (horizontal or vertical) and easy compatibility with IEC standard motors via B5 or B14a flanges. Thanks to their compact design, stable transmission, and ability to handle high shock loads, WPWS worm gearboxes are widely used in industries such as plastics, metallurgy, mining, and more.

WPWS Worm Gear Reducer Specifications

| Type: | WPWS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWS Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | BB | AC | BC | CC | HL | LL | H | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 114 | 74 | 95 | 61 | 40 | 45 | 60 | 135 | 100 | 130 | 80 | 110 | 10 | 10 |

| 50 | 175 | 108 | 150 | 97 | 111 | 68 | 50 | 50 | 80 | 165 | 120 | 140 | 95 | 110 | 15 | 12 | |

| 60 | 198 | 120 | 168 | 112 | 127 | 76 | 60 | 60 | 93 | 195 | 130 | 150 | 105 | 120 | 18 | 12 | |

| 70 | 231 | 140 | 194 | 131 | 152 | 86 | 70 | 73 | 108 | 233 | 150 | 190 | 115 | 150 | 18 | 15 | |

| 80 | 261 | 160 | 214 | 142 | 169 | 102 | 80 | 83 | 123 | 268 | 170 | 220 | 135 | 180 | 18 | 15 | |

| 100 | 322 | 190 | 254 | 169 | 216 | 117 | 100 | 100 | 150 | 330 | 190 | 270 | 155 | 220 | 20 | 15 | |

| 120 | 371 | 219 | 282 | 190 | 256 | 124 | 120 | 120 | 180 | 395 | 230 | 320 | 180 | 260 | 25 | 18 | |

| 135 | 422 | 249 | 317 | 210 | 296 | 147 | 135 | 135 | 215 | 455 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 155 | 497 | 295 | 382 | 252 | 345 | 185 | 155 | 135 | 235 | 493 | 280 | 380 | 220 | 320 | 32 | 21 | |

| 175 | 534 | 314 | 372 | 255 | 374 | 192 | 175 | 160 | 260 | 558 | 310 | 410 | 250 | 350 | 37 | 21 | |

| 200 | 580 | 342 | 456 | 319 | 412 | 230 | 200 | 175 | 290 | 620 | 355 | 445 | 290 | 390 | 45 | 24 | |

| 250 | 705 | 420 | 552 | 385 | 500 | 285 | 250 | 200 | 350 | 750 | 460 | 560 | 380 | 480 | 50 | 28 |

| Input shaft | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 4.5 |

| 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 7.5 |

| 40 | 15 | 5×3 | 50 | 22 | 7×4 | 11.5 |

| 40 | 18 | 5×3 | 60 | 28 | 7×4 | 15.5 |

| 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 24 |

| 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 39 |

| 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 57 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 85 |

| 85 | 40 | 12×5 | 110 | 60 | 18×7 | 110 |

| 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 152 |

| 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 216 |

| 110 | 60 | 18×7 | 155 | 90 | 25×9 | 350 |

WPWS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWS Worm Gear Speed Reducer Features

- High Torque Output and Compact Design

The WPWS worm gear speed reducer delivers high torque in a compact footprint, ideal for space-constrained applications. Its worm and worm wheel configuration efficiently converts high-speed input into low-speed, high-torque output, making it suitable for heavy-duty industrial tasks like conveyors and lifts. - Durable Construction with Cast Iron Housing

The worm drive gearbox features a robust cast iron housing that ensures long-term durability and resistance to harsh environments. This sturdy build protects internal components, such as the tin bronze worm wheel and hardened steel worm, from wear, extending the gearbox’s operational life in demanding settings. - Wide Range of Gear Ratios

Offering gear ratios from 5:1 to 60:1, and up to 10,000:1 with double reduction, the WPWS worm reducer gearboxes provide flexibility for various applications. This range allows precise speed control, catering to industries like metallurgy, mining, and plastics requiring tailored power transmission solutions. - Low Noise and Vibration Operation

Designed for smooth performance, the right angle worm gearbox minimizes noise and vibration through precision-engineered gears and high-quality lubrication. This feature enhances operator comfort and reduces wear on components, making it ideal for continuous operation in environments where quiet performance is critical. - Self-Locking Capability at High Ratios

At gear ratios typically above 50:1 to 60:1, the WPWS worm gear reducers offer self-locking functionality, preventing back-driving under load. This ensures safety and stability in applications like hoists or elevators, where maintaining position without external braking is essential for operational reliability. - Flexible Mounting and Motor Compatibility

The worm drive reduction gearbox features an upper input shaft and supports versatile mounting options, including horizontal and vertical orientations. It is compatible with standard IEC motors via B5 or B14a flanges, simplifying integration into existing systems and enhancing adaptability across diverse industrial setups.

WPWS Worm Gearbox Application Scenarios

- Conveyor Systems in Manufacturing

WPWS worm gearboxes are widely used in conveyor systems for manufacturing industries like automotive and food processing. Their high torque output and compact design enable efficient material handling. The self-locking feature ensures stable operation, preventing rollback on inclined conveyors, enhancing safety and productivity. - Elevators and Lifting Equipment

In elevators and lifting systems, worm reducer gearboxes provide reliable torque for heavy loads. Their self-locking capability at high gear ratios ensures safe load holding without additional brakes. The durable cast iron housing withstands continuous operation, making them ideal for commercial and industrial lifting applications. - Packaging Machinery

WPWS worm gear reducers drive packaging equipment, such as bottling and labeling machines. Their precise speed control and low noise operation ensure smooth performance in high-speed production lines. The compact design allows easy integration into tight spaces, optimizing efficiency in automated packaging processes. - Metallurgy and Mining Equipment

In metallurgy and mining, right angle worm gear reducers power heavy machinery like crushers and mixers. Their robust construction handles high shock loads and harsh environments. The wide range of gear ratios allows tailored speed adjustments, ensuring efficient operation in demanding industrial settings. - Textile Machinery

WPWS worm gear drive gearboxes are used in textile machines, such as spinning and weaving equipment. Their low vibration and quiet operation minimize disruptions in precision-driven processes. The flexible mounting options and motor compatibility simplify integration, supporting consistent performance in textile production lines. - Solar Tracking Systems

WPWS worm reduction gearboxes are employed in solar tracking systems to adjust panel angles for optimal sunlight exposure. Their high torque and self-locking features ensure precise positioning and stability against wind loads. The durable design withstands outdoor conditions, enhancing reliability in renewable energy applications.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Metallurgy Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Chemical Industry |

Difference Between Worm Gearbox and Helical Gearbox

Worm Gearbox

A worm gearbox utilizes a worm (a screw-like gear) and a worm wheel to achieve power transmission. The design creates a right-angle configuration, allowing high-speed, low-torque input to be converted into low-speed, high-torque output. Worm gearboxes are compact and often feature self-locking capabilities at higher gear ratios, preventing back-driving under certain conditions. They are ideal for applications requiring precise motion control, such as conveyors, lifts, and industrial equipment. The worm is typically made of hardened steel for strength, while the worm wheel is crafted from bronze for wear resistance. A key advantage of worm gearboxes is their ability to handle shock loads while operating with minimal noise and vibration.

Helical Gearbox

A helical gearbox uses helical gears, which have teeth angled at a specific helix angle. This design allows for continuous contact between gear teeth, resulting in smoother power transmission and higher efficiency compared to worm gearboxes. Helical gearboxes are well-suited for applications requiring high efficiency and durability, such as pumps, compressors, and heavy machinery. They are typically used for parallel or inline power transmission, with the ability to handle higher speeds and heavier loads. Helical gears are constructed from materials like hardened steel or alloy steel, ensuring excellent durability and performance under tough conditions.

Key Differences

- Efficiency: Worm gear gearboxes generally have lower efficiency due to the sliding motion between the worm and worm wheel, causing energy loss through friction. Helical gearboxes, with rolling contact between gear teeth, offer much higher efficiency.

- Torque Output: Worm gearboxes excel at delivering high torque at low speeds, making them suitable for heavy-duty applications. Helical gearboxes, while capable of handling heavy loads, are better for high-speed applications requiring moderate torque.

- Self-Locking Capability: Worm drive gearboxes can provide self-locking at higher gear ratios, preventing reverse motion. Helical gearboxes lack this feature and require additional brakes or locking mechanisms for such functionality.

- Compactness: Worm gearboxes are more compact and better suited for tight spaces, while helical gearboxes are generally larger due to their design and higher gear efficiency.

- Noise and Vibration: Worm gear drive gearboxes operate more quietly due to their sliding motion and lower speed. Helical gearboxes, while smooth, may generate more noise at high speeds due to rolling contact.

- Applications: Worm gearboxes are preferred for precise motion control in conveyors, lifts, and hoisting equipment. Helical gearboxes are ideal for high-speed, high-efficiency applications like pumps, compressors, and processing equipment.

|  |

| Worm Gearbox | Helical Gearbox |

Additional information

| Edited by | Yjx |

|---|