WPWKV Worm Gear Reducers/Worm Gearbox

WPWKV worm gear reducers, part of the WP series worm gearboxes, are highly efficient mechanical power transmission devices designed for speed reduction and torque multiplication in a compact and versatile form. These worm gear speed reducers are housed in durable cast iron casings, ensuring strength and long service life. At their core, they feature a worm gear mechanism consisting of a worm (a screw-like gear made of heat-treated 45# steel for enhanced durability) and a worm wheel made of tin bronze, contributing to smooth and efficient operation.

WPWKV worm gear reducers, part of the WP series worm gearboxes, are highly efficient mechanical power transmission devices designed for speed reduction and torque multiplication in a compact and versatile form. These worm gear speed reducers are housed in durable cast iron casings, ensuring strength and long service life. At their core, they feature a worm gear mechanism consisting of a worm (a screw-like gear made of heat-treated 45# steel for enhanced durability) and a worm wheel made of tin bronze, contributing to smooth and efficient operation.

The WPWKV worm gearboxes have a universal integral design with a shaft hole output and a downward input shaft, which allows for flexible mounting and easy integration into various systems. These gearboxes offer a wide range of gear ratios, typically from 5:1 to 60:1, providing high torque output, low noise operation, and self-locking capabilities under certain conditions. This makes them ideal for demanding applications such as conveyors, hoists, and industrial machinery, where reliability, efficiency, and compactness are essential.

WPWKV Worm Gear Reducer Specifications

| Type: | WPWKV Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

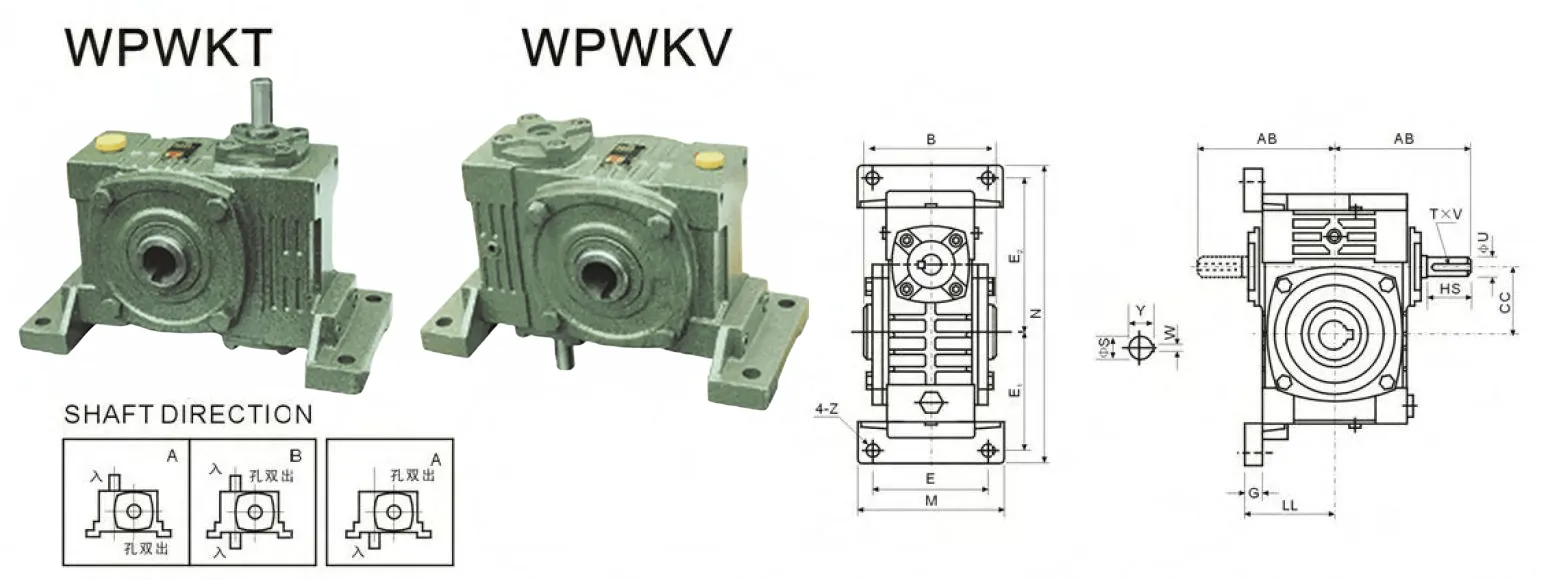

WPWKV Worm Gearbox Dimensions

| Model | Ratio | AB | B | CC | LL | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 87 | 85 | 40 | 63 | 90 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 108 | 105 | 50 | 70 | 120 | 226 | 95 | 90 | 110 | 14 | 12 | |

| 60 | 120 | 110 | 60 | 80 | 130 | 257 | 105 | 102 | 129 | 15 | 12 | |

| 70 | 140 | 130 | 70 | 95 | 150 | 305 | 115 | 120 | 155 | 20 | 15 | |

| 80 | 160 | 150 | 80 | 105 | 170 | 350 | 135 | 140 | 180 | 20 | 15 | |

| 100 | 190 | 160 | 100 | 135 | 190 | 410 | 155 | 165 | 215 | 22 | 15 | |

| 120 | 219 | 175 | 120 | 160 | 230 | 494 | 180 | 195 | 255 | 25 | 18 | |

| 135 | 249 | 210 | 135 | 185 | 250 | 559 | 200 | 230 | 285 | 30 | 18 | |

| 155 | 295 | 256 | 155 | 220 | 275 | 605 | 220 | 250 | 305 | 35 | 21 | |

| 175 | 314 | 282 | 175 | 240 | 310 | 675 | 250 | 273 | 348 | 40 | 21 | |

| 200 | 342 | 320 | 200 | 280 | 360 | 749 | 290 | 305 | 390 | 40 | 24 | |

| 250 | 420 | 400 | 250 | 315 | 460 | 920 | 380 | 375 | 475 | 45 | 28 |

| Input shaft | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×V | (kg) |

| 25 | 12 | 4×2.5 | 16 | 6×18.8 | 5 |

| 30 | 12 | 4×2.5 | 20 | 6×22.8 | 8 |

| 40 | 15 | 5×3 | 25 | 8×28.3 | 11 |

| 40 | 18 | 5×3 | 30 | 8×33.3 | 15.5 |

| 50 | 22 | 7×4 | 35 | 10×38.3 | 24 |

| 50 | 25 | 7×4 | 40 | 12×43.3 | 38 |

| 65 | 30 | 7×4 | 45 | 14×48.8 | 56 |

| 75 | 35 | 10×4.5 | 60 | 18×64.4 | 84 |

| 85 | 40 | 12×5.5 | 70 | 20×74.9 | 129 |

| 85 | 45 | 14×5.5 | 80 | 22×85.4 | 157 |

| 95 | 50 | 14×5.5 | 85 | 22×90.4 | 224 |

| 110 | 60 | 18×7 | 110 | 28×116.4 | 374 |

WPWKV Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWKV Worm Gear Speed Reducer Features

- High Torque Output

WPWKV worm gear speed reducers deliver exceptional torque multiplication, ideal for heavy-duty applications like conveyors and hoists. Their worm and wheel design ensures efficient power transfer, providing reliable performance under high loads with ratios ranging from 5:1 to 60:1, and up to 10,000:1 in double reduction setups. - Compact and Versatile Design

The worm drive gearboxes feature a square cast iron housing for universal mounting flexibility. Its compact structure, with a downward input shaft and shaft hole output, allows easy integration into various machinery, optimizing space without compromising strength or functionality in diverse industrial environments. - Durable Material Construction

Constructed with a high-strength cast iron housing, the WPWKV worm gear reducers use a 45# steel worm and tin bronze worm wheel, heat-treated for enhanced durability. Premium NSK bearings and Simrit oil seals ensure long-lasting performance, resisting wear even in demanding, continuous-operation settings. - Low Noise and Vibration

Engineered for smooth operation, the worm reducer gearboxes minimize noise and vibration through precision-machined gears and robust housing. This feature enhances workplace comfort and reduces mechanical stress, making it suitable for applications requiring quiet performance, such as in food processing or packaging industries. - Self-Locking Capability

Under specific conditions, the WPWKV worm and wheel gearbox offers self-locking, preventing back-driving when the motor is off. This safety feature is critical for applications like lifts or winches, where load stability is essential, ensuring secure operation without additional braking mechanisms in certain configurations. - High Efficiency and Low Maintenance

With optimized gear designs and quality lubrication systems, the worm drive reduction gearbox ensures efficient power transmission with minimal energy loss. Its robust build reduces maintenance needs, offering reliable, long-term operation in industries like mining, agriculture, or manufacturing, lowering overall operational costs.

WPWKV Worm Gear Reducer Application Industry

- Material Handling Industry

WPWKV worm gear reducers are widely used in conveyor systems for material handling. Their high torque and compact design efficiently drive belts and rollers, ensuring smooth transport of goods in warehouses, distribution centers, and manufacturing plants with reliable, low-maintenance operation. - Agricultural Machinery

In agriculture, worm reducer gearboxes power equipment like grain augers, feed mixers, and irrigation systems. Their robust construction and self-locking feature provide dependable performance in harsh environments, handling heavy loads while reducing maintenance needs for farming operations. - Mining and Quarrying

WPWKV worm gear speed reducers are employed in mining equipment such as crushers, conveyors, and hoists. Their durability and ability to handle high torque under dusty, rugged conditions make them ideal for continuous operation in extracting and processing minerals. - Packaging Industry

The WPWKV worm and wheel gearbox’s low noise and smooth operation suit packaging machinery like filling, sealing, and labeling systems. Its compact design and precise speed control ensure efficient, quiet performance, meeting the high-speed demands of automated packaging lines in various sectors. - Construction Equipment

In construction, worm drive gearboxes drive machinery like concrete mixers and winches. Their high torque output and self-locking capability ensure safe, reliable operation under heavy loads, supporting tasks in building and infrastructure development with minimal maintenance requirements. - Food Processing Industry

WPWKV worm reduction gearboxes are utilized in food processing equipment, such as mixers and conveyors. Their low noise, efficient torque, and durable, easy-to-clean design meet hygiene and performance standards, ensuring consistent operation in food production environments.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Construction Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Food and Beverage Industry |

Other Worm Gearbox Types

Additional information

| Edited by | Yjx |

|---|