WPWKS Worm Gear Reducers/Worm Gearbox

WPWKS worm gear reducers, part of the WP series worm gearboxes, are high-efficiency mechanical devices designed for industrial power transmission. They feature a compact cast iron housing, worm gears (typically made from 45# high-quality steel, heat-treated for durability), and a tin bronze worm wheel, ensuring robust load capacity and wear resistance. The WPWKS worm drive gearbox has an integral universal type shaft hole output with the input shaft positioned on the upper side, offering versatile mounting options (horizontal or vertical) for both input and output shafts.

WPWKS worm gear reducers, part of the WP series worm gearboxes, are high-efficiency mechanical devices designed for industrial power transmission. They feature a compact cast iron housing, worm gears (typically made from 45# high-quality steel, heat-treated for durability), and a tin bronze worm wheel, ensuring robust load capacity and wear resistance. The WPWKS worm drive gearbox has an integral universal type shaft hole output with the input shaft positioned on the upper side, offering versatile mounting options (horizontal or vertical) for both input and output shafts.

With gear ratios ranging from 10:1 to 60:1, they provide high torque multiplication and speed reduction, ideal for applications like conveyors, food processing equipment, and hoists. Their self-locking capability under specific conditions (e.g., high reduction ratios) enhances safety by preventing reverse rotation. These worm gear speed reducers are known for low noise, minimal vibration, and maintenance-free operation due to sealed lubrication systems. They are widely used in industries such as plastics, metallurgy, and chemical processing, offering reliable performance in compact spaces.

WPWKS Worm Gear Reducer Specifications

| Type: | WPWDS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

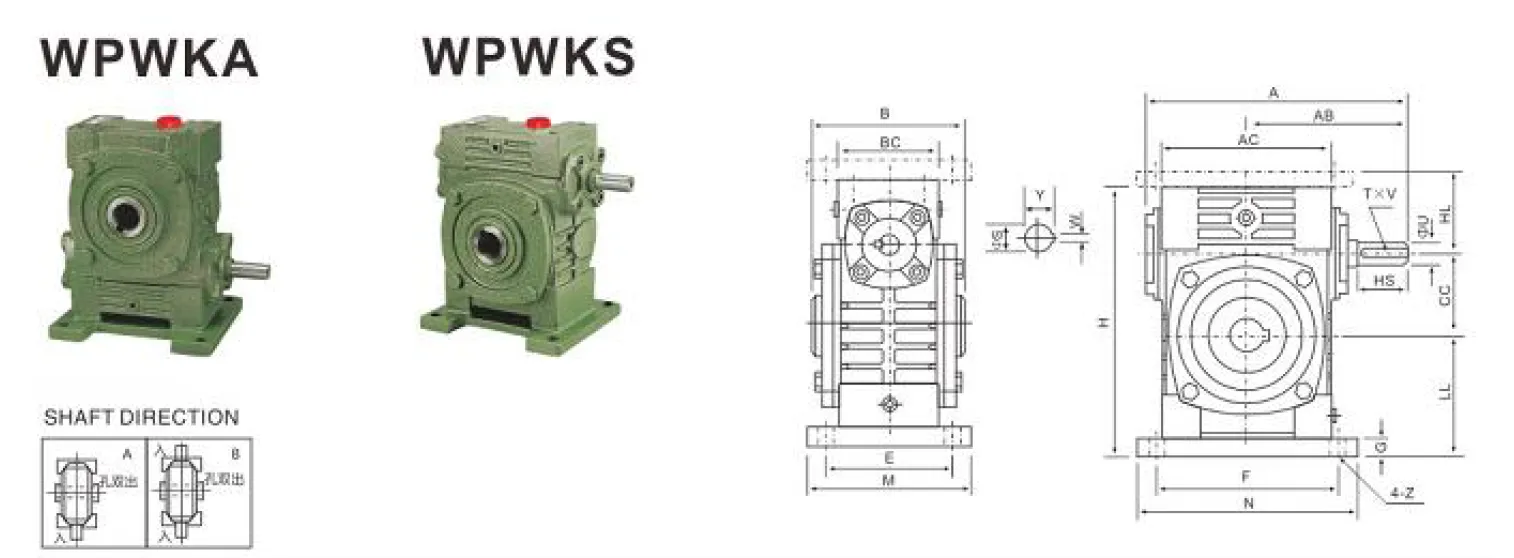

WPWKS Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | AC | BC | CC | HL | LL | H | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/20 1/25 1/30 1/40 1/50 1/60 | 149 | 89 | 90 | 95 | 61 | 40 | 45 | 60 | 135 | 100 | 130 | 80 | 110 | 10 | 10 |

| 50 | 175 | 107 | 110 | 111 | 68 | 50 | 50 | 80 | 165 | 120 | 140 | 95 | 110 | 15 | 12 | |

| 60 | 198 | 122 | 120 | 127 | 76 | 60 | 60 | 93 | 195 | 130 | 150 | 105 | 120 | 18 | 12 | |

| 70 | 231 | 140 | 132 | 152 | 86 | 70 | 73 | 108 | 233 | 150 | 190 | 115 | 150 | 18 | 15 | |

| 80 | 261 | 160 | 150 | 169 | 102 | 80 | 83 | 123 | 268 | 170 | 220 | 135 | 180 | 18 | 15 | |

| 100 | 322 | 180 | 174 | 216 | 117 | 100 | 100 | 150 | 330 | 190 | 270 | 155 | 220 | 20 | 15 | |

| 120 | 381 | 229 | 180 | 256 | 124 | 120 | 120 | 180 | 395 | 230 | 320 | 180 | 260 | 25 | 18 | |

| 135 | 433 | 260 | 214 | 296 | 147 | 135 | 135 | 215 | 455 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 155 | 504 | 302 | 256 | 345 | 185 | 155 | 135 | 235 | 493 | 280 | 380 | 220 | 320 | 32 | 21 | |

| 175 | 545 | 325 | 282 | 374 | 192 | 175 | 160 | 260 | 558 | 310 | 410 | 250 | 350 | 37 | 21 | |

| 200 | 587 | 350 | 324 | 412 | 230 | 200 | 175 | 290 | 620 | 355 | 445 | 290 | 390 | 45 | 24 | |

| 250 | 705 | 420 | 400 | 500 | 285 | 250 | 200 | 350 | 750 | 460 | 560 | 380 | 480 | 50 | 28 |

| Input shaft | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 16 | 5×3 | 4.5 |

| 30 | 12 | 4×2.5 | 20 | 6×2.8 | 7.5 |

| 40 | 15 | 5×3 | 25 | 8×2.8 | 11.5 |

| 40 | 19 | 6×3.5 | 30 | 8×3.3 | 15.5 |

| 50 | 22 | 6×3.5 | 35 | 10×3.8 | 24 |

| 50 | 25 | 8×4 | 40 | 12×4.3 | 39 |

| 65 | 30 | 8×4 | 45 | 14×4.8 | 57 |

| 75 | 35 | 10×5 | 50 | 18×6.4 | 85 |

| 85 | 40 | 12×5 | 70 | 20×7.4.9 | 110 |

| 85 | 45 | 14×5.5 | 80 | 22×8.5.4 | 152 |

| 100 | 50 | 14×5.5 | 85 | 22×9.0.4 | 216 |

| 120 | 60 | 18×7 | 110 | 28×11.6.4 | 350 |

WPWKS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWKS Worm Gear Reducer Characteristic

- High Efficiency and Torque Output

WPWKS worm gear reducers deliver exceptional torque multiplication with gear ratios from 10:1 to 60:1. Constructed with a 45# steel worm and tin bronze worm wheel, they ensure efficient power transmission, ideal for heavy-duty applications like conveyors and hoists, providing reliable performance. - Compact and Versatile Design

The worm drive gearbox features a compact cast iron housing, enabling easy integration into space-constrained setups. Its universal shaft hole output and upper-side input shaft allow flexible horizontal or vertical mounting, making it adaptable for diverse industrial applications such as food processing and metallurgy. - Self-Locking Capability

Under high reduction ratios, the WPWKS worm reducer gearboxes offers self-locking functionality, preventing reverse rotation. This feature enhances safety in applications like lifting equipment, ensuring loads remain secure without additional braking systems, making it a preferred choice for hoists and cranes. - Low Noise and Vibration

Designed for smooth operation, worm gear speed reducers minimize noise and vibration through precision-engineered gears and a sealed lubrication system. This ensures quiet performance, making them suitable for environments like packaging or chemical processing where noise reduction is critical for operational comfort. - Durable and Low Maintenance

Built with wear-resistant materials like heat-treated steel and tin bronze, WPWKS worm gearboxes are highly durable. The sealed lubrication system reduces maintenance needs, ensuring long service life in demanding industries such as plastics, cement, and beverage production. - Wide Industrial Applications

Worm gear drive gearboxes are versatile, supporting industries like metallurgy, chemical processing, and textiles. Their robust load capacity and reliable speed reduction make them ideal for conveyors, mixers, and other machinery, ensuring consistent performance across various heavy-duty operational environments.

WPWKS Worm Reducer Gearbox Application Industry

- Plastics Industry

The WPWKS worm reducer gearboxes are widely used in the plastics industry for driving equipment like extruders and injection molding machines. Its ability to provide precise speed control and high torque makes it ideal for managing the demanding requirements of material mixing, shaping, and processing in plastic production. - Metallurgy Industry

In the metallurgy industry, worm gear gearboxes are employed in equipment such as rolling mills, crushers, and conveyors. Their robust construction and high load-bearing capacity allow them to handle the heavy-duty operations required for processing metals, including cutting, shaping, and transporting raw materials and finished products. - Food Processing Industry

Food processing machinery, such as conveyors, mixers, and packaging equipment, frequently incorporates worm gear reducers. Their low noise and vibration levels, along with sealed lubrication systems, ensure hygienic operation and reliable performance in environments where cleanliness and efficiency are critical for maintaining product quality. - Chemical Processing Industry

The chemical industry relies on WPWKS worm reduction gearboxes for applications in reactors, mixers, and pumps. Their ability to provide stable speed reduction and torque multiplication ensures precise control over chemical reactions, blending, and material handling, even under harsh conditions involving corrosive substances and extreme temperatures. - Material Handling and Conveying Systems

Worm gear reducer gearboxes are integral to conveyor systems and hoists used in warehouses, factories, and construction sites. Their self-locking capability enhances safety by preventing reverse motion, while their compact design allows them to operate effectively in space-constrained environments where efficient material transport is essential. - Textile Industry

In the textile industry, WPWKS worm gear speed reducers are used in spinning machines, looms, and other fabric manufacturing equipment. Their precise speed control and reliable operation enable the smooth processing of fibers and fabrics, ensuring uniformity and high-quality output in the production of textiles and garments.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Textile Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Plastic and Rubber Machinery |

Other Worm Gearbox Types

- Single Reduction Worm Gearbox

This type features a single worm and worm wheel pair, offering simple speed reduction with ratios typically from 5:1 to 100:1. It is compact, cost-effective, and widely used in applications like conveyors, small machinery, and material handling systems requiring moderate torque output. - Double Reduction Worm Gearbox

Comprising two worm gear sets, this double reduction worm gearbox achieves higher reduction ratios, often up to 3600:1. It is ideal for heavy-duty applications like cranes and mining equipment, providing substantial torque multiplication while maintaining compact design and reliable performance in demanding industrial environments. - Right Angle Worm Gearbox

Designed with perpendicular input and output shafts, this type suits space-constrained setups. It offers efficient power transmission for applications like packaging machines and robotics, delivering high torque and self-locking capabilities, ensuring stability in operations requiring precise motion control. - Hollow Shaft Worm Gearbox

Featuring a hollow output shaft, this type allows direct mounting onto driven equipment, reducing alignment issues. It is used in textile machinery and conveyor systems, offering flexibility, easy installation, and high torque for applications requiring seamless integration with existing setups. - Modular Worm Gearbox

This type supports customizable configurations with interchangeable components like flanges and shafts. It is versatile for industries such as food processing and automotive, providing adaptable solutions for varied speed and torque needs while maintaining durability and ease of maintenance across applications. - Servo Worm Gearbox

Tailored for precision, this servo worm gearbox integrates with servo motors for accurate control in automation and CNC machinery. It offers low backlash, high efficiency, and smooth operation, making it ideal for robotics and high-precision tasks requiring consistent torque and minimal positional errors.

Additional information

| Edited by | Yjx |

|---|