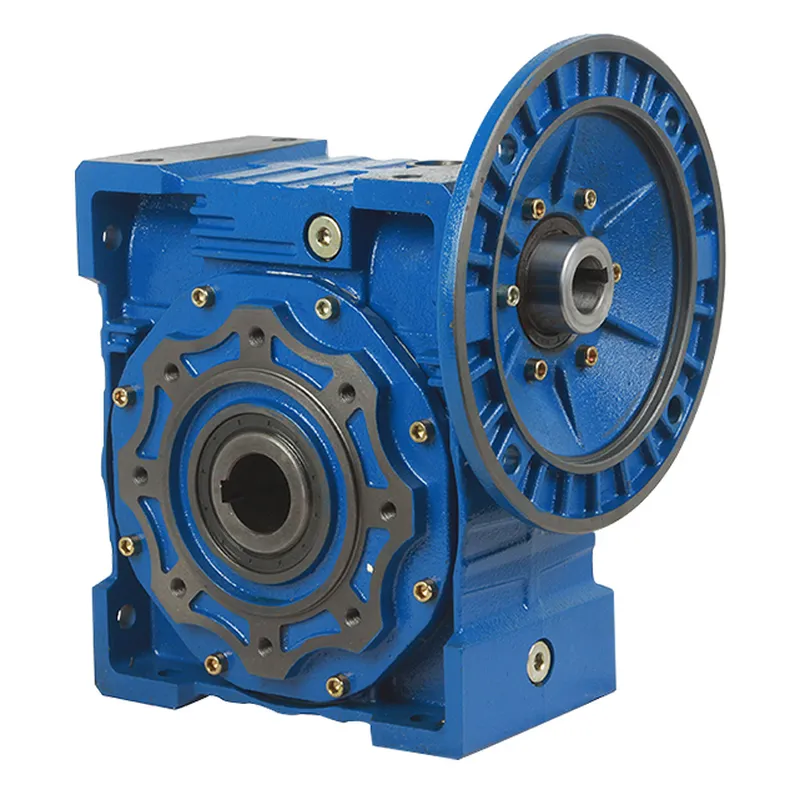

WPWKO Worm Gear Reducers/Worm Gearbox

WPWKO worm gear reducers, commonly known as worm gearboxes, are highly efficient mechanical devices engineered for reliable power transmission across a wide range of industrial applications. These worm gear speed reducers consist of two key components: a worm (a screw-like gear) and a worm wheel (a toothed gear), housed within a durable cast iron chassis. This robust construction ensures excellent resistance to deformation under load and long-term durability.

WPWKO worm gear reducers, commonly known as worm gearboxes, are highly efficient mechanical devices engineered for reliable power transmission across a wide range of industrial applications. These worm gear speed reducers consist of two key components: a worm (a screw-like gear) and a worm wheel (a toothed gear), housed within a durable cast iron chassis. This robust construction ensures excellent resistance to deformation under load and long-term durability. The WPWKO series, a part of the renowned WP series worm gearbox, stands out for its compact design, high reduction ratios (up to 60:1 or more in multi-stage configurations), and self-locking features under specific conditions, which prevent reverse motion. These worm gearboxes offer versatile mounting options, allowing for horizontal or vertical installation based on application needs.

The worm is typically made from heat-treated 45# steel for optimal strength, while the worm wheel is crafted from tin bronze, providing superior wear resistance. These materials, combined with precision design, ensure stable, smooth, and low-noise operation, even under demanding conditions. Widely used in industries such as plastics, metallurgy, and conveyor systems, WPWKO worm reducer gearboxes deliver dependable performance, long service life, and high efficiency in power transmission tasks.

WPWKO Worm Gear Reducer Specifications

| Type: | WPWKO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

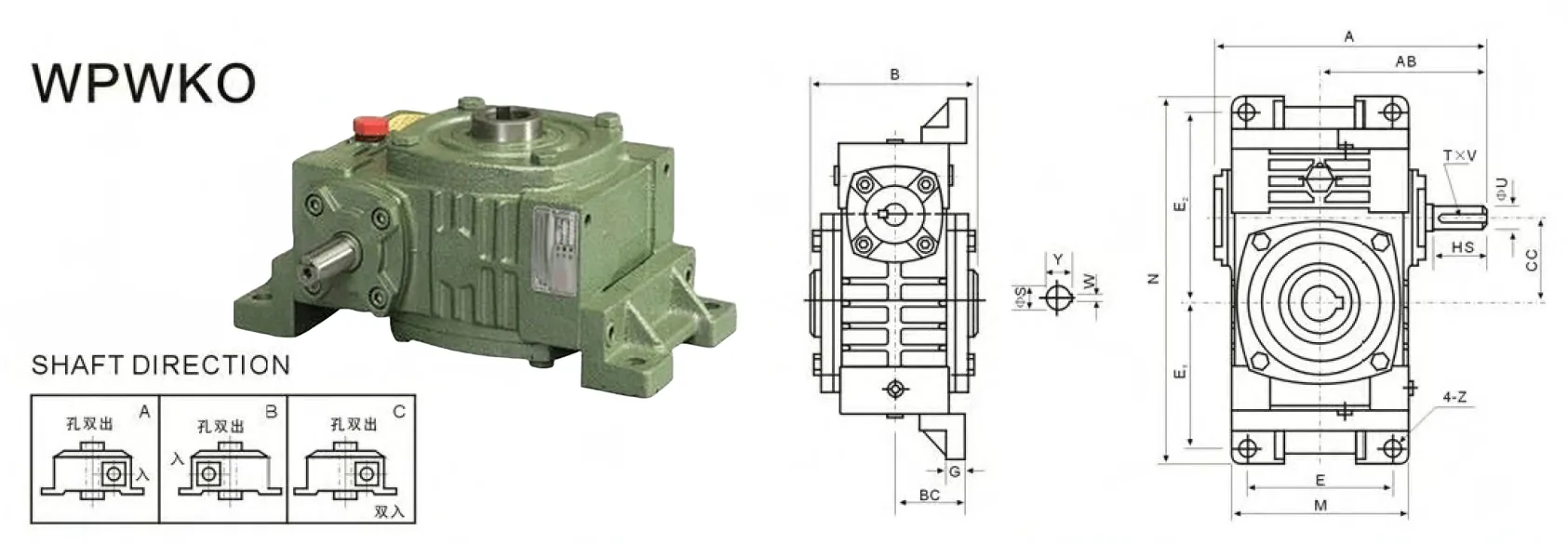

WPWKO Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | BC | CC | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 85 | 45 | 40 | 95 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 175 | 108 | 105 | 50 | 50 | 111 | 226 | 90 | 90 | 110 | 14 | 12 | |

| 60 | 198 | 120 | 110 | 55 | 60 | 127 | 257 | 100 | 102 | 129 | 15 | 12 | |

| 70 | 231 | 140 | 130 | 65 | 70 | 152 | 305 | 120 | 120 | 155 | 20 | 15 | |

| 80 | 261 | 160 | 150 | 70 | 80 | 174 | 350 | 140 | 140 | 180 | 20 | 15 | |

| 100 | 322 | 190 | 160 | 90 | 100 | 224 | 410 | 190 | 165 | 215 | 22 | 15 | |

| 120 | 371 | 219 | 175 | 100 | 120 | 264 | 494 | 220 | 195 | 255 | 25 | 18 | |

| 135 | 422 | 249 | 210 | 110 | 135 | 304 | 559 | 260 | 230 | 285 | 30 | 18 | |

| 155 | 497 | 295 | 256 | 140 | 155 | 345 | 605 | 290 | 250 | 305 | 35 | 21 | |

| 175 | 534 | 314 | 282 | 150 | 175 | 374 | 675 | 320 | 273 | 348 | 40 | 21 | |

| 200 | 580 | 342 | 320 | 175 | 200 | 424 | 749 | 370 | 305 | 390 | 40 | 24 | |

| 250 | 705 | 420 | 400 | 200 | 250 | 510 | 920 | 440 | 375 | 475 | 45 | 28 |

| Input shaft | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 16 | 6×18.8 | 5 |

| 30 | 12 | 4×2.5 | 20 | 6×22.8 | 8 |

| 40 | 15 | 5×3 | 25 | 8×28.3 | 11 |

| 40 | 18 | 5×3 | 30 | 8×33.3 | 15.5 |

| 50 | 22 | 7×4 | 35 | 10×38.3 | 24 |

| 50 | 25 | 7×4 | 40 | 12×43.3 | 38 |

| 65 | 30 | 7×4 | 45 | 14×48.8 | 56 |

| 75 | 35 | 10×4.5 | 60 | 18×64.4 | 84 |

| 85 | 40 | 12×5.5 | 70 | 20×74.9 | 129 |

| 85 | 45 | 14×5.5 | 80 | 22×85.4 | 157 |

| 95 | 50 | 14×5.5 | 85 | 22×90.4 | 224 |

| 110 | 60 | 18×7 | 110 | 28×116.4 | 374 |

WPWKO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWKO Worm Gear Reducer Characteristic

1. High Reduction Ratio

WPWKO worm gear reducers achieve significant speed reduction with ratios ranging from 10:1 to 60:1 or higher in multi-stage configurations. This allows precise control of output speed, making them ideal for applications requiring low-speed, high-torque output, such as conveyor systems or heavy machinery.

2. Self-Locking Capability

Under specific conditions, these worm reducer gearboxes exhibit self-locking, preventing reverse motion without external braking. This feature enhances safety and reliability in applications like hoists or lifts, where maintaining position under load is critical, reducing the need for additional locking mechanisms.

3. Durable Material Construction

The worm is typically crafted from heat-treated 45# steel, while the worm wheel uses tin bronze. These materials ensure excellent wear resistance and durability, enabling the gearbox to withstand heavy loads and harsh operating environments, prolonging service life.

4. Compact and Versatile Design

WPWKO worm gear speed reducers feature a compact structure, allowing easy integration into space-constrained systems. Their versatile mounting options, including horizontal and vertical orientations, provide flexibility for diverse applications in industries like plastics, metallurgy, and material handling.

5. Low Noise and Smooth Operation

Precision-engineered gears and high-quality lubrication minimize vibration and noise during operation. This ensures a quiet, stable performance, which is essential for environments where noise reduction is critical, such as in automated production lines or indoor machinery setups.

6. High Efficiency and Reliability

With robust cast iron housing and optimized gear meshing, WPWKO worm drive gearboxes deliver efficient power transmission with minimal energy loss. Their design ensures consistent performance under varying loads, making them reliable for continuous operation in demanding industrial settings.

WPWKO Worm Reducer Gearbox Applications

1. Conveyor Systems

WPWKO worm gear reducers are widely used in conveyor systems for material handling in industries like mining and manufacturing. Their high reduction ratios and self-locking feature ensure precise speed control and prevent rollback, enhancing efficiency in transporting heavy loads.

2. Plastics Machinery

In plastic extrusion and injection molding machines, worm reducer gearboxes provide the high torque needed for consistent material processing. Their compact design allows seamless integration into complex machinery, ensuring reliable operation and precise control over rotational speed during production.

3. Metallurgy Equipment

WPWKO worm and wheel gearboxes drive heavy-duty metallurgical equipment, such as rolling mills and furnaces. Their durable construction, using heat-treated steel and tin bronze, withstands high loads and harsh conditions, delivering stable power transmission for continuous metal processing operations.

4. Hoisting and Lifting Equipment

The self-locking capability of worm gear speed reducers makes them ideal for hoists and cranes. They ensure safe load holding without additional braking systems, providing reliable performance in construction and logistics for lifting heavy materials with precision.

5. Packaging Machinery

WPWKO worm gear gearboxes are employed in packaging equipment, such as filling and sealing machines. Their low-noise operation and smooth performance support high-speed, precise movements, ensuring efficient packaging processes in food, beverage, and pharmaceutical industries.

6. Automated Production Lines

In automated assembly lines, worm drive gearboxes facilitate precise motion control for robotic arms and conveyors. Their versatility in mounting and high reliability under continuous operation make them essential for maintaining productivity in automotive and electronics manufacturing.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Plastic and Rubber Machinery |

|  |

| Worm Gearbox for Metallurgy Industry | Worm Gearbox for Construction Industry |

WPWKO Worm Gear Speed Reducer Troubleshooting

1. Excessive Noise During Operation

If the reducer produces excessive noise, it may indicate improper lubrication, worn gears, or misalignment between the worm and worm wheel. Inspect the lubricant for contamination or insufficient levels and check the gear alignment to ensure smooth and quiet operation.

2. Overheating of the Gearbox

Overheating can result from insufficient lubrication, excessive load, or poor ventilation. Verify that the correct type and amount of lubricant is being used, reduce the load if it exceeds the worm gear drive gearbox's rated capacity, and ensure proper ventilation around the unit.

3. Oil Leaks from the Gearbox

Oil leaks may occur due to damaged seals, loose bolts, or excessive oil levels. Inspect and replace worn or damaged seals, tighten bolts to the recommended torque, and ensure that the lubricant is filled to the correct level as per the manufacturer's guidelines.

4. Reduced Output Torque or Efficiency

A drop in output torque or efficiency can result from worn gears, internal contamination, or incorrect installation. Inspect the internal components for wear or debris, clean the gearbox thoroughly, and ensure proper alignment during reassembly to restore optimal performance.

5. Vibration During Operation

Vibrations can be caused by gear wear, misalignment, or an unstable mounting surface. Check for worn or damaged gears, ensure that the worm drive reduction gearbox is aligned correctly with the connected equipment, and secure the unit to a stable and level mounting base.

6. Unusual Wear on Gears or Components

Unusual wear is often due to inadequate lubrication, using the wrong lubricant type, or operating under excessive loads. Regularly monitor lubrication levels, use the manual-recommended lubricant, and ensure that the load does not exceed the rated capacity of the gearbox.

Additional information

| Edited by | Yjx |

|---|