WPWKA Worm Gear Reducers/Worm Gearbox

WPWKA worm gear reducers, part of the WP series worm gearboxes, are advanced mechanical devices engineered for efficient power transmission in industrial applications. These gearboxes feature a robust cast iron housing that provides exceptional rigidity, high load capacity, and resistance to deformation, ensuring durability in demanding environments. The internal components include a worm made from heat-treated 45# high-quality steel and a tin bronze worm gear, which together deliver excellent wear resistance and reliable torque output.

WPWKA worm gear reducers, part of the WP series worm gearboxes, are advanced mechanical devices engineered for efficient power transmission in industrial applications. These gearboxes feature a robust cast iron housing that provides exceptional rigidity, high load capacity, and resistance to deformation, ensuring durability in demanding environments. The internal components include a worm made from heat-treated 45# high-quality steel and a tin bronze worm gear, which together deliver excellent wear resistance and reliable torque output. A distinctive feature of the WPWKA worm gearbox is its integral input shaft positioned in the lower location, optimizing its compact design.

Available in frame sizes ranging from 40 to 250 mm with center distances between 40–250 mm, these worm gear speed reducers support gear ratios from 5:1 to 60:1. They are known for their stable transmission, low noise operation, and self-locking capabilities under specific conditions. This makes them ideal for industries such as plastics, metallurgy, mining, and chemicals. The worm reducer gearboxes are versatile, offering horizontal or vertical mounting options, solid or hollow output shafts, and compatibility with IEC B5 motor flanges, ensuring seamless integration into various systems.

WPWKA Worm Gear Reducer Specifications

| Type: | WPWKA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

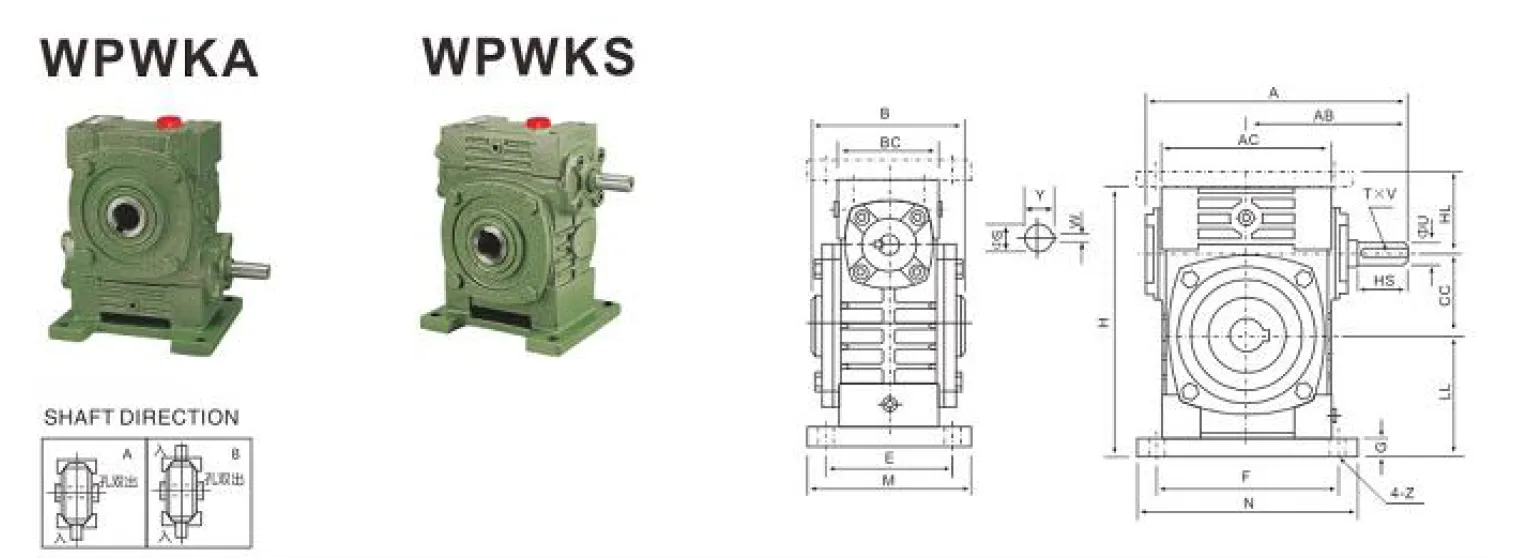

WPWKA Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | AC | BC | CC | HL | LL | H | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/20 1/25 1/30 1/40 1/50 1/60 | 149 | 89 | 90 | 95 | 61 | 40 | 45 | 60 | 135 | 100 | 130 | 80 | 110 | 10 | 10 |

| 50 | 175 | 107 | 110 | 111 | 68 | 50 | 50 | 80 | 165 | 120 | 140 | 95 | 110 | 15 | 12 | |

| 60 | 198 | 122 | 120 | 127 | 76 | 60 | 60 | 93 | 195 | 130 | 150 | 105 | 120 | 18 | 12 | |

| 70 | 231 | 140 | 132 | 152 | 86 | 70 | 73 | 108 | 233 | 150 | 190 | 115 | 150 | 18 | 15 | |

| 80 | 261 | 160 | 150 | 169 | 102 | 80 | 83 | 123 | 268 | 170 | 220 | 135 | 180 | 18 | 15 | |

| 100 | 322 | 180 | 174 | 216 | 117 | 100 | 100 | 150 | 330 | 190 | 270 | 155 | 220 | 20 | 15 | |

| 120 | 381 | 229 | 180 | 256 | 124 | 120 | 120 | 180 | 395 | 230 | 320 | 180 | 260 | 25 | 18 | |

| 135 | 433 | 260 | 214 | 296 | 147 | 135 | 135 | 215 | 455 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 155 | 504 | 302 | 256 | 345 | 185 | 155 | 135 | 235 | 493 | 280 | 380 | 220 | 320 | 32 | 21 | |

| 175 | 545 | 325 | 282 | 374 | 192 | 175 | 160 | 260 | 558 | 310 | 410 | 250 | 350 | 37 | 21 | |

| 200 | 587 | 350 | 324 | 412 | 230 | 200 | 175 | 290 | 620 | 355 | 445 | 290 | 390 | 45 | 24 | |

| 250 | 705 | 420 | 400 | 500 | 285 | 250 | 200 | 350 | 750 | 460 | 560 | 380 | 480 | 50 | 28 |

| Input shaft | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 16 | 5×3 | 4.5 |

| 30 | 12 | 4×2.5 | 20 | 6×2.8 | 7.5 |

| 40 | 15 | 5×3 | 25 | 8×2.8 | 11.5 |

| 40 | 19 | 6×3.5 | 30 | 8×3.3 | 15.5 |

| 50 | 22 | 6×3.5 | 35 | 10×3.8 | 24 |

| 50 | 25 | 8×4 | 40 | 12×4.3 | 39 |

| 65 | 30 | 8×4 | 45 | 14×4.8 | 57 |

| 75 | 35 | 10×5 | 50 | 18×6.4 | 85 |

| 85 | 40 | 12×5 | 70 | 20×7.4.9 | 110 |

| 85 | 45 | 14×5.5 | 80 | 22×8.5.4 | 152 |

| 100 | 50 | 14×5.5 | 85 | 22×9.0.4 | 216 |

| 120 | 60 | 18×7 | 110 | 28×11.6.4 | 350 |

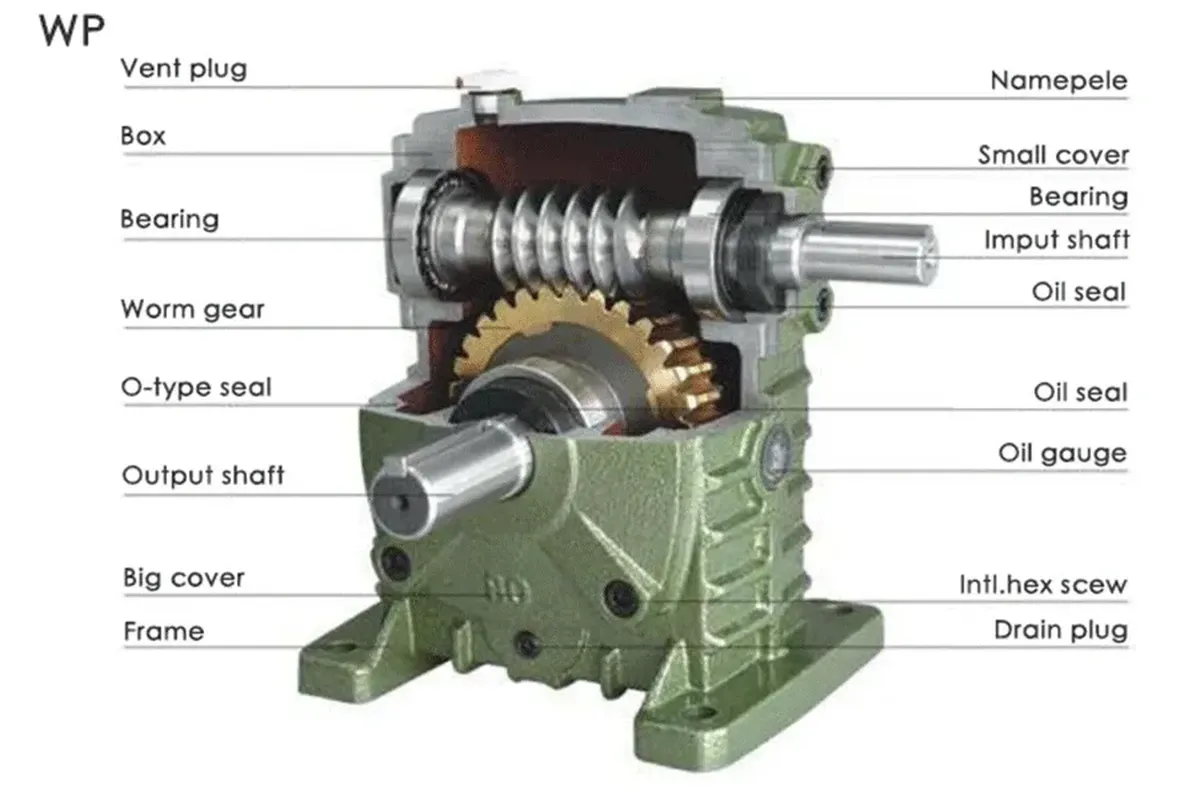

WPWKA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWKA Worm Gear Speed Reducer Characteristic

- High Efficiency and Torque Output

WPWKA worm gear speed reducers deliver exceptional power transmission efficiency. Constructed with a heat-treated 45# steel worm and a durable tin bronze worm gear, they ensure high torque output, making them suitable for heavy-duty applications in industries like metallurgy and mining. - Compact and Robust Design

These worm gear reducers feature a compact cast iron housing that enhances structural rigidity and resists deformation under heavy loads. The design ensures durability and space efficiency, allowing seamless integration into various machinery setups, including those with limited installation space. - Versatile Gear Ratios

WPWKA worm drive gearboxes support a wide range of gear ratios, from 5:1 to 100:1, with double reduction units extending up to 10,000:1. This versatility enables precise speed control, catering to diverse operational requirements across industrial applications. - Low Noise and Stable Operation

The precision-engineered worm and worm gear combination ensures smooth and stable transmission. This results in minimal vibration and low noise levels, improving workplace conditions and extending the lifespan of the worm reducer gearbox in continuous operation. - Flexible Mounting Options

WPWKA right angle worm gearboxes offer horizontal or vertical mounting configurations with solid or hollow output shafts. Compatibility with IEC B5 motor flanges allows easy integration with various motor types, enhancing adaptability for different industrial setups and machinery designs. - Self-Locking Capability

Under specific conditions, these worm gear reducer gearboxes provide self-locking functionality, preventing back-driving and enhancing safety in applications requiring load holding. This feature is particularly valuable in industries like chemical processing, where precise control and stability are critical for operational reliability.

WPWKA Worm Reducer Gearbox Application Fields

- Plastics Industry

In the plastics industry, the WPWKA worm reducer gearbox is used for precise speed control in extrusion and molding machines. Its stable transmission and self-locking capabilities ensure high efficiency and safety in processes requiring consistent torque and minimal backlash. - Metallurgy and Steel Processing

The worm gearboxes are widely applied in metallurgy for handling equipment like rolling mills and material conveyors. Its robust cast iron housing and high load capacity allow it to operate reliably under heavy loads and challenging environments, ensuring sustained performance. - Mining Operations

Mining equipment such as crushers, conveyors, and hoists benefits significantly from the WPWKA worm gear gearbox. Its durability, wear resistance, and ability to handle high torque make it ideal for heavy-duty operations in abrasive and demanding conditions. - Chemical Processing Industry

In chemical plants, the worm and wheel gearbox supports mixers, agitators, and pumps by providing stable and low-noise speed reduction. Its compatibility with IEC B5 motor flanges allows seamless integration with various machinery, ensuring efficiency and reliability in continuous processing operations. - Textile Machinery

The WPWKA worm reducer gearboxes are essential in textile machinery for precise control of spinning and weaving processes. Its compact design, smooth transmission, and noise reduction capabilities make it suitable for maintaining high-quality production in noise-sensitive environments. - Material Handling Systems

The worm gear speed reducers are a key component in conveyors, elevators, and automated handling systems. Its flexible mounting options and ability to maintain stable operation under load variations ensure efficient material transport in logistics, warehousing, and industrial production lines.

|  |

| Worm Gearbox for Plastic and Rubber Machinery | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Metallurgy Industry | Worm Gearbox for Chemical Industry |

WPWKA Worm Gear Reducer Components

- Cast Iron Housing

The housing of the worm gear reducer is made from high-strength cast iron, providing exceptional rigidity and durability. It protects internal components from external impacts and deformation, ensuring long-term performance even in harsh industrial environments with heavy vibration and load conditions. - Worm Shaft

The worm shaft is crafted from heat-treated 45# high-quality steel, offering excellent strength and wear resistance. This component is essential for transmitting torque and reducing speed efficiently, ensuring smooth and stable operation under various load conditions in industrial machinery. - Tin Bronze Worm Gear

The worm gear is made of tin bronze, which provides superior wear resistance and low friction. This material combination enhances the reducer’s efficiency and longevity, allowing it to operate reliably in applications requiring high torque and frequent usage. - Input Shaft

The integral input shaft, positioned in the lower section of the WPWKA model, is designed for direct motor coupling. This compact and efficient design simplifies the connection process, reduces space requirements, and enhances the gearbox's adaptability to different motor configurations. - Output Shaft

The output shaft is available in both solid and hollow designs, allowing for versatile integration with various mechanical systems. Its precise construction ensures accurate torque transmission and stable operation, making it suitable for a wide range of industrial applications. - Sealing System

The reducer includes high-quality seals that prevent oil leaks and protect internal components from dust and contaminants. This ensures smooth operation, reduces maintenance frequency, and prolongs the overall lifespan of the gearbox even in dusty or humid environments. - Cooling Fins

The exterior of the housing is equipped with cooling fins, which improve heat dissipation during operation. This feature prevents overheating, maintains optimal performance, and extends the service life of the gearbox, especially in high-temperature industrial applications.

Additional information

| Edited by | Yjx |

|---|