WPWEKO Worm Gear Reducers/Worm Gearbox

WPWEKO worm gear reducers, also known as double reduction worm gearboxes, are advanced, compact, and highly efficient double-stage reduction systems designed for diverse industrial applications. The WPWEKO worm reducer gearbox integrates a single-stage worm gearbox with a universal gearbox, enhancing performance, flexibility, and torque output. These double reduction worm gearboxes deliver a single-stage speed ratio range of 1:10 to 1:60, while the double-stage configuration achieves higher ratios from 1:200 to 1:900 by combining the ratios of two single-stage units.

WPWEKO worm gear reducers, also known as double reduction worm gearboxes, are advanced, compact, and highly efficient double-stage reduction systems designed for diverse industrial applications. The WPWEKO worm reducer gearbox integrates a single-stage worm gearbox with a universal gearbox, enhancing performance, flexibility, and torque output. These double reduction worm gearboxes deliver a single-stage speed ratio range of 1:10 to 1:60, while the double-stage configuration achieves higher ratios from 1:200 to 1:900 by combining the ratios of two single-stage units.

Worm gear speed reducer used for applications requiring significant speed reduction and high torque, such as plastics processing, metallurgy, beverage production, mining, lifting and transportation, and chemical construction industries. Their robust design ensures durability, low maintenance, and reliable operation in demanding environments, offering superior efficiency and adaptability across various industrial sectors.

WPWEKO Worm Gear Reducer Specifications

| Type: | WPWEKO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

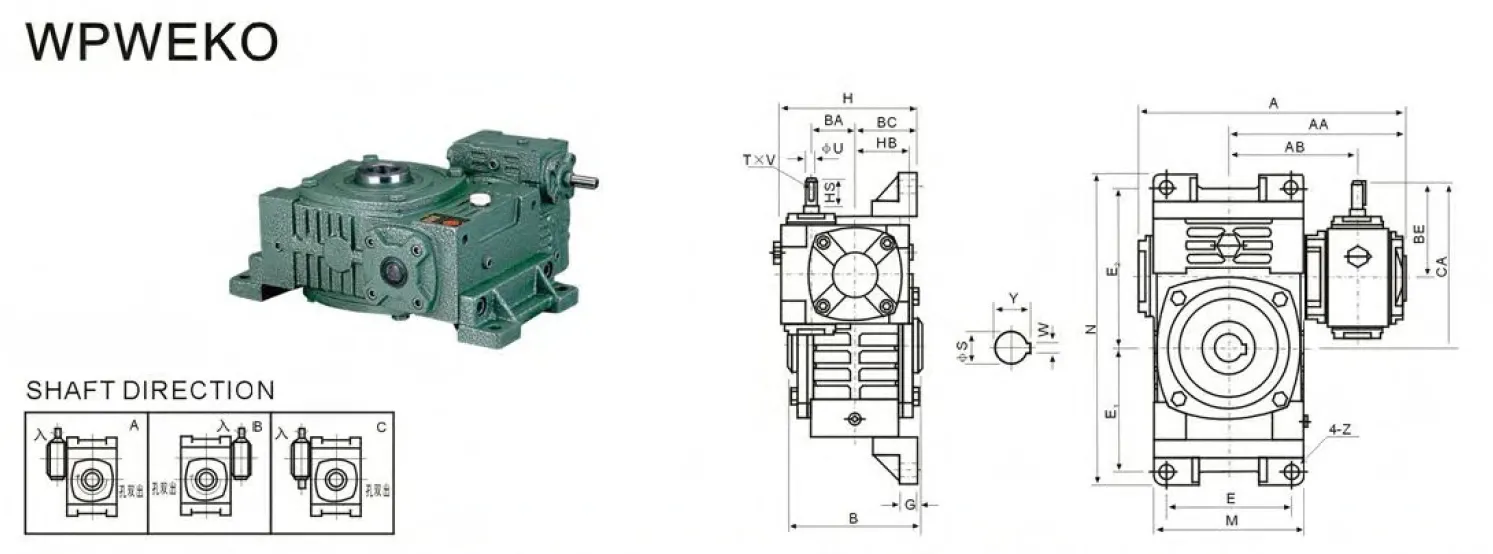

WPWEKO Worm Gearbox Dimensions

| Model | Ratio | A | AA | AB | B | BA | BC | BE | HB | CA | H | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 .... .... | 286 | 195 | 153 | 130 | 40 | 65 | 87 | 50 | 157 | 140 | 152 | 305 | 120 | 120 | 155 | 20 | 15 |

| 50-80 | 297 | 197 | 144 | 150 | 50 | 70 | 108 | 65 | 188 | 155 | 174 | 350 | 140 | 140 | 180 | 20 | 15 | |

| 60-100 | 363 | 231 | 175 | 160 | 60 | 90 | 120 | 76 | 222 | 192 | 224 | 410 | 190 | 165 | 215 | 22 | 15 | |

| 70-120 | 408 | 256 | 193 | 175 | 70 | 100 | 140 | 90 | 260 | 225 | 264 | 494 | 220 | 195 | 255 | 25 | 18 | |

| 80-135 | 471 | 298 | 226 | 210 | 80 | 110 | 160 | 105 | 295 | 255 | 304 | 559 | 260 | 230 | 285 | 30 | 18 | |

| 100-155 | 555 | 354 | 269 | 256 | 100 | 140 | 190 | 130 | 345 | 320 | 345 | 605 | 290 | 250 | 305 | 35 | 21 | |

| 120-175 | 598 | 379 | 287 | 282 | 120 | 150 | 219 | 155 | 394 | 365 | 374 | 675 | 320 | 273 | 348 | 40 | 21 | |

| 135-200 | 662 | 425 | 318 | 320 | 135 | 175 | 256 | 185 | 456 | 415 | 424 | 749 | 370 | 305 | 390 | 40 | 24 | |

| 155-250 | 795 | 510 | 380 | 400 | 155 | 200 | 295 | 203 | 545 | 458 | 510 | 920 | 440 | 375 | 475 | 45 | 28 |

| Input shaft | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 30 | 8×33.3 | 19.5 |

| 30 | 12 | 4×2.5 | 35 | 10×38.3 | 30.5 |

| 40 | 15 | 5×3 | 40 | 12×43.3 | 47 |

| 40 | 18 | 5×3 | 45 | 14×48.8 | 69 |

| 50 | 22 | 7×4 | 60 | 18×64.4 | 105 |

| 50 | 25 | 7×4 | 70 | 20×74.9 | 163 |

| 65 | 30 | 7×4 | 80 | 22×85.4 | 208 |

| 75 | 35 | 10×4.5 | 85 | 22×90.4 | 302 |

| 85 | 40 | 12×5 | 110 | 28×116.4 | 476 |

WPWEKO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWEKO Double Reduction Worm Gear Reducer Characteristic

- High Efficiency and Significant Torque Output

The WPWEKO double reduction worm gear reducer is designed to deliver exceptional torque output with minimal energy loss. Its advanced engineering ensures efficient power transmission, making it suitable for applications requiring high torque and precise speed reduction in demanding industrial environments. - Wide Range of Speed Ratios

These worm gear speed reducers offer a single-stage speed ratio between 1:10 and 1:60, while the double-stage configuration achieves ratios from 1:200 to 1:900. This wide range allows for versatile applications, meeting the needs of industries requiring precise and significant speed adjustments. - Robust and Durable Construction

Manufactured using high-quality materials, the WPWEKO worm reducer gearboxes boast a robust design capable of withstanding heavy loads and challenging conditions. Its durable construction ensures long service life and reliable performance, even in harsh industrial environments with continuous operation. - Compact and Space-Saving Design

The compact design of the worm drive gearboxes integrates two reduction stages into a single unit, saving valuable space. This makes it an ideal choice for industries where equipment footprint is a concern while still delivering high torque and efficient operation. - Low Noise and Smooth Operation

The precision-engineered worm and gear components provide smooth, vibration-free operation with minimal noise. This characteristic is crucial in industries like beverage production and plastics processing, where quiet and reliable machinery enhances overall productivity and working conditions. - Low Maintenance and High Reliability

These worm reduction gearboxes are designed for minimal maintenance, reducing downtime and operational costs. Their reliable performance, combined with low maintenance requirements, makes them a cost-effective solution for industries like mining, metallurgy, and material handling that demand consistent, long-term operation.

WPWEKO Worm Drive Gearbox Application Industry

- Plastics Manufacturing Industry

The WPWEKO worm drive gearbox is widely used in the plastics industry for machinery like extruders, injection molding machines, and blow molding equipment. Its high torque output and precise speed control ensure efficient material processing, improving product quality and operational reliability. - Metallurgy and Steel Industry

In the metallurgy and steel sector, these worm reducer gearboxes are essential for handling heavy-duty operations such as rolling mills, conveyors, and steel-cutting machines. Their robust construction and durability ensure reliable performance under extreme loads and high-temperature conditions, enhancing process efficiency. - Beverage and Food Processing Industry

The worm gear reduction gearbox is ideal for beverage and food processing applications, powering equipment like bottling lines, conveyors, and mixers. Its smooth operation, compact design, and low noise levels contribute to a hygienic and efficient production environment, meeting the industry’s stringent standards. - Mining and Quarrying Industry

The mining sector requires heavy-duty machinery for tasks like crushing, drilling, and material transportation. WPWEKO double reduction worm gear reducers provide the high torque and durability needed to withstand demanding conditions, ensuring reliable performance in harsh environments such as mines and quarries. - Lifting and Material Handling Industry

These worm gearbox reducers are extensively used in cranes, hoists, elevators, and conveyor systems. Their capability to handle high torque and precise movement makes them ideal for lifting and transportation applications, ensuring safety and efficiency in warehouses and construction sites. - Chemical and Construction Industry

In the chemical and construction industries, WPWEKO worm gear speed reducers are crucial for mixers, pumps, and other heavy machinery. Their corrosion-resistant design, high efficiency, and ability to operate under harsh conditions make them indispensable for applications involving chemicals and construction materials.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Construction Industry |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Food and Beverage Industry |

WPWEKO Worm Reducer Gearbox Troubleshooting

- Excessive Noise During Operation

Excessive noise can result from improper alignment, worn-out gears, or insufficient lubrication. Inspect the worm drive reduction gearbox for misalignment of shafts or damaged components. Ensure that appropriate lubricants are used and applied regularly to reduce friction and minimize noise during operation. - Overheating of the Gearbox

Overheating may occur due to excessive load, insufficient lubrication, or blocked ventilation. Verify that the load is within the worm reduction gearbox’s capacity and clean any obstructions from the ventilation system. Regularly check and maintain adequate lubrication levels to prevent overheating. - Oil Leakage from the Gearbox

Oil leakage is often caused by worn-out seals, loose bolts, or overfilled oil levels. Inspect and replace damaged seals, tighten any loose bolts, and ensure the oil level is within the recommended range to prevent further leakage issues. - Reduced Output Torque or Performance

A drop in output torque may result from worn gears, improper assembly, or insufficient lubrication. Inspect the gear teeth for wear or damage and replace them if necessary. Ensure proper assembly and maintain adequate lubrication to restore optimal performance. - Unusual Vibrations During Operation

Excessive vibration can stem from misaligned shafts, imbalanced loads, or damaged components. Check for alignment issues and ensure that the load is evenly distributed. Inspect internal parts like gears and bearings for damage and replace them if necessary. - Gearbox Fails to Operate

Complete failure to operate can result from motor issues, damaged internal components, or electrical faults. Verify the motor’s functionality and inspect the worm gear reduction gearbox for internal damage, such as broken gears. Resolve electrical faults by checking connections and replacing faulty wiring.

Additional information

| Edited by | Yjx |

|---|