WPWDX Worm Gear Reducers/Worm Gearbox

WPWDX worm gear reducers, commonly referred to as worm gearboxes, are a specialized type of gearbox within the WP series worm gearbox, designed for efficient speed reduction and torque multiplication in compact industrial settings. These reducers feature a robust cast iron housing, ensuring durability and resistance to wear, even in demanding applications. The primary transmission components include a worm gear, typically crafted from tin bronze for optimal performance and wear resistance, and a worm made from heat-treated 45# steel for enhanced strength and durability.

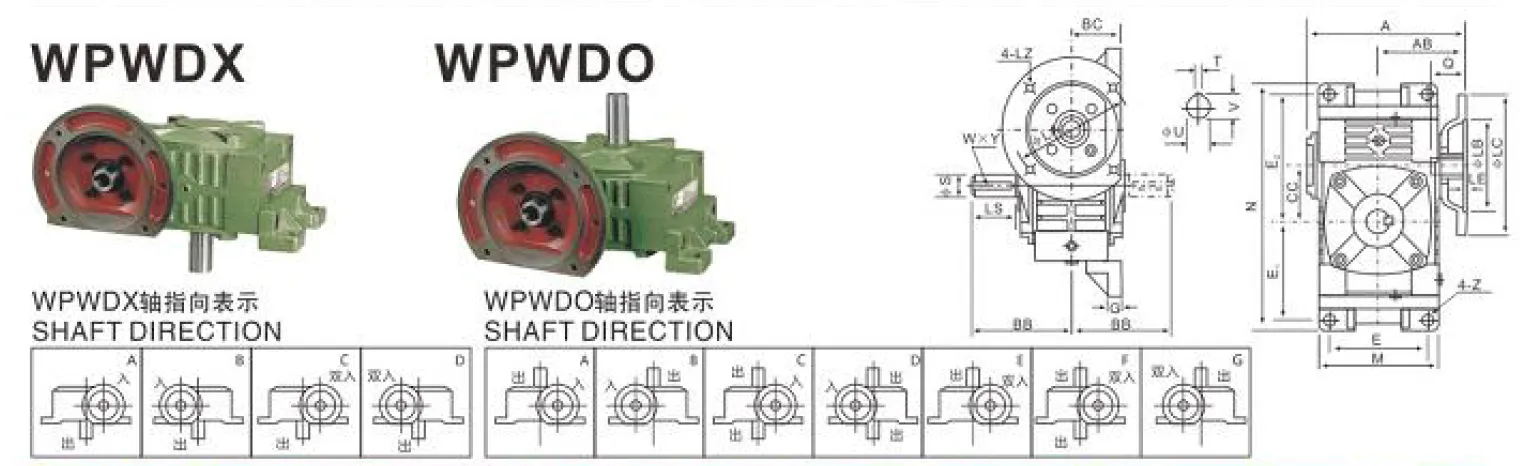

WPWDX worm gear reducers, commonly referred to as worm gearboxes, are a specialized type of gearbox within the WP series worm gearbox, designed for efficient speed reduction and torque multiplication in compact industrial settings. These reducers feature a robust cast iron housing, ensuring durability and resistance to wear, even in demanding applications. The primary transmission components include a worm gear, typically crafted from tin bronze for optimal performance and wear resistance, and a worm made from heat-treated 45# steel for enhanced strength and durability. The WPWDX worm gear speed reducer is distinguished by its vertical downward output shaft and input flange, providing flexible mounting options to suit various installation requirements.

Key features of WPWDX worm gearboxes include a wide reduction ratio range (1/10 to 1/60), low vibration, minimal noise, and a self-locking capability in specific conditions, which can eliminate the need for additional braking devices. These worm reducer gearboxes are highly valued for their stable transmission, high load capacity, and reliability, making them ideal for industries like plastics, metallurgy, mining, and chemical construction. They are equipped with high-quality bearings and seals, contributing to their long operational lifespan and minimal maintenance needs.

WPWDX Worm Gear Reducer Specifications

| Type: | WPWDX Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWDX Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | A | AB | BB | BC | CC | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 0.12 | 1/5 1/10 1/20 1/25 1/30 1/40 1/50 1/60 | 151 | 83 | 97 | 45 | 40 | 95 | 187 | 70 | 72 | 97 | 12 | 10 |

| 60 | 0.18 | 175 | 108 | 97 | 50 | 50 | 111 | 226 | 90 | 90 | 110 | 14 | 12 | |

| 70 | 0.37 | 198 | 120 | 112 | 55 | 60 | 127 | 257 | 100 | 102 | 129 | 15 | 12 | |

| 80 | 0.75 | 231 | 140 | 131 | 65 | 70 | 152 | 305 | 120 | 120 | 155 | 20 | 15 | |

| 100 | 1.5 | 261 | 160 | 142 | 70 | 80 | 174 | 350 | 140 | 140 | 180 | 20 | 15 | |

| 120 | 2.2 | 322 | 190 | 169 | 90 | 100 | 224 | 410 | 190 | 165 | 215 | 22 | 15 | |

| 135 | 3.0 | 371 | 219 | 190 | 100 | 120 | 264 | 494 | 220 | 195 | 255 | 25 | 18 | |

| 155 | 4.0 | 422 | 249 | 210 | 110 | 135 | 304 | 559 | 260 | 230 | 285 | 30 | 18 | |

| 175 | 5.5 | 497 | 295 | 252 | 140 | 155 | 345 | 605 | 290 | 250 | 305 | 35 | 21 | |

| 200 | 7.5 | 534 | 314 | 255 | 150 | 175 | 374 | 675 | 320 | 273 | 348 | 40 | 21 | |

| 250 | 11.0 | 580 | 342 | 319 | 175 | 200 | 424 | 749 | 370 | 305 | 390 | 40 | 24 | |

| 250 | 15.0 | 705 | 420 | 385 | 200 | 250 | 510 | 920 | 440 | 375 | 475 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5.4 |

| 130 | 110 | 160 | 4 | M8 | 31 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8.5 |

| 130 | 110 | 180 | 4 | M10 | 40 | 14 | 5×16.3 | 50 | 22 | 6×3.5 | 12 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 28 | 8×4 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 65 | 32 | 10×5 | 26 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 75 | 38 | 10×5 | 40.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 45 | 14×5.5 | 59 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 89 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 138 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 172 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 246 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 410 |

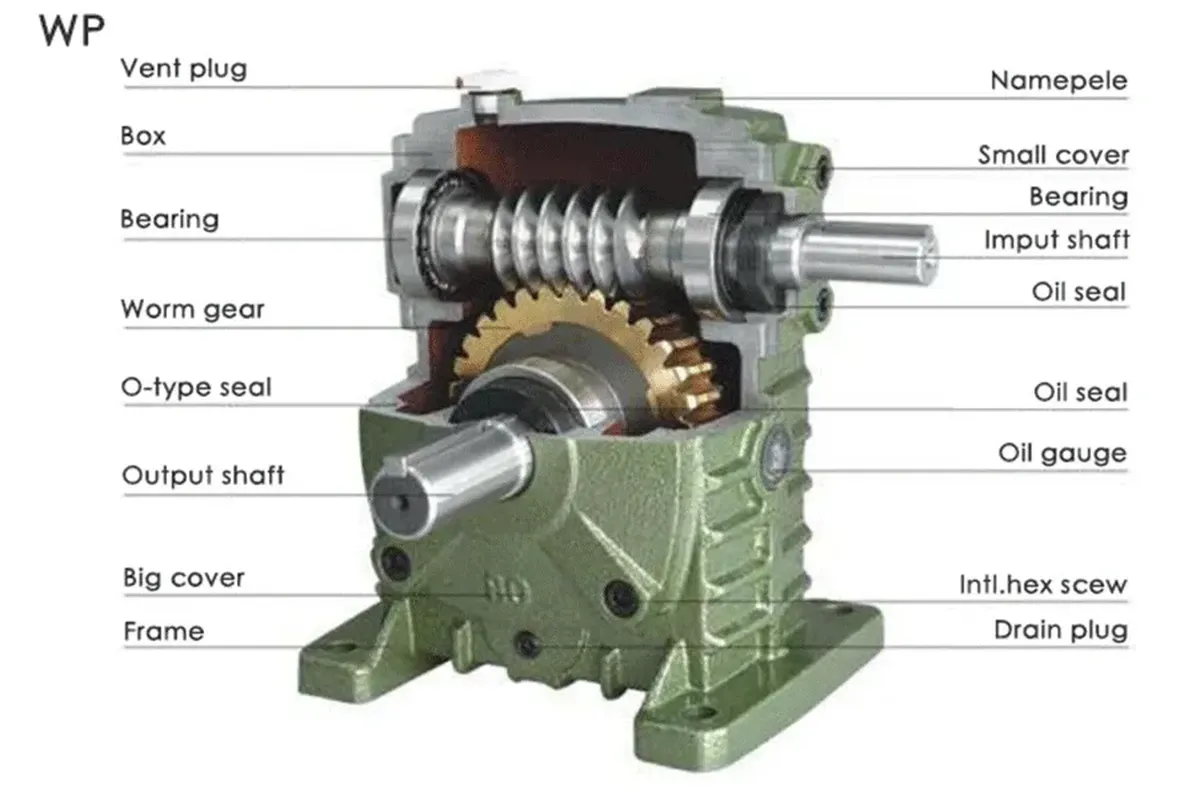

WPWDX Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWDX Worm Gear Speed Reducer Features

- High Reduction Ratio

The WPWDX worm gear speed reducer offers a wide range of reduction ratios, typically between 1/10 and 1/60. This allows for precise speed control and torque multiplication, making it suitable for applications requiring efficient power transmission in compact spaces. - Durable Construction

Designed with a cast iron housing, the worm reducer gearboxes ensure maximum durability and resistance to wear. The worm is made from heat-treated 45# steel, while the worm gear is constructed from tin bronze, providing excellent strength, wear resistance, and long-term performance under heavy loads. - Self-Locking Capability

Under certain conditions, the WPWDX worm drive gearboxes exhibit a self-locking feature, allowing the system to hold its position without additional braking devices. This eliminates the need for external components, enhancing safety, reducing costs, and simplifying system design while improving reliability. - Low Noise and Vibration

The design of the WPWDX worm gear reducers minimizes operational noise and vibration, even under heavy workloads. This makes it ideal for industrial environments where quiet operation is important, contributing to enhanced workplace comfort and reduced mechanical stress on connected equipment. - Versatile Mounting Options

Featuring a vertical downward output shaft and an input flange, the worm and wheel gearbox provides flexibility in installation. Its versatile design accommodates various mounting configurations, ensuring compatibility with different machinery setups across industries like plastics, mining, and chemical processing. - Reliable Bearings and Seals

Equipped with high-quality bearings and seals, the WPWDX worm drive reduction gearbox ensures smooth and reliable operation over extended periods. These components enhance the reducer’s lifespan by minimizing maintenance requirements, preventing oil leaks, and ensuring consistent performance even in harsh industrial environments.

WPWDX Worm Gear Reducer Applications

- Plastics Industry

WPWDX worm gear reducers are widely used in plastic machinery, such as extruders and molding equipment. Their ability to deliver precise speed reduction, high torque, and stable performance ensures efficient operations, contributing to the production of high-quality plastic products in automated processes. - Metallurgy Industry

In metallurgy applications, these reducers are crucial for heavy-duty equipment like rolling mills and material conveyors. Their robust construction and high load capacity enable them to withstand harsh environments while providing reliable power transmission for processes that require precise control and durability. - Mining Industry

WPWDX gear reducers are integral to mining operations, powering equipment such as conveyors, crushers, and hoists. Their self-locking capability, low vibration, and ability to handle high loads make them ideal for demanding tasks in challenging and abrasive mining conditions. - Chemical Processing

The chemical industry relies on WPWDX reducers for applications like mixers, agitators, and pumps. Their resistance to wear, stable transmission, and compact design make them suitable for handling chemical processes that require consistent performance in environments with exposure to corrosive materials. - Construction Machinery

These gear reducers are utilized in construction equipment such as concrete mixers, cranes, and hoists. Their durability, efficient torque multiplication, and ability to handle heavy loads ensure reliable performance in construction projects that demand rugged, long-lasting components for critical operations. - Power Generation and Energy

WPWDX reducers are used in renewable energy systems, such as wind turbines and solar trackers, as well as in traditional power plants. Their ability to provide precise motion control and stable power transmission makes them a key component in energy production and distribution systems.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Chemical Industry |

|  |

| Worm Gearbox for Plastic and Rubber Machinery | Worm Gearbox for Metallurgy Industry |

Worm Gearbox Parts Production Process

The basic structure of a worm gearbox consists of a housing, worm wheel, worm, covers, shaft, bearing, fasteners and seals. The precise processing and quality control of each component is the basis for producing a quality worm gearbox.

Housing Processing

The housing casting purchased from the casting factory will be finely finished in our housing machining center, including the big hole, small hole and bottom foot of the housing. Then they will be moved to the CNC drilling machine for large hole, small hole, bottom foot, oil plug hole, oil marker hole processing. After testing, they are moved into the parts warehouse.

Worm Wheel Processing

The worm wheel consists of a cast iron wheel core and a bronze wheel rim. The wheel core casting will firstly be finished on the inner hole, outer diameter, and thickness of the wheel core at our CNC lathe area. Then the copper cladding process will be carried out by the copper casting factory. Then they will be processed at our CNC machining area, processed on our hobbing machine, and finally moved into storage after inspection.

Worm Processing

Worm is a component made of steel through rough machining, thread milling machining, heat treatment machining, external cylindrical grinding machining, thread grinding, keyway milling machining, etc.

The raw steel material will be cut according to different specifications at the sawing machine processing area, then be rough machined by a CNC lathe. And our workers will conduct thread milling according to different speed ratios. After testing, they will be put into storage.

The heat treatment of the worm will be processed by a heat treatment factory, which can improve the hardness of the worm, improve the wear resistance, and extend the service life.

After that, our workers will carry out external cylindrical grinding processing on the tooth, bearing carriers, and input shaft carrier of the worm. Next will be the grinding process. The thread grinding is to make the worm wheel & worm mesh better with low noise.

Finally, they will be processed at a keyway milling machine, enabling the gearbox to connect with other parts through the shaft and key pin.

After testing, the worms will be moved into the warehouse.

Cover Processing

The covers of worm gearboxes include a big cover, an output cover, an oil marker cover, and an input cover. The cover castings will be fine machined at our CNC lathe, for the seal carrier, housing big holes connecting the carrier and bearing carriers of the big cover and output cover, and for housing small holes connecting the carrier and oil seal carriers of the oil marker cover and input cover. The precise dimensions can prevent the worm gearbox from oil leakage and overheating problems.

Finally drilling process of the covers will be done at the drilling machine processing area, enabling the covers and the housing to connect by fasteners.

After inspection, qualified covers will be put into storage.

Shaft Processing

Shaft is a component made of steel through the process of rough machining, external cylindrical grinding machining and milling. Similar to worm processing, the steel is firstly cut by a sawing machine, then rough machined at the CNC lathe area, including bearing carrier, worm wheel carrier, and output shaft carrier. Then moved to the external grinding processing area for the fine process. Finally, the shafts will be milled. After testing, the shafts will be moved into the warehouse.

Bearings, Fasteners, and Seals

Our bearings, fasteners, seals, and other accessories are supplied by well-known manufacturers, such as bearings from C&U, HRB, oil seals from NAK, SKF, and other brands. Fasteners are with grade 8.8, we can upgrade the bearings, oil seals, and fasteners according to customer needs.

Additional information

| Edited by | Yjx |

|---|