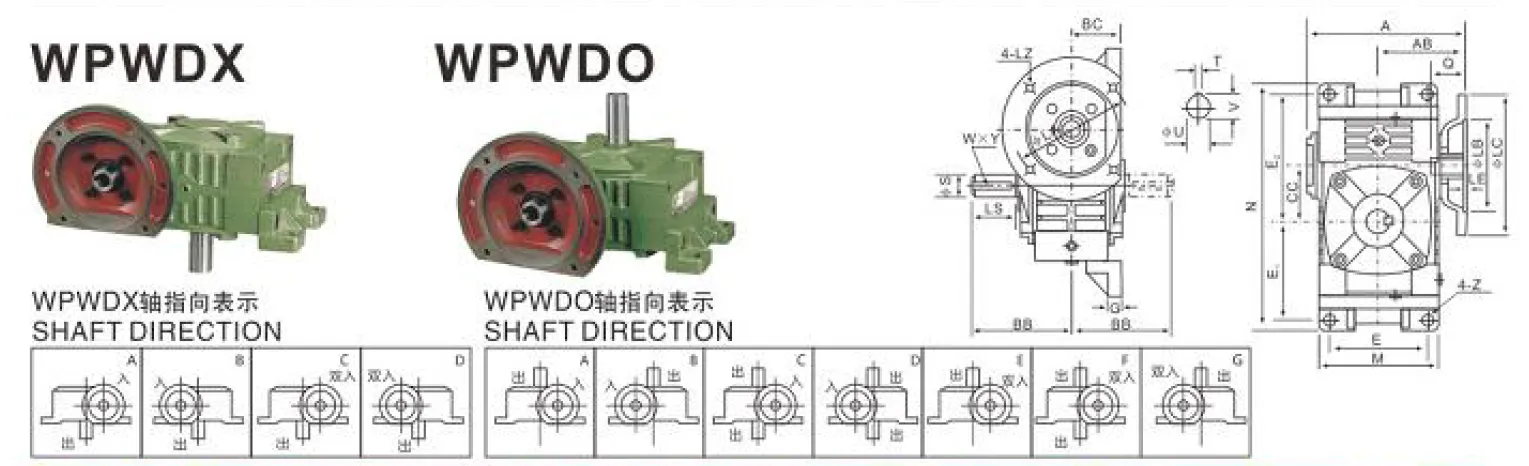

WPWDO Worm Gear Reducers/Worm Gearbox

WPWDO worm gear reducers, part of the WP series worm gearboxes, are advanced mechanical power transmission devices engineered for efficient speed reduction and torque amplification in compact industrial applications. These worm gearboxes feature a worm gear mechanism, comprising a worm (a screw-like gear) and a worm wheel (similar to a spur gear), which allows smooth and reliable motion transfer. The WPWDO worm reducer gearbox configuration is designed with a vertical upward output shaft and an input flange, enabling seamless integration with standard IEC motors.

WPWDO worm gear reducers, part of the WP series worm gearboxes, are advanced mechanical power transmission devices engineered for efficient speed reduction and torque amplification in compact industrial applications. These worm gearboxes feature a worm gear mechanism, comprising a worm (a screw-like gear) and a worm wheel (similar to a spur gear), which allows smooth and reliable motion transfer. The WPWDO worm reducer gearbox configuration is designed with a vertical upward output shaft and an input flange, enabling seamless integration with standard IEC motors.

Constructed with a durable cast iron housing, these worm gear speed reducers use single-stage worm gearing to ensure quiet operation and robust performance. They are available in frame sizes ranging from 40 mm to 250 mm, offering gear ratios between 1:10 and 1:60. This makes them suitable for various applications, including conveyor systems, packaging machinery, and hoisting equipment. The compact design, self-locking capability under specific conditions, and ability to withstand high shock loads make WPWDO worm gear reducers ideal for space-constrained setups requiring high torque.

WPWDO Worm Gear Reducer Specifications

| Type: | WPWDO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWDO Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | A | AB | BB | BC | CC | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 0.12 | 1/5 1/10 1/20 1/25 1/30 1/40 1/50 1/60 | 151 | 83 | 97 | 45 | 40 | 95 | 187 | 70 | 72 | 97 | 12 | 10 |

| 60 | 0.18 | 175 | 108 | 97 | 50 | 50 | 111 | 226 | 90 | 90 | 110 | 14 | 12 | |

| 70 | 0.37 | 198 | 120 | 112 | 55 | 60 | 127 | 257 | 100 | 102 | 129 | 15 | 12 | |

| 80 | 0.75 | 231 | 140 | 131 | 65 | 70 | 152 | 305 | 120 | 120 | 155 | 20 | 15 | |

| 100 | 1.5 | 261 | 160 | 142 | 70 | 80 | 174 | 350 | 140 | 140 | 180 | 20 | 15 | |

| 120 | 2.2 | 322 | 190 | 169 | 90 | 100 | 224 | 410 | 190 | 165 | 215 | 22 | 15 | |

| 135 | 3.0 | 371 | 219 | 190 | 100 | 120 | 264 | 494 | 220 | 195 | 255 | 25 | 18 | |

| 155 | 4.0 | 422 | 249 | 210 | 110 | 135 | 304 | 559 | 260 | 230 | 285 | 30 | 18 | |

| 175 | 5.5 | 497 | 295 | 252 | 140 | 155 | 345 | 605 | 290 | 250 | 305 | 35 | 21 | |

| 200 | 7.5 | 534 | 314 | 255 | 150 | 175 | 374 | 675 | 320 | 273 | 348 | 40 | 21 | |

| 250 | 11.0 | 580 | 342 | 319 | 175 | 200 | 424 | 749 | 370 | 305 | 390 | 40 | 24 | |

| 250 | 15.0 | 705 | 420 | 385 | 200 | 250 | 510 | 920 | 440 | 375 | 475 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5.4 |

| 130 | 110 | 160 | 4 | M8 | 31 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8.5 |

| 130 | 110 | 180 | 4 | M10 | 40 | 14 | 5×16.3 | 50 | 22 | 6×3.5 | 12 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 28 | 8×4 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 65 | 32 | 10×5 | 26 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 75 | 38 | 10×5 | 40.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 45 | 14×5.5 | 59 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 89 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 138 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 172 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 246 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 410 |

WPWDO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWDO Worm Gear Speed Reducer Advantages

- High Torque Output

WPWDO worm gear speed reducers deliver exceptional torque multiplication due to their worm and wheel design. This enables efficient power transmission for heavy-duty applications like conveyors and hoists, ensuring reliable performance under high load conditions with minimal energy loss. - Compact Design

The worm gear reducer's compact structure allows installation in space-constrained environments. Its vertical upward output shaft and flange-mounted configuration optimize space usage, making it ideal for industrial setups where footprint reduction is critical without compromising on power or efficiency. - Self-Locking Capability

Under certain conditions, WPWDO worm reducer gearboxes offer self-locking, preventing back-driving. This feature enhances safety in applications like lifting equipment, ensuring loads remain secure without additional braking mechanisms, thus reducing system complexity and maintenance costs. - Quiet Operation

The worm gear design ensures smooth and low-noise performance. Precision-engineered gears minimize vibration and noise, making worm drive gearboxes suitable for noise-sensitive environments like packaging or food processing industries, improving workplace comfort and compliance. - Durability and Reliability

Constructed with robust cast iron housing and high-quality materials, WPWDO worm wheel gearboxes withstand harsh industrial conditions. Their resistance to wear and corrosion ensures long service life, reducing downtime and maintenance costs in demanding applications. - Versatile Mounting Options

The worm reduction gearbox’s flange-mounted input and vertical output shaft provide flexible integration with standard IEC motors. This adaptability supports diverse applications, from material handling to automation, allowing easy customization and installation in various industrial systems.

WPWDO Worm Gear Reducer Application Fields

- Conveyor Systems

WPWDO worm gear reducers are widely used in conveyor systems for material handling in industries like mining and manufacturing. Their high torque output and compact design ensure efficient movement of heavy loads, enhancing productivity in automated transport processes. - Packaging Machinery

In packaging equipment, worm gear reduction gearboxes provide precise speed control and reliable torque for tasks like filling and sealing. Their quiet operation and durability make them ideal for high-speed, continuous-use environments, ensuring consistent performance in food and beverage industries. - Hoisting Equipment

WPWDO worm gear speed reducers are employed in hoisting systems like cranes and lifts. Their self-locking capability prevents load slippage, enhancing safety. The robust construction handles high shock loads, making them suitable for construction and warehouse applications. - Automation Systems

In automated production lines, worm reducer gearboxes drive robotic arms and actuators. Their compact size and versatile mounting options allow seamless integration, providing precise motion control and high torque for tasks requiring accuracy in industrial automation. - Textile Machinery

WPWDO worm drive gearboxes support textile manufacturing equipment, such as spinning and weaving machines. Their smooth operation and ability to handle variable loads ensure consistent performance, reducing maintenance needs and improving efficiency in textile production processes. - Food Processing Equipment

In food processing, worm and wheel gearboxes drive mixers, slicers, and conveyors. Their corrosion-resistant materials and quiet operation meet hygiene and noise standards, ensuring reliable performance in sensitive environments while maintaining product quality and safety.

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Conveyor Equipment |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Packaging Industry |

WPWDO Worm Gearbox Oil Level Check

- Preparation and Safety

Before checking the oil level in a WPWDO worm gearbox, ensure the equipment is powered off and cooled down to avoid burns or electrical hazards. Gather necessary tools like a dipstick, wrench, or sight glass, and wear appropriate personal protective equipment to ensure safety during the process. - Locate the Oil Level Indicator

Identify the oil level indicator on the worm drive reduction gearbox, typically a dipstick or sight glass located on the housing. Consult the manual for the exact position, as it varies by model, ensuring accurate inspection without disassembling unnecessary components. - Clean the Inspection Area

Wipe the area around the dipstick or sight glass with a clean cloth to prevent contaminants from entering the worm gear drive gearbox. This step is critical to maintain oil purity and prevent debris from affecting the gearbox’s performance or causing internal damage during operation. - Check Oil Level with Dipstick or Sight Glass

If using a dipstick, remove it, wipe it clean, reinsert it fully, then withdraw it to check the oil level against marked indicators. For a sight glass, observe the oil level against the reference line, ensuring it falls within the recommended range for proper lubrication. - Assess Oil Condition

While checking the level, inspect the oil’s color and clarity. Clean oil should be clear and free of debris or metallic particles. Cloudy or dark oil indicates contamination or degradation, signaling the need for an oil change to maintain gearbox efficiency and longevity. - Top Up or Replace Oil if Needed

If the oil level is low, add the manual-recommended lubricant through the fill port until it reaches the correct level. Avoid overfilling, as it can cause overheating. If the oil is contaminated, drain and replace it, following proper disposal guidelines to ensure environmental compliance.

Additional information

| Edited by | Yjx |

|---|