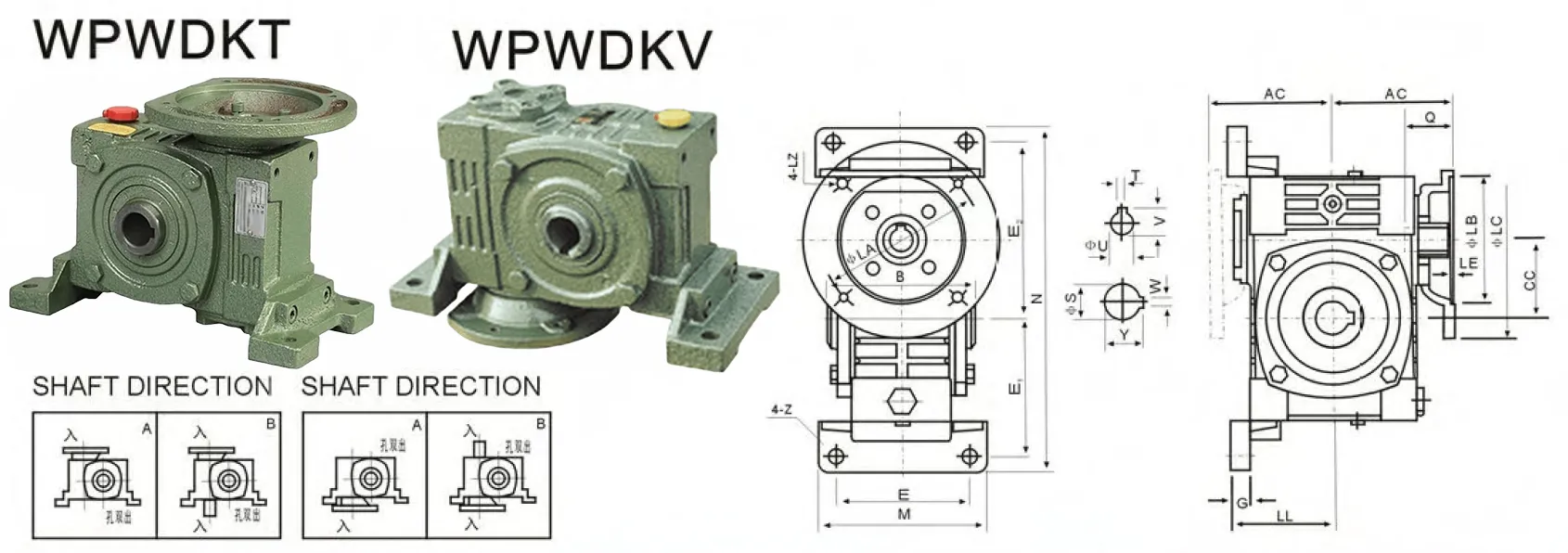

WPWDKV Worm Gear Reducers/Worm Gearbox

The WPWDKV worm gear reducer, commonly referred to as a worm gearbox, is a high-efficiency mechanical device crafted for precise power transmission in industrial applications. Part of the renowned WP series, it features a rugged and compact cast iron housing, ensuring exceptional durability and resistance to deformation under heavy loads. The internal components include a worm, manufactured from high-quality 45# steel and heat-treated to enhance its strength and longevity, paired with a worm wheel made from tin bronze, which provides excellent wear resistance.

The WPWDKV worm gear reducer, commonly referred to as a worm gearbox, is a high-efficiency mechanical device crafted for precise power transmission in industrial applications. Part of the renowned WP series, it features a rugged and compact cast iron housing, ensuring exceptional durability and resistance to deformation under heavy loads. The internal components include a worm, manufactured from high-quality 45# steel and heat-treated to enhance its strength and longevity, paired with a worm wheel made from tin bronze, which provides excellent wear resistance. This combination allows the gearbox to achieve high reduction ratios ranging from 5:1 to 60:1, delivering substantial torque output while significantly reducing rotational speed.

The WPWDKV worm gearboxes incorporate a universal worm reducer design, featuring a motor flange shaft hole output and a downward input shaft for versatile horizontal or vertical mounting. It also offers self-locking capabilities under certain conditions, eliminating the need for external braking systems in specific applications. Designed for low vibration, minimal noise, and a hermetically sealed, maintenance-free operation, the WPWDKV worm gear speed reducers are ideal for demanding industries such as plastics manufacturing, metallurgy, mining, and chemical processing, where reliability, efficiency, and long service life are critical.

WPWDKV Worm Gear Reducer Specifications

| Type: | WPWDKV Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWDKV Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | AC | B | CC | LL | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 75 | 85 | 40 | 63 | 90 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 0.18 | 83 | 105 | 50 | 70 | 120 | 226 | 95 | 90 | 110 | 14 | 12 | |

| 60 | 0.37 | 91 | 110 | 60 | 80 | 130 | 257 | 105 | 102 | 129 | 15 | 12 | |

| 70 | 0.37 0.75 | 109 111 | 130 | 70 | 95 | 150 | 305 | 115 | 120 | 155 | 20 | 15 | |

| 80 | 0.75 1.5 | 125 | 150 | 80 | 105 | 170 | 350 | 135 | 140 | 180 | 20 | 15 | |

| 100 | 1.5 | 148 | 160 | 100 | 135 | 190 | 410 | 155 | 165 | 215 | 22 | 15 | |

| 120 | 2.2 3.0 | 181 | 175 | 120 | 160 | 230 | 494 | 180 | 195 | 255 | 25 | 18 | |

| 135 | 3.0 4.0 | 202 | 210 | 135 | 185 | 250 | 559 | 200 | 230 | 285 | 30 | 18 | |

| 155 | 5.5 | 247 | 256 | 155 | 220 | 275 | 605 | 220 | 250 | 305 | 35 | 21 | |

| 175 | 5.5 7.5 | 262 | 282 | 175 | 240 | 310 | 675 | 250 | 273 | 348 | 40 | 21 | |

| 200 | 11.0 | 285 | 320 | 200 | 280 | 360 | 749 | 290 | 305 | 390 | 40 | 24 | |

| 250 | 11.0 15.0 | 330 | 400 | 250 | 315 | 460 | 920 | 380 | 375 | 475 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 16 | 6×18.8 | 5.4 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 20 | 6×22.8 | 8.5 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 25 | 8×28.3 | 12 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 35 | 10×38.3 | 26 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 40 | 12×43.3 | 40.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 45 | 14×48.8 | 59 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 60 | 18×64.4 | 89 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 70 | 20×74.9 | 138 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 80 | 22×85.4 | 172 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 85 | 22×90.4 | 246 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 110 | 28×116.4 | 400 |

WPWDKV Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWDKV Worm Gear Reducer Advantages

- High Torque Output and Reduction Ratio

The WPWDKV worm gear reducers deliver exceptional torque through high reduction ratios, up to 100:1 in a single stage and 10,000:1 in double stages. This allows precise speed reduction while maintaining power, ideal for heavy-duty applications like conveyors and mixers. - Durable and Robust Construction

Constructed with a high-strength cast iron housing, the worm reducer gearboxes ensure long-lasting durability and resistance to deformation under heavy loads. The worm, made from heat-treated 45# steel, and the tin bronze worm wheel enhance wear resistance, ensuring reliability in demanding industrial environments. - Self-Locking Capability

The WPWDKV worm drive gearboxes offer self-locking under specific conditions, preventing reverse rotation without additional braking systems. This feature is crucial for applications requiring positional stability, such as hoists or elevators, enhancing safety and reducing the need for extra components, thus lowering costs. - Low Noise and Vibration

Designed for smooth operation, the worm gear speed reducers minimize noise and vibration due to their precision-engineered gears and sealed housing. This makes it suitable for noise-sensitive environments like food processing or pharmaceutical industries, improving workplace comfort and equipment longevity. - Compact and Versatile Design

The right angle worm gearboxes' compact structure with a universal motor flange shaft hole output and downward input shaft allows flexible horizontal or vertical mounting. This adaptability suits diverse applications, from mining to chemical processing, optimizing space and installation efficiency in tight setups. - Maintenance-Free Operation

Featuring a hermetically sealed design, the WPWDKV worm gearbox reducer requires minimal maintenance, reducing downtime and operational costs. Its efficient lubrication system and high-quality materials ensure long service life, making it a cost-effective choice for industries like metallurgy and plastics manufacturing.

WPWDKV Worm Drive Gearbox Application Industry

- Plastics Industry

The WPWDKV worm drive gearbox is widely used in plastics manufacturing for extruders and injection molding machines. Its high torque output and precise speed control ensure consistent material processing. The compact design fits seamlessly into space-constrained production lines, enhancing efficiency and reliability in plastic forming. - Metallurgy Industry

In metallurgical applications, the worm gear reducers drive rolling mills and conveyors. Its robust cast iron housing withstands harsh conditions, while the high reduction ratio delivers the torque needed for heavy metal processing. The self-locking feature ensures safety during operations, preventing unintended equipment movement. - Mining Industry

The WPWDKV worm reducer gearboxes are ideal for mining equipment like crushers and belt conveyors. Its durable construction resists dust and extreme conditions, ensuring reliable performance. The gearbox’s high torque and low-speed output efficiently handle heavy loads, improving productivity in mineral extraction and processing operations. - Chemical Processing Industry

In chemical plants, the worm reduction gearboxes power mixers and pumps. Its low noise and vibration ensure smooth operation in sensitive environments. The sealed design prevents leaks, protecting against corrosive substances. High torque output supports consistent mixing and fluid transfer, critical for chemical production. - Food and Beverage Industry

The WPWDKV worm gearbox reducers are used in food processing for conveyors and packaging machines. Its low-noise operation and maintenance-free design meet hygiene standards. The gearbox’s precise speed control ensures consistent product handling, while its compact size fits into space-limited food production facilities, enhancing efficiency. - Construction Industry

The worm gear speed reducers drive construction equipment like hoists and concrete mixers. Its self-locking capability ensures safety by preventing load slippage. The durable design withstands rugged job site conditions, and high torque output supports heavy lifting, making it essential for efficient construction operations.

|  |

| Worm Gearbox for Plastic and Rubber Machinery | Worm Gearbox for Metallurgy Industry |

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Chemical Industry |

Worm Gearbox Oil Lubrication

- Importance of Proper Lubrication

Proper oil lubrication in the worm gearbox is critical for minimizing friction and wear between the worm and worm wheel. It ensures smooth operation, extends the lifespan of internal components, and reduces the risk of overheating during continuous or heavy-duty industrial use. - Recommended Lubricant Types

The worm drive reduction gearbox requires high-quality gear oils, typically synthetic or mineral-based, designed specifically for worm gears. These oils must have high viscosity and excellent thermal stability, ensuring they form a durable film that resists breakdown even under high torque and load conditions. - Regular Oil Level Maintenance

Maintaining the correct oil level is essential for optimal performance. Insufficient lubrication can lead to increased friction and premature wear, while overfilling can cause oil foaming and leakage. Regular inspections and adherence to manufacturer guidelines for oil levels ensure reliable worm gear gearbox operation. - Oil Change Intervals

Oil in the worm reducer gearbox should be replaced at recommended intervals, depending on operating conditions and the type of lubricant used. Regular oil changes prevent contamination buildup, maintain the oil’s effectiveness, and ensure the gearbox continues to perform efficiently over its service life. - Operating Temperature Management

The oil's performance can be affected by operating temperature. High temperatures may degrade the oil, reducing its ability to lubricate effectively. Using heat-resistant lubricants and monitoring temperature levels helps maintain optimal lubrication, particularly in applications with continuous or heavy-duty operation. - Sealed Design for Oil Retention

The hermetically sealed housing of the worm drive gearbox ensures effective oil retention and prevents contamination from external elements. This design minimizes oil leakage and maintains consistent lubrication, reducing maintenance requirements and ensuring reliable performance even in harsh environmental conditions.

Additional information

| Edited by | Yjx |

|---|