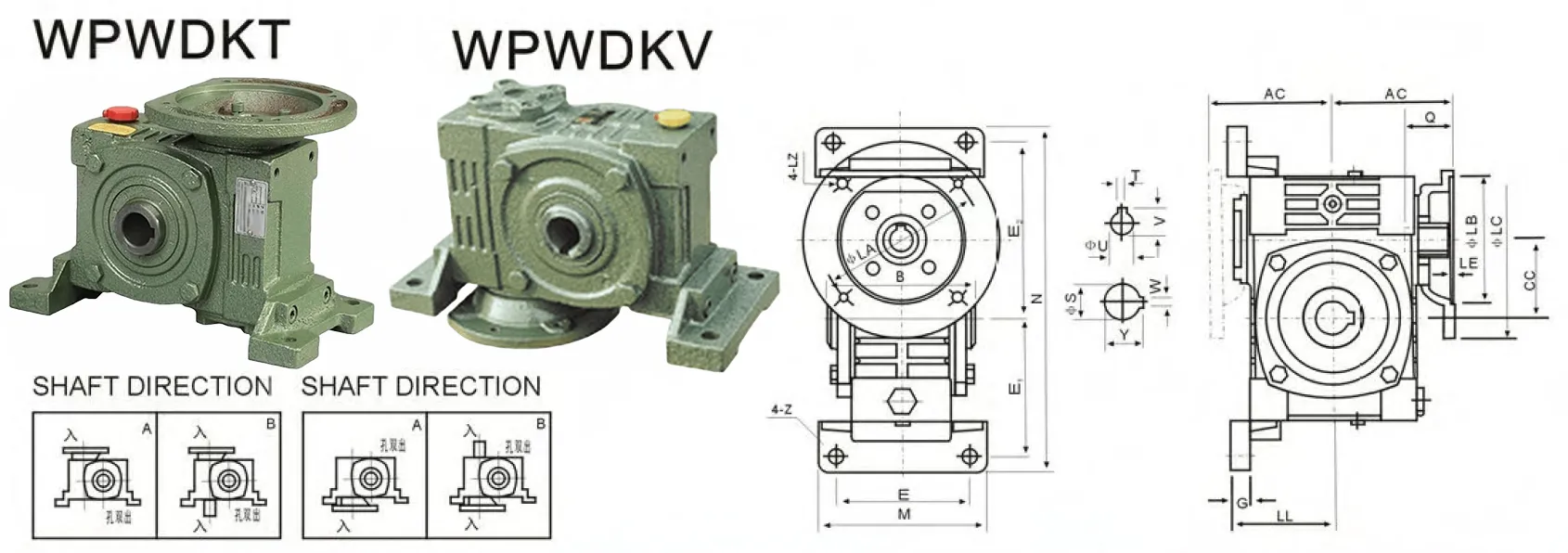

WPWDKT Worm Gear Reducers/Worm Gearbox

WPWDKT worm gear reducers, a model within the WP series worm gearboxes, are compact and efficient mechanical devices engineered for power transmission across a wide range of industrial applications. These reducers utilize a worm (a helical, screw-like gear) and a worm wheel, typically constructed from high-grade materials such as 45# steel for the worm and tin bronze for the worm wheel, ensuring exceptional durability and wear resistance.

WPWDKT worm gear reducers, a model within the WP series worm gearboxes, are compact and efficient mechanical devices engineered for power transmission across a wide range of industrial applications. These reducers utilize a worm (a helical, screw-like gear) and a worm wheel, typically constructed from high-grade materials such as 45# steel for the worm and tin bronze for the worm wheel, ensuring exceptional durability and wear resistance. The WPWDKT worm gearboxes are designed with a universal axial worm reducer integrated with a motor flange, offering flexible input and output options through a shaft hole. It supports versatile mounting configurations, including horizontal and vertical placements.

With gear ratios spanning from 5:1 to 60:1, these worm gear speed reducers deliver high torque output and self-locking capability under specific conditions, enhancing operational safety. Their cast iron housing provides superior rigidity and load capacity, while premium features like bearings and oil seals contribute to reduced noise, improved efficiency, and extended service life. Thanks to their stable transmission, low vibration, and high performance, WPWDKT worm gear reducers are widely employed in industries such as plastics, metallurgy, mining, and chemicals, where reliability and precision are essential.

WPWDKT Worm Gear Reducer Specifications

| Type: | WPWDKT Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWDKT Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | AC | B | CC | LL | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 75 | 85 | 40 | 63 | 90 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 0.18 | 83 | 105 | 50 | 70 | 120 | 226 | 95 | 90 | 110 | 14 | 12 | |

| 60 | 0.37 | 91 | 110 | 60 | 80 | 130 | 257 | 105 | 102 | 129 | 15 | 12 | |

| 70 | 0.37 0.75 | 109 111 | 130 | 70 | 95 | 150 | 305 | 115 | 120 | 155 | 20 | 15 | |

| 80 | 0.75 1.5 | 125 | 150 | 80 | 105 | 170 | 350 | 135 | 140 | 180 | 20 | 15 | |

| 100 | 1.5 | 148 | 160 | 100 | 135 | 190 | 410 | 155 | 165 | 215 | 22 | 15 | |

| 120 | 2.2 3.0 | 181 | 175 | 120 | 160 | 230 | 494 | 180 | 195 | 255 | 25 | 18 | |

| 135 | 3.0 4.0 | 202 | 210 | 135 | 185 | 250 | 559 | 200 | 230 | 285 | 30 | 18 | |

| 155 | 5.5 | 247 | 256 | 155 | 220 | 275 | 605 | 220 | 250 | 305 | 35 | 21 | |

| 175 | 5.5 7.5 | 262 | 282 | 175 | 240 | 310 | 675 | 250 | 273 | 348 | 40 | 21 | |

| 200 | 11.0 | 285 | 320 | 200 | 280 | 360 | 749 | 290 | 305 | 390 | 40 | 24 | |

| 250 | 11.0 15.0 | 330 | 400 | 250 | 315 | 460 | 920 | 380 | 375 | 475 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 16 | 6×18.8 | 5.4 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 20 | 6×22.8 | 8.5 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 25 | 8×28.3 | 12 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 35 | 10×38.3 | 26 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 40 | 12×43.3 | 40.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 45 | 14×48.8 | 59 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 60 | 18×64.4 | 89 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 70 | 20×74.9 | 138 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 80 | 22×85.4 | 172 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 85 | 22×90.4 | 246 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 110 | 28×116.4 | 400 |

WPWDKT Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWDKT Worm Drive Gearbox Characteristic

- High Efficiency and Torque Output

The WPWDKT worm drive gearbox delivers exceptional efficiency through its precision-engineered worm and worm wheel design. Crafted from 45# steel and tin bronze, it ensures high torque transmission, ideal for heavy-duty applications in industries like metallurgy and mining, with minimal energy loss. - Versatile Mounting Configurations

These worm reducer gearboxes offer flexible installation options, supporting both horizontal and vertical mounting. Its universal axial design, combined with a motor flange and shaft hole output/input, allows seamless integration into diverse machinery, enhancing adaptability across various industrial setups. - Robust and Durable Construction

Featuring a cast iron housing, the WPWDKT worm gear reducers provide superior rigidity and load-bearing capacity. High-quality components, including NSK bearings and Simrit oil seals, ensure long-term durability, resistance to wear, and consistent performance under demanding operational conditions. - Wide Range of Gear Ratios

The worm gear speed reducer supports gear ratios from 5:1 to 60:1, extendable to 10,000:1 with double reduction. This versatility enables precise speed control and torque adjustment, catering to specific application needs in industries like plastics and chemical processing. - Low Noise and Vibration

Engineered for smooth operation, the WPWDKT worm and wheel gearbox minimizes noise and vibration through its precision gearing and high-quality bearings. This ensures a quieter working environment and reduces mechanical stress, enhancing the longevity of both the gearbox and connected equipment. - Self-Locking Capability

Under specific conditions, the worm drive reduction gearbox offers self-locking functionality, preventing back-driving and enhancing safety in applications requiring load holding. This feature is particularly valuable in machinery where stability and secure positioning are critical during operation or downtime.

Applications of WPWDKT Worm Gear Reducers

- Plastic Manufacturing Machinery

WPWDKT worm gear reducers are widely used in plastic manufacturing equipment, such as extruders and injection molding machines. Their high torque output and precise speed control ensure smooth and efficient operation, essential for maintaining product quality and meeting production demands. - Metallurgical Industry Equipment

In the metallurgy industry, these worm gear speed reducers drive heavy-duty machinery like rolling mills and conveyors. Their robust construction, high load capacity, and ability to handle extreme operating conditions make them ideal for applications requiring stability, reliability, and long-term performance. - Mining and Material Handling Systems

WPWDKT worm drive gearboxes are frequently employed in mining applications, including crushers, conveyor belts, and hoisting systems. Their self-locking capability ensures safety during load handling, while their durability and efficiency withstand the harsh and abrasive conditions of mining environments. - Chemical Processing Industry

The chemical industry benefits from the stable transmission and low vibration provided by these worm reducer gearboxes, which are used in mixers, pumps, and agitators. Their ability to operate reliably under corrosive and high-temperature conditions makes them suitable for demanding chemical processing tasks. - Food and Beverage Industry Machinery

These worm gearbox reducers are used in food processing and packaging machinery, where precise control and quiet operation are critical. Their high efficiency and compact design contribute to the seamless operation of conveyors, mixers, and filling systems in hygienic environments. - Textile and Paper Industries

WPWDKT worm drive reduction gearboxes are integral to textile and paper machinery, such as looms, printing presses, and paper cutters. Their ability to provide consistent torque and speed control ensures smooth operation, improving productivity and maintaining product quality in these fast-paced industries.

|  |

| Worm Gearbox for Metallurgy Industry | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Textile Industry |

WPWDKT Worm Gearbox Material Selection

Worm Material - 45# Steel

The worm in worm gearboxes is made from 45# high-quality carbon steel, known for its excellent strength and wear resistance. This material undergoes precision hardening and tempering to ensure durability, enabling the worm to withstand high torque and prolonged operational stress in demanding industrial applications.Worm Wheel - Tin Bronze

The worm wheel is crafted from tin bronze, offering superior wear resistance and low friction. This material ensures smooth meshing with the worm, reducing heat generation and extending service life, making it ideal for high-load applications in industries like metallurgy and plastics.Housing - Cast Iron

The worm gearbox reducer housing is constructed from high-grade cast iron, providing exceptional rigidity and load-bearing capacity. This robust material absorbs vibrations and resists deformation under heavy loads, ensuring stable performance and protection of internal components in harsh industrial environments.Bearings - NSK Brand

Worm gear drive gearboxes utilize NSK bearings, renowned for their precision and durability. These high-quality bearings minimize friction and noise, supporting smooth operation and extending the gearbox’s lifespan, even under continuous high-speed or high-torque conditions in mining and chemical processing.Oil Seals - Simrit Brand

Simrit oil seals are incorporated to ensure leak-proof performance and protect internal components from contaminants. Made from premium materials, these seals maintain lubrication integrity, enhancing worm reduction gearbox efficiency and reliability in dusty or corrosive environments like mining and chemical industries.

Additional information

| Edited by | Yjx |

|---|