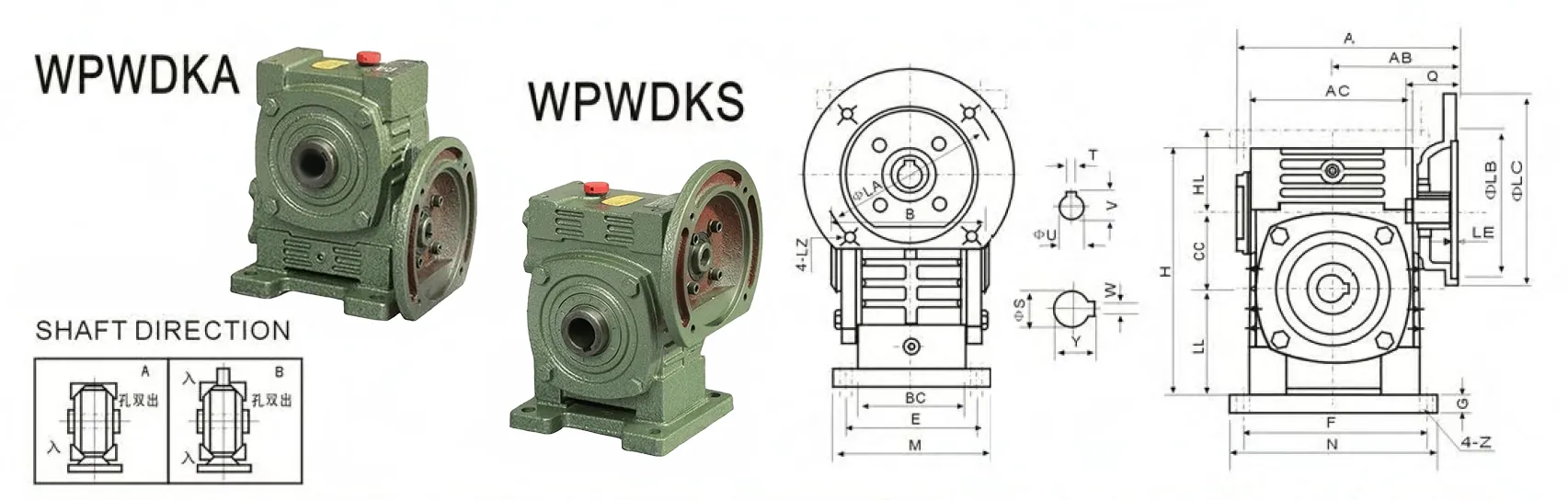

WPWDKS Worm Gear Reducers/Worm Gearbox

The WPWDKS worm gear reducer, commonly referred to as a worm gearbox, is a highly efficient and compact mechanical power transmission device designed for applications requiring significant speed reduction and increased torque. Part of the WP series worm gearbox, it features a robust cast iron housing and incorporates a single-stage worm gear system, consisting of a worm (resembling a screw-like pinion) and a worm wheel (spur gear). These components are oriented at 90 degrees to enable perpendicular power transmission.

The WPWDKS worm gear reducer, commonly referred to as a worm gearbox, is a highly efficient and compact mechanical power transmission device designed for applications requiring significant speed reduction and increased torque. Part of the WP series worm gearbox, it features a robust cast iron housing and incorporates a single-stage worm gear system, consisting of a worm (resembling a screw-like pinion) and a worm wheel (spur gear). These components are oriented at 90 degrees to enable perpendicular power transmission. The WPWDKS worm drive gearbox is distinguished by its integral universal worm reducer design, which includes a motor flange with a shaft hole output and an upper input shaft, providing versatile mounting options for horizontal or vertical configurations.

This worm gear speed reducer offers a solid or hollow output shaft, a compact structure, and self-locking capabilities at high reduction ratios, typically ranging from 5:1 to 60:1, with double-stage ratios reaching up to 10,000:1. Its precision-machined components ensure low noise, minimal vibration, and long-lasting durability. These features make it ideal for industrial applications such as conveyors, elevators, and heavy machinery, where reliable, efficient, and quiet operation is essential.

WPWDKS Worm Gear Reducer Specifications

| Type: | WPWDKS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWDKS Worm Gearbox Dimensions

| Model | Input Power(kW) | Ratio | A | AB | BB | AC | BC | CC | HL | LL | H | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 85 | 95 | 61 | 40 | 45 | 60 | 135 | 100 | 130 | 80 | 110 | 10 | 10 |

| 50 | 0.18 | 151 | 83 | 105 | 111 | 68 | 50 | 50 | 80 | 165 | 120 | 140 | 95 | 110 | 15 | 12 | |

| 60 | 0.37 | 167 | 91 | 110 | 127 | 76 | 60 | 60 | 93 | 195 | 130 | 150 | 105 | 120 | 18 | 12 | |

| 70 | 0.37 | 200 202 | 109 111 | 130 | 152 | 86 | 70 | 73 | 108 | 233 | 150 | 190 | 115 | 150 | 18 | 15 | |

| 80 | 0.75 1.5 | 225 | 125 | 150 | 169 | 102 | 80 | 83 | 123 | 268 | 170 | 220 | 135 | 180 | 18 | 15 | |

| 100 | 1.5 | 280 | 148 | 169 | 216 | 117 | 100 | 100 | 150 | 330 | 190 | 270 | 155 | 220 | 20 | 15 | |

| 120 | 2.2 2.2 | 333 | 181 | 190 | 256 | 124 | 120 | 120 | 180 | 395 | 230 | 320 | 180 | 260 | 25 | 18 | |

| 135 | 3.0 4.0 | 375 | 202 | 210 | 296 | 147 | 135 | 135 | 215 | 455 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 155 | 5.5 | 448 | 247 | 253 | 345 | 185 | 155 | 135 | 235 | 493 | 280 | 380 | 220 | 320 | 32 | 21 | |

| 175 | 5.5 7.5 | 481 | 262 | 255 | 374 | 192 | 175 | 160 | 260 | 558 | 310 | 410 | 250 | 350 | 37 | 21 | |

| 200 | 7.5 | 543 | 285 | 319 | 412 | 230 | 200 | 175 | 290 | 620 | 355 | 445 | 290 | 390 | 45 | 24 | |

| 250 | 11.0 15.0 | 615 | 330 | 385 | 500 | 285 | 250 | 200 | 350 | 750 | 460 | 560 | 380 | 480 | 50 | 28 |

| Flange | Input Hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kW) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 16 | 6×18.8 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 20 | 6×22.8 | 8 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 25 | 8×28.3 | 12.5 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 35 | 10×38.3 | 26 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 40 | 12×43.3 | 41.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 45 | 14×48.8 | 60 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 60 | 18×64.4 | 90 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 70 | 20×74.9 | 118 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 80 | 22×85.4 | 167 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 85 | 22×90.4 | 237 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 110 | 28×116.4 | 395 |

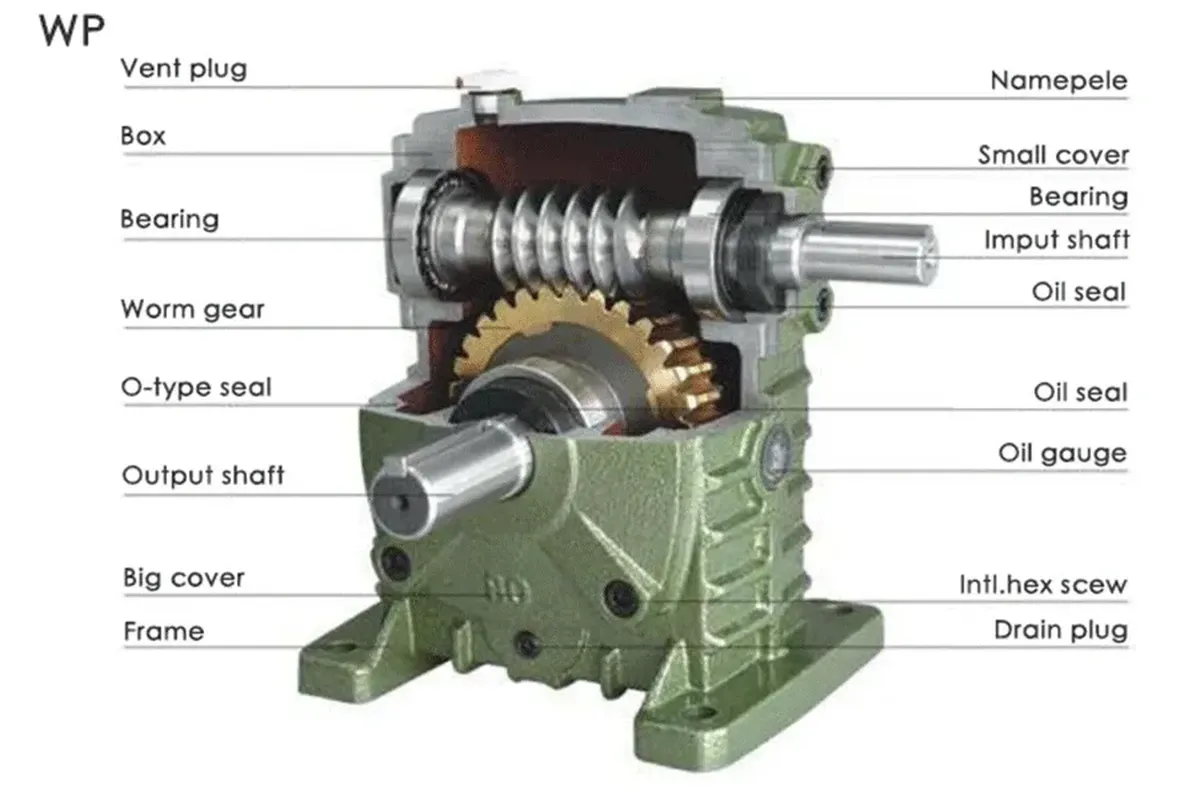

WPWDKS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWDKS Worm Gear Reducer Parts

- Worm Gear Housing

The housing of the WPWDKS worm gear reducer is made from durable cast iron, ensuring high strength and resistance to wear. It provides structural support for the gear system and protects internal components from external damage, contaminants, and harsh operating conditions. - Worm Shaft (Pinion)

The worm shaft, resembling a screw, is crafted with precision to ensure smooth engagement with the worm wheel. It transmits input power into the system, enabling torque multiplication and speed reduction. Its high-quality material and accurate threading contribute to the gearbox's efficiency and durability. - Worm Wheel (Gear)

The worm wheel is a spur gear that interacts with the worm shaft to produce the speed reduction and torque increase. It is typically made of high-strength bronze or similar materials, ensuring smooth operation, wear resistance, and long service life under heavy loads. - Input Shaft

Positioned at the top of the gearbox, the input shaft connects to the power source, such as an electric motor. It is designed to handle high rotational speeds and transmits this motion to the worm shaft for further processing within the gearbox. - Output Shaft

The output shaft, available in solid or hollow configurations, delivers the reduced speed and enhanced torque to the connected machinery. It is designed to accommodate various mounting options, allowing flexibility in industrial applications like conveyors and elevators. - Motor Flange

The motor flange is an integral part of the design, providing a secure and standardized mounting interface for connecting electric motors. It ensures precise alignment between the motor and the gearbox, reducing vibration and ensuring efficient power transmission. - Bearing System

Bearings within the gearbox support the worm shaft and output shaft, reducing friction and ensuring smooth rotation. They are engineered for high-load capacity and long service life, contributing to the gearbox's reliability and ability to handle demanding industrial applications. - Oil Seal and Lubrication System

The oil seal prevents leakage and ensures proper lubrication of internal components, reducing friction and wear. The lubrication system enhances heat dissipation and maintains smooth operation under heavy loads, prolonging the lifespan of the gearbox even in continuous operation.

WPWDKS Worm Gear Speed Reducer Uses

- Material Handling Industry

WPWDKS worm gear reducers are integral in conveyor systems and material handling equipment. Their ability to provide high torque at low speeds ensures smooth and controlled movement of heavy loads. The compact design and self-locking feature enhance safety and efficiency in warehouses and distribution centers. - Packaging Machinery

In packaging industries, worm gear speed reducers drive equipment like filling machines, labeling systems, and carton sealers. Their precise speed control and high torque output enable consistent operation under varying loads. The robust cast iron housing ensures durability, reducing downtime in high-speed production lines. - Textile Industry

Textile machinery, such as spinning frames and looms, relies on WPWDKS worm drive gearboxes for consistent power transmission. The reducer’s smooth operation and low noise levels are critical for maintaining precision in fabric production. Its versatile mounting options allow integration into complex textile equipment setups. - Food Processing Industry

WPWDKS worm reducer gearboxes are used in food processing equipment like mixers, slicers, and conveyors. Their corrosion-resistant materials and reliable sealing systems prevent contamination. The high reduction ratios ensure precise control over processing speeds, meeting strict hygiene and operational standards in food production. - Construction Equipment

In construction, right angle worm gearboxes power hoists, cranes, and concrete mixers. Their ability to handle heavy loads with high torque makes them ideal for rugged environments. The self-locking feature prevents unintended movement, enhancing safety on construction sites with demanding operational requirements. - Agricultural Machinery

Agricultural equipment, such as grain augers and irrigation systems, utilizes WPWDKS worm reduction gearboxes for efficient power transmission. Their durable construction withstands harsh outdoor conditions, while the high torque output supports heavy-duty tasks. The hollow output shaft option allows flexible integration with various farm machinery.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Construction Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Food and Beverage Industry |

WPWDKS Worm Drive Gearbox Advantages

- High Torque Output

The WPWDKS worm drive gearbox delivers exceptional torque output, making it ideal for heavy-duty applications. Its worm and worm wheel design ensures significant torque multiplication, enabling the gearbox to handle high loads efficiently while maintaining smooth operation even under demanding industrial conditions. - Self-Locking Capability

One of its key advantages is the self-locking feature at high reduction ratios. This prevents reverse motion without the need for additional braking systems, ensuring safety and stability in applications like elevators, conveyors, and lifting equipment, where motion control is critical. - Compact and Space-Saving Design

The worm reducer gearboxes are designed to be compact, with a 90-degree perpendicular orientation of its worm and wheel system. This space-efficient configuration allows it to be easily integrated into machinery with limited mounting space, enhancing versatility across various industrial applications. - Low Noise and Vibration

The precision-machined components of the WPWDKS worm gear gearbox contribute to its quiet operation and minimal vibration. This makes it suitable for applications requiring noise reduction, such as in food processing or textile industries, where a smooth and controlled environment is essential. - Durable and Long-Lasting Construction

Built with a robust cast iron housing and high-quality materials for internal components, the worm drive reduction gearbox is highly resistant to wear and tear. Its durable construction ensures long service life, even in harsh environments or applications involving continuous operation under heavy loads. - Wide Range of Reduction Ratios

The WPWDKS worm gear drive gearbox offers a broad range of reduction ratios, from 5:1 to 60:1 in single-stage configurations, with double-stage options going up to 10,000:1. This flexibility allows it to meet the specific speed reduction and torque requirements of diverse industries.

Additional information

| Edited by | Yjx |

|---|