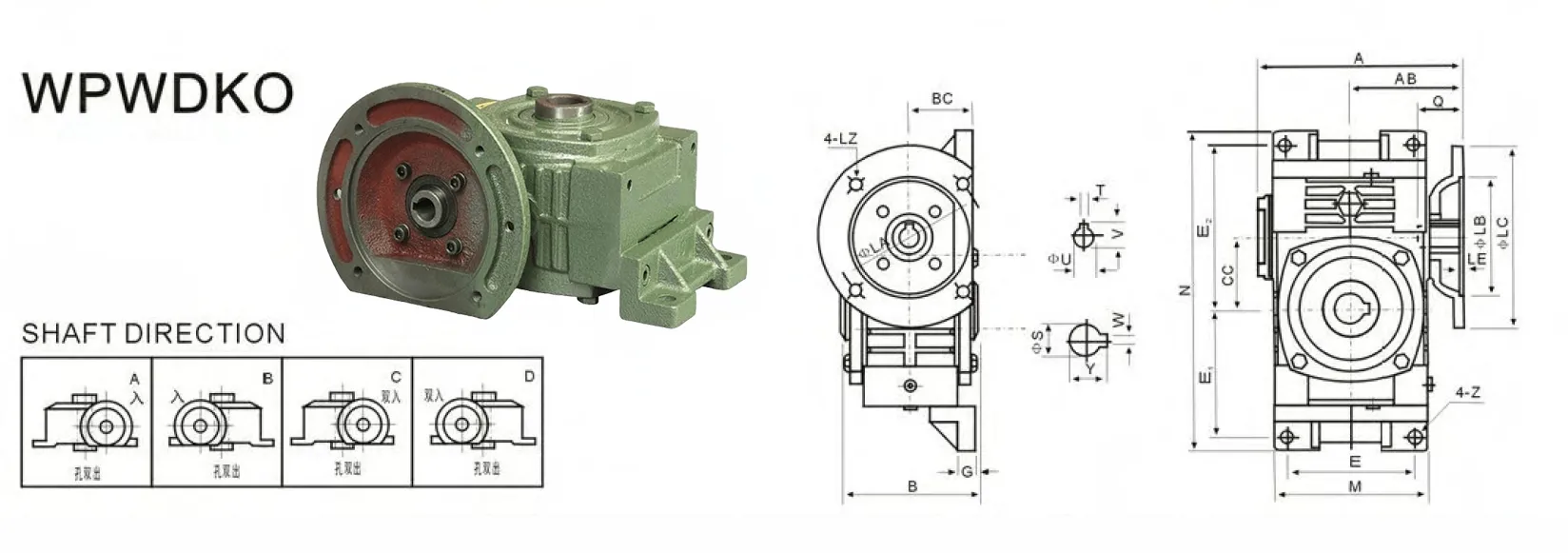

WPWDKO Worm Gear Reducers/Worm Gearbox

WPWDKO worm gear reducers, commonly referred to as worm gearboxes, are advanced mechanical devices designed for efficient power transmission in industrial applications. These worm gear speed reducers are crafted to deliver significant speed reduction and torque multiplication within a compact and durable structure. Enclosed in a robust cast iron housing, they feature a single-stage worm gear system composed of a worm (a screw-like input gear) and a worm wheel (a spur-like output gear). The WPWDKO worm gearboxes stand out with their universal design, incorporating a motor flange shaft hole output that enables flexible mounting options, such as horizontal or vertical configurations.

WPWDKO worm gear reducers, commonly referred to as worm gearboxes, are advanced mechanical devices designed for efficient power transmission in industrial applications. These worm gear speed reducers are crafted to deliver significant speed reduction and torque multiplication within a compact and durable structure. Enclosed in a robust cast iron housing, they feature a single-stage worm gear system composed of a worm (a screw-like input gear) and a worm wheel (a spur-like output gear). The WPWDKO worm gearboxes stand out with their universal design, incorporating a motor flange shaft hole output that enables flexible mounting options, such as horizontal or vertical configurations.

Key components include a solid or hollow output shaft, an IEC B5 motor flange for input, and premium materials like 45# steel for the worm and tin bronze for the worm gear, ensuring exceptional wear resistance and high load capacity. With gear ratios ranging from 1:10 to 1:60, WPWDKO worm reducer gearboxes offer large reduction ratios, self-locking capabilities under specific conditions, reduced vibration, and low noise levels. Their versatility and reliability make them indispensable in industries such as plastics, metallurgy, mining, and chemical construction, where stable and efficient power transmission is critical.

WPWDKO Worm Gear Reducer Specifications

| Type: | WPWDKO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWDKO Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | A | AB | B | BC | CC | M | N | E | E1 | E2 | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 85 | 45 | 40 | 95 | 187 | 70 | 72 | 97 | 12 | 10 |

| 50 | 0.18 | 151 | 83 | 105 | 50 | 50 | 111 | 226 | 90 | 90 | 110 | 14 | 12 | |

| 60 | 0.37 | 167 | 91 | 110 | 55 | 60 | 127 | 257 | 100 | 102 | 129 | 15 | 12 | |

| 70 | 0.37 0.75 | 200 202 | 109 111 | 130 | 65 | 70 | 152 | 305 | 120 | 120 | 155 | 20 | 15 | |

| 80 | 0.75 1.5 | 225 | 125 | 150 | 70 | 80 | 174 | 350 | 140 | 140 | 180 | 20 | 15 | |

| 100 | 1.5 | 280 | 148 | 160 | 90 | 100 | 224 | 410 | 190 | 165 | 215 | 22 | 15 | |

| 120 | 2.2 3.0 | 333 | 181 | 175 | 100 | 120 | 264 | 494 | 220 | 195 | 255 | 25 | 18 | |

| 135 | 3.0 4.0 | 375 | 202 | 210 | 110 | 135 | 304 | 559 | 260 | 230 | 285 | 30 | 18 | |

| 155 | 5.5 | 448 | 247 | 256 | 140 | 155 | 345 | 605 | 290 | 250 | 305 | 35 | 21 | |

| 175 | 5.5 7.5 | 481 | 262 | 282 | 150 | 175 | 374 | 675 | 320 | 273 | 348 | 40 | 21 | |

| 200 | 11.0 | 543 | 285 | 320 | 175 | 200 | 424 | 749 | 370 | 305 | 390 | 40 | 24 | |

| 250 | 11.0 15.0 | 615 | 330 | 400 | 200 | 250 | 510 | 920 | 440 | 375 | 475 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 16 | 6×18.8 | 5.4 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 20 | 6×22.8 | 8.5 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 25 | 8×28.3 | 12 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 35 | 10×38.3 | 26 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 40 | 12×43.3 | 40.5 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 45 | 14×48.8 | 59 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 60 | 18×64.4 | 89 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 70 | 20×74.9 | 138 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 80 | 22×85.4 | 172 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 85 | 22×90.4 | 246 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 110 | 28×116.4 | 410 |

WPWDKO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWDKO Worm Drive Gearbox Benefits

- High Torque Output and Efficiency

WPWDKO worm drive gearboxes deliver exceptional torque multiplication, ideal for heavy-duty industrial applications. Their single-stage worm gear design ensures efficient power transmission, providing high torque with minimal energy loss, making them suitable for demanding tasks in machinery and equipment. - Compact and Versatile Design

The worm gear reducers feature a compact cast iron housing, enabling space-saving installation in various configurations, including horizontal or vertical mounting. This versatility, combined with a universal motor flange, allows seamless integration into diverse systems like conveyors, mixers, and material handling equipment. - Self-Locking Capability

Under specific conditions, WPWDKO worm reducer gearboxes offer self-locking, preventing reverse rotation without additional braking mechanisms. This feature enhances safety and stability in applications requiring precise positioning, such as hoists or lifts, ensuring reliable operation under load without unintended movement or slippage. - Durability and Wear Resistance

Constructed with high-quality materials like 45# steel for the worm and tin bronze for the worm wheel, worm gear speed reducers resist wear and corrosion. This robust build ensures long service life, reducing maintenance costs and downtime in industries like metallurgy and mining. - Low Noise and Vibration

The precision-engineered worm and wheel design minimizes noise and vibration during operation. This smooth performance enhances workplace comfort and reduces mechanical stress, making WPWDKO worm and wheel gearboxes ideal for continuous-use applications in noise-sensitive environments like chemical or food processing plants. - Wide Range of Gear Ratios

Offering gear ratios from 1:10 to 1:60, worm reduction gearboxes provide flexible speed reduction options. This adaptability supports precise control in various applications, from slow-speed conveyors to high-torque machinery, ensuring optimal performance across industries like plastics and construction.

WPWDKO Worm Reduction Gearbox Applications

- Plastics Industry

WPWDKO worm reduction gearboxes are extensively used in plastic extrusion and molding machines. Their high torque output and precise speed control ensure consistent material flow and shaping, enabling efficient production of plastic products like pipes, sheets, and films with minimal energy waste. - Metallurgy Industry

In metallurgical processes, worm gear reducers drive heavy machinery such as rolling mills and conveyors. Their robust cast iron housing and wear-resistant materials handle high loads and harsh conditions, ensuring reliable performance in metal forming, cutting, and processing applications. - Mining Industry

WPWDKO worm gear motors power equipment like crushers, conveyors, and hoists in mining operations. Their self-locking feature and high torque capacity support safe and efficient handling of heavy ore loads, enhancing productivity in rugged environments while reducing maintenance needs. - Chemical Industry

These worm reducer gearboxes are integral to mixers, reactors, and pumps in chemical plants. Their low noise and vibration, combined with corrosion-resistant materials, ensure stable operation in sensitive processes, maintaining precise control over mixing and material transfer in chemical production. - Construction Industry

WPWDKO worm drive gearboxes drive construction equipment such as concrete mixers and lifting systems. Their compact design and versatile mounting options allow integration into various machinery, providing reliable torque and speed reduction for heavy-duty tasks on construction sites. - Food Processing Industry

In food production, WPWDKOworm gearboxes are used in conveyors, mixers, and packaging machines. Their smooth operation and low maintenance requirements ensure hygienic and efficient processing, meeting strict industry standards while handling tasks like dough mixing or product sorting.

|  |

| Worm Gearbox for Plastic and Rubber Machinery | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Construction Industry |

WPWDKO Worm Gear Reducer Installation Steps

- Prepare the Installation Area

Ensure the installation site is clean, level, and free of debris to prevent misalignment. Verify that the mounting surface is stable and capable of supporting the gearbox’s weight and operational forces. Gather necessary tools, including wrenches, bolts, and alignment equipment, to streamline the process. - Inspect the Gearbox Components

Before installation, thoroughly inspect the worm gear reducer for any damage or defects. Check the worm, worm wheel, output shaft, and motor flange for wear or irregularities. Confirm that all components, including seals and bearings, are intact and properly lubricated. - Align the Gearbox and Motor

Position the worm drive reduction gearbox on the mounting surface, ensuring proper alignment with the driven equipment and motor. Use precision alignment tools to verify that the input shaft (IEC B5 flange) and output shaft are correctly aligned to avoid stress and ensure efficient power transmission. - Secure the Gearbox to the Mounting Surface

Fasten the gearbox to the mounting base using appropriate bolts and washers, as specified in the worm gear drive gearbox manual. Tighten bolts evenly in a cross pattern to ensure uniform pressure, preventing distortion of the cast iron housing and maintaining structural integrity. - Connect the Motor to the Gearbox

Attach the motor to the gearbox’s IEC B5 flange, ensuring a secure connection. Verify that the motor shaft aligns with the worm input shaft. Tighten all coupling bolts and check for any play to ensure a stable, vibration-free connection during operation. - Test and Adjust the Installation

After securing the gearbox and motor, perform a test run at low speed to check for abnormal noise, vibration, or overheating. Adjust alignment or lubrication if necessary, ensuring the gearbox operates smoothly within specified parameters before full operational use.

Additional information

| Edited by | Yjx |

|---|