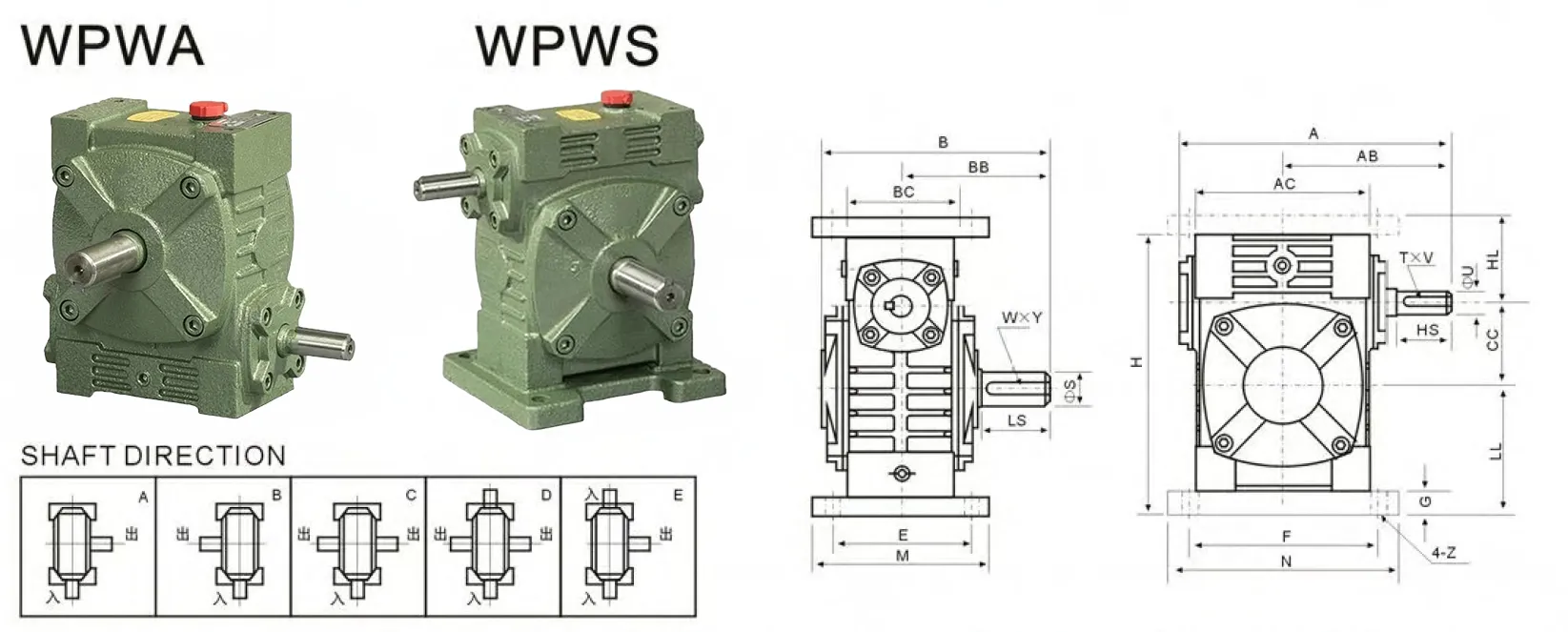

WPWA Worm Gear Reducers/Worm Gearbox

WPWA worm gear reducers, part of the WP series worm gearboxes, are mechanical power transmission devices designed for efficient speed reduction and torque multiplication in compact spaces. They feature a cast iron housing for durability, a worm (made of heat-treated 45# high-quality steel) and a worm wheel (typically tin bronze) for smooth operation and high wear resistance. The WPWA worm gear speed reducer has a lower input shaft configuration and is available in frame sizes from 40 to 250 mm, with reduction ratios ranging from 1:10 to 1:60.

WPWA worm gear reducers, part of the WP series worm gearboxes, are mechanical power transmission devices designed for efficient speed reduction and torque multiplication in compact spaces. They feature a cast iron housing for durability, a worm (made of heat-treated 45# high-quality steel) and a worm wheel (typically tin bronze) for smooth operation and high wear resistance. The WPWA worm gear speed reducer has a lower input shaft configuration and is available in frame sizes from 40 to 250 mm, with reduction ratios ranging from 1:10 to 1:60.

These worm drive gearboxes offer stable transmission, low vibration, and noise, with a self-locking feature under certain conditions, eliminating the need for additional braking devices. They support horizontal or vertical mounting, with solid or hollow output shaft options, and are compatible with IEC B5 motor flanges. Widely used in industries like plastics, metallurgy, mining, and chemical construction, WPWA worm gear speed reducers ensure reliable performance with minimal maintenance.

WPWA Worm Gear Reducer Specifications

| Type: | WPWA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic & Mineral |

WPWA Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | BB | AC | BC | CC | HL | LL | H | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 114 | 74 | 95 | 61 | 40 | 45 | 60 | 135 | 100 | 130 | 80 | 110 | 10 | 10 |

| 50 | 175 | 108 | 150 | 97 | 111 | 68 | 50 | 50 | 80 | 165 | 120 | 140 | 95 | 110 | 15 | 12 | |

| 60 | 198 | 120 | 168 | 112 | 127 | 76 | 60 | 60 | 93 | 195 | 130 | 150 | 105 | 120 | 18 | 12 | |

| 70 | 231 | 140 | 194 | 131 | 152 | 86 | 70 | 73 | 108 | 233 | 150 | 190 | 115 | 150 | 18 | 15 | |

| 80 | 261 | 160 | 214 | 142 | 169 | 102 | 80 | 83 | 123 | 268 | 170 | 220 | 135 | 180 | 18 | 15 | |

| 100 | 322 | 190 | 254 | 169 | 216 | 117 | 100 | 100 | 150 | 330 | 190 | 270 | 155 | 220 | 20 | 15 | |

| 120 | 371 | 219 | 282 | 190 | 256 | 124 | 120 | 120 | 180 | 395 | 230 | 320 | 180 | 260 | 25 | 18 | |

| 135 | 422 | 249 | 317 | 210 | 296 | 147 | 135 | 135 | 215 | 455 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 155 | 497 | 295 | 382 | 252 | 345 | 185 | 155 | 135 | 235 | 493 | 280 | 380 | 220 | 320 | 32 | 21 | |

| 175 | 534 | 314 | 372 | 255 | 374 | 192 | 175 | 160 | 260 | 558 | 310 | 410 | 250 | 350 | 37 | 21 | |

| 200 | 580 | 342 | 456 | 319 | 412 | 230 | 200 | 175 | 290 | 620 | 355 | 445 | 290 | 390 | 45 | 24 | |

| 250 | 705 | 420 | 552 | 385 | 500 | 285 | 250 | 200 | 350 | 750 | 460 | 560 | 380 | 480 | 50 | 28 |

| Input shaft | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 4.5 |

| 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 7.5 |

| 40 | 15 | 5×3 | 50 | 22 | 7×4 | 11.5 |

| 40 | 18 | 5×3 | 60 | 28 | 7×4 | 15.5 |

| 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 24 |

| 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 39 |

| 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 57 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 85 |

| 85 | 40 | 12×5 | 110 | 60 | 18×7 | 110 |

| 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 152 |

| 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 216 |

| 110 | 60 | 18×7 | 155 | 90 | 25×9 | 350 |

WPWA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPWA Worm Gear Speed Reducer Features

1. Durable Construction

WPWA worm gear speed reducers feature a robust cast iron housing ensuring high strength and longevity. This material resists corrosion and withstands harsh industrial environments. The design enhances structural integrity, making it ideal for heavy-duty applications like metallurgy and mining.

2. High-Quality Worm and Wheel

The worm gear reducer incorporates a worm made of heat-treated 45# steel and a tin bronze worm wheel. This combination ensures excellent wear resistance and smooth operation. Precision machining of these components guarantees efficient power transmission and minimal energy loss in demanding conditions.

3. Compact and Versatile Design

With frame sizes from 40 to 250 mm, WPWA worm drive gearboxes offer a compact footprint suitable for space-constrained setups. They support multiple mounting options, including horizontal and vertical configurations, providing flexibility for diverse applications in industries like plastics and chemical processing.

4. Wide Ratio Range

These worm reducer gearboxes provide reduction ratios from 1:10 to 1:60, allowing precise speed control and torque multiplication. This versatility meets varied operational needs, enabling efficient performance in conveyor systems, mixers, and other machinery requiring specific speed adjustments.

5. Self-Locking Capability

Under certain conditions, WPWA worm gearboxes exhibit self-locking, preventing reverse rotation without additional braking mechanisms. This feature enhances safety and reduces system complexity, making it suitable for applications requiring precise positioning, such as hoists and automated production lines.

6. Low Noise and Vibration

Engineered for smooth and stable transmission, worm reduction gearboxes minimize noise and vibration during operation. The precision-crafted worm and wheel, combined with high-quality bearings, ensure quiet performance, improving workplace comfort and extending component lifespan in continuous-use scenarios.

WPWA Worm Gear Reducer Application Industry

1. Plastics Industry

WPWA worm gear reducers are extensively used in plastic processing equipment like extruders and injection molding machines. Their precise speed control and high torque output ensure consistent material flow and shaping. The compact design fits seamlessly into space-constrained production lines, enhancing operational efficiency.

2. Metallurgy Industry

In metallurgical applications, worm gearbox reducers drive heavy machinery such as rolling mills and conveyors. Their robust cast iron housing withstands extreme conditions, while the self-locking feature ensures safe operation. High torque and durability make them ideal for handling heavy metal processing tasks.

3. Mining Industry

WPWA worm drive gearboxes power mining equipment like crushers and conveyor belts. Their ability to handle high loads and resist wear in dusty, rugged environments ensures reliable performance. The wide ratio range allows precise speed adjustments for efficient material handling and processing.

4. Chemical Industry

These worm reducer gearboxes are vital in chemical plants for driving mixers, agitators, and pumps. The corrosion-resistant housing and smooth operation ensure safe handling of volatile substances. Their low maintenance and stable transmission support continuous operation in demanding chemical processing environments.

5. Construction Industry

WPWA worm gear speed reducers are used in construction machinery like concrete mixers and hoists. Their high torque and self-locking capability provide precise control and safety. The durable design withstands harsh outdoor conditions, ensuring reliable performance in building and infrastructure development projects.

6. Food Processing Industry

In food production, worm drive reduction gearboxes drive conveyors, mixers, and packaging machines. Their low noise and vibration ensure a hygienic, quiet operation suitable for food-grade environments. The compact design and versatile mounting options optimize space in automated food processing lines.

|  |

| Worm Gearbox for Metallurgy Industry | Worm Gearbox for Plastic Machinery |

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Food and Beverage Industry |

Worm Drive Gearbox Troubleshooting

Excessive Noise During Operation

If the worm gearbox produces unusual noise, inspect for worn worm or wheel components due to prolonged use. Check for improper lubrication or misalignment. Ensure proper oil levels and use recommended lubricants. Realign the worm gear drive gearbox and motor to restore smooth, quiet operation.

Overheating Issues

Overheating may result from overloading, insufficient lubrication, or improper ventilation. Verify the load does not exceed the gearbox’s rated capacity. Check oil quality and levels, topping up with manufacturer-specified lubricant. Ensure the gearbox is in a well-ventilated area to dissipate heat effectively.

Vibration Problems

Excessive vibration often stems from misalignment, loose mounting bolts, or damaged bearings. Inspect and tighten all mounting bolts. Realign the input and output shafts. Replace worn bearings with compatible parts to ensure stable operation and prevent further damage to internal components.

Output Shaft Not Rotating

If the output shaft fails to rotate, check for a seized worm gear or broken keyway. Inspect for debris or insufficient lubrication. Disassemble and clean the gearbox, replacing damaged parts. Ensure proper lubrication to prevent recurrence and restore full functionality.

Oil Leakage

Leaks may occur due to worn seals, damaged gaskets, or overfilled oil reservoirs. Inspect seals and gaskets for wear and replace as needed. Check oil levels against manual specifications and drain excess. Regularly monitor for leaks to maintain gearbox integrity and performance.

Reduced Torque Output

If torque output is low, examine for worn worm or wheel teeth, insufficient lubrication, or incorrect gear ratio. Inspect components for wear and replace if necessary. Ensure proper lubrication with high-quality oil. Verify the gear ratio matches application requirements for optimal performance.

Additional information

| Edited by | Yjx |

|---|