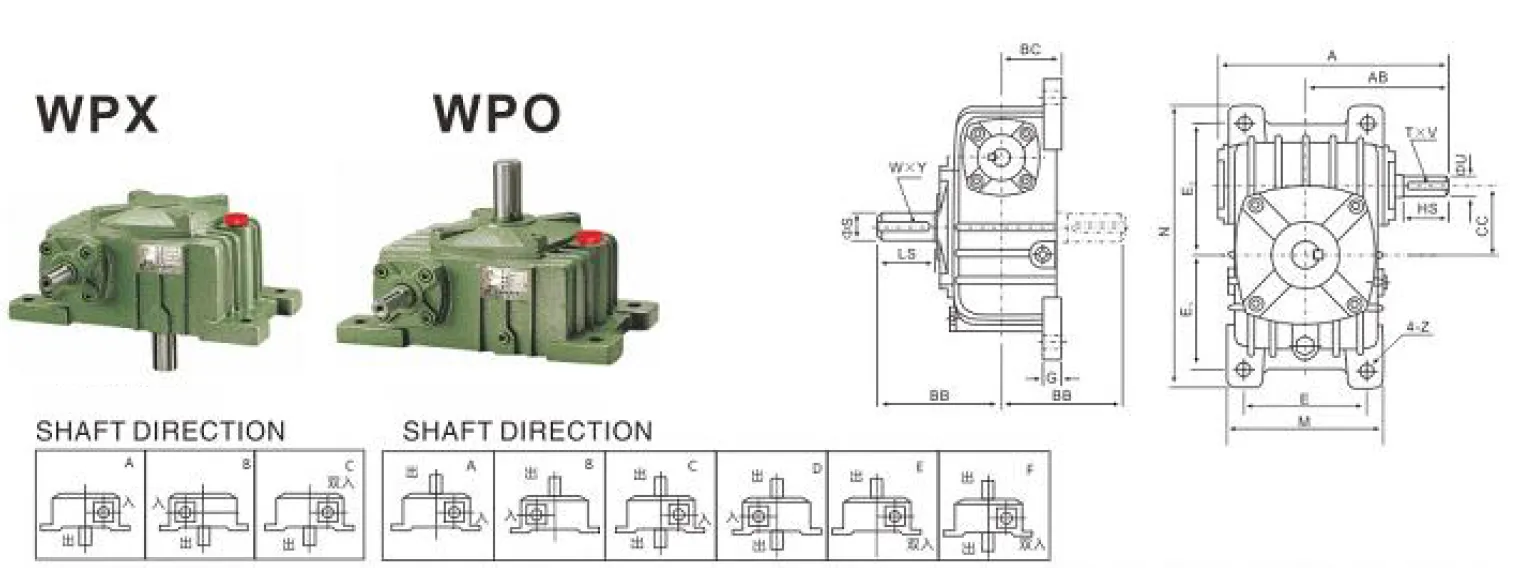

WPO Worm Gear Reducers/Worm Gearbox

WPO worm gear reducers (also known as worm gearboxes) are a specific variant of the WP series worm gearboxes, characterized by their output shaft being positioned on the upper side. These reducers are crafted from high-strength cast iron, providing a robust and durable housing that ensures long-term performance in demanding applications. The WPO worm gearboxes are known for their compact structure, which allows for space-saving installation, and their ability to provide stable transmission with minimal vibration and low noise levels. They feature a high reduction ratio, making them suitable for applications that require significant torque at reduced speed.

WPO worm gear reducers (also known as worm gearboxes) are a specific variant of the WP series worm gearboxes, characterized by their output shaft being positioned on the upper side. These reducers are crafted from high-strength cast iron, providing a robust and durable housing that ensures long-term performance in demanding applications. The WPO worm gearboxes are known for their compact structure, which allows for space-saving installation, and their ability to provide stable transmission with minimal vibration and low noise levels. They feature a high reduction ratio, making them suitable for applications that require significant torque at reduced speed.

These worm reducer gearboxes exhibit exceptional versatility, as they can be paired with various mechanical equipment. Their design ensures smooth operation with minimal shock, making them ideal for industries such as metallurgy, mining, transportation, water conservancy, chemical processing, food production, beverage manufacturing, and textiles. With their durable construction and reliable performance, WPO worm gear reducers are a preferred choice for heavy-duty and precision-driven applications.

WPO Worm Gear Reducer Specifications

| Product Name: | WPO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPO |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.12kW~15kW |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

WPO Worm Gearbox Dimensions

| Model | Ratio | A | AB | BB | CC | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 74 | 40 | 94 | 184 | 70 | 74 | 86 | 10 | 10 |

| 50 | 175 | 108 | 97 | 50 | 116 | 220 | 90 | 93 | 102 | 15 | 12 | |

| 60 | 198 | 120 | 112 | 60 | 126 | 260 | 100 | 105 | 120 | 20 | 12 | |

| 70 | 231 | 140 | 131 | 70 | 156 | 295 | 120 | 120 | 135 | 20 | 15 | |

| 80 | 261 | 160 | 142 | 80 | 175 | 325 | 140 | 130 | 150 | 20 | 15 | |

| 100 | 322 | 190 | 169 | 100 | 224 | 375 | 190 | 155 | 180 | 25 | 15 | |

| 120 | 371 | 219 | 190 | 120 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 135 | 422 | 249 | 210 | 135 | 306 | 495 | 250 | 210 | 235 | 30 | 18 | |

| 147 | 438 | 256 | 210 | 147 | 302 | 558 | 250 | 230 | 278 | 32 | 18 | |

| 155 | 497 | 295 | 252 | 155 | 350 | 590 | 290 | 245 | 295 | 35 | 21 | |

| 175 | 534 | 314 | 255 | 175 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 200 | 580 | 342 | 319 | 200 | 440 | 710 | 370 | 290 | 360 | 40 | 24 | |

| 250 | 705 | 420 | 385 | 250 | 510 | 860 | 440 | 350 | 440 | 45 | 28 |

| Input shaft | Output shaft | Weight | Oil quantity | ||||

|---|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) | (L) |

| 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 5 | 0.36 |

| 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 6 | 0.50 |

| 40 | 15 | 5×3 | 50 | 22 | 7×4 | 10 | 0.60 |

| 40 | 18 | 5×3 | 60 | 28 | 7×4 | 15 | 1.00 |

| 50 | 22 | 7×4 | 65 | 32 | 10×4.5 | 20 | 1.50 |

| 50 | 25 | 7×4 | 75 | 38 | 10×4.5 | 35 | 2.00 |

| 65 | 30 | 7×4 | 85 | 45 | 12×4.5 | 50 | 4.20 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 75 | 6.50 |

| 75 | 35 | 10×4.5 | 95 | 55 | 16×6 | 96 | 6.50 |

| 85 | 40 | 12×5 | 110 | 60 | 18×7 | 115 | 9.30 |

| 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 140 | 10.5 |

| 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 200 | 12.7 |

| 110 | 60 | 18×7 | 155 | 90 | 25×9 | 340 | 23.0 |

WPO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPO Worm Drive Gearbox Characteristic

- Robust Cast Iron Housing

The WPO worm drive gearbox features a high-hardness cast iron housing, ensuring exceptional durability and resistance to wear. This robust construction protects internal components, making it suitable for harsh industrial environments like metallurgy, mining, and chemical processing, while maintaining long-term reliability. - Compact Structural Design

Designed with a compact footprint, the worm reducer gearbox optimizes space in mechanical setups. Its efficient layout allows seamless integration into various equipment, enhancing versatility across industries such as food, beverage, and textile, without compromising performance or requiring excessive installation space. - Stable and Smooth Transmission

The WPO worm gear reducers ensure stable power transmission with minimal fluctuations. Its precision-engineered worm gear mechanism delivers consistent torque and speed reduction, making it ideal for applications requiring steady operation, such as water conservancy and transportation systems, ensuring operational efficiency. - Low Noise and Vibration

Engineered for quiet operation, the worm gear speed reducer minimizes noise, vibration, and shock during use. This feature enhances workplace safety and comfort, particularly in industries like food processing and textiles, where low disturbance levels are critical for operational environments. - High Reduction Ratio

The WPO worm reduction gearbox offers a large reduction ratio, enabling significant torque multiplication and precise speed control. This characteristic is crucial for heavy-duty applications in mining and metallurgy, where high torque is needed to drive large machinery efficiently and effectively. - Wide Versatility

With its adaptable design, the worm gear drive gearbox is compatible with various mechanical equipment across multiple sectors. Its versatility supports diverse applications in chemical, water conservancy, and transportation industries, providing reliable performance and flexibility in complex industrial systems.

WPO Worm Gear Speed Reducer Uses

- Metallurgy Industry

WPO worm gear speed reducers are extensively used in metallurgy for driving heavy machinery like rolling mills and conveyors. Their high reduction ratio and robust cast iron housing ensure reliable torque transmission and durability under intense operational conditions, enhancing efficiency in metal processing. - Mining Industry

In mining, worm gearboxes power equipment such as crushers, conveyors, and hoists. Their compact design and stable transmission handle high-torque demands, ensuring consistent performance in harsh environments while minimizing vibration and noise, critical for safe and efficient mineral extraction processes. - Transportation Systems

WPO worm gear reducers are integral to transportation applications, driving conveyor belts and material handling systems. Their ability to provide precise speed control and high torque supports smooth operation in logistics and port facilities, ensuring reliable movement of goods with minimal maintenance needs. - Water Conservancy Projects

In water conservancy, worm reducer gearboxes operate pumps and sluice gate mechanisms. Their low noise and stable transmission ensure efficient water flow management. The durable housing withstands environmental challenges, making them ideal for irrigation systems and flood control equipment in demanding conditions. - Chemical Industry

WPO worm drive gearboxes drive mixers, reactors, and pumps in chemical processing. Their versatility and stable performance ensure precise speed regulation under corrosive conditions. The compact design allows integration into complex systems, supporting consistent production in chemical manufacturing plants. - Food and Beverage Industry

In food and beverage production, worm drive reduction gearboxes power conveyors, mixers, and packaging machines. Their low noise and vibration, combined with a hygienic cast iron housing, ensure compliance with industry standards, delivering reliable performance for high-speed, high-volume processing environments.

|  |

| Worm Gearbox for Metallurgy Industry | Worm Gearbox for Conveyor Equipment |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Food and Beverage Industry |

WPO Worm Gear Reducer Troubleshooting

- Excessive Noise During Operation

If the worm gear reducer produces unusual noise, inspect for worn gears or bearings. Misalignment or insufficient lubrication may also cause this. Check gear alignment, replace damaged components, and ensure proper lubrication to restore quiet operation and prevent further damage. - Overheating Issues

Overheating in a worm reducer gearbox often results from overloading, inadequate lubrication, or poor ventilation. Verify load capacity against specifications, ensure sufficient high-quality lubricant, and clear cooling vents. Regular monitoring of operating temperatures can prevent damage and maintain efficient performance in industrial applications. - Vibration Problems

Excessive vibration may indicate loose mounting bolts, misaligned shafts, or worn gears. Tighten all mounting hardware, realign input and output shafts, and inspect gears for wear. Addressing these issues promptly ensures stable transmission and prolongs the gearbox’s lifespan in demanding environments like mining. - Oil Leakage

Oil leaks in worm gear speed reducers typically stem from damaged seals, loose fittings, or overfilled lubricant. Inspect seals for wear, tighten connections, and check oil levels against manufacturer guidelines. Replacing faulty seals and maintaining proper oil levels prevent contamination and ensure reliable operation. - Reduced Output Torque

If the gearbox delivers low torque, check for gear wear, insufficient lubrication, or input power issues. Inspect gears for damage, ensure proper lubrication, and verify motor performance. Regular maintenance and timely repairs restore torque output, critical for applications like metallurgy. - Gearbox Seizure or Jamming

Seizure may occur due to foreign debris, severe gear wear, or inadequate lubrication. Disassemble the gearbox to remove contaminants, inspect gears and bearings for damage, and relubricate with recommended oil. Preventive maintenance avoids jamming, ensuring smooth operation in chemical processing.

Additional information

| Edited by | Yjx |

|---|