WPKS Worm Gear Reducers/Worm Gearbox

WPKS worm gear reducers, part of the WP series worm gearboxes, are mechanical devices designed for efficient power transmission in various industrial applications. These reducers feature a worm (a screw-like gear) and a worm wheel, typically enclosed in a robust cast iron housing for durability in harsh environments. The WPKS worm gearbox is characterized by its compact structure, stable transmission, low vibration, and minimal noise, making it ideal for applications requiring high torque and low speed.

WPKS worm gear reducers, part of the WP series worm gearboxes, are mechanical devices designed for efficient power transmission in various industrial applications. These reducers feature a worm (a screw-like gear) and a worm wheel, typically enclosed in a robust cast iron housing for durability in harsh environments. The WPKS worm gearbox is characterized by its compact structure, stable transmission, low vibration, and minimal noise, making it ideal for applications requiring high torque and low speed. It supports versatile mounting options, with input configurations like solid shaft or IEC B5/B14 motor flanges and output options including solid or hollow shafts.

The WPKS worm gear speed reducer offers gear ratios from 1/10 to 1/60, providing significant speed reduction and torque multiplication. Commonly used in industries like plastics, metallurgy, mining, and chemical processing, these reducers may include self-locking capabilities under specific conditions, enhancing safety by preventing reverse rotation. High-quality materials, such as tin bronze worm gears and hardened steel worms, ensure longevity and reliability.

WPKS Worm Gear Reducer Specifications

| Product Name: | WPKS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPKS |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.18kW~15kW |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

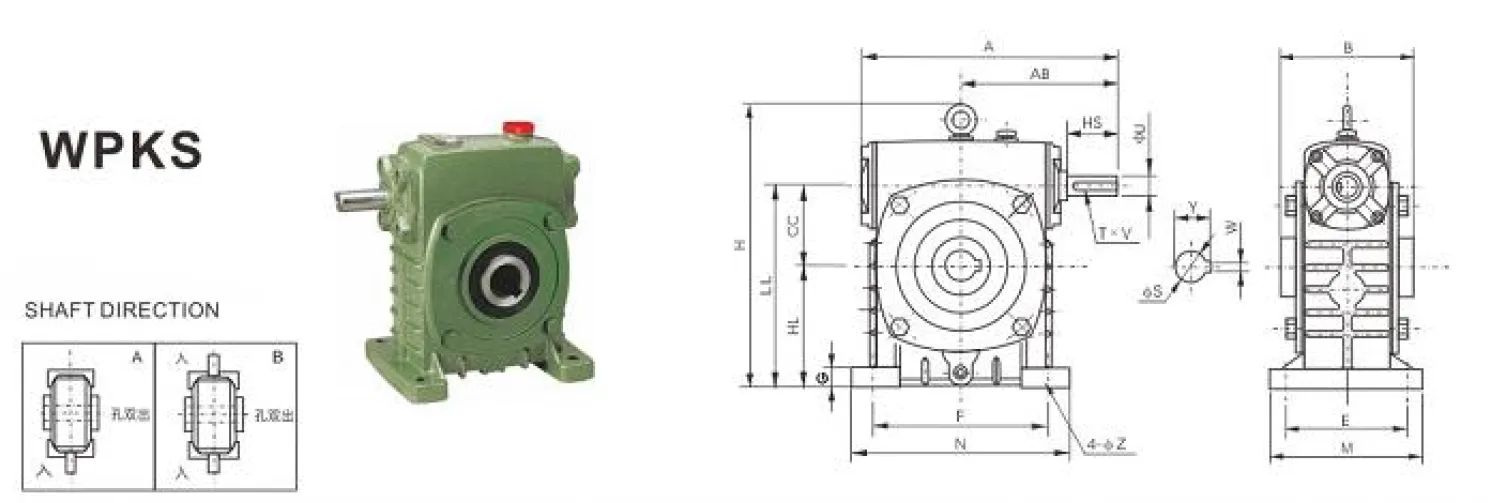

WPKS Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | CC | H | LL | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 85 | 40 | 141 | 60 | 90 | 100 | 70 | 80 | 13 | 10 |

| 50 | 175 | 108 | 105 | 50 | 180 | 80 | 120 | 140 | 95 | 110 | 15 | 11 | |

| 60 | 198 | 120 | 110 | 60 | 207 | 90 | 130 | 150 | 105 | 120 | 20 | 11 | |

| 70 | 231 | 140 | 130 | 70 | 238 | 105 | 150 | 190 | 115 | 150 | 25 | 15 | |

| 80 | 261 | 160 | 150 | 80 | 270 | 120 | 170 | 220 | 135 | 180 | 25 | 15 | |

| 100 | 322 | 190 | 160 | 100 | 331 | 150 | 190 | 260 | 155 | 220 | 25 | 15 | |

| 120 | 371 | 219 | 175 | 120 | 423 | 180 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 135 | 422 | 249 | 200 | 135 | 482 | 215 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 147 | 438 | 262 | 210 | 147 | 460 | 123 | 250 | 350 | 200 | 280 | 32 | 18 | |

| 155 | 497 | 295 | 256 | 155 | 495 | 235 | 280 | 390 | 220 | 320 | 38 | 20 | |

| 175 | 534 | 314 | 282 | 175 | 541 | 260 | 310 | 430 | 250 | 350 | 40 | 20 | |

| 200 | 580 | 342 | 320 | 200 | 594 | 290 | 360 | 480 | 290 | 390 | 42 | 22 | |

| 250 | 705 | 420 | 400 | 250 | 800 | 350 | 460 | 560 | 380 | 480 | 45 | 28 |

| Input hole | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 16 | 6×18.8 | 4 |

| 35 | 12 | 4×2.5 | 20 | 6×22.8 | 7 |

| 40 | 15 | 5×3 | 25 | 8×28.3 | 10.5 |

| 40 | 18 | 5×3 | 30 | 8×33.3 | 14.5 |

| 50 | 22 | 7×4 | 35 | 10×38.3 | 22 |

| 60 | 25 | 7×4 | 40 | 12×43.3 | 36 |

| 65 | 30 | 7×4 | 45 | 14×48.8 | 63 |

| 75 | 35 | 10×4.5 | 60 | 18×64.4 | 80 |

| 85 | 40 | 12×5 | 70 | 20×74.9 | 114 |

| 85 | 45 | 14×5.5 | 80 | 22×85.4 | 150 |

| 95 | 50 | 14×5.5 | 85 | 22×90.4 | 218 |

| 110 | 60 | 18×7 | 110 | 28×9 | 365 |

WPKS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPKS Worm Gear Speed Reducer Features

1. Compact and Robust Design

The WPKS worm gear speed reducer features a compact structure crafted from high-strength cast iron. This design ensures durability and resistance to wear in demanding industrial environments. Its small footprint allows for easy integration into various machinery setups, optimizing space without compromising performance.

2. High Torque and Low-Speed Output

Engineered for high torque transmission, the worm drive gearbox excels in applications requiring substantial power at reduced speeds. With gear ratios ranging from 1/10 to 1/60, it delivers precise speed reduction, making it ideal for heavy-duty tasks in industries like mining and metallurgy.

3. Low Noise and Vibration

The WPKS worm gear reducer incorporates precision-engineered components, including a hardened steel worm and tin bronze worm wheel. This combination minimizes vibration and noise during operation, ensuring a quieter workplace. The smooth transmission enhances operational efficiency and reduces wear on mechanical components.

4. Versatile Mounting and Configuration Options

Offering flexible installation, the worm reducer gearbox supports multiple mounting positions and configurations. Input options include solid shafts or IEC B5/B14 motor flanges, while output shafts can be solid or hollow. This versatility accommodates diverse industrial applications and machinery requirements.

5. Self-Locking Capability

Under specific conditions, the right angle worm gear reducer provides self-locking functionality, preventing reverse rotation. This feature enhances safety in applications where back-driving could pose risks, such as in conveyor systems or hoisting equipment, ensuring stable and secure operation.

6. High Durability and Longevity

Constructed with premium materials like tin bronze and hardened steel, the WPKS worm drive reduction gearbox is built for long-term reliability. Its robust housing protects internal components from environmental stressors, reducing maintenance needs and extending service life in industries like plastics and chemical processing.

WPKS Worm Reducer Gearbox Applications

1. Plastics Industry

The WPKS worm reducer gearbox is widely used in plastic processing equipment such as extrusion machines, injection molding machines, and blow molding machines. Its ability to provide precise torque control and stable speed reduction ensures accurate and consistent operation, improving product quality and production efficiency in this demanding sector.

2. Metallurgy and Steel Industry

In metallurgy applications, such as rolling mills, furnaces, and material handling systems, the worm drive gearbox is valued for its durability and capacity to handle high torque loads. It ensures reliable performance in extreme conditions involving high temperatures, heavy vibrations, and continuous operation.

3. Mining and Quarrying

The WPKS worm gear reducer is essential in mining equipment like conveyors, crushers, and screening machines. Its robust construction and self-locking capabilities enhance safety and efficiency, even in harsh environments with abrasive materials, making it ideal for heavy-duty tasks in the mining industry.

4. Chemical and Pharmaceutical Processing

In the chemical and pharmaceutical industries, the worm and wheel gearbox plays a crucial role in mixers, agitators, and pumps. Its ability to operate quietly with precise speed reduction ensures the controlled mixing and processing of sensitive materials, meeting stringent production and safety standards.

5. Food and Beverage Industry

The WPKS worm gear speed reducer is used in food processing equipment such as conveyors, packaging machines, and dough mixers. Its smooth operation, low noise levels, and ability to handle heavy loads ensure hygienic and efficient production processes, adhering to strict industry regulations.

6. Material Handling Systems

The worm reduction gearbox is integral to material handling systems, including conveyor belts, hoists, and automated storage systems. Its versatility in mounting configurations and ability to deliver high torque at low speeds make it a reliable choice for efficient and safe material movement.

|  |

| Worm Gearbox for Plastic and Rubber Machinery | Worm Gearbox for Metallurgy Industry |

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Food and Beverage Industry |

WPKS Worm Gear Reducer Maintenance Tips

Additional information

| Edited by | Yjx |

|---|