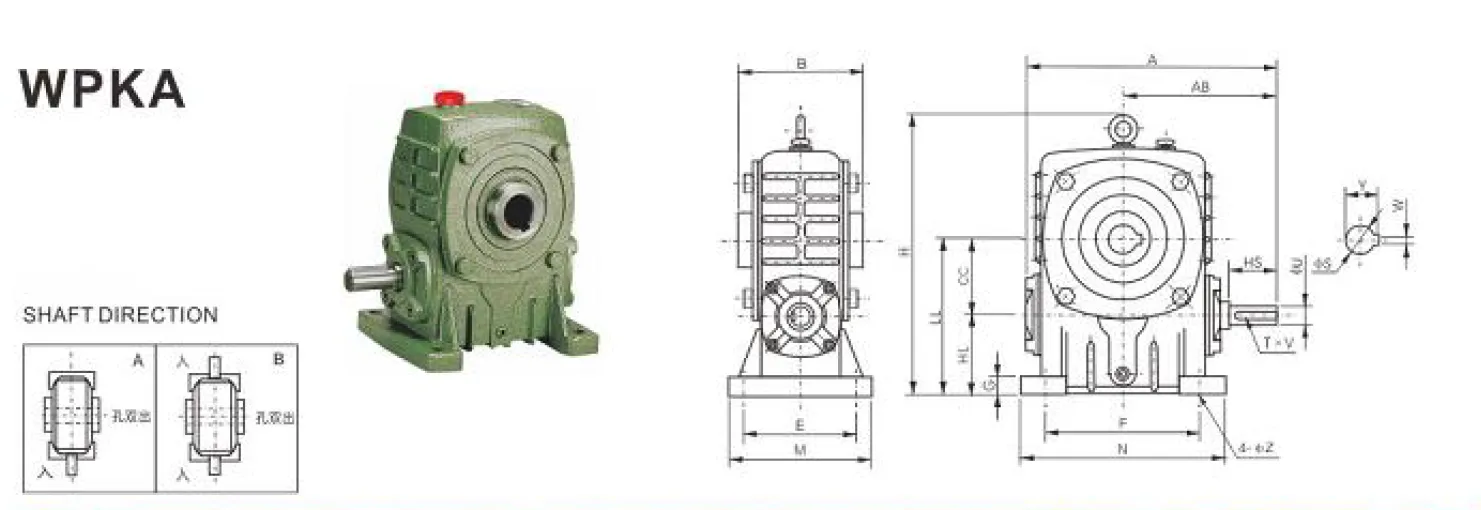

WPKA Worm Gear Reducers/Worm Gearbox

WPKA worm gear reducers, also known as worm gearboxes, are mechanical devices designed for efficient power transmission in compact spaces. They feature a cast iron housing and a single-stage worm gear system, comprising a worm (a screw-like input gear) and a worm wheel (a spur-like output gear). The WPKA series worm gearbox offers versatile mounting options, with input and output shafts configurable horizontally or vertically. With gear ratios ranging from 7.5:1 to 100:1, they provide high torque multiplication and low-speed output, ideal for applications like conveyors, packaging machines, and elevators.

WPKA worm gear reducers, also known as worm gearboxes, are mechanical devices designed for efficient power transmission in compact spaces. They feature a cast iron housing and a single-stage worm gear system, comprising a worm (a screw-like input gear) and a worm wheel (a spur-like output gear). The WPKA series worm gearbox offers versatile mounting options, with input and output shafts configurable horizontally or vertically. With gear ratios ranging from 7.5:1 to 100:1, they provide high torque multiplication and low-speed output, ideal for applications like conveyors, packaging machines, and elevators. Their compact design, self-locking capability under certain conditions, and low noise operation make them suitable for industries requiring reliable, space-saving solutions.

WPKA Worm Gear Reducer Specifications

| Product Name: | WPKA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPKA |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.12kw ~ 33kw |

| Output Form: | Solid shaft, hollow shaft |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

WPKA Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | CC | H | HL | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 85 | 40 | 138 | 40 | 90 | 100 | 70 | 80 | 13 | 10 |

| 50 | 175 | 108 | 105 | 50 | 176 | 50 | 120 | 140 | 95 | 110 | 15 | 11 | |

| 60 | 198 | 120 | 110 | 60 | 204 | 60 | 130 | 150 | 105 | 120 | 20 | 11 | |

| 70 | 231 | 140 | 130 | 70 | 236 | 70 | 150 | 190 | 115 | 150 | 20 | 15 | |

| 80 | 261 | 160 | 150 | 80 | 268 | 80 | 170 | 220 | 135 | 180 | 20 | 15 | |

| 100 | 322 | 190 | 160 | 100 | 336 | 100 | 190 | 270 | 155 | 220 | 25 | 15 | |

| 120 | 371 | 219 | 175 | 120 | 430 | 120 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 135 | 422 | 249 | 210 | 135 | 480 | 135 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 147 | 438 | 262 | 210 | 147 | 460 | 123 | 250 | 350 | 200 | 280 | 32 | 18 | |

| 155 | 497 | 295 | 256 | 155 | 531 | 135 | 275 | 390 | 220 | 320 | 35 | 20 | |

| 175 | 534 | 314 | 282 | 175 | 600 | 160 | 310 | 430 | 250 | 350 | 40 | 20 | |

| 200 | 580 | 342 | 320 | 200 | 666 | 175 | 360 | 480 | 290 | 390 | 40 | 22 | |

| 250 | 705 | 420 | 400 | 250 | 800 | 200 | 460 | 560 | 380 | 480 | 45 | 28 |

| Input hole | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 16 | 6×18.8 | 5 |

| 30 | 12 | 4×2.5 | 20 | 6×22.8 | 7.5 |

| 40 | 15 | 5×3 | 25 | 8×28.3 | 11 |

| 40 | 18 | 5×3 | 30 | 8×33.3 | 15.5 |

| 50 | 22 | 7×4 | 35 | 10×38.3 | 22 |

| 60 | 25 | 7×4 | 40 | 12×43.3 | 36 |

| 65 | 30 | 7×4 | 45 | 14×48.8 | 62 |

| 75 | 35 | 10×4.5 | 60 | 18×64.4 | 80 |

| 75 | 35 | 10×4.5 | 65 | 18×64.4 | 90 |

| 85 | 40 | 12×5 | 70 | 20×74.9 | 114 |

| 85 | 45 | 14×5.5 | 80 | 22×85.4 | 150 |

| 95 | 50 | 14×5.5 | 85 | 22×90.4 | 215 |

| 110 | 60 | 18×7 | 110 | 28×90 | 360 |

WPKA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPKA Worm Gear Reducer Design Features

- High-Quality Materials for Durability

WPKA worm gear reducers are constructed using premium-grade cast iron housings and alloy steel worm shafts. These materials ensure exceptional strength, resistance to wear, and a long operational lifespan, even in demanding industrial applications where continuous performance and durability are critical. - Compact and Space-Saving Design

The compact structure of worm drive gearboxes allows easy integration into confined spaces. Their efficient design minimizes the overall system footprint, making them ideal for applications where space is limited without compromising performance or reliability. - High Torque Transmission Efficiency

The worm gear speed reducers are specifically engineered to provide excellent torque transmission capabilities. The worm and worm wheel combination enables maximum power output, supporting heavy loads while maintaining smooth and consistent performance, even under high-stress operating conditions. - Self-Locking Mechanism for Safety

WPKA worm gearboxes feature a self-locking mechanism in specific configurations. This prevents reverse motion when the input power is turned off, enhancing operational safety and stability in applications like hoists, elevators, and other load-bearing systems. - Low Noise and Vibration Levels

The worm reducer gearboxes are designed for quiet operation with reduced vibration. The meshing of the worm and worm wheel ensures smooth engagement, making them suitable for environments where minimal noise is crucial, such as medical or residential settings. - Versatile Mounting and Installation Options

WPKA worm drive reduction gearboxes are designed with multiple mounting configurations, including flange, foot, and shaft-mounted options. This flexibility ensures compatibility with various machinery setups, simplifying installation and reducing the need for significant modifications.

WPKA Worm Drive Gearbox Applications

- Material Handling Industry

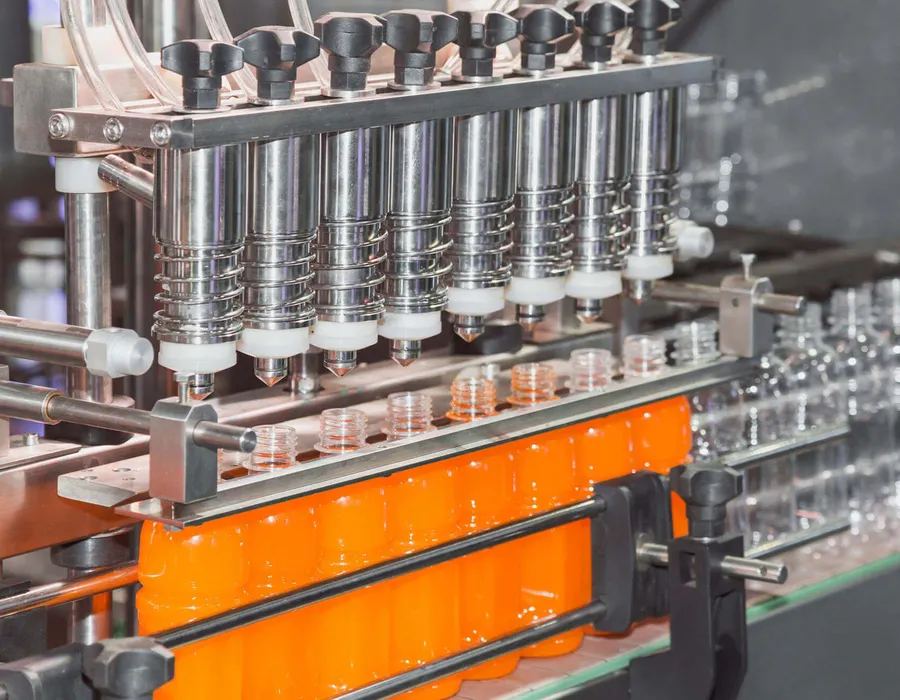

WPKA worm drive gearboxes are widely used in conveyor systems for material handling. Their high torque output and compact design enable efficient movement of heavy loads in warehouses and distribution centers, ensuring reliable operation and precise speed control for bulk material transport. - Packaging Machinery

In packaging industries, worm gear gearboxes drive equipment like bottling lines and sealing machines. Their low-noise operation and precise speed reduction ensure smooth performance, enhancing productivity while maintaining accuracy in high-speed packaging processes, critical for food, beverage, and pharmaceutical sectors. - Elevator and Lift Systems

WPKA worm reducer gearboxes are integral to elevator and lift mechanisms due to their self-locking capability. This feature prevents unintended reverse motion, ensuring safety and reliability in vertical transport systems used in buildings, construction sites, and industrial facilities. - Mining and Quarrying

The robust cast iron housing of worm gear reducers makes them ideal for mining applications. They power heavy-duty equipment like crushers and conveyors, withstanding harsh conditions while delivering consistent torque for processing raw materials in quarries and mines. - Food Processing Industry

WPKA worm gear speed reducers are employed in food processing for mixers, grinders, and conveyors. Their low-vibration and quiet operation, combined with durable construction, ensure hygienic and efficient performance, meeting strict industry standards for cleanliness and reliability in food production. - Textile Manufacturing

In textile production, worm reducer gearboxes drive spinning and weaving machines. Their precise speed control and compact design support intricate processes, ensuring consistent fabric quality while accommodating the space constraints and continuous operation demands of textile manufacturing facilities.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Packaging Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Textile Industry |

WPKA Worm Gearbox Oil Lubrication

Verify Gearbox Specifications

Before lubrication, consult the worm reducer gearbox manual to identify the recommended oil type, viscosity, and capacity. Typically, synthetic gear oils or mineral-based oils with specific additives are suggested to ensure optimal performance and longevity in industrial applications.Drain Existing Oil

Place a container beneath the gearbox drain plug. Remove the plug to drain old oil completely, ensuring no contaminants remain. Inspect the drained oil for metal particles or discoloration, which may indicate wear or damage requiring further investigation.Clean the Gearbox

Flush the worm drive gearbox with a compatible cleaning fluid to remove residual sludge or debris. Use a clean cloth to wipe accessible areas around the drain and fill ports, preventing contaminants from entering during refilling, which ensures efficient lubrication.Select and Prepare New Oil

Choose high-quality gear oil matching the manufacturer’s specifications, typically ISO VG 220 or 320 for WPKA worm gearboxes. Ensure the oil is free of contaminants by using a clean, dedicated funnel or pump for transfer to avoid introducing impurities.Fill with New Oil

Close the drain plug securely and remove the fill plug. Pour the recommended oil volume into the gearbox through the fill port, monitoring the level via the sight glass or dipstick to avoid overfilling, which can cause overheating or seal damage.Check and Test Operation

Replace the fill plug and run the worm wheel gearbox briefly to circulate the oil. Inspect for leaks around seals and plugs. Verify the oil level after operation, topping up if necessary, to ensure smooth performance and extended gearbox lifespan.

Additional information

| Edited by | Yjx |

|---|