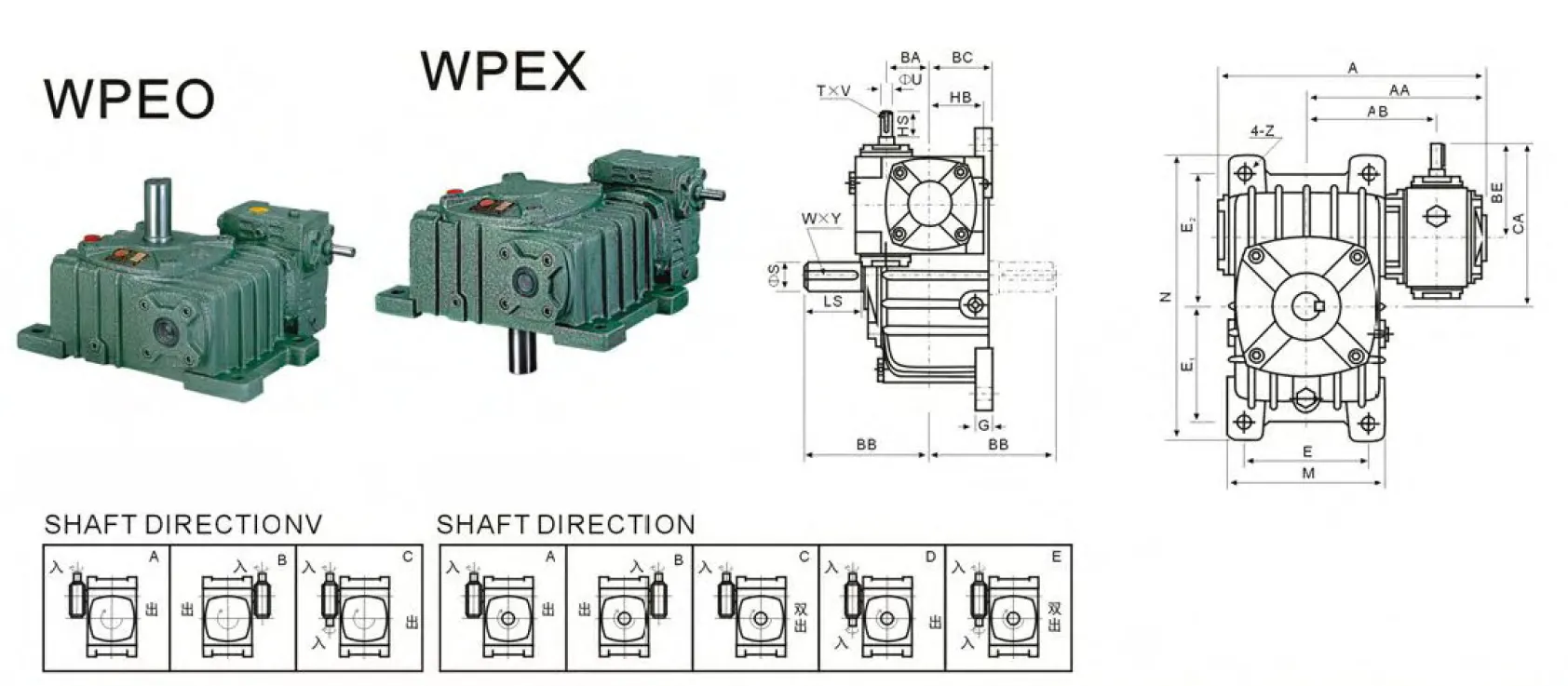

WPEO Worm Gear Reducers/Worm Gearbox

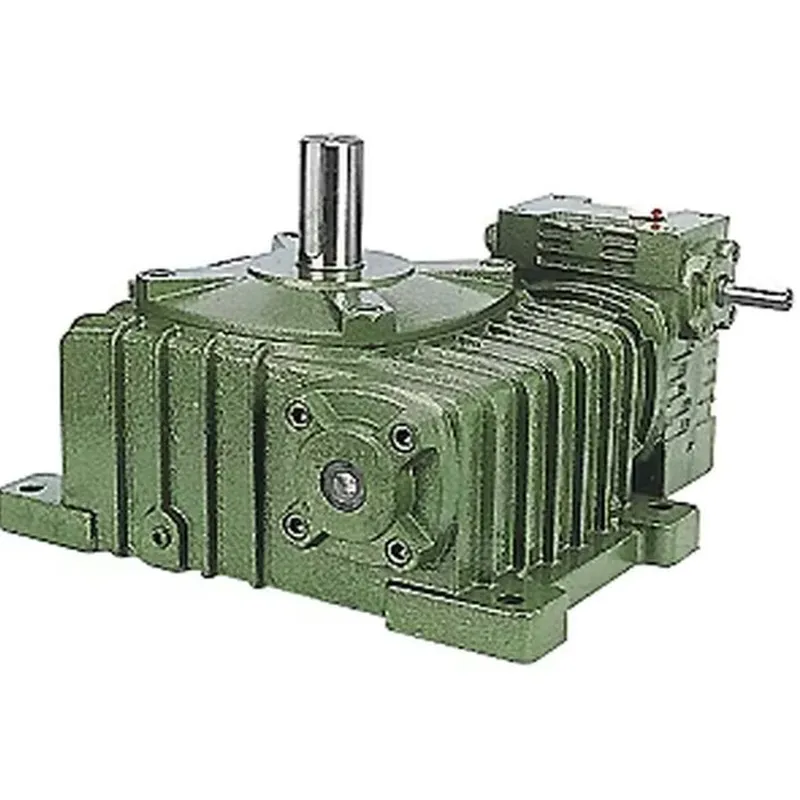

WPEO worm gear reducers, also referred to as double reduction worm gearboxes, are advanced mechanical solutions engineered for a broad range of industrial applications. These worm reducer gearboxes integrate a single-stage worm gearbox with a universal gearbox to deliver superior performance, high torque output, and precise speed control in a compact and efficient design. The double reduction mechanism excels in achieving significantly higher reduction ratios, ranging from 1:200 to 1:900, by combining the ratios of two single-stage gearboxes. For simpler setups, single-stage configurations offer ratios between 1:10 and 1:60.

WPEO worm gear reducers, also referred to as double reduction worm gearboxes, are advanced mechanical solutions engineered for a broad range of industrial applications. These worm reducer gearboxes integrate a single-stage worm gearbox with a universal gearbox to deliver superior performance, high torque output, and precise speed control in a compact and efficient design. The double reduction mechanism excels in achieving significantly higher reduction ratios, ranging from 1:200 to 1:900, by combining the ratios of two single-stage gearboxes. For simpler setups, single-stage configurations offer ratios between 1:10 and 1:60.

WPEO worm gear speed reducers are valued for their robust construction, low maintenance requirements, and ability to operate under demanding conditions. They are particularly suitable for heavy-duty machinery, conveyors, and industrial automation systems, where high torque transmission and precise control are essential. With their versatility, durability, and efficiency, WPEO double reduction worm gearboxes provide reliable performance across industries.

WPEO Worm Gear Reducer Specifications

| Type: | WPEO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

WPEO Worm Gearbox Dimensions

| Model | Ratio | A | AA | AB | BA | BB | BC | BE | HB | CA | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 1/200 1/300 1/400 1/400 1/500 1/600 1/800 1/900 .... | 286 | 195 | 153 | 40 | 131 | 65 | 87 | 50 | 157 | 195 | 295 | 120 | 120 | 135 | 20 | 15 |

| 50-80 | 297 | 197 | 144 | 50 | 142 | 70 | 108 | 65 | 188 | 175 | 320 | 140 | 130 | 150 | 20 | 15 | |

| 60-100 | 363 | 231 | 175 | 60 | 169 | 90 | 120 | 75 | 222 | 224 | 375 | 190 | 155 | 180 | 25 | 15 | |

| 70-120 | 408 | 256 | 193 | 70 | 190 | 100 | 140 | 90 | 260 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 80-135 | 471 | 298 | 226 | 80 | 210 | 110 | 160 | 105 | 295 | 306 | 495 | 260 | 210 | 235 | 30 | 18 | |

| 100-155 | 555 | 354 | 269 | 100 | 252 | 140 | 190 | 130 | 345 | 350 | 590 | 290 | 245 | 295 | 35 | 21 | |

| 120-175 | 598 | 379 | 287 | 120 | 255 | 150 | 219 | 155 | 394 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 135-200 | 662 | 425 | 318 | 135 | 319 | 175 | 256 | 185 | 456 | 440 | 710 | 370 | 290 | 360 | 40 | 24 | |

| 155-250 | 795 | 510 | 380 | 155 | 385 | 200 | 295 | 203 | 545 | 510 | 860 | 440 | 350 | 440 | 45 | 28 |

| Input shaft | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 60 | 28 | 8×4 | 19 |

| 30 | 12 | 4×2.5 | 65 | 32 | 10×4.5 | 27 |

| 40 | 15 | 5×3 | 75 | 38 | 10×4.5 | 44 |

| 40 | 18 | 5×3 | 85 | 45 | 12×4.5 | 63 |

| 50 | 22 | 7×4 | 95 | 55 | 16×6 | 96 |

| 50 | 25 | 7×4 | 110 | 60 | 18×7 | 149 |

| 65 | 30 | 7×4 | 110 | 65 | 18×7 | 191 |

| 75 | 35 | 10×4.5 | 125 | 70 | 20×7.5 | 278 |

| 85 | 40 | 12×5 | 155 | 90 | 25×9 | 442 |

WPEO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEO Double Reduction Worm Gearbox Features

- High Reduction Ratios

The WPEO double reduction worm gearbox achieves impressive reduction ratios ranging from 1:200 to 1:900 by combining two single-stage worm gearboxes. This allows precise speed control and high torque output, making it ideal for heavy-duty industrial applications requiring substantial power transmission. - Compact and Efficient Design

Engineered for space efficiency, the worm gear speed reducer integrates a single-stage worm gear with a universal gearbox. This compact design ensures high performance in confined spaces, delivering reliable power transmission while maintaining efficiency and reducing energy consumption in various industrial settings. - Robust Construction

Built with durable materials, the WPEO worm reducer gearbox is designed to withstand harsh operating conditions. Its sturdy housing and high-quality worm gears ensure long-term reliability, minimizing wear and tear, and providing consistent performance in demanding applications like conveyors and heavy machinery. - Versatile Applications

The worm gear reducers are highly adaptable, suitable for industries such as manufacturing, material handling, and automation. Its flexible design supports diverse configurations, enabling seamless integration into various systems, from conveyor belts to industrial mixers, enhancing operational versatility and productivity. - Low Maintenance Requirements

Designed for minimal upkeep, the worm drive gearbox features self-lubricating components and a sealed structure to prevent contamination. This reduces maintenance costs and downtime, ensuring continuous operation and making it a cost-effective solution for industrial environments with rigorous demands. - Enhanced Torque Transmission

The double-stage configuration amplifies torque output, making the WPEO worm gear reduction gearbox ideal for applications requiring high torque at low speeds. Its efficient gear meshing ensures smooth power delivery, improving system performance in tasks like lifting, crushing, or precise motion control.

WPEO Worm Gear Speed Reducer Applications

Double Reduction Worm Gear Reducer Maintenance

- Regular Lubrication Checks

Ensure the WPEO worm reduction gearbox is adequately lubricated by inspecting oil levels monthly. Use manufacturer-recommended lubricants to maintain optimal performance. Proper lubrication reduces friction, prevents overheating, and extends the lifespan of gears in demanding industrial applications. - Inspect for Wear and Damage

Conduct quarterly visual inspections of gears, bearings, and housing for signs of wear or damage. Early detection of issues like pitting or cracks prevents costly failures, ensuring the gearbox operates reliably in heavy-duty systems like conveyors or mixers. - Monitor Operating Temperature

Check the worm reducer gearbox temperature during operation to ensure it remains within specified limits. Excessive heat indicates overloading or lubrication issues. Addressing these promptly prevents component degradation, maintaining efficiency and reliability in high-torque industrial environments. - Clean External Surfaces

Keep the worm drive gearbox exterior free of dust, debris, and contaminants. Monthly cleaning prevents buildup that could affect heat dissipation or seal integrity. A clean unit ensures efficient cooling and protects internal components, supporting consistent performance in harsh conditions. - Check Seals and Gaskets

Inspect seals and gaskets biannually to ensure they are intact and free of leaks. Replace worn seals promptly to prevent lubricant loss and contamination ingress. This maintains the gearbox’s sealed environment, crucial for reliable operation in food processing or mining. - Verify Alignment and Mounting

Annually confirm that the worm drive reduction gearbox is properly aligned and securely mounted. Misalignment can cause uneven wear and vibration, reducing efficiency. Correct mounting ensures smooth torque transmission, enhancing the longevity of the worm gearbox reducer in automation or packaging systems.

Additional information

| Edited by | Yjx |

|---|