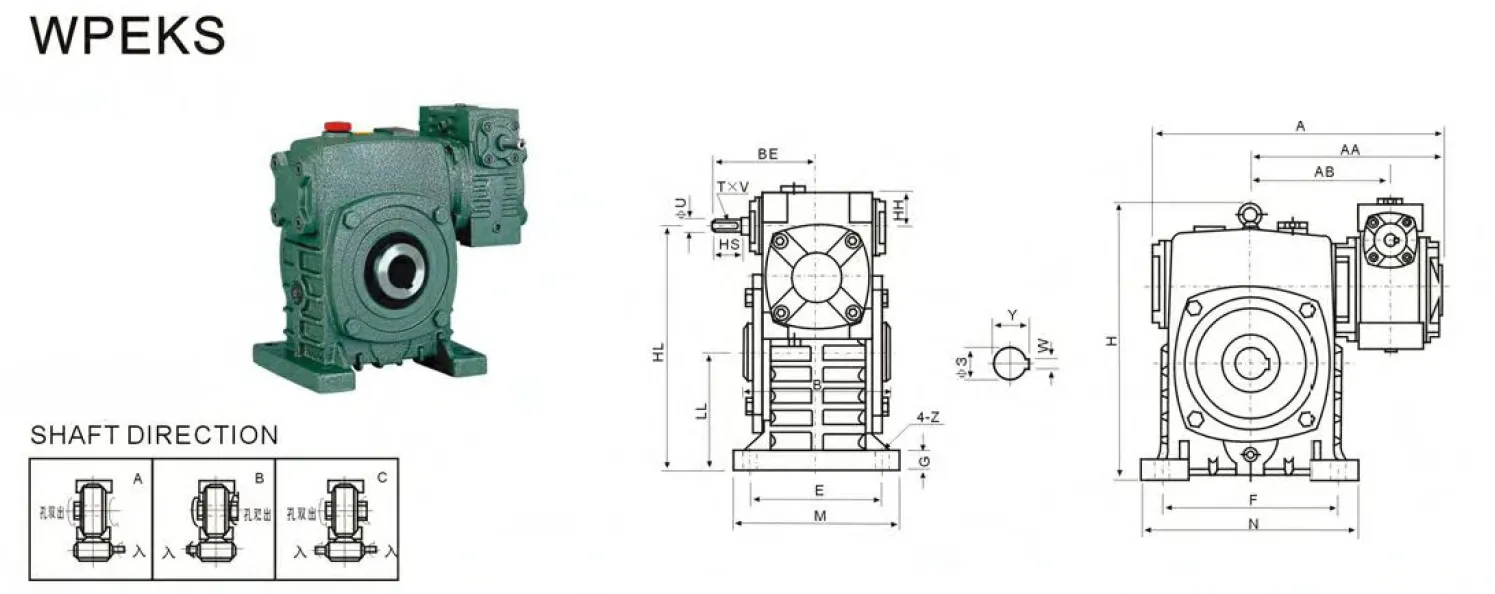

WPEKS Worm Gear Reducers/Worm Gearbox

WPEKS worm gear reducers, also known as double reduction worm gearboxes, are highly efficient, compact, and versatile solutions designed for a wide range of industrial applications. These worm gear speed reducers feature a unique double-stage reduction system that combines a single-stage worm gearbox with a universal gearbox, delivering enhanced performance, flexibility, and high torque output. WPEKS worm reducer gearboxes are used for applications requiring precise speed control and high torque, such as conveyors, mixers, and heavy machinery.

WPEKS worm gear reducers, also known as double reduction worm gearboxes, are highly efficient, compact, and versatile solutions designed for a wide range of industrial applications. These worm gear speed reducers feature a unique double-stage reduction system that combines a single-stage worm gearbox with a universal gearbox, delivering enhanced performance, flexibility, and high torque output.

The WPEKS worm gear reduction gearbox is particularly valued for its ability to achieve significant speed reduction, with single-stage setups offering speed ratios from 1:10 to 1:60, and double-stage configurations providing ratios from 1:200 to 1:900 by multiplying the ratios of two single-stage gearboxes. This makes them ideal for applications requiring precise speed control and high torque, such as conveyors, mixers, and heavy machinery. Their compact design ensures easy integration, while the robust construction guarantees durability and reliable operation in demanding environments, making WPEKS worm reducer gearboxes a preferred choice for industrial efficiency.

WPEKS Worm Gear Reducer Specifications

| Type: | WPEKS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

WPEKS Worm Gearbox Dimensions

| Model | Ratio | A | AA | AB | B | BE | HL | LL | H | HA | HB | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 ... ... | 286 | 195 | 153 | 180 | 87 | 110 | 140 | 236 | 70 | 50 | 150 | 190 | 115 | 150 | 20 | 15 |

| 50-80 | 297 | 197 | 144 | 150 | 108 | 130 | 160 | 268 | 80 | 65 | 170 | 220 | 135 | 180 | 20 | 15 | |

| 60-100 | 363 | 231 | 175 | 160 | 120 | 160 | 200 | 336 | 100 | 75 | 190 | 270 | 155 | 220 | 25 | 15 | |

| 70-120 | 408 | 256 | 193 | 175 | 140 | 190 | 240 | 430 | 120 | 90 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 80-135 | 471 | 298 | 226 | 210 | 160 | 215 | 270 | 480 | 135 | 105 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 100-155 | 555 | 354 | 269 | 256 | 190 | 235 | 290 | 531 | 135 | 130 | 275 | 390 | 220 | 320 | 35 | 21 | |

| 120-175 | 598 | 379 | 287 | 282 | 219 | 280 | 335 | 660 | 160 | 155 | 310 | 430 | 250 | 350 | 40 | 21 | |

| 135-200 | 662 | 425 | 318 | 320 | 256 | 310 | 375 | 666 | 175 | 185 | 360 | 480 | 290 | 390 | 40 | 24 | |

| 155-250 | 795 | 510 | 380 | 400 | 295 | 355 | 450 | 800 | 200 | 203 | 460 | 560 | 380 | 480 | 45 | 28 |

| Input shaft | Output shaft | Weight | |||

|---|---|---|---|---|---|

| HS | U | T×V | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 30 | 8×33.3 | 20 |

| 30 | 12 | 4×2.5 | 35 | 10×38.3 | 27 |

| 40 | 15 | 5×3 | 40 | 12×43.3 | 44 |

| 40 | 18 | 5×3 | 45 | 14×48.8 | 73 |

| 50 | 22 | 7×4 | 60 | 18×64.4 | 101 |

| 50 | 25 | 7×4 | 70 | 20×74.9 | 144 |

| 65 | 30 | 7×4 | 80 | 22×85.4 | 201 |

| 75 | 35 | 10×4.5 | 85 | 22×90.4 | 293 |

| 85 | 40 | 12×5 | 110 | 28×116.4 | 462 |

WPEKS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEKS Double Reduction Worm Gear Reducer Benefits

- High Torque Output

WPEKS double reduction worm gear reducers deliver exceptional torque due to their dual-stage design combining a single-stage worm gearbox with a universal gearbox. This configuration multiplies torque effectively, making them ideal for heavy-duty applications like conveyors and industrial mixers requiring robust power transmission. - Wide Speed Ratio Range

These worm drive gearboxes offer a versatile speed ratio range from 1:200 to 1:900 in double-stage setups. This extensive range allows precise speed control, catering to diverse industrial needs, ensuring optimal performance in applications requiring significant speed reduction and enhanced operational flexibility. - Compact and Space-Saving Design

The WPEKS worm gear speed reducers are engineered for compactness, integrating two reduction stages into a single unit. This space-efficient design facilitates easy installation in constrained environments, reducing footprint while maintaining high performance, making them suitable for modern industrial setups with limited space. - Enhanced Durability and Reliability

Built with robust materials and precision engineering, worm reducer gearboxes ensure long-lasting performance under demanding conditions. Their sturdy construction minimizes wear and tear, reducing maintenance needs and downtime, which is critical for continuous operation in industries like manufacturing and material handling. - Energy Efficiency

The double reduction mechanism optimizes power transmission, reducing energy losses compared to single-stage systems. This efficiency lowers operational costs and supports sustainable practices, making WPEKS double reduction worm gearboxes an economical choice for industries aiming to enhance energy conservation without compromising performance. - Versatile Application Compatibility

Worm gear reduction gearboxes are designed for flexibility, seamlessly integrating with various industrial systems such as pumps, agitators, and packaging machines. Their universal gearbox component ensures adaptability across different machinery, providing reliable performance tailored to specific operational requirements.

WPEKS Double Reduction Worm Reducer Gearbox Uses

- Conveyor Systems

WPEKS double reduction worm gear reducers are widely used in conveyor systems for material handling in industries like mining and manufacturing. Their high torque and precise speed control ensure smooth and efficient transport of heavy loads over long distances. - Mixing Equipment

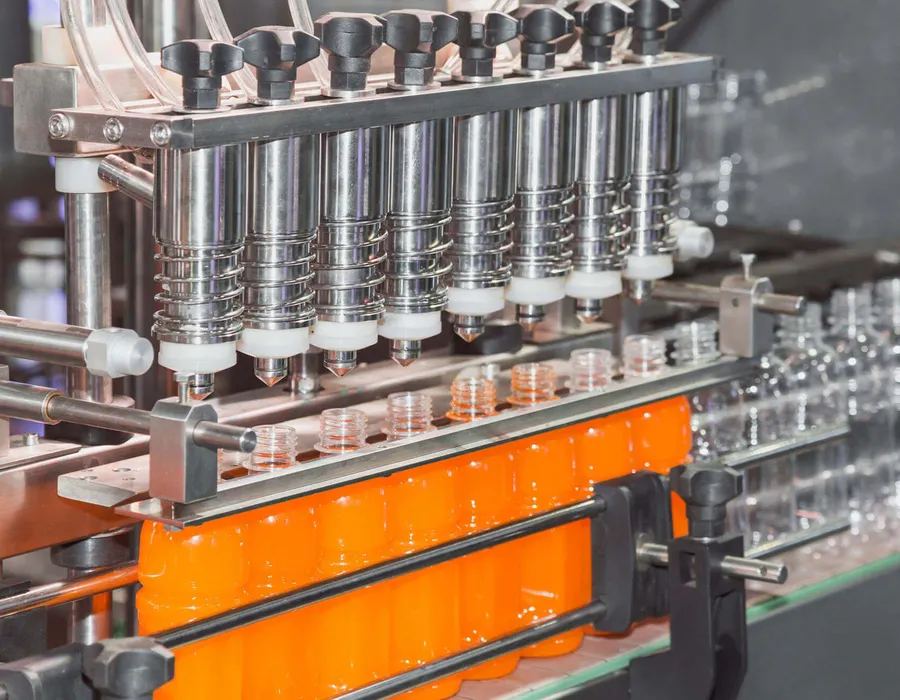

In chemical and food processing industries, double reduction worm gearboxes power mixing equipment. The double-stage reduction provides the high torque needed to handle viscous materials, ensuring consistent mixing and blending for applications like paint production or food preparation. - Packaging Machinery

WPEKS worm gear reduction gearboxes are integral to packaging machinery, enabling precise control in automated packing lines. Their compact design and wide speed ratio range support efficient operation in tasks like sealing, labeling, and filling in high-speed production environments. - Pumping Systems

These worm gearbox reducers are employed in industrial pumping systems for water treatment and the oil industry. Their robust construction and high torque output ensure reliable performance in driving pumps, maintaining consistent flow rates under varying pressure conditions. - Cranes and Hoists

WPEKS worm reduction gearboxes are used in cranes and hoists for lifting heavy loads. The enhanced torque and durability allow precise and safe operation, making them suitable for construction sites and heavy industrial applications. - Automated Manufacturing

In automated manufacturing lines, worm gear reducer gearboxes drive robotic arms and assembly systems. Their ability to provide significant speed reduction and reliable power transmission supports precise movements, enhancing efficiency in automotive and electronics production processes.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Packaging Industry |

|  |

| Worm Gearbox for Construction Industry | Worm Gearbox for Chemical Industry |

Double Reduction Worm Gearbox Oil Level Check

- Preparation and Safety

Before checking the oil level in a double reduction worm gearbox, ensure the equipment is powered off and cooled down to avoid burns or injuries. Gather necessary tools, including a wrench, a clean cloth, and a dipstick or sight glass for inspection. - Locate the Oil Level Indicator

Identify the oil level indicator, typically a dipstick or sight glass, on the worm drive reduction gearbox housing. Refer to the manual for the exact location, as it varies by model. Ensure the gearbox is on a level surface for an accurate reading. - Clean the Inspection Area

Wipe the area around the dipstick or sight glass with a clean cloth to prevent dirt or debris from entering the worm gear reduction gearbox. This step is crucial to maintain the integrity of the oil and prevent contamination during the inspection process. - Check Oil Level with Dipstick

If using a dipstick, remove it carefully and wipe it clean. Reinsert it fully, then withdraw it to check the oil level against the marked indicators. The oil should be within the recommended range, typically between the minimum and maximum lines. - Inspect via Sight Glass

For gearboxes with a sight glass, observe the oil level through the transparent window. The oil should be at or near the halfway mark. Ensure the glass is clean for a clear view, and note any discoloration or debris in the oil. - Top Up or Replace Oil if Needed

If the oil level is low, add the manual-recommended lubricant through the fill port until the correct level is reached. If the oil appears contaminated or degraded, drain and replace it according to the worm gear reducer gearbox maintenance schedule.

Additional information

| Edited by | Yjx |

|---|