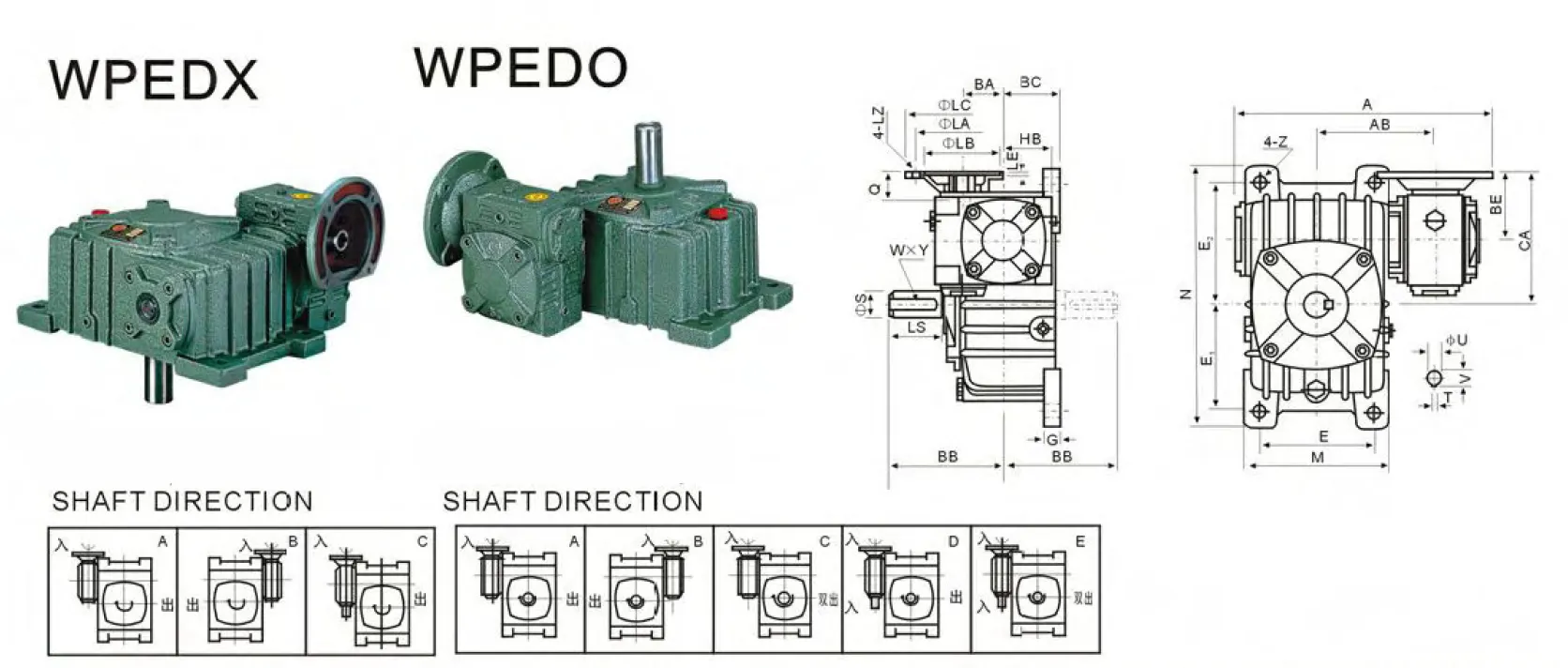

WPEDX Worm Gear Reducers/Worm Gearbox

WPEDX worm gear reducers, also known as double reduction worm gearboxes, are advanced mechanical devices designed for applications that require precise speed reduction and significant torque multiplication. These worm gear speed reducers utilize a unique combination of a single-stage worm gearbox and a universal gearbox, forming a double-stage system that enhances their efficiency, adaptability, and durability. This design allows them to achieve a wide range of speed reduction ratios, from 1:10 to 1:60 in single-stage configurations, and from 1:200 to 1:900 in double-stage setups, by multiplying the ratios of two single-stage gearboxes.

WPEDX worm gear reducers, also known as double reduction worm gearboxes, are advanced mechanical devices designed for applications that require precise speed reduction and significant torque multiplication. These worm gear speed reducers utilize a unique combination of a single-stage worm gearbox and a universal gearbox, forming a double-stage system that enhances their efficiency, adaptability, and durability. This design allows them to achieve a wide range of speed reduction ratios, from 1:10 to 1:60 in single-stage configurations, and from 1:200 to 1:900 in double-stage setups, by multiplying the ratios of two single-stage gearboxes.

Known for their smooth and quiet operation, WPEDX worm gear reduction gearboxes are built for long-term reliability and require minimal maintenance. They are widely used in industrial systems such as conveyors, material handling equipment, and packaging machinery, where high torque, low-speed operation, and compact design are essential. Their robust construction and versatility make them an ideal choice for space-constrained environments or demanding applications where consistent performance is crucial.

WPEDX Worm Gear Reducer Specifications

| Type: | WPEDX Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

WPEDX Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | BA | BB | BC | BE | HB | CA | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 .... | 314 | 153 | 40 | 131 | 65 | 75 | 50 | 145 | 156 | 295 | 120 | 120 | 135 | 20 | 15 |

| 50-80 | 0.18 | 314 | 144 | 50 | 142 | 70 | 83 | 65 | 163 | 175 | 320 | 140 | 130 | 150 | 20 | 15 | |

| 60-100 | 0.37 | 387 | 175 | 60 | 169 | 90 | 91 | 75 | 191 | 224 | 375 | 190 | 155 | 180 | 25 | 15 | |

| 70-120 | 0.37 0.75 | 425 | 193 | 70 | 190 | 100 | 109 | 90 | 229 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 80-135 | 0.75 1.5 | 499 | 226 | 80 | 210 | 110 | 125 | 105 | 260 | 306 | 495 | 260 | 210 | 235 | 30 | 18 | |

| 100-155 | 1.5 | 570 | 269 | 100 | 252 | 140 | 148 | 130 | 303 | 350 | 590 | 290 | 245 | 295 | 35 | 21 | |

| 120-175 | 2.2 3.0 | 631 | 287 | 120 | 255 | 150 | 181 | 155 | 356 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 135-200 | 3.0 4.0 | 680 | 318 | 135 | 319 | 175 | 202 | 185 | 402 | 440 | 710 | 370 | 290 | 360 | 40 | 24 | |

| 155-250 | 5.5 | 815 | 380 | 155 | 385 | 200 | 247 | 203 | 497 | 510 | 860 | 440 | 350 | 440 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 60 | 28 | 7×4 | 19 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 65 | 32 | 10×4.5 | 27 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 75 | 38 | 10×4.5 | 45 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 75 | 38 | 10×4.5 | 45 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 85 | 45 | 12×4.5 | 65 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 95 | 55 | 16×6 | 98 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 110 | 60 | 18×7 | 152 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 110 | 65 | 18×7 | 194 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 125 | 70 | 20×7.5 | 283 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 155 | 90 | 25×9 | 450 |

WPEDX Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEDX Worm Gear Reduction Gearbox Features

- High Reduction Ratios

The WPEDX double reduction worm gearbox offers a wide range of speed reduction ratios, from 1:200 to 1:900 in its double-stage configuration. This is achieved by multiplying the ratios of two single-stage gearboxes, enabling precise control of output speed for applications requiring significant torque multiplication. This versatility suits industries like material handling and packaging. - Compact and Space-Saving Design

Engineered with a compact structure, the worm drive gearbox is ideal for space-constrained environments. Its small footprint, achieved through the use of a worm pinion and worm wheel, allows for efficient power transmission without requiring bulky setups, making it suitable for tight machinery layouts. - Self-Locking Capability

The WPEDX worm reducer gearbox features a self-locking mechanism due to the worm gear’s high friction and low lead angle, typically less than 4°. This prevents the output shaft from rotating backward when the motor is off, enhancing safety in applications like hoists and elevators. - High Torque Output

Designed for high torque multiplication, the worm gear reducer efficiently converts high-speed input into low-speed, high-torque output. This makes it ideal for heavy-duty applications such as conveyors and industrial mixers, where robust power transmission is critical for consistent performance under load. - Durable Construction

The worm gear reduction gearbox is built with robust materials, often featuring a cast iron housing and hardened steel or bronze gears. This ensures high wear resistance and long service life, even in demanding industrial environments, reducing maintenance costs and downtime for equipment. - Quiet and Smooth Operation

The sliding contact between the worm and worm wheel, combined with precision manufacturing, results in low noise and vibration. This makes the WPEDX worm gear speed reducer suitable for applications requiring minimal disturbance, such as medical equipment or precision machinery, enhancing operational comfort.

WPEDX Double Reduction Worm Gearbox Applications

- Material Handling Industry

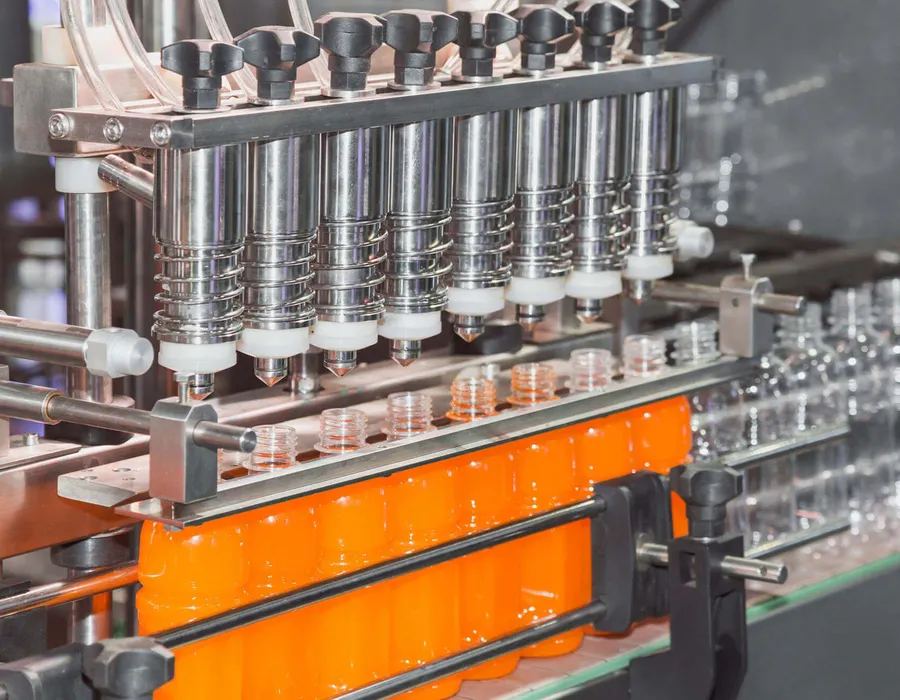

WPEDX worm drive gearboxes are integral in material handling systems like conveyors and automated warehouses. Their high reduction ratios (1:200 to 1:900) and robust torque output ensure smooth movement of heavy loads, enhancing efficiency in logistics and distribution centers with minimal maintenance requirements. - Packaging Machinery

In packaging industries, worm reducer gearboxes drive equipment such as filling machines and labeling systems. Their compact design fits space-constrained setups, while the self-locking feature ensures precise positioning, improving accuracy and reliability in high-speed packaging lines for consumer goods. - Food and Beverage Processing

The WPEDX worm and wheel gearbox supports food processing equipment like mixers and slicers. Its durable construction, often with corrosion-resistant materials, withstands hygienic washdowns, and its quiet operation minimizes noise in production facilities, ensuring compliance with stringent industry standards. - Construction Equipment

Double reduction worm gearboxes are used in construction machinery such as hoists and winches. Their self-locking capability prevents load slippage, enhancing safety, while high torque output enables lifting heavy materials, making them essential for reliable performance on construction sites. - Textile Industry

In textile manufacturing, WPEDX worm gear reducers power looms and spinning machines. Their smooth and quiet operation reduces vibration, ensuring precision in fabric production, while the compact design integrates seamlessly into complex machinery, supporting high-volume textile output with consistent performance. - Renewable Energy Systems

Worm gear speed reducers are employed in renewable energy applications like solar trackers and small wind turbines. Their high reduction ratios enable precise positioning for optimal energy capture, and durable construction ensures reliability in harsh outdoor environments, contributing to sustainable energy solutions.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Packaging Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Textile Industry |

WPEDX Worm Gear Speed Reducer Manufacturing Process

- Material Selection and Quality Assurance

The manufacturing process begins with selecting high-quality materials such as hardened steel and advanced alloys. Each material undergoes rigorous quality checks to ensure it meets the required specifications for durability, strength, and resistance to wear and corrosion. - Precision Machining of Components

Advanced CNC machines are used to precisely manufacture the gearbox components, including the worm, worm wheel, and housing. This ensures accurate dimensions, smooth surface finishes, and tight tolerances, resulting in optimal gear alignment and efficient power transmission. - Heat Treatment for Enhanced Strength

Key components like the worm and gear wheel undergo heat treatment processes such as carburizing, quenching, and tempering. These treatments enhance the hardness and strength of the components, improving their resistance to wear, deformation, and heavy-duty operation. - Gear Teeth Cutting and Finishing

The gear teeth are meticulously cut using specialized machines to ensure proper meshing and smooth operation. Afterward, the teeth are polished or ground to eliminate imperfections, reducing friction and ensuring quieter, more efficient performance. - Assembly of Gearbox Components

The worm, worm wheel, housing, and other parts are carefully assembled by skilled technicians. During assembly, precise alignment is maintained to ensure smooth operation and efficient torque transmission while avoiding unnecessary wear on the internal components. - Lubrication and Sealing

High-quality lubricants are applied to the worm gearbox reducer during assembly to minimize friction and wear. The sealing system is then installed to prevent contamination and leakage, ensuring long-lasting performance and reducing maintenance needs. - Rigorous Performance Testing

Each worm gear reduction gearbox undergoes comprehensive performance tests, including load testing, noise checks, and efficiency analysis. These tests ensure that the gearbox meets strict quality standards and performs reliably under various operating conditions before leaving the factory. - Surface Treatment and Final Inspection

The worm reduction gearbox housing is coated with corrosion-resistant paint or plating to protect it from harsh environmental conditions. A thorough final inspection is conducted to verify the product’s quality, appearance, and functionality, ensuring it meets customer requirements before shipping.

Additional information

| Edited by | Yjx |

|---|