WPEDS Worm Gear Reducers/Worm Gearbox

WPEDS worm gear reducers, commonly known as double reduction worm gearboxes, are advanced mechanical devices engineered for industrial applications requiring high torque, precise speed control, and compact design. These worm gear speed reducers combine a single-stage worm gearbox with a universal gearbox, forming a double-stage system that significantly enhances efficiency, flexibility, and performance. The design allows a basic speed ratio range of 1:10 to 1:60 in single-stage configurations, while the double-stage arrangement achieves much higher ratios, typically from 1:200 to 1:900, by multiplying the ratios of two single-stage gearboxes.

WPEDS worm gear reducers, commonly known as double reduction worm gearboxes, are advanced mechanical devices engineered for industrial applications requiring high torque, precise speed control, and compact design. These worm gear speed reducers combine a single-stage worm gearbox with a universal gearbox, forming a double-stage system that significantly enhances efficiency, flexibility, and performance. The design allows a basic speed ratio range of 1:10 to 1:60 in single-stage configurations, while the double-stage arrangement achieves much higher ratios, typically from 1:200 to 1:900, by multiplying the ratios of two single-stage gearboxes.

Known for their robust construction, WPEDS worm reducer gearboxes deliver exceptional durability and quiet operation, handling high torque loads with ease. Their versatility makes them ideal for conveyors, packaging machinery, and other systems operating in demanding environments. Additionally, they offer excellent efficiency, low maintenance requirements, and reliable performance, making them a preferred choice in industries where space-saving and precise speed reduction are critical.

WPEDS Worm Gear Reducer Specifications

| Type: | WPEDS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

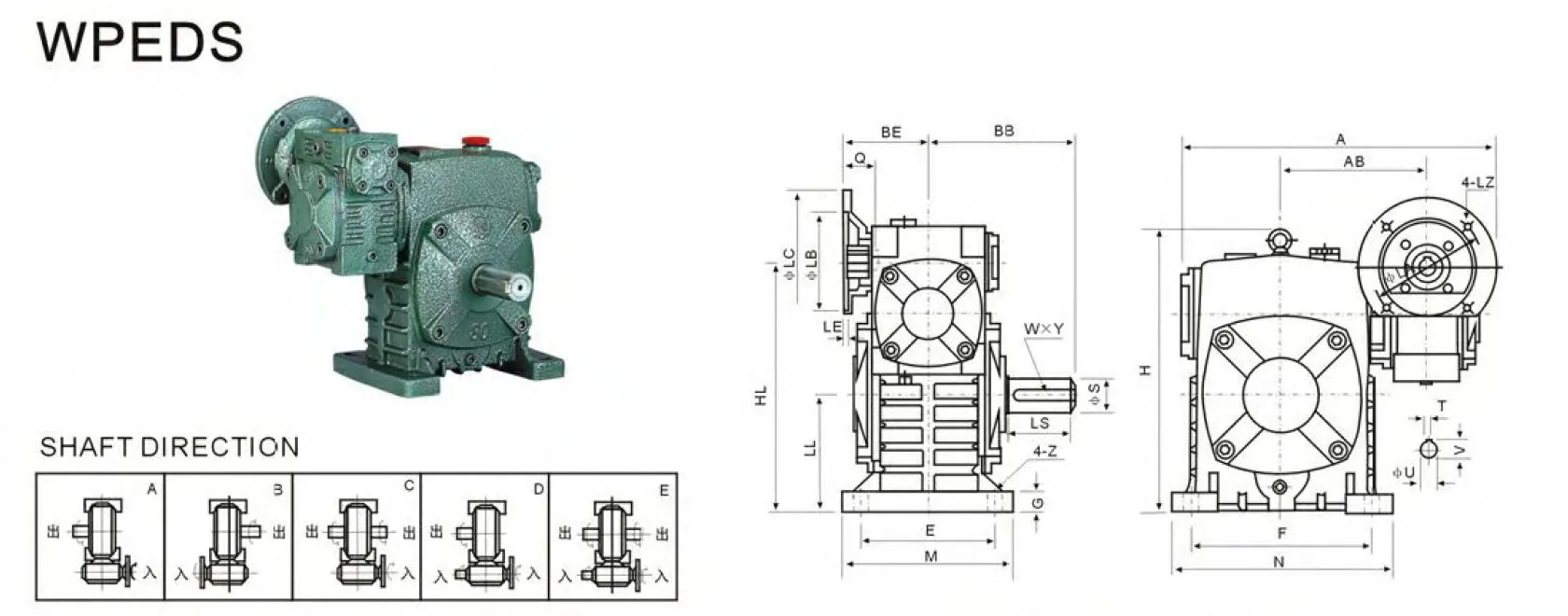

WPEDS Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | BB | BE | HL | LL | H | HA | HB | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 | 314 | 153 | 131 | 75 | 110 | 140 | 236 | 70 | 50 | 150 | 190 | 115 | 150 | 20 | 15 |

| 50-80 | 0.18 | 314 | 144 | 142 | 83 | 130 | 160 | 268 | 80 | 165 | 170 | 220 | 135 | 180 | 20 | 15 | |

| 60-100 | 0.37 | 337 | 175 | 169 | 91 | 160 | 200 | 336 | 100 | 75 | 190 | 270 | 155 | 220 | 25 | 15 | |

| 70-120 | 0.37 0.75 | 425 | 193 | 190 | 109 | 190 | 240 | 430 | 120 | 90 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 80-135 | 0.75 1.5 | 499 | 226 | 210 | 125 | 215 | 270 | 480 | 135 | 105 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 100-155 | 1.5 | 570 | 269 | 252 | 148 | 235 | 290 | 531 | 135 | 130 | 275 | 390 | 220 | 320 | 35 | 21 | |

| 120-175 | 2.2 3.0 | 631 | 287 | 255 | 219 | 280 | 335 | 660 | 160 | 155 | 310 | 430 | 250 | 350 | 40 | 21 | |

| 135-200 | 3.0 4.0 | 680 | 318 | 319 | 256 | 310 | 375 | 666 | 175 | 185 | 360 | 480 | 290 | 390 | 40 | 24 | |

| 155-250 | 5.5 | 815 | 380 | 385 | 247 | 355 | 450 | 800 | 200 | 205 | 460 | 560 | 380 | 480 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 35 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 60 | 28 | 7×4 | 19 |

| 115 | 35 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 65 | 32 | 10×4.5 | 27 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 75 | 38 | 10×4.5 | 45 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 85 | 45 | 12×4.5 | 75 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 95 | 55 | 16×6 | 103 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 110 | 60 | 18×7 | 147 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 110 | 65 | 18×7 | 204 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 125 | 70 | 20×7.5 | 298 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 155 | 90 | 25×9 | 470 |

WPEDS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEDS Double Reduction Worm Gearbox Parts

- Worm Shaft

The worm shaft is a screw-like component made from high-quality alloy steel or carbon steel, heat-treated for enhanced hardness (typically 35-55HRC). It engages with the worm gear to transmit power between perpendicular shafts, providing high torque and precise speed reduction in compact designs. - Worm Gear (Worm Wheel)

Crafted from wear-resistant tin bronze, the worm gear meshes with the worm shaft to achieve significant speed reduction. Its centrifugal casting ensures superior mechanical properties, enabling high torque output and smooth operation in demanding industrial environments. - Housing

The housing, typically made of rigid cast iron, provides structural support and alignment for internal components. Its robust design ensures durability in harsh conditions, protecting the worm reducer gearbox from external stresses while maintaining precise positioning of the worm and gear. - Bearings

High-quality bearings, such as NSK brands, support the worm shaft and output shaft, reducing friction and ensuring smooth operation. They enhance the double reduction worm gearbox’s longevity by handling high loads and minimizing wear, which is critical for continuous industrial applications. - Oil Seals

Premium oil seals, like Simrit, prevent lubricant leakage and protect internal components from contaminants. These seals maintain proper lubrication, reducing friction and heat, which extends the worm drive gearbox’s lifespan and ensures reliable performance in diverse operating conditions. - Output Shaft

Available in solid or hollow configurations, the output shaft transfers torque to the driven equipment. Its versatile design allows horizontal or vertical mounting, accommodating various installation needs while ensuring efficient power transmission in compact setups. - Input Flange

The input flange, often compatible with IEC B5 or B14 motors, facilitates easy motor connection. This component ensures secure mounting and alignment, enabling direct or indirect drive configurations for enhanced flexibility in industrial applications.

WPEDS Worm Gear Reducer Application Scenarios

- Material Handling and Conveyor Systems

WPEDS worm gear reducers are extensively used in material handling systems, including conveyor belts and rollers. They provide precise speed control and high torque, enabling the smooth movement of heavy loads. Their compact design makes them ideal for space-constrained industrial setups. - Packaging Machinery

In the packaging industry, these worm gear speed reducers ensure accurate speed regulation and torque delivery for equipment like wrapping, sealing, and filling machines. Their quiet operation and durability help maintain efficiency and reliability in environments requiring continuous, high-speed production. - Textile Industry

Textile machinery relies on WPEDS worm gear reduction gearboxes for consistent, precise operation in spinning, weaving, and dyeing machines. Their ability to handle high torque loads while maintaining low noise levels ensures smooth production processes and helps meet the industry's demand for precision and efficiency. - Mining and Construction Equipment

The mining and construction industries use double reduction worm gearboxes in equipment such as crushers, hoists, and conveyors. Their robust construction and high efficiency make them suitable for heavy-duty applications where reliability and durability in harsh environments are essential. - Food Processing Industry

These worm drive gearboxes are critical in food processing machinery, including mixers, grinders, and conveyors. Their compact design, quiet performance, and ability to handle high torque loads make them ideal for maintaining hygiene and efficiency in food production facilities. - Chemical and Pharmaceutical Industry

WPEDS worm and wheel gearboxes are widely used in the chemical and pharmaceutical sectors for mixers, agitators, and conveyors. They ensure precise speed control and reliable operation, which are crucial for maintaining consistency and safety in processes involving sensitive or hazardous materials.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Textile Industry |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Food and Beverage Industry |

WPEDS Worm Drive Gearbox Precautions for Use

- Proper Installation Alignment

Ensure that the worm reduction gearbox is installed with accurate alignment between the input and output shafts. Misalignment can cause excessive wear, vibration, and loss of efficiency. Secure mounting is essential to prevent unnecessary strain on the components during operation. - Regular Lubrication Maintenance

Use the recommended lubricant type and maintain proper oil levels to ensure smooth operation and reduce friction. Inspect the oil periodically for contamination or degradation. Timely lubrication replacement extends the service life of internal components and prevents overheating. - Load Capacity Adherence

Operate the worm gearbox reducer within its specified load capacity to avoid damage to the worm gear and worm wheel. Overloading can lead to premature wear, excessive heat generation, and potential failure of the gearbox under continuous or demanding applications. - Appropriate Operating Conditions

Avoid exposing the worm reducer gearbox to extreme environmental conditions, such as excessive humidity, high temperatures, or corrosive substances. These factors can deteriorate the housing, seals, and internal components, compromising the gearbox's performance and longevity over time. - Avoid Frequent Start-Stop Cycles

Minimize frequent and abrupt start-stop operations, as these can create undue stress on the worm gear speed reducer components. Smooth and gradual engagement of the system helps maintain the integrity of the worm and wheel mechanism, ensuring consistent performance. - Routine Inspection and Cleaning

Conduct regular inspections to detect wear, loose fasteners, or damaged seals. Clean the exterior to prevent dust or debris accumulation, which can affect heat dissipation. Early identification of potential issues allows for timely maintenance and avoids unplanned downtime.

Additional information

| Edited by | Yjx |

|---|