WPEDO Worm Gear Reducers/Worm Gearbox

WPEDO worm gear reducers, also known as double reduction worm gearboxes, are highly advanced mechanical devices engineered to deliver precise speed reduction and high torque output across various industrial applications. These worm reducer gearboxes combine a single-stage worm gearbox with a universal gearbox, creating a double-stage system that enhances their performance, efficiency, and reliability. This configuration allows for a broad speed ratio range, typically spanning from 1:200 to 1:900, achieved by multiplying the ratios of two single-stage gearboxes (each ranging from 1:10 to 1:60).

WPEDO worm gear reducers, also known as double reduction worm gearboxes, are highly advanced mechanical devices engineered to deliver precise speed reduction and high torque output across various industrial applications. These worm reducer gearboxes combine a single-stage worm gearbox with a universal gearbox, creating a double-stage system that enhances their performance, efficiency, and reliability. This configuration allows for a broad speed ratio range, typically spanning from 1:200 to 1:900, achieved by multiplying the ratios of two single-stage gearboxes (each ranging from 1:10 to 1:60).

Known for their robust, compact design, WPEDO double reduction worm gearboxes are ideal for space-constrained systems, offering smooth, quiet operation with excellent durability and high torque transmission. Their double reduction mechanism improves load-handling capabilities, making them well-suited for demanding applications such as conveyors, mixers, and heavy machinery. Additionally, their efficiency and versatility provide a reliable solution for industries requiring precise, heavy-duty performance.

WPEDO Worm Gear Reducer Specifications

| Type: | WPEDO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Green/Brown/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

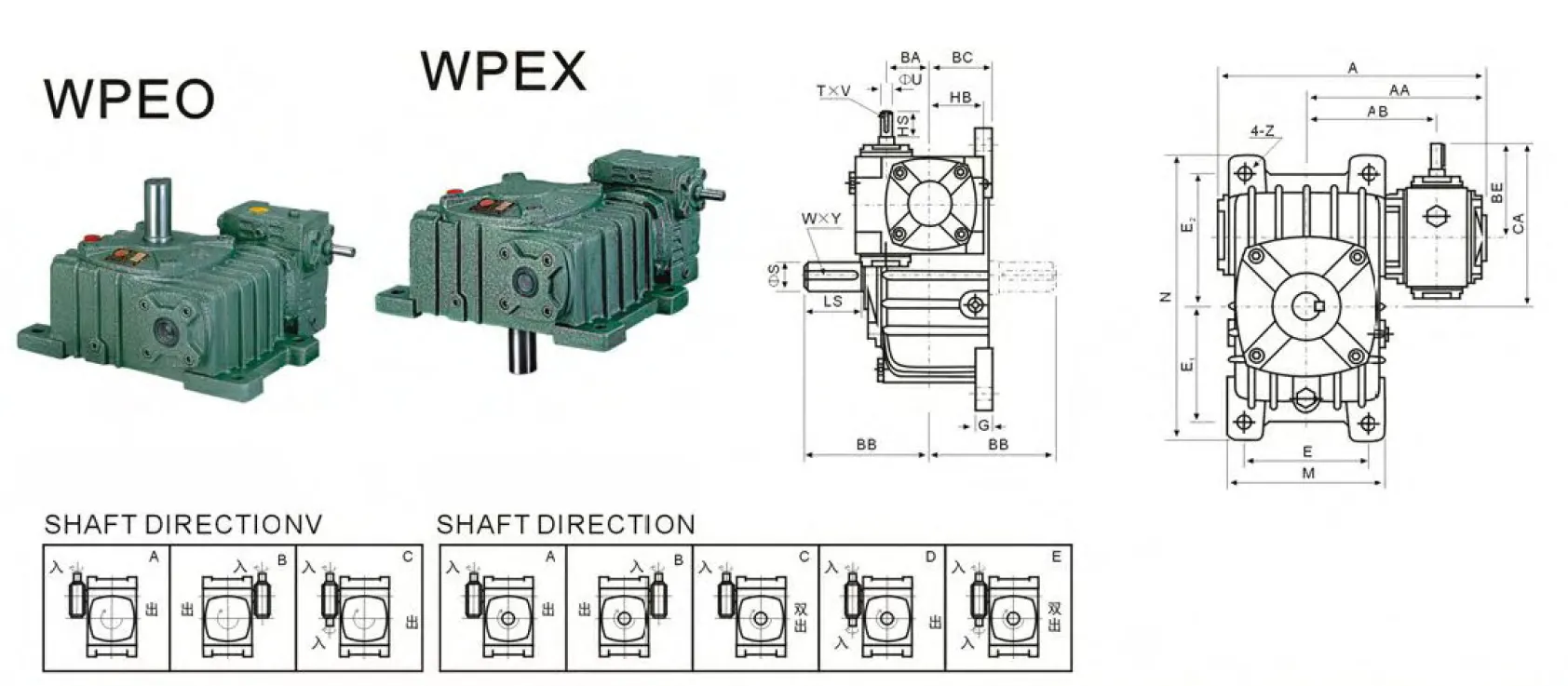

WPEDO Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | BA | BB | BC | BE | HB | CA | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 .... | 314 | 153 | 40 | 131 | 65 | 75 | 50 | 145 | 156 | 295 | 120 | 120 | 135 | 20 | 15 |

| 50-80 | 0.18 | 314 | 144 | 50 | 142 | 70 | 83 | 65 | 163 | 175 | 320 | 140 | 130 | 150 | 20 | 15 | |

| 60-100 | 0.37 | 387 | 175 | 60 | 169 | 90 | 91 | 75 | 191 | 224 | 375 | 190 | 155 | 180 | 25 | 15 | |

| 70-120 | 0.37 0.75 | 425 | 193 | 70 | 190 | 100 | 109 | 90 | 229 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 80-135 | 0.75 1.5 | 499 | 226 | 80 | 210 | 110 | 125 | 105 | 260 | 306 | 495 | 260 | 210 | 235 | 30 | 18 | |

| 100-155 | 1.5 | 570 | 269 | 100 | 252 | 140 | 148 | 130 | 303 | 350 | 590 | 290 | 245 | 295 | 35 | 21 | |

| 120-175 | 2.2 3.0 | 631 | 287 | 120 | 255 | 150 | 181 | 155 | 356 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 135-200 | 3.0 4.0 | 680 | 318 | 135 | 319 | 175 | 202 | 185 | 402 | 440 | 710 | 370 | 290 | 360 | 40 | 24 | |

| 155-250 | 5.5 | 815 | 380 | 155 | 385 | 200 | 247 | 203 | 497 | 510 | 860 | 440 | 350 | 440 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 60 | 28 | 7×4 | 19 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 65 | 32 | 10×4.5 | 27 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 75 | 38 | 10×4.5 | 45 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 75 | 38 | 10×4.5 | 45 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 85 | 45 | 12×4.5 | 65 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 95 | 55 | 16×6 | 98 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 110 | 60 | 18×7 | 152 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 110 | 65 | 18×7 | 194 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 125 | 70 | 20×7.5 | 283 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 155 | 90 | 25×9 | 450 |

WPEDO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEDO Double Reduction Worm Gearbox Advantages

- High Torque Output

The WPEDO double reduction worm gearbox delivers exceptional torque multiplication due to its dual-stage design. By combining two single-stage gearboxes, it achieves ratios from 1:200 to 1:900, making it ideal for heavy-duty applications requiring substantial power transmission in industrial settings. - Compact and Space-Saving Design

Despite its powerful performance, the worm reducer gearboxes maintain a compact footprint. This space-efficient design allows for seamless integration into machinery with limited space, providing flexibility for engineers designing systems where size constraints are critical without compromising on performance or reliability. - Enhanced Efficiency and Smooth Operation

The double reduction mechanism ensures smooth and quiet operation by minimizing vibrations and noise. This efficiency reduces energy losses, making the WPEDO worm drive gearbox suitable for continuous-duty applications, such as conveyors or mixers, where consistent performance and minimal downtime are essential. - Wide Range of Speed Ratios

With a versatile speed ratio range of 1:200 to 1:900, the double reduction worm gear reducers offer precise speed control. This adaptability allows it to meet diverse application requirements, from slow, high-torque tasks to faster operations, enhancing its utility across various industries. - Robust and Durable Construction

Built with high-quality materials, the WPEDO worm gear reduction gearbox is designed for longevity and reliability. Its sturdy construction withstands harsh industrial environments, reducing maintenance needs and ensuring consistent performance under heavy loads, making it a cost-effective solution for long-term use. - Improved Load-Handling Capabilities

The double reduction mechanism significantly enhances the worm reduction gearbox's ability to handle heavy loads efficiently. This capability ensures optimal performance in demanding applications, reducing mechanical strain and improving the lifespan of connected machinery, making it a cost-effective and reliable solution.

WPEDO Worm Gear Reduction Gearbox Applications

- Material Handling Industry

WPEDO worm gear reduction gearboxes are widely used in conveyor systems for material handling. Their high torque output and compact design enable efficient movement of heavy loads, ensuring reliable performance in warehouses, distribution centers, and manufacturing facilities where precise speed control is critical. - Food and Beverage Processing

In food processing equipment, worm gearboxes drive mixers, blenders, and packaging machines. Their smooth operation and robust construction ensure consistent performance, while the compact design fits into space-constrained setups, meeting hygiene standards and delivering reliable power for continuous production processes. - Mining and Quarrying

WPEDO worm gear reducers are employed in mining equipment like crushers and conveyors. Their high torque and durable build handle heavy loads and harsh conditions, providing reliable speed reduction and power transmission, which enhances operational efficiency in demanding mining and quarrying environments. - Packaging Machinery

The worm gear speed reducers are ideal for packaging machines, such as fillers and sealers. Its wide speed ratio range allows precise control, ensuring accurate and efficient packaging processes, while its durability supports high-speed, repetitive tasks in industries like pharmaceuticals and consumer goods. - Textile Industry

In textile manufacturing, WPEDO worm reducer gearboxes power looms, spinning machines, and dyeing equipment. Their ability to deliver consistent torque and smooth operation ensures precise control over fabric production processes, improving quality and efficiency in high-volume textile manufacturing environments. - Construction Equipment

Worm drive gearboxes are used in construction machinery, such as hoists and concrete mixers. Their robust design withstands rugged conditions, while the high torque output and flexible speed ratios provide reliable performance, enhancing productivity in construction projects requiring heavy-duty power transmission.

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Construction Industry |

Double Reduction Worm Gear Reducer Lubrication

Select Appropriate Lubricant

Choose a high-quality, synthetic gear oil specifically designed for worm gearboxes, such as ISO VG 320 or 460. Ensure the lubricant has excellent thermal stability and anti-wear properties to handle the high friction and heat generated in the worm drive gearbox during operation, extending its lifespan.Regular Lubricant Inspection

Check the lubricant level and condition monthly to ensure optimal performance. Look for signs of contamination, such as water or metal particles, which can degrade performance. Maintaining clean oil prevents wear on gears and bearings, ensuring the worm reducer gearbox operates efficiently in demanding industrial environments.Follow the Manual’s Guidelines

Adhere to the manufacturer’s recommended oil change intervals, typically every 6–12 months, depending on usage. Use the specified oil type and viscosity to maintain proper lubrication film strength, which reduces friction and protects the worm gear reducer components from premature wear and failure.Proper Lubricant Application

Ensure the gearbox is filled to the correct oil level, as overfilling or underfilling can cause overheating or inadequate lubrication. Use the fill and drain plugs to add oil, and verify levels with the dipstick or sight glass to keep the worm gear speed reducer running smoothly.Monitor Operating Temperature

Regularly check the gearbox temperature during operation, as excessive heat can degrade lubricant performance. Maintain temperatures below 80°C by ensuring proper ventilation and avoiding overloading. Effective thermal management preserves the lubricant’s viscosity, enhancing the worm drive reduction gearbox’s efficiency and component longevity.Implement a Maintenance Schedule

Establish a routine lubrication maintenance plan, including oil changes, filter cleaning, and inspections. Document each service to track lubricant performance and identify potential issues early. Consistent maintenance ensures the worm gearbox reducer remains reliable, minimizing downtime and costly repairs in industrial applications.

Additional information

| Edited by | Yjx |

|---|