WPEDKS Worm Gear Reducers/Worm Gearbox

WPEDKS worm gear reducers, also known as double reduction worm gearboxes, are advanced mechanical solutions designed for industrial applications requiring precise speed control and high torque. These worm reducer gearboxes integrate a single-stage worm gearbox with a universal gearbox, creating a double-stage reduction mechanism that significantly enhances performance. The double-stage design allows for extensive speed reduction ratios ranging from 1:200 to 1:900, surpassing the typical 1:10 to 1:60 ratios of single-stage setups.

WPEDKS worm gear reducers, also known as double reduction worm gearboxes, are advanced mechanical solutions designed for industrial applications requiring precise speed control and high torque. These worm reducer gearboxes integrate a single-stage worm gearbox with a universal gearbox, creating a double-stage reduction mechanism that significantly enhances performance. The double-stage design allows for extensive speed reduction ratios ranging from 1:200 to 1:900, surpassing the typical 1:10 to 1:60 ratios of single-stage setups.

This makes them particularly suited for demanding applications like conveyors, mixers, and heavy machinery, where precision and power are critical. Built with robust materials, WPEDKS worm gear speed reducers are engineered for durability, low maintenance, and reliable operation in harsh environments. Their compact and versatile design facilitates seamless integration into diverse systems, offering cost-effective and energy-efficient solutions. These worm gear reduction gearboxes are widely used in industries such as manufacturing, material handling, and automation, where their high torque output, efficiency, and adaptability provide exceptional value.

WPEDKS Worm Gear Reducer Specifications

| Type: | WPEDKS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

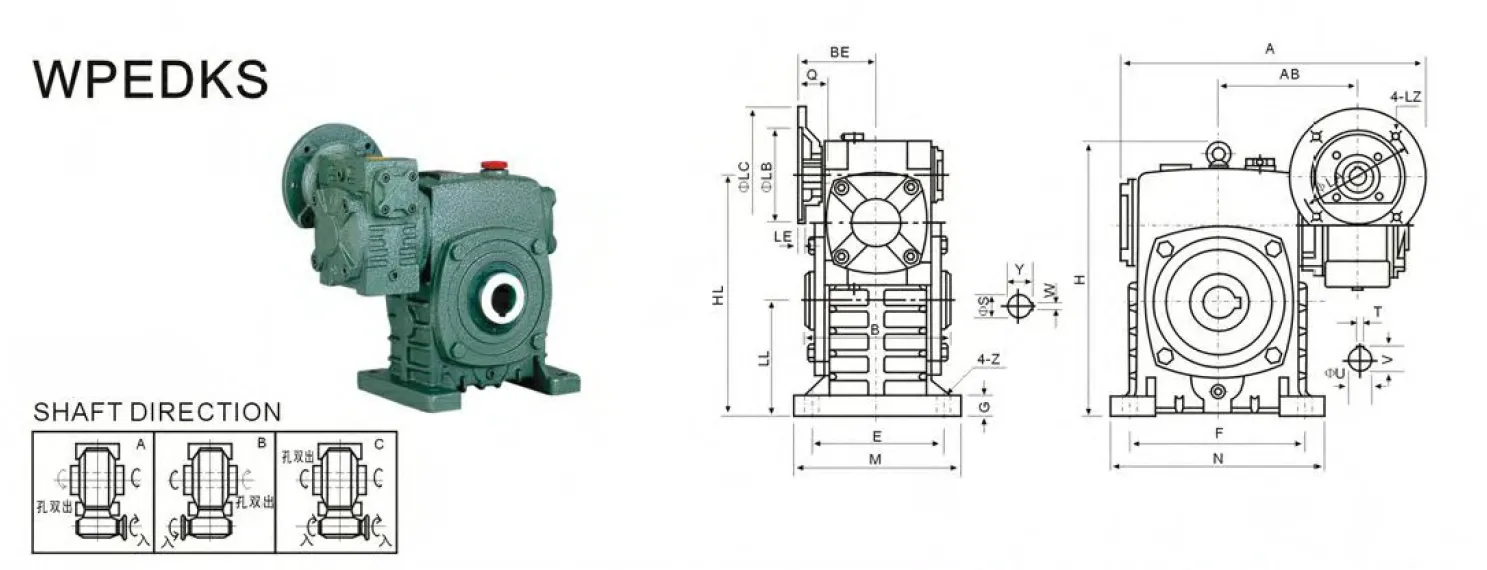

WPEDKS Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | B | BE | HL | LL | H | HA | HB | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 | 314 | 153 | 130 | 75 | 110 | 140 | 236 | 70 | 50 | 150 | 190 | 115 | 150 | 20 | 15 |

| 50-80 | 0.18 | 314 | 144 | 150 | 83 | 130 | 160 | 268 | 80 | 65 | 170 | 220 | 135 | 180 | 20 | 15 | |

| 60-100 | 0.37 | 337 | 175 | 160 | 91 | 160 | 200 | 336 | 100 | 75 | 190 | 270 | 155 | 220 | 25 | 15 | |

| 70-120 | 0.37 0.75 | 425 | 193 | 175 | 109 | 190 | 240 | 430 | 120 | 90 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 80-135 | 0.37 1.5 | 499 | 226 | 210 | 125 | 215 | 270 | 480 | 135 | 105 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 100-155 | 2.2 | 570 | 269 | 256 | 148 | 235 | 290 | 531 | 135 | 130 | 275 | 390 | 220 | 320 | 35 | 21 | |

| 120-175 | 2.2 3.0 | 631 | 287 | 282 | 219 | 280 | 335 | 660 | 160 | 155 | 310 | 430 | 250 | 350 | 40 | 21 | |

| 135-200 | 3.0 4.0 | 680 | 318 | 320 | 256 | 310 | 375 | 666 | 175 | 185 | 360 | 480 | 290 | 390 | 40 | 24 | |

| 155-250 | 5.5 | 815 | 380 | 400 | 247 | 355 | 450 | 800 | 200 | 203 | 460 | 560 | 380 | 480 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 30 | 8×33.3 | 19 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 35 | 10×38.3 | 27 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 40 | 12×43.3 | 45 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 45 | 14×48.8 | 75 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 18×64.4 | 103 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 70 | 20×74.9 | 147 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 80 | 22×85.4 | 204 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 22×90.4 | 298 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 28×116.4 | 470 |

WPEDKS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEDKS Double Reduction Worm Drive Gearbox Features

- High Reduction Ratios for Enhanced Torque

The WPEDKS double reduction worm gearbox achieves impressive reduction ratios ranging from 1:200 to 1:900 by combining two single-stage worm gearboxes. This double-stage configuration significantly multiplies torque output, making it ideal for heavy-duty applications like conveyors, mixers, and material handling systems where substantial power is required. - Compact and Space-Saving Design

Despite its high torque capabilities, the worm gear reducers feature a compact footprint, allowing easy integration into space-constrained systems. Its efficient design reduces overall system weight and simplifies installation, making it a cost-effective choice for industries such as automation and manufacturing. - Durable Construction for Longevity

Constructed with precision-engineered components, including hardened steel worms and phosphor bronze worm wheels, the WPEDKS worm gear speed reducers ensure durability and reliable performance. This robust build withstands harsh industrial environments, minimizing maintenance needs and extending operational life even under continuous heavy loads. - Self-Locking Capability for Safety

The worm reducer gearbox offers a self-locking feature, particularly effective at high reduction ratios, preventing back-driving without additional braking mechanisms. This enhances safety in applications like lifting equipment and hoists, ensuring loads remain secure during operation or power loss. - Enhanced Thermal Management System

The worm gear reduction gearbox incorporates advanced cooling mechanisms, such as optimized housing with cooling fins and high-quality lubricants, to dissipate heat effectively. This ensures consistent performance under heavy loads, reduces thermal-related failures, and extends maintenance intervals for sustained operation. - Versatile Mounting and Configuration Options

The WPEDKS worm gearbox reducers support multiple mounting configurations, including horizontal, vertical, and shaft-mounted setups with torque arms. This flexibility allows seamless integration into diverse industrial systems, accommodating various motor interfaces and application-specific requirements for enhanced operational adaptability.

WPEDKS Double Reduction Worm Gear Speed Reducer Uses

- Material Handling Industry

WPEDKS worm gear speed reducers are widely used in material handling equipment such as conveyors, stackers, and palletizers. Their high reduction ratios provide precise speed control and substantial torque, ensuring smooth and efficient movement of heavy loads in warehouses, distribution centers, and logistics facilities. - Manufacturing and Automation

In manufacturing, worm reduction gearboxes drive machinery like assembly lines, robotic arms, and packaging systems. Their compact design and reliable torque output enable seamless integration into automated processes, enhancing productivity and precision in automotive, electronics, and consumer goods production lines. - Mining and Quarrying

The WPEDKS worm drive gearboxes are ideal for mining applications, powering crushers, conveyors, and drilling equipment. Its durable construction withstands harsh conditions, while high torque ensures efficient operation under heavy loads, supporting continuous material extraction and processing in rugged environments. - Food and Beverage Processing

Worm reducer gearboxes are employed in food processing equipment like mixers, grinders, and bottling lines. Their self-locking feature ensures safety, while corrosion-resistant materials and smooth operation meet hygiene standards, making them suitable for handling food products efficiently. - Construction and Heavy Machinery

In construction, WPEDKS worm and wheel gearboxes power hoists, cranes, and concrete mixers. Their ability to deliver high torque at low speeds ensures reliable performance for lifting and mixing tasks, while robust design withstands the rigors of construction sites. - Renewable Energy Systems

Double reduction worm gearboxes are used in renewable energy applications, such as solar panel tracking systems and small wind turbines. Their precise speed control and high reduction ratios enable accurate positioning and efficient energy conversion, supporting sustainable energy production in challenging environments.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Food and Beverage Industry |

|  |

| Worm Gearbox for Construction Industry | Worm Gearbox for Chemical Industry |

Common Troubleshooting of Worm Gear Reducers

- Excessive Noise or Vibration

Unusual noise or vibration often indicates misalignment, worn gears, or inadequate lubrication. Inspect the double reduction worm gear reducer for proper alignment with the motor and driven equipment. Check gear and bearing conditions for wear. Ensure proper lubrication levels and replace damaged components to restore smooth operation. - Overheating During Operation

Overheating can result from overloading, insufficient lubrication, or poor ventilation. Verify that the worm reducer gearbox load is within its rated capacity. Check lubricant quality and levels, topping up with manufacturer-recommended oil. Ensure adequate airflow around the gearbox to improve heat dissipation. - Oil Leakage from Seals

Leaks often stem from worn seals, overfilled lubricant, or housing damage. Inspect seals for wear or cracks and replace them if necessary. Check oil levels to avoid overfilling. Examine the housing for damage and repair or replace it to prevent further leakage. - Reduced Output Torque

Low torque output may indicate gear wear, improper lubrication, or motor issues. Inspect gears for wear or damage and replace if needed. Ensure the correct lubricant type and quantity are used. Verify motor performance to confirm it meets gearbox requirements. - Gearbox Locking or Jamming

Jamming can occur due to debris, gear damage, or insufficient lubrication. Disassemble the worm gear reduction gearbox to remove any foreign particles. Inspect gears for damage or excessive wear and replace faulty components. Lubricate adequately to ensure smooth gear engagement and prevent seizing. - Premature Wear of Components

Early wear is often caused by improper installation, overloading, or contaminated lubricant. Confirm proper installation and alignment during setup. Ensure the worm reduction gearbox operates within its load capacity. Regularly change the lubricant and use filters to prevent contamination and extend component life.

Additional information

| Edited by | Yjx |

|---|