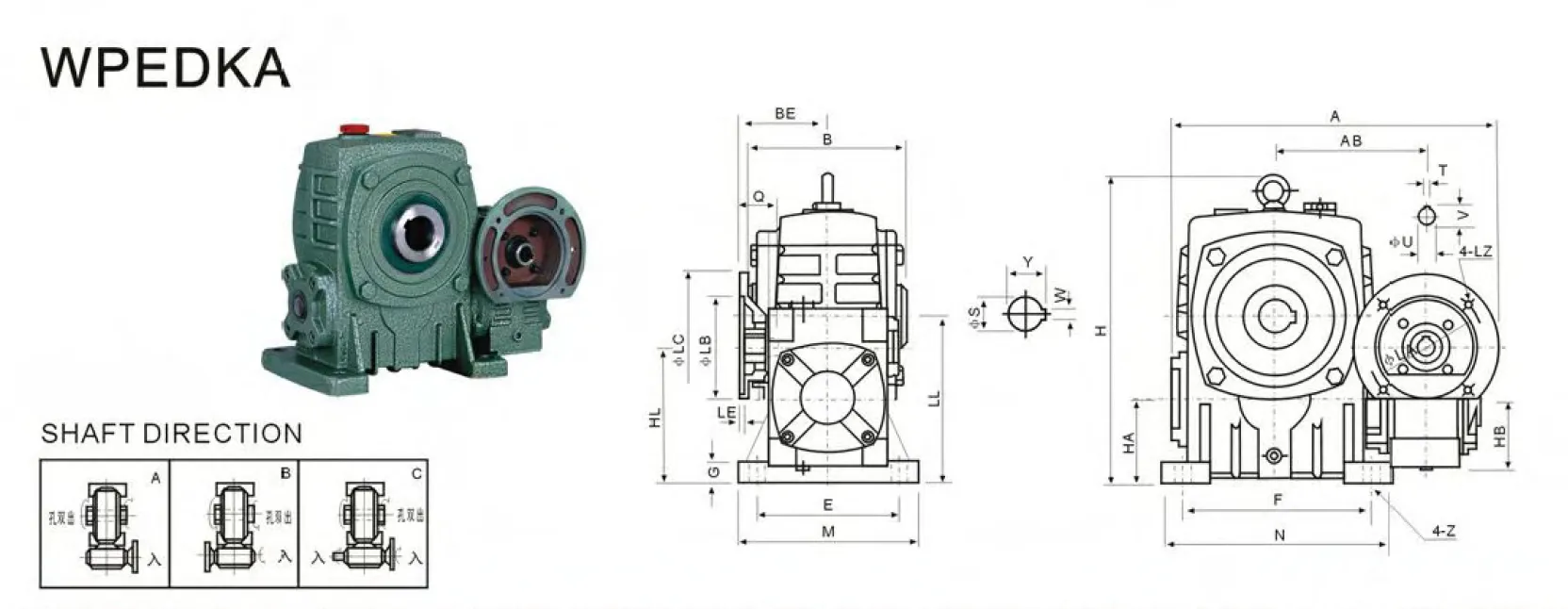

WPEDKA Worm Gear Reducers/Worm Gearbox

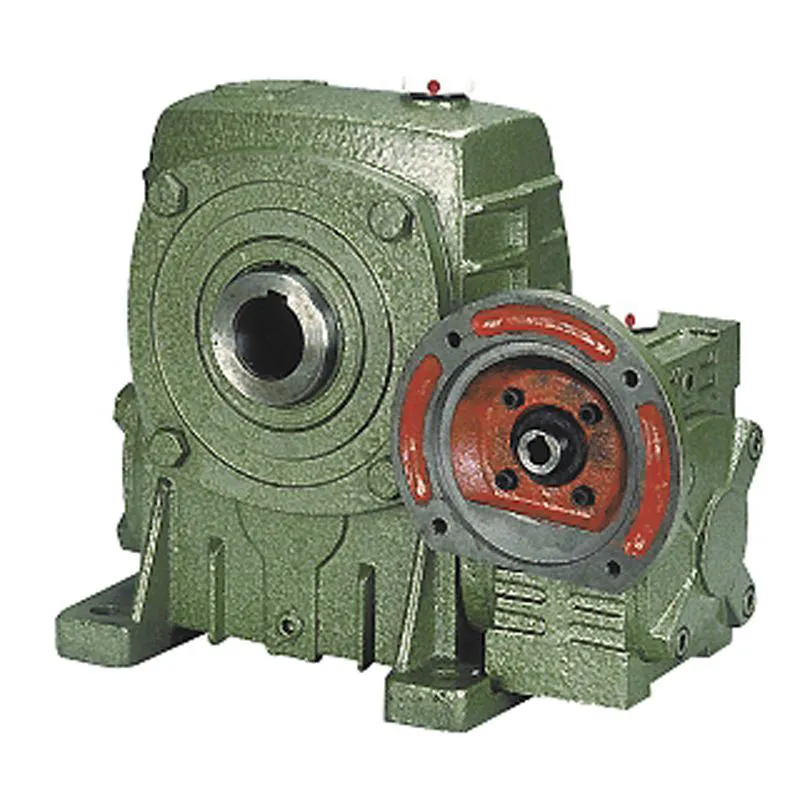

WPEDKA worm gear reducers, commonly referred to as double reduction worm gearboxes, are advanced and compact mechanical devices designed for efficient power transmission across various industrial applications. These gearboxes integrate a single-stage worm gearbox with a universal gearbox, creating a double-stage reduction system that enhances torque output, performance, and adaptability. For applications requiring higher reductions, the double-stage arrangement achieves ratios from 1:200 to 1:900 by combining two single-stage gearboxes. This makes them suitable for high-torque, low-speed applications such as conveyors, mixers, and material handling systems.

WPEDKA worm gear reducers, commonly referred to as double reduction worm gearboxes, are advanced and compact mechanical devices designed for efficient power transmission across various industrial applications. These gearboxes integrate a single-stage worm gearbox with a universal gearbox, creating a double-stage reduction system that enhances torque output, performance, and adaptability. The "W" in the designation highlights the worm gear mechanism, known for its smooth and quiet operation, while the "P" refers to the robust overall box structure ensuring durability and reliability. The "E" denotes the double-stage reduction system, which allows for greater gear ratios, and the "A" represents the lower input shaft configuration, ideal for specific setups.

WPEDKA worm gear speed reducers offer a wide speed ratio range, with single-stage configurations providing ratios from 1:10 to 1:60. For applications requiring higher reductions, the double-stage arrangement achieves ratios from 1:200 to 1:900 by combining two single-stage gearboxes. This makes them suitable for high-torque, low-speed applications such as conveyors, mixers, and material handling systems. Their compact design, high efficiency, and ability to handle heavy loads make WPEDKA worm reducer gearboxes an optimal choice for industries like manufacturing, mining, and energy.

WPEDKA Worm Gear Reducer Specifications

| Type: | WPEDKA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

WPEDKA Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | B | BE | HL | LL | H | HA | HB | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 | 314 | 153 | 130 | 75 | 110 | 140 | 236 | 70 | 50 | 150 | 190 | 115 | 150 | 20 | 15 |

| 50-80 | 0.18 | 314 | 144 | 150 | 83 | 130 | 160 | 268 | 80 | 65 | 170 | 220 | 135 | 180 | 20 | 15 | |

| 60-100 | 0.37 | 337 | 175 | 160 | 91 | 160 | 200 | 336 | 100 | 75 | 190 | 270 | 155 | 220 | 25 | 15 | |

| 70-120 | 0.37 0.75 | 425 | 193 | 175 | 109 | 190 | 240 | 430 | 120 | 90 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 80-135 | 0.37 1.5 | 499 | 226 | 210 | 125 | 215 | 270 | 480 | 135 | 105 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 100-155 | 2.2 | 570 | 269 | 256 | 148 | 235 | 290 | 531 | 135 | 130 | 275 | 390 | 220 | 320 | 35 | 21 | |

| 120-175 | 2.2 3.0 | 631 | 287 | 282 | 219 | 280 | 335 | 660 | 160 | 155 | 310 | 430 | 250 | 350 | 40 | 21 | |

| 135-200 | 3.0 4.0 | 680 | 318 | 320 | 256 | 310 | 375 | 666 | 175 | 185 | 360 | 480 | 290 | 390 | 40 | 24 | |

| 155-250 | 5.5 | 815 | 380 | 400 | 247 | 355 | 450 | 800 | 200 | 203 | 460 | 560 | 380 | 480 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 30 | 8×33.3 | 19 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 35 | 10×38.3 | 27 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 40 | 12×43.3 | 45 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 45 | 14×48.8 | 75 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 18×64.4 | 103 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 70 | 20×74.9 | 147 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 80 | 22×85.4 | 204 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 22×90.4 | 298 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 28×116.4 | 470 |

WPEDKA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEDKA Double Reduction Worm Gear Reducer Benefits

- High Torque Output

The WPEDKA double reduction worm gear reducer delivers exceptional torque through its dual-stage design, combining two single-stage gearboxes. This configuration multiplies torque output, making it ideal for heavy-duty industrial applications requiring robust power transmission and reliable performance in compact systems. - Wide Ratio Range

With a double-stage setup, worm gear reducers achieve speed ratios from 1:200 to 1:900, offering unparalleled flexibility. This extensive range allows precise speed control, catering to diverse applications like conveyors and machinery, ensuring optimal performance across various operational requirements. - Compact Design

Despite its powerful output, the WPEDKA worm reducer gearboxes maintain a compact footprint, integrating a single-stage worm gear with a universal gearbox. This space-saving design is perfect for installations with limited space, providing efficient power transmission without compromising on performance or reliability. - Enhanced Efficiency

The double reduction worm gearbox's worm gear mechanism ensures smooth and efficient operation with minimal energy loss. Its double reduction system optimizes power transfer, reducing wear and extending the lifespan of machinery, making it a cost-effective solution for industrial applications. - Versatile Applications

The WPEDKA worm gear reduction gearbox's adaptable design suits a wide range of industries, including automation, material handling, and manufacturing. Its universal gearbox compatibility and lower input shaft configuration enable seamless integration into various systems, enhancing operational flexibility and productivity. - Durable Construction

Built with high-quality materials, the worm gear speed reducers offer exceptional durability and resistance to wear. Its robust structure withstands harsh industrial environments, ensuring long-term reliability and reducing maintenance costs, making it a dependable choice for continuous operation in demanding settings.

WPEDKA Double Reduction Worm Gearbox Applications

- Conveyor Systems

WPEDKA double reduction worm gearboxes are widely used in conveyor systems for material handling in industries like mining and logistics. Their high torque and wide ratio range ensure precise speed control, enabling efficient and reliable transport of goods over long distances. - Packaging Machinery

In packaging equipment, worm gear reducers provide consistent power transmission for tasks like sealing and labeling. Their compact design fits into space-constrained machines, while the double-stage reduction ensures smooth operation, enhancing productivity and accuracy in high-speed packaging processes. - Automation Systems

WPEDKA worm gear speed reducers are integral to automation systems in manufacturing, offering robust torque and precise speed control. Their versatility and durable construction support robotic arms and automated assembly lines, ensuring reliable performance in repetitive, high-precision industrial tasks. - Textile Machinery

Textile production relies on worm reducer gearboxes for driving looms and spinning machines. The double reduction system delivers high torque at low speeds, ensuring smooth operation and reducing wear, which is critical for maintaining consistent fabric quality in demanding environments. - Food Processing Equipment

In food processing, WPEDKA worm reduction gearboxes power mixers, grinders, and conveyors. Their robust design withstands frequent cleaning and harsh conditions, while the high ratio range allows precise control, ensuring efficient and hygienic processing in compliance with industry standards. - Cranes and Hoists

Worm gearbox reducers are used in cranes and hoists for heavy lifting in construction and manufacturing. Their high torque output and compact size enable reliable load handling, while the double-stage reduction ensures safe and controlled movement in critical lifting applications.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Packaging Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Construction Industry |

WPEDKA Worm Reducer Gearbox Material Manufacturing

- High-Strength Cast Iron Housing

The WPEDKA worm reducer gearbox housing is crafted from high-strength cast iron, ensuring durability and stability. This material withstands heavy loads and harsh industrial environments, providing a robust foundation for the gearbox, enhancing longevity and resistance to deformation under stress. - Precision-Ground Steel Worm Gears

The worm gears are manufactured from high-quality, precision-ground steel, hardened for superior strength. This process ensures smooth meshing and efficient power transmission, reducing wear and extending the gearbox’s operational life in demanding applications requiring high torque and reliability. - Bronze Worm Wheel

The worm wheel is made from high-grade bronze, offering excellent wear resistance and low friction. This material choice enhances efficiency and durability, allowing the double reduction worm gear reducer to handle high torque loads while maintaining smooth operation in industrial settings. - Heat-Treated Alloy Steel Shafts

Input and output shafts are constructed from heat-treated alloy steel, providing exceptional strength and fatigue resistance. This manufacturing process ensures the shafts can endure high stress and torque, maintaining structural integrity and reliable performance in heavy-duty applications. - Sealed Lubrication System

The worm gear reduction gearbox incorporates a sealed lubrication system using synthetic lubricants, applied during manufacturing. This ensures optimal performance and reduces maintenance needs, as the high-quality lubricant minimizes friction and wear, protecting components in harsh operating conditions over extended periods. - Precision CNC Machining

WPEDKA worm reduction gearboxes are manufactured using advanced CNC machining for precise component fabrication. This process ensures tight tolerances and perfect alignment of gears and shafts, resulting in smooth operation, reduced vibration, and enhanced efficiency across various industrial applications.

Additional information

| Edited by | Yjx |

|---|