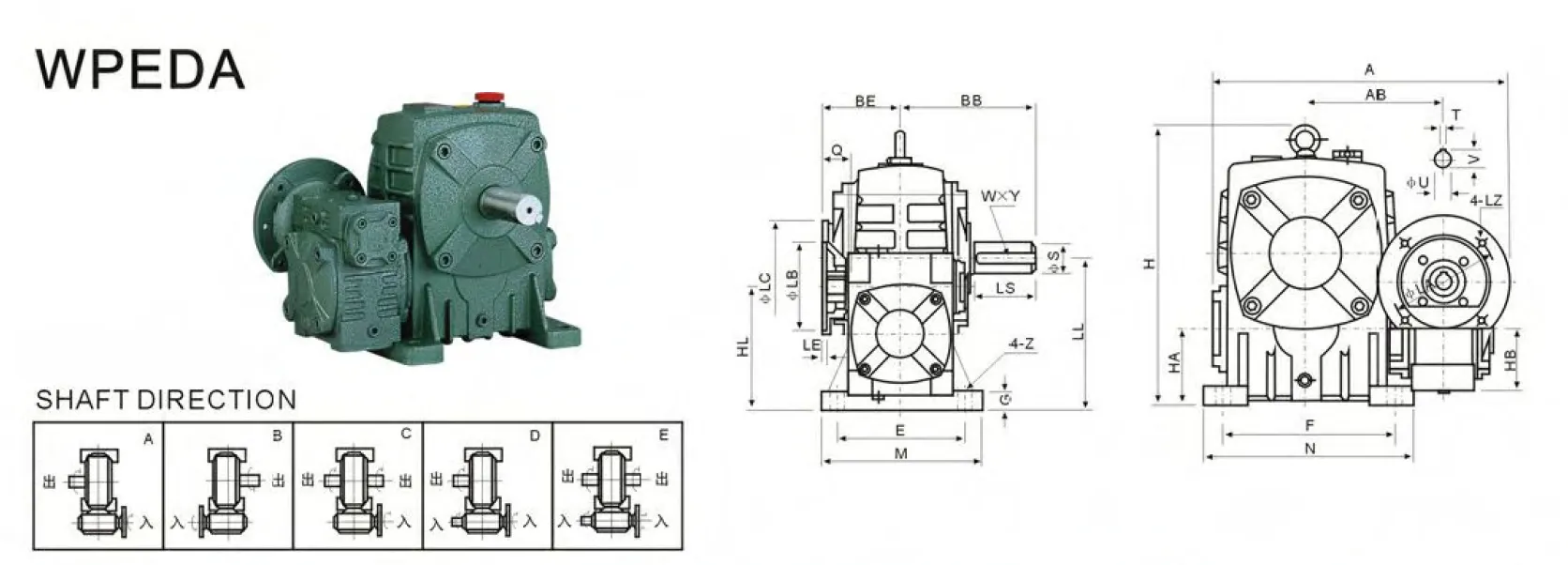

WPEDA Worm Gear Reducers/Worm Gearbox

WPEDA worm gear reducers, commonly known as double reduction worm gearboxes, are precision-engineered power transmission devices designed to deliver high torque and substantial speed reduction in compact and efficient designs. These advanced worm reducer gearboxes utilize two worm gear stages for enhanced performance: a primary worm shaft engages with a worm wheel to achieve the initial reduction, followed by a secondary stage that provides further speed reduction. This configuration allows for exceptionally high reduction ratios, typically ranging from 200:1 to 900:1, making them suitable for demanding applications.

WPEDA worm gear reducers, commonly known as double reduction worm gearboxes, are precision-engineered power transmission devices designed to deliver high torque and substantial speed reduction in compact and efficient designs. These advanced worm reducer gearboxes utilize two worm gear stages for enhanced performance: a primary worm shaft engages with a worm wheel to achieve the initial reduction, followed by a secondary stage that provides further speed reduction. This configuration allows for exceptionally high reduction ratios, typically ranging from 200:1 to 900:1, making them suitable for demanding applications.

Constructed with durable materials, they feature hardened steel worms and phosphor bronze worm wheels to ensure long-lasting performance and smooth operation. The housings, made from either die-cast aluminum or cast iron, provide excellent thermal efficiency and superior shock load absorption. Additionally, WPEDA worm gear speed reducers are equipped with permanent synthetic oil lubrication for maintenance-free operation, double taper roller bearings for high load capacities, and versatile mounting options to adapt to different industrial setups. These gearboxes are widely used in industries such as material handling, conveyors, and heavy machinery.

WPEDA Worm Gear Reducer Specifications

| Type: | WPEDA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

WPEDA Worm Gearbox Dimensions

| Model | Power (kW) | Ratio | A | AB | BB | BE | HL | LL | H | HA | HB | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 0.12 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 | 314 | 153 | 131 | 75 | 110 | 140 | 236 | 70 | 50 | 150 | 190 | 115 | 150 | 20 | 15 |

| 50-80 | 0.18 | 314 | 144 | 142 | 83 | 130 | 160 | 268 | 80 | 165 | 170 | 220 | 135 | 180 | 20 | 15 | |

| 60-100 | 0.37 | 337 | 175 | 169 | 91 | 160 | 200 | 336 | 100 | 75 | 190 | 270 | 155 | 220 | 25 | 15 | |

| 70-120 | 0.37 0.75 | 425 | 193 | 190 | 109 | 190 | 240 | 430 | 120 | 90 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 80-135 | 0.75 1.5 | 499 | 226 | 210 | 125 | 215 | 270 | 480 | 135 | 105 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 100-155 | 1.5 | 570 | 269 | 252 | 148 | 235 | 290 | 531 | 135 | 130 | 275 | 390 | 220 | 320 | 35 | 21 | |

| 120-175 | 2.2 3.0 | 631 | 287 | 255 | 219 | 280 | 335 | 660 | 160 | 155 | 310 | 430 | 250 | 350 | 40 | 21 | |

| 135-200 | 3.0 4.0 | 680 | 318 | 319 | 256 | 310 | 375 | 666 | 175 | 185 | 360 | 480 | 290 | 390 | 40 | 24 | |

| 155-250 | 5.5 | 815 | 380 | 385 | 247 | 355 | 450 | 800 | 200 | 205 | 460 | 560 | 380 | 480 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 35 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 60 | 28 | 7×4 | 19 |

| 115 | 35 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 65 | 32 | 10×4.5 | 27 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 75 | 38 | 10×4.5 | 45 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 85 | 45 | 12×4.5 | 75 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 95 | 55 | 16×6 | 103 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 110 | 60 | 18×7 | 147 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 110 | 65 | 18×7 | 204 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 125 | 70 | 20×7.5 | 298 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 155 | 90 | 25×9 | 470 |

WPEDA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEDA Worm Gear Reducer Components

- Worm Shaft

The worm shaft is a precision-machined, hardened steel component that serves as the primary input drive. Its helical thread engages the worm wheel to transmit power. The high-strength material and polished surface ensure minimal friction, high efficiency, and extended service life in demanding industrial applications. - Worm Gear

Made from phosphor bronze, the worm gear meshes with the worm shaft to facilitate torque transmission. Its robust construction allows it to handle high loads while resisting wear. The large contact area ensures smooth operation, reducing noise and vibration in double reduction setups. - Housing

The worm gear reducer's housing is typically constructed from cast iron. This component provides structural integrity, protects internal parts, and aids in heat dissipation. Its design supports versatile mounting configurations for various industrial applications. - Double Reduction Gear Set

This consists of two worm gear stages, enabling high reduction ratios (200:1 to 900:1). The secondary stage amplifies torque while maintaining compact size. Precision alignment of gears ensures efficient power transfer, making it ideal for heavy-duty machinery requiring significant speed reduction. - Bearings

Double taper roller bearings support the worm shaft and wheel, accommodating high radial and axial loads. These bearings enhance stability, reduce friction, and ensure smooth operation under heavy loads, contributing to the gearbox’s reliability and longevity in continuous industrial use. - Lubrication System

The worm drive gearbox uses permanent synthetic oil lubrication to minimize wear and heat generation. The sealed system prevents leaks and contamination, ensuring consistent performance. This maintenance-free design reduces downtime and extends the operational life of the gearbox in harsh environments. - Output Shaft

The output shaft delivers the reduced speed and amplified torque to the driven equipment. Made from high-strength steel, it is designed to withstand heavy loads and torsional stress, ensuring reliable power transmission in applications like conveyors and material handling systems. - Seals

High-quality seals prevent lubricant leakage and protect internal components from dust, moisture, and contaminants. These seals ensure the double reduction worm gearbox operates efficiently in harsh environments, maintaining lubrication integrity and extending component life, which is critical for consistent performance in industrial settings.

WPEDA Double Reduction Worm Gearbox Applications

Material Handling Systems

WPEDA double reduction worm gearboxes are widely used in conveyor belts and material handling equipment. Their high torque output and precise speed control ensure smooth and efficient movement of heavy loads, enhancing productivity in warehouses, distribution centers, and manufacturing facilities.Industrial Machinery

These worm reducer gearboxes power heavy-duty industrial machines like mixers, crushers, and presses. The double reduction design provides substantial torque for demanding tasks, while the compact structure allows integration into space-constrained setups, ensuring reliable performance in harsh industrial environments.Packaging Equipment

In packaging lines, WPEDA worm drive gearboxes drive rollers, fillers, and sealing machines. Their ability to deliver consistent low-speed, high-torque output ensures precise operation, reducing downtime and improving efficiency in high-speed packaging processes for food, beverage, and pharmaceutical industries.Agricultural Equipment

Worm and wheel gearboxes are integral to agricultural machinery such as irrigation systems, feed mixers, and harvesters. Their robust construction and high reduction ratios enable efficient handling of heavy loads, ensuring reliable operation in rugged outdoor conditions and variable terrains.Construction Machinery

In construction, these worm gear reduction gearboxes are used in equipment like concrete mixers and hoists. The high torque and shock-load resistance of worm gear reducers ensure dependable performance under heavy-duty conditions, supporting critical tasks in building and infrastructure development projects.Mining Operations

WPEDA worm reduction gearboxes are employed in mining equipment like conveyors and crushers. Their durability and ability to handle extreme loads make them ideal for harsh mining environments, ensuring consistent operation and minimal maintenance in high-stress, dust-filled conditions.

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Construction Industry |

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Packaging Industry |

WPEDA Worm Gear Reducer Advantages

- High Torque Output

WPEDA double reduction worm gearboxes deliver exceptional torque through their dual-stage design, enabling them to handle heavy loads efficiently. This makes them ideal for applications requiring significant power, such as conveyors and industrial machinery, ensuring robust performance in demanding conditions. - Compact Design

The worm gear reducer's compact structure allows it to fit into space-constrained environments without sacrificing performance. Its efficient design maximizes torque output while minimizing footprint, making it suitable for integration into various industrial setups where space is a critical factor. - High Reduction Ratios

With reduction ratios ranging from 200:1 to 900:1, WPEDA worm gear speed reducers provide precise speed control. This capability ensures smooth operation in applications requiring low speeds and high torque, such as material handling and packaging equipment, enhancing operational accuracy. - Durability and Reliability

Constructed with hardened steel worms and phosphor bronze wheels, worm reducer gearboxes are built for longevity. Their robust materials and sealed lubrication system ensure reliable performance, reducing wear and maintenance needs in harsh industrial environments. - Low Noise and Vibration

The precision-engineered worm and wheel design minimizes noise and vibration during operation. This feature enhances workplace comfort and equipment longevity, making worm gearbox reducers suitable for applications where quiet and smooth performance is essential, like packaging lines. - Versatile Mounting Options

WPEDA worm gear motors offer flexible mounting configurations, allowing easy integration into diverse systems. This adaptability supports various industrial applications, from construction machinery to agricultural equipment, providing design flexibility and simplifying installation in complex setups.

Additional information

| Edited by | Yjx |

|---|