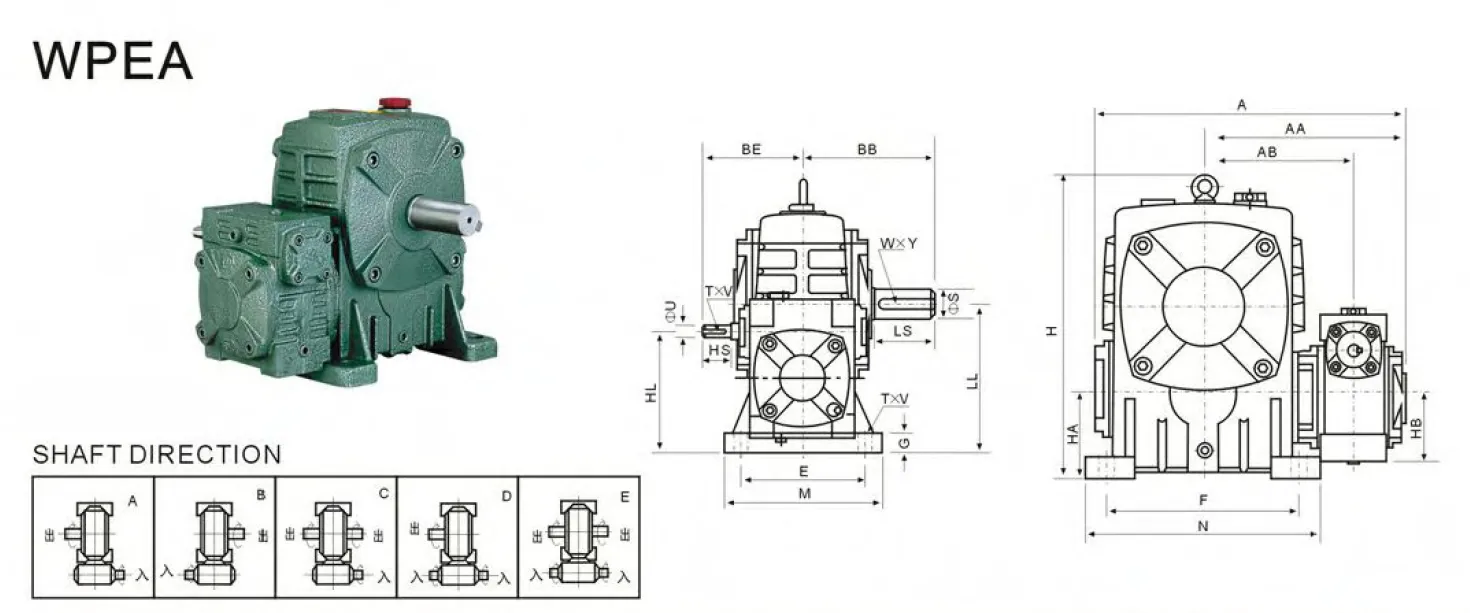

WPEA Worm Gear Reducers/Worm Gearbox

WPEA worm gear reducers, also known as worm gearboxes, are highly efficient and compact double-stage reduction gearboxes designed for various industrial applications. The WPEA model combines a single-stage worm gearbox with a universal gearbox, enabling it to achieve enhanced performance and flexibility. The “W” represents the worm gear mechanism, “P” signifies the overall box structure, “E” indicates the double-stage reduction system, and “A” refers to the lower input shaft configuration.

WPEA worm gear reducers, also known as worm gearboxes, are highly efficient and compact double-stage reduction gearboxes designed for various industrial applications. The WPEA model combines a single-stage worm gearbox with a universal gearbox, enabling it to achieve enhanced performance and flexibility. The "W" represents the worm gear mechanism, "P" signifies the overall box structure, "E" indicates the double-stage reduction system, and "A" refers to the lower input shaft configuration.

These worm reducer gearboxes offer a basic speed ratio range of 1:10 to 1:60 for single-stage setups, while the double-stage arrangement achieves ratios from 1:200 up to 1:900 by multiplying the ratios of two single-stage gearboxes. This high reduction capability makes WPEA gearboxes suitable for applications requiring precise motion control and heavy-load transmission. Each gearbox is meticulously packed in durable plywood boxes to ensure safe delivery and an intact appearance upon arrival. Known for their durability and superior performance, WPEA worm gear speed reducers are among the best-selling models in double-stage solutions.

WPEA Worm Gear Reducer Specifications

| Type: | WPEA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | 40-70, 50-80, 60-100, 70-120, 80-135, 100-155, 120-175, 135-200, 155-250 |

| Ratio: | 200, 300, 400, 500, 600, 800, 900 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper-9-4# | |

| Worm: 20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

| Lubricant: | Synthetic & Mineral |

WPEA Worm Gearbox Dimensions

| Model | Ratio | A | AA | AB | BB | BE | HL | LL | H | HA | HB | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-70 | 1/200 1/300 1/400 1/500 1/600 1/800 1/900 ... | 286 | 195 | 153 | 131 | 87 | 110 | 140 | 236 | 70 | 50 | 150 | 190 | 115 | 150 | 20 | 15 |

| 50-80 | 297 | 197 | 144 | 142 | 108 | 130 | 160 | 268 | 80 | 65 | 170 | 220 | 135 | 180 | 20 | 15 | |

| 60-100 | 363 | 231 | 175 | 169 | 120 | 160 | 200 | 336 | 100 | 75 | 190 | 270 | 155 | 220 | 25 | 15 | |

| 70-120 | 408 | 256 | 193 | 190 | 140 | 190 | 240 | 430 | 120 | 90 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 80-135 | 471 | 298 | 226 | 210 | 160 | 215 | 270 | 480 | 135 | 105 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 100-155 | 555 | 354 | 269 | 252 | 190 | 235 | 290 | 531 | 135 | 130 | 275 | 390 | 220 | 320 | 35 | 21 | |

| 120-175 | 598 | 379 | 287 | 255 | 219 | 280 | 335 | 660 | 160 | 155 | 310 | 430 | 250 | 350 | 40 | 21 | |

| 135-200 | 662 | 425 | 318 | 319 | 256 | 310 | 375 | 666 | 175 | 185 | 360 | 480 | 290 | 390 | 40 | 24 | |

| 155-250 | 795 | 510 | 380 | 385 | 295 | 355 | 450 | 800 | 200 | 205 | 460 | 560 | 380 | 480 | 45 | 28 |

| Input hole | Output shaft | Weight | ||||

|---|---|---|---|---|---|---|

| HS | U | T×V | LS | S | W×Y | (kg) |

| 25 | 12 | 4×2.5 | 60 | 28 | 7×4 | 20 |

| 30 | 12 | 4×2.5 | 65 | 32 | 10×4.5 | 27 |

| 40 | 15 | 5×3 | 75 | 38 | 10×4.5 | 44 |

| 40 | 18 | 5×3 | 85 | 45 | 12×4.5 | 73 |

| 50 | 22 | 7×4 | 95 | 55 | 16×6 | 101 |

| 50 | 25 | 7×4 | 110 | 60 | 18×7 | 144 |

| 65 | 30 | 7×4 | 110 | 65 | 18×7 | 201 |

| 75 | 35 | 10×5 | 125 | 70 | 20×7.5 | 293 |

| 85 | 40 | 12×5 | 155 | 90 | 25×9 | 462 |

WPEA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPEA Worm Gear Speed Reducer Advantages

1. High Torque Output

WPEA worm gear speed reducers deliver exceptional torque for demanding applications. The double-stage design multiplies torque through two worm gear sets, enabling efficient power transmission for heavy machinery, ensuring reliable performance under high loads with ratios up to 1:900.

2. Wide Speed Ratio Range

Offering speed ratios from 1:200 to 1:900 in double-stage configurations, worm reducer gearboxes provide flexibility for diverse industrial needs. This broad range allows precise speed control, making them suitable for applications requiring significant speed reduction and consistent operation.

3. Compact and Robust Design

The WPEA worm drive gearbox’s compact structure optimizes space without compromising strength. Its durable box construction (denoted by “P”) ensures stability and longevity, making it ideal for harsh environments where space constraints and reliability are critical, such as in automation systems.

4. Efficient Power Transmission

With a double-stage worm gear system, worm gear reducers achieve high efficiency in power transfer. The precise meshing of gears minimizes energy loss, providing smooth operation and reducing wear, which enhances performance in continuous-duty industrial applications.

5. Low Noise and Vibration

WPEA worm gear reduction gearboxes are engineered for quiet operation. The worm gear design and high-quality materials reduce noise and vibration, creating a smoother and more comfortable working environment, particularly in settings where noise control is essential, like manufacturing plants.

6. Secure Packaging for Delivery

Each worm gearbox reducer is packaged in a sturdy wooden box, ensuring protection during transport. This careful packaging preserves the gearbox’s integrity, preventing damage to critical components and guaranteeing that customers receive a product in pristine condition, ready for installation.

WPEA Worm Gear Reduction Gearbox Applications

1. Conveyor Systems

WPEA worm gear reduction gearboxes are widely used in conveyor systems for material handling in industries such as manufacturing, logistics, and mining. Their high torque output and precise speed control ensure smooth operation, enabling the efficient transport of materials over long distances.

2. Hoisting and Lifting Equipment

These worm gearboxes are ideal for hoists, cranes, and other lifting equipment due to their high load-bearing capacity and compact design. The double-stage reduction ensures the reliable transmission of force, making them suitable for handling heavy loads in construction and industrial applications.

3. Packaging Machinery

In the packaging industry, WPEA worm drive gearboxes are used for controlling the precise movement of packaging systems. Their smooth operation and quiet performance make them perfect for automated machines, ensuring accurate and efficient wrapping, sealing, or labeling processes.

4. Textile Machinery

Worm gear reducers are essential components in textile machines, where precise speed and torque control are critical. They help in driving processes like spinning, weaving, and dyeing, ensuring consistent operation and high productivity in textile manufacturing plants.

5. Automation and Robotics

These worm gear reducer gearboxes are utilized in automation and robotic systems that require precise and reliable motion control. Their compact design and ability to handle varying speeds and loads make them ideal for industrial robots, assembly lines, and pick-and-place systems.

6. Mining and Heavy Machinery

The WPEA worm gear speed reducers are highly suitable for heavy machinery used in mining and excavation. Its robust construction and high reduction ratios enable it to handle demanding conditions, ensuring the efficient operation of equipment such as crushers, conveyors, and drilling rigs.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Construction Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Packaging Industry |

Double Reduction Worm Gearbox Vs Single Reduction Worm Gearbox

A double reduction worm gearbox and a single reduction worm gearbox differ primarily in their design, speed ratio capabilities, and applications. Both types are widely used in industries for power transmission, but their functionality and efficiency vary based on the specific requirements of the application.

Single Reduction Worm Gearbox

A single reduction worm gearbox consists of one worm and worm wheel pair. It is designed for applications requiring a speed reduction ratio typically ranging from 1:5 to 1:60. These gearboxes are simpler in design, more compact, and easier to install. They are suitable for moderate torque and speed reduction needs, making them ideal for applications like conveyors, small machinery, and light-duty industrial equipment. The single-stage design allows for efficient power transmission with minimal heat generation and smooth operation, but it is limited in achieving extremely high reduction ratios. As a result, single reduction gearboxes are more commonly used in applications requiring lower torque and speed control.

Double Reduction Worm Gearbox

A double reduction worm gearbox, on the other hand, consists of two worm and worm wheel pairs, connected in series. This configuration allows for much higher reduction ratios, ranging from 1:100 to 1:900 or more. The cascading gear stages multiply the reduction, making the double reduction gearbox ideal for applications requiring precise and substantial speed control with very high torque output. These gearboxes are often used in heavy-duty industrial applications, such as hoists, cranes, mining equipment, and large conveyor systems. However, double reduction gearboxes are larger in size, generate more heat due to the additional gearing, and may have slightly lower efficiency compared to single-stage models.

Single reduction gearboxes are compact and suitable for light-duty tasks, while double reduction gearboxes provide higher reduction ratios and torque for heavy-duty applications. The choice between them depends on the specific torque, speed, and space constraints of the application.

|  |

| Double Reduction Worm Gearbox | Single Reduction Worm Gearbox |

Additional information

| Edited by | Yjx |

|---|