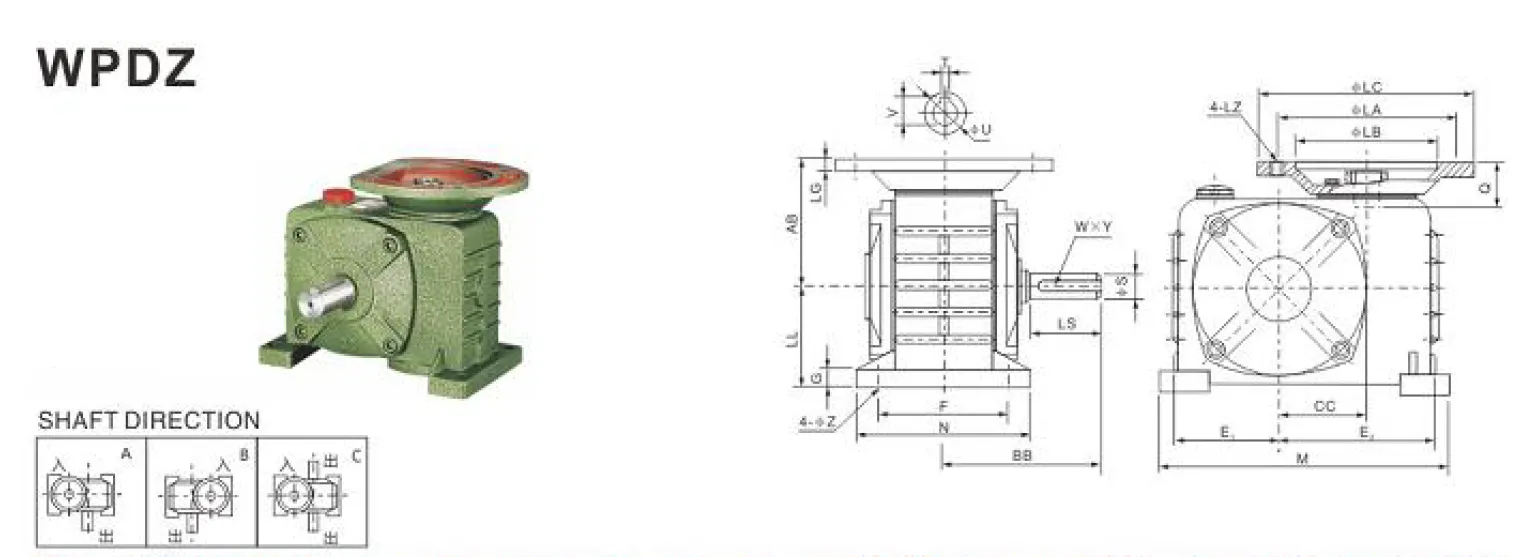

WPDZ Worm Gear Reducers/Worm Gearbox

WPDZ worm gear reducers, also known as worm gearboxes, are mechanical power transmission devices designed to reduce rotational speed while increasing torque. They belong to the WP series of worm gear reducers and feature a compact, right-angle design, making them ideal for applications with limited space. The WPDZ worm gearbox typically includes a cast iron housing, a single-stage worm gear system, and configurations for solid or hollow output shafts. Input options include a solid input shaft or an IEC B5 motor flange, allowing flexibility in motor integration.

WPDZ worm gear reducers, also known as worm gearboxes, are mechanical power transmission devices designed to reduce rotational speed while increasing torque. They belong to the WP series of worm gear reducers and feature a compact, right-angle design, making them ideal for applications with limited space. The WPDZ worm gearbox typically includes a cast iron housing, a single-stage worm gear system, and configurations for solid or hollow output shafts. Input options include a solid input shaft or an IEC B5 motor flange, allowing flexibility in motor integration.

These worm gear speed reducers offer high gear ratios (e.g., 1:10 to 1:60), providing significant torque multiplication and self-locking capabilities under certain conditions. Their robust construction ensures durability, low noise, and high efficiency, making them suitable for industries like manufacturing, conveyors, and material handling.

WPDZ Worm Gear Reducer Specifications

| Product Name: | WPDZ Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPDZ |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.12kW~15kW |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

WPDZ Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | AB | LL | BB | CC | E₁ | E₂ | F | G | M | N | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 0.18 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 88 | 77 | 97 | 50 | 53 | 77 | 100 | 15 | 125 | 160 | 11 |

| 60 | 0.18 0.37 | 80 | 82 | 112 | 60 | 68 | 92 | 100 | 15 | 130 | 190 | 11 | |

| 70 | 0.37 0.75 | 100 | 95 | 131 | 70 | 75 | 115 | 120 | 20 | 155 | 230 | 15 | |

| 80 | 0.75 1.5 | 120 | 100 | 142 | 80 | 96 | 144 | 125 | 20 | 160 | 265 | 15 | |

| 100 | 1.5 | 150 | 135 | 169 | 100 | 100 | 150 | 155 | 22 | 195 | 310 | 15 | |

| 120 | 2.2 3.0 | 165 | 160 | 190 | 120 | 120 | 180 | 180 | 28 | 230 | 360 | 18 | |

| 135 | 3.0 4.0 | 185 | 170 | 210 | 135 | 130 | 200 | 200 | 30 | 250 | 390 | 18 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LB | LC | LA | LG | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 10 | M8 | 26 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8 |

| 115 | 95 | 140 | 10 | M8 | 26 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8 |

| 130 | 110 | 160 | 10 | M8 | 37 | 14 | 5×16.3 | 50 | 22 | 7×4 | 12.5 |

| 130 | 110 | 160 | 10 | M8 | 37 | 14 | 5×16.3 | 50 | 22 | 7×4 | 12.5 |

| 165 | 130 | 200 | 10 | M10 | 42 | 19 | 6×21.8 | 60 | 28 | 7×4 | 16 |

| 165 | 130 | 200 | 12 | M10 | 45 | 19 | 6×21.8 | 65 | 32 | 10×4.5 | 23 |

| 165 | 130 | 200 | 12 | M10 | 57 | 24 | 8×27.3 | 65 | 32 | 10×4.5 | 23 |

| 165 | 130 | 200 | 12 | M10 | 60 | 24 | 8×27.3 | 75 | 38 | 10×4.5 | 38 |

| 215 | 180 | 250 | 15 | M12 | 70 | 28 | 8×31.3 | 75 | 38 | 10×4.5 | 38 |

| 215 | 180 | 250 | 18 | M12 | 70 | 28 | 8×31.3 | 85 | 45 | 12×4.5 | 60 |

| 215 | 180 | 250 | 18 | M12 | 70 | 28 | 8×31.3 | 85 | 45 | 12×4.5 | 60 |

| 215 | 180 | 250 | 20 | M12 | 68 | 28 | 8×31.3 | 95 | 55 | 16×6 | 80 |

WPDZ Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPDZ Worm Gear Speed Reducer Benefits

- Compact and Space-Saving Design

The WPDZ worm gear speed reducer features a right-angle design, allowing it to fit easily into applications with limited space. Its compact structure reduces the overall machine footprint, making it ideal for industries where spatial efficiency is critical. - High Torque Output and Gear Ratios

With gear ratios ranging from 1:10 to 1:60, the worm drive gearbox provides significant torque multiplication. This ensures powerful performance while maintaining smooth operation, making it suitable for heavy-duty applications such as conveyors, material handling, and industrial machinery. - Durable and Robust Construction

Built with a cast iron housing and precision-engineered worm gear components, the WPDZ worm reducer gearbox is designed to withstand harsh working environments. Its durability ensures long-term operation, reducing downtime and maintenance costs, even under high-load or continuous-use conditions. - Self-Locking Capability for Safety

The inherent self-locking feature of the worm gear reducers prevents back-driving under certain conditions. This adds a layer of safety, particularly in applications where loads must be held securely in place without requiring additional braking mechanisms. - Low Noise and Smooth Operation

The unique design of the worm gear system minimizes vibrations and noise during operation. This ensures a quieter working environment, making it an excellent choice for industries requiring low-noise equipment, such as production lines and automated systems. - Versatile Motor Integration and Output Options

The WPDZ worm gear reduction gearbox offers flexible input configurations, including solid input shafts and IEC B5 motor flanges, for easy motor compatibility. Additionally, it supports both solid and hollow output shafts, allowing it to adapt to diverse mechanical setups and application requirements.

WPDZ Worm Reducer Gearbox Application Industry

- Material Handling and Conveyor Systems

WPDZ worm gearboxes are widely used in material handling equipment and conveyor systems. Their high torque output and compact design make them ideal for powering conveyor belts, hoists, and elevators, ensuring smooth and efficient movement of goods in industrial facilities. - Manufacturing and Production Machinery

In manufacturing industries, WPDZ gearboxes enhance the performance of production machinery such as presses, mixers, and assembly lines. Their durability and precise speed reduction capabilities ensure consistent operation, enabling optimal performance for heavy-duty tasks and prolonged operational cycles. - Packaging and Automation Equipment

The compact and quiet operation of WPDZ reducers makes them suitable for packaging and automation systems. They are often used in automated packaging lines, robotic arms, and labeling machines, where precision, reliability, and low noise levels are critical for efficient output. - Agricultural Machinery and Equipment

Agricultural applications benefit from WPDZ reducers due to their robust design and resistance to harsh environments. They are commonly applied in equipment like irrigation systems, grain conveyors, and soil preparation tools, where they deliver reliable power and withstand challenging working conditions. - Mining and Heavy-Duty Applications

WPDZ worm gearboxes are essential in mining and heavy-duty industries, where equipment operates under extreme loads. Their high torque capacity and self-locking feature make them suitable for crushers, conveyors, and lifting mechanisms, ensuring safety and efficiency in demanding environments. - Food Processing and Pharmaceutical Industries

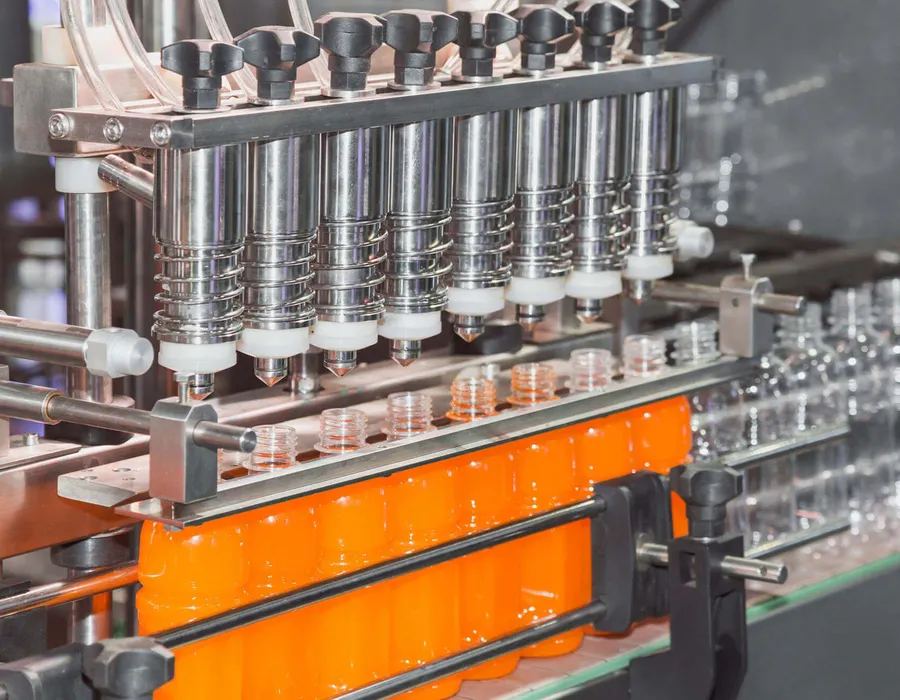

In food processing and pharmaceutical sectors, where hygiene and precision are critical, WPDZ reducers play a vital role. They are used in processing equipment like mixers, grinders, and filling machines, providing controlled speeds and smooth operation for sensitive and precise applications.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Packaging Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Mining and Quarrying Industry |

Difference Between Worm Gearbox and Helical Gearbox

Worm gearboxes and helical gearboxes are both mechanical power transmission devices but differ significantly in design, operation, and applications. These differences make them suitable for specific use cases depending on performance requirements and industry needs.

1. Design and Gear Arrangement

A worm gearbox consists of a worm (a screw-like component) and a worm wheel. This design allows for right-angle power transmission, making it ideal for applications with limited space. In contrast, a helical gearbox uses helical gears with teeth set at an angle. This arrangement enables smoother and more efficient power transmission, typically in parallel or inline configurations.

2. Efficiency and Power Loss

Helical gearboxes are generally more efficient than worm gearboxes because of reduced friction between the gear teeth. Worm gearboxes tend to lose more energy to heat due to sliding contact between the worm and the worm wheel, resulting in lower efficiency.

3. Torque and Gear Ratio

Worm gearboxes are known for their high gear ratios (e.g., 1:10 to 1:60) and significant torque multiplication. They are also self-locking under certain conditions, adding safety advantages. Helical gearboxes, while offering moderate torque, excel in high-speed and high-efficiency applications.

4. Noise and Smoothness

Helical gearboxes operate more quietly and smoothly due to the gradual engagement of angled teeth. Worm gearboxes, while slightly noisier, are still relatively quiet, though they generate more vibration.

5. Applications

Worm gearboxes are ideal for heavy-duty applications requiring high torque and compact size, such as conveyors, hoists, and material handling. Helical gearboxes are preferred in industries like automotive, manufacturing, and packaging, where high efficiency and speed are critical.

|  |

| Worm Gearbox | Helical Gearbox |

Additional information

| Edited by | Yjx |

|---|