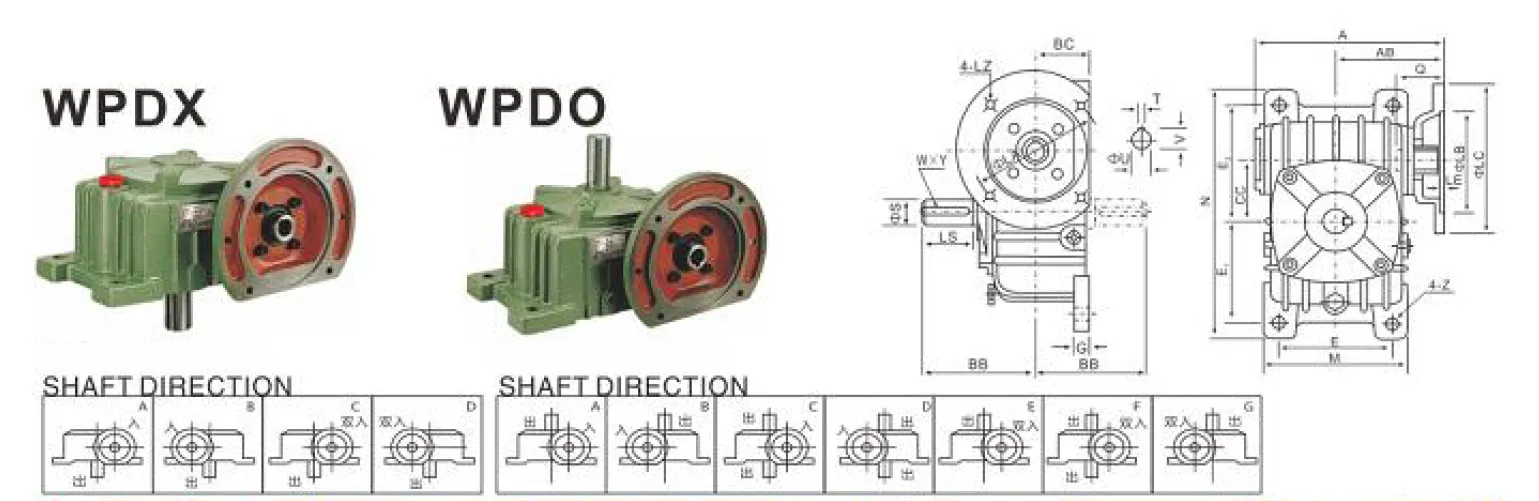

WPDX Worm Gear Reducers/Worm Gearbox

WPDX worm gear reducers, part of the WP series worm gearboxes, are mechanical power transmission devices designed to reduce speed and increase torque between non-intersecting shafts at right angles. Specifically, the WPDX worm gearbox features a vertical downward output shaft and an input flange, allowing direct connection to motors for enhanced safety by minimizing contact with moving parts. Constructed with a cast iron housing for durability and rigidity, the worm is made from 45# high-quality steel via heat treatment, and the worm wheel uses tin bronze for superior wear resistance.

WPDX worm gear reducers, part of the WP series worm gearboxes, are mechanical power transmission devices designed to reduce speed and increase torque between non-intersecting shafts at right angles. Specifically, the WPDX worm gearbox features a vertical downward output shaft and an input flange, allowing direct connection to motors for enhanced safety by minimizing contact with moving parts. Constructed with a cast iron housing for durability and rigidity, the worm is made from 45# high-quality steel via heat treatment, and the worm wheel uses tin bronze for superior wear resistance. These worm gear speed reducers support ratios from 10:1 to 60:1, with input power ranging from 0.18kW to 15kW and input speeds up to 1500 RPM. They are widely used in industries like metallurgy, mining, and plastics for reliable, compact, and low-maintenance operation.

WPDX Worm Gear Reducer Specifications

| Type: | WPDX Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPDX40-250 |

| Ratio: | 10,15,20,25,30,40,50,60 |

| Color: | Blue/Green or On Customer Request |

| Material: | Housing: die-cast cast iron |

| Worm Gear-Copper-9-4# | |

| Worm-20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft-chromium steel-45# | |

| Packing: | Carton and Wooden Case |

| Bearing: | HH / XZX Bearing |

| Seal: | KSK |

| Warranty: | 12Months |

| Input Power: | 0.12kw~15kw |

| Usages: | Industrial Machine: Food Stuff, Ceramics, Chemical, Packing, Dyeing, Woodworking, Glass. |

| IEC Flange: | B5 |

| Lubricant: | Synthetic&Mineral |

WPDX Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | A | AB | BB | BC | CC | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 74 | 45 | 40 | 94 | 104 | 70 | 74 | 86 | 10 | 10 |

| 50 | 0.18 | 151 | 83 | 97 | 50 | 50 | 116 | 220 | 90 | 93 | 102 | 15 | 12 | |

| 60 | 0.37 | 167 | 91 | 112 | 55 | 60 | 126 | 260 | 100 | 105 | 120 | 20 | 12 | |

| 70 | 0.37 | 200 | 109 | 131 | 65 | 70 | 156 | 295 | 120 | 120 | 135 | 20 | 15 | |

| 80 | 0.75 | 202 | 111 | 142 | 70 | 80 | 175 | 320 | 140 | 130 | 150 | 20 | 15 | |

| 80 | 1.5 | 225 | 125 | 142 | 70 | 80 | 175 | 320 | 140 | 130 | 150 | 20 | 15 | |

| 100 | 1.5 | 280 | 148 | 169 | 90 | 100 | 224 | 375 | 190 | 155 | 180 | 25 | 15 | |

| 120 | 2.2 | 333 | 181 | 190 | 100 | 120 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 120 | 3.0 | 333 | 181 | 190 | 100 | 120 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 135 | 3.0 | 375 | 202 | 210 | 110 | 135 | 306 | 495 | 260 | 210 | 235 | 30 | 18 | |

| 135 | 4.0 | 375 | 202 | 210 | 110 | 135 | 306 | 495 | 260 | 210 | 235 | 30 | 18 | |

| 147 | 3.0 | 415 | 235 | 210 | 114 | 147 | 302 | 558 | 250 | 254 | 254 | 32 | 18 | |

| 147 | 4.0 | 415 | 235 | 210 | 114 | 147 | 302 | 558 | 250 | 254 | 254 | 32 | 18 | |

| 155 | 5.5 | 448 | 247 | 252 | 140 | 155 | 350 | 590 | 290 | 245 | 295 | 35 | 21 | |

| 175 | 5.5 | 481 | 262 | 255 | 150 | 175 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 175 | 7.5 | 481 | 262 | 255 | 150 | 175 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 200 | 11.0 | 543 | 285 | 319 | 175 | 200 | 440 | 710 | 370 | 290 | 360 | 40 | 24 | |

| 250 | 11.0 | 615 | 330 | 385 | 200 | 250 | 510 | 860 | 440 | 350 | 440 | 45 | 28 | |

| 250 | 15.0 | 615 | 330 | 385 | 200 | 250 | 510 | 860 | 440 | 350 | 440 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 50 | 22 | 7×4 | 11 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 60 | 28 | 7×4 | 17 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 28 | 7×4 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 65 | 32 | 10×4.5 | 22 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 75 | 38 | 10×4.5 | 38 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 45 | 12×4.5 | 64 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 85 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 105 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 118 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 165 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 236 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 396 |

WPDX Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPDX Worm Gear Reducer Features

1. Vertical Downward Output Shaft Design

The WPDX worm gear reducer features a vertical downward output shaft, which is particularly suited for space-constrained installations. This design allows for efficient torque transmission while maintaining a compact structure, making it ideal for various industrial applications with limited mounting space.

2. Input Flange for Direct Motor Connection

Equipped with an input flange, the reducer facilitates seamless and secure direct motor integration. This worm gear speed reducers the need for additional coupling components, enhances operational safety by minimizing exposure to moving parts, and ensures smooth power transfer between the motor and the gearbox.

3. Durable Cast Iron Housing

The worm drive gearbox housing is made of high-quality cast iron, offering exceptional durability and rigidity. This robust construction provides superior resistance to mechanical stress, vibrations, and external impacts, ensuring long-lasting performance even in demanding industrial environments such as mining and metallurgy.

4. High-Quality Heat-Treated Worm Gear

The worm gear is manufactured from 45# high-grade steel and undergoes advanced heat treatment. This process improves its hardness and strength, ensuring excellent load-bearing capacity and resistance to wear, which enhances the overall efficiency and lifespan of the gear reducer.

5. Tin Bronze Worm Wheel for Wear Resistance

The worm wheel is constructed from premium tin bronze, a material renowned for its superior wear resistance. This ensures smooth and reliable operation over time, reducing maintenance frequency and making it suitable for continuous use in heavy-duty applications.

6. Wide Range of Ratios and Power Options

The WPDX worm reducer gearbox supports gear ratios ranging from 10:1 to 60:1 and accommodates input power from 0.18kW to 15kW with speeds up to 1500 RPM. This versatility makes it adaptable for various industrial applications, ensuring optimal performance across different operational demands.

WPDX Worm Drive Gearbox Applications

1. Metallurgy Industry

In the metallurgy industry, WPDX worm drive gearboxes are essential for powering equipment such as conveyors, crushers, and rolling mills. Their ability to handle high torque and provide reliable performance under heavy loads ensures efficient operation in harsh and demanding environments.

2. Mining Industry

The mining industry relies on worm gearboxes for machinery like hoists, conveyors, and drilling rigs. Their robust construction, wear-resistant components, and ability to function under extreme conditions make them ideal for handling the rigorous demands of extracting and processing raw materials.

3. Plastics Industry

WPDX worm reducer gearboxes are widely used in plastic extrusion machines, injection molding systems, and other processing equipment. Their precise speed reduction capabilities and reliable torque output ensure consistent and efficient operation, helping maintain product quality across various plastic manufacturing processes.

4. Textile Industry

In textile production, these worm gear speed reducers are applied in looms, spinning machines, and dyeing equipment. Their compact design, smooth operation, and low maintenance requirements make them an excellent choice for ensuring uninterrupted production in environments that demand consistent speed and precision.

5. Food Processing Industry

WPDX worm gear reducers are used in food processing machinery like mixers, conveyors, and packaging systems. Their compact size, quiet operation, and ability to deliver consistent torque make them suitable for maintaining hygiene and efficiency in food production environments.

6. Chemical Industry

The chemical industry utilizes worm drive reduction gearboxes in mixers, agitators, and pumps that handle various chemical processes. Their durability, resistance to wear, and ability to operate under varying speeds and loads make them reliable for handling corrosive materials and extreme operating conditions.

|  |

| Worm Gearbox for Metallurgy Industry | Worm Gearbox for Mining and Quarrying Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Chemical Industry |

WPDX Worm Gear Speed Reducer Maintenance

- Regular Lubrication Checks

Proper lubrication is critical to the gearbox’s performance and longevity. Regularly check the oil level and quality, and replace it with the recommended lubricant at specified intervals to reduce friction, minimize wear, and ensure smooth operation under varying load conditions. - Inspection for Wear and Tear

Periodically inspect the worm gear, worm wheel, and bearings for signs of wear or damage. Identifying and addressing these issues early prevents further deterioration, avoids unexpected downtime, and ensures the gearbox continues to function efficiently over extended periods of use. - Ensure Proper Alignment

Verify that the input flange, output shaft, and connected machinery are properly aligned. Misalignment can lead to increased vibration, excessive noise, and premature wear on components, which can compromise the gearbox’s performance and result in costly repairs or replacements. - Monitor Operating Temperatures

Regularly monitor the operating temperature of the gearbox to ensure it remains within the recommended range. Excessive heat can indicate overloading, insufficient lubrication, or internal damage, and addressing these issues promptly can prevent component failure and extend the gearbox’s lifespan. - Clean External Surfaces Regularly

Keep the exterior of the worm gear reducer gearbox clean and free from dust, dirt, and debris. Accumulated grime can trap heat and hinder proper cooling, potentially leading to overheating and reduced efficiency. Regular cleaning also helps identify external damage or leaks early. - Check for Unusual Noise or Vibrations

Listen for unusual noises or feel for vibrations during operation, as these can indicate internal issues such as worn bearings, misaligned components, or insufficient lubrication. Promptly investigating and resolving these abnormalities ensures smooth and reliable gearbox performance.

Additional information

| Edited by | Yjx |

|---|