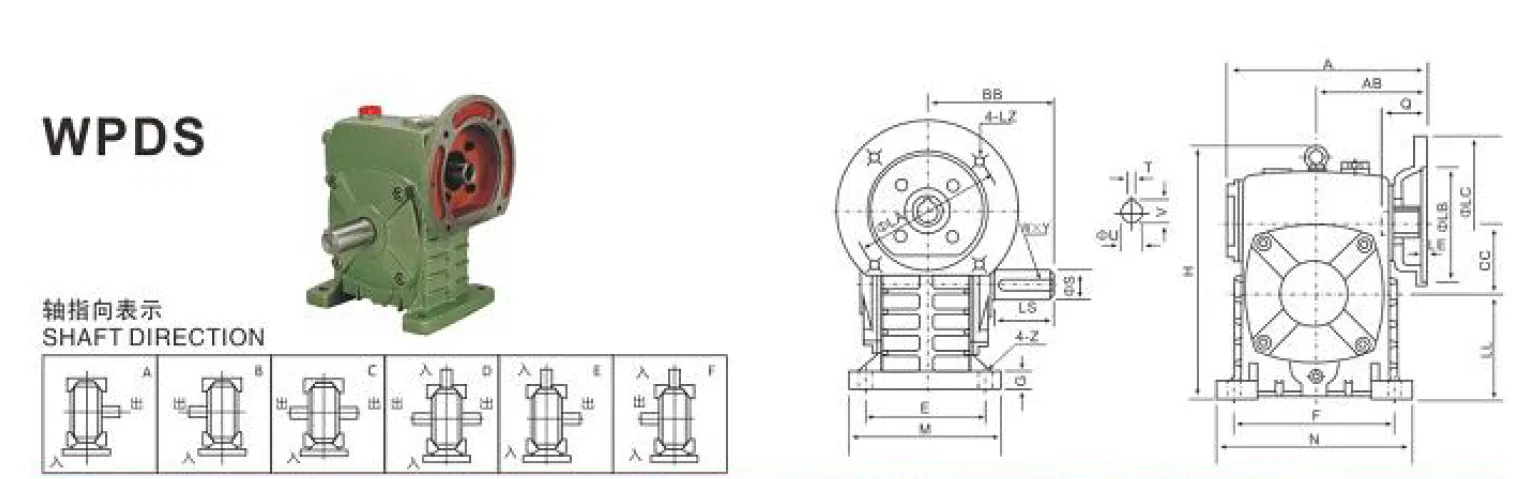

WPDS Worm Gear Reducers/Worm Gearbox

WPDS worm gear reducers, part of the WP series worm gearbox family, are compact, efficient power transmission devices designed for various industrial applications. Featuring a flange-mounted design (indicated by the “D” in WPDS), these worm drive gearboxes allow direct motor installation on the side flange plate, eliminating the need for additional transmission components like couplings, chains, or sprockets. This streamlines assembly, reduces costs, and saves space.

WPDS worm gear reducers, part of the WP series worm gearbox family, are compact, efficient power transmission devices designed for various industrial applications. Featuring a flange-mounted design (indicated by the “D” in WPDS), these worm drive gearboxes allow direct motor installation on the side flange plate, eliminating the need for additional transmission components like couplings, chains, or sprockets. This streamlines assembly, reduces costs, and saves space.

With input power ranging from 0.18kW to 15kW, WPDS worm gear speed reducers offer flexibility for diverse machinery. They are known for their small size, lightweight construction, stable operation, long service life, and high load capacity. Installation options include foot or flange mounting, ensuring adaptability. These features make WPDS gearboxes ideal for applications requiring reliable, low-maintenance, and space-efficient power transmission solutions.

WPDS Worm Gear Reducer Specifications

| Product Name: | WPDS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPDS |

| Size: | 50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.18kW to 15kW |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

WPDS Worm Gearbox Dimensions

| Model | Input Power(kW) | Ratio | A | AB | BB | CC | H | LL | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 74 | 40 | 141 | 60 | 9C | 100 | 70 | 80 | 13 | 10 |

| 50 | 0.18 | 151 | 83 | 97 | 50 | 176 | 80 | 12D | 140 | 95 | 110 | 15 | 12 | |

| 60 | 0.37 | 167 | 91 | 112 | 60 | 202 | 90 | 13D | 150 | 105 | 120 | 20 | 12 | |

| 70 | 0.75 | 202 | 111 | 131 | 70 | 238 | 105 | 15D | 190 | 115 | 150 | 20 | 15 | |

| 80 | 0.75 | 225 | 125 | 142 | 80 | 273 | 120 | 17D | 220 | 135 | 180 | 20 | 15 | |

| 100 | 1.5 | 280 | 148 | 169 | 100 | 334 | 150 | 19D | 270 | 155 | 220 | 25 | 15 | |

| 120 | 2.2 | 333 | 181 | 190 | 120 | 423 | 180 | 23D | 320 | 180 | 260 | 30 | 18 | |

| 120 | 3.0 | 333 | 181 | 190 | 120 | 423 | 180 | 23D | 320 | 180 | 260 | 30 | 18 | |

| 135 | 3.0 | 375 | 202 | 210 | 135 | 482 | 215 | 25D | 350 | 200 | 290 | 30 | 18 | |

| 135 | 4.0 | 375 | 202 | 210 | 135 | 482 | 215 | 25D | 350 | 200 | 290 | 30 | 18 | |

| 155 | 5.5 | 448 | 247 | 252 | 155 | 541 | 235 | 27.5D | 390 | 220 | 320 | 35 | 21 | |

| 175 | 5.5 | 481 | 262 | 255 | 175 | 600 | 260 | 31D | 430 | 250 | 350 | 40 | 21 | |

| 175 | 7.5 | 481 | 262 | 255 | 175 | 600 | 260 | 31D | 430 | 250 | 350 | 40 | 21 | |

| 200 | 11.0 | 543 | 285 | 319 | 200 | 677 | 290 | 36D | 480 | 290 | 390 | 40 | 24 | |

| 250 | 11.0 | 615 | 330 | 385 | 250 | 824 | 350 | 46D | 560 | 380 | 480 | 45 | 28 | |

| 250 | 15.0 | 615 | 330 | 385 | 250 | 824 | 350 | 46D | 560 | 380 | 480 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 40 | 17 | 5×3 | 8 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 50 | 22 | 7×4 | 11 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 28 | 7×4 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 65 | 32 | 10×4.5 | 22 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 75 | 38 | 10×4.5 | 38 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 45 | 12×4.5 | 64 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 85 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 118 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 165 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 236 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 396 |

WPDS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPDS Worm Gear Speed Reducer Benefits

- Space-Saving Design

The WPDS worm gear speed reducer features a flange-mounted structure, allowing the motor to be directly installed on the gearbox. This eliminates the need for external transmission components such as chains or couplings. Its compact and lightweight design ensures it saves valuable space in constrained industrial setups, making it an excellent choice for applications requiring efficient use of limited space. - Cost-Effective Solution

By removing the necessity for additional transmission parts like sprockets and couplings, the worm drive gearbox reduces both material and assembly costs. Its direct motor mounting design simplifies the installation process, saving labor time and reducing operational expenses for users over the long term. - Stable and Reliable Operation

The WPDS worm gearbox is designed for smooth and stable power transmission. Its robust worm gear design ensures minimal vibration and noise during operation. This reliability makes it suitable for continuous industrial applications, where consistent and uninterrupted performance is critical to operational efficiency. - High Load Capacity

Built with high-quality materials and precision engineering, the worm gear reducer provides excellent load-bearing capabilities. It is designed to handle heavy loads under demanding conditions while maintaining performance and durability. This makes it ideal for industries requiring high torque transmission in compact systems. - Long Service Life

The WPDS worm reducer gearbox is engineered for longevity, with durable components that resist wear and tear over time. Its worm gear mechanism is designed to ensure minimal maintenance needs, making it a reliable choice for applications where downtime must be minimized and operational continuity is essential. - Versatility in Applications

With input power ranging from 0.18 kW to 15 kW, the worm gear speed reducer is highly adaptable to various industrial scenarios. Its ability to support flange-mounted installations makes it suitable for diverse machinery, including conveyors, mixers, and automated production equipment, enhancing its overall utility.

WPDS Worm Reduction Gearbox Applications

- Conveyor Systems

WPDS worm reduction gearboxes are widely used in conveyor systems for material handling in industries like mining and logistics. Their high load capacity and stable operation ensure reliable movement of heavy materials, enhancing efficiency in automated transport processes across various production facilities. - Packaging Machinery

In packaging equipment, worm gear motors provide precise speed control and smooth operation. Their compact flange-mounted design saves space in tight machinery layouts, making them ideal for driving rollers, sealers, and other components in high-speed packaging lines for food, pharmaceuticals, and consumer goods. - Textile Machinery

WPDS worm gearboxes are employed in textile manufacturing for driving looms, spinning machines, and dyeing equipment. Their long service life and ability to handle consistent loads ensure uninterrupted operation, improving productivity and maintaining precision in fabric production processes under demanding conditions. - Food Processing Equipment

The worm gear reducers are utilized in food processing machinery, such as mixers, grinders, and slicers. Its stable performance and compact design optimize space in food production lines, ensuring hygienic and efficient operation while meeting strict industry standards for reliability and durability. - Automated Assembly Lines

In automated assembly systems, WPDS worm gear reduction gearboxes deliver controlled torque for robotic arms and positioning devices. Their cost-effective installation and high load capacity support precise movements, enabling seamless integration into manufacturing processes for automotive, electronics, and other precision industries. - Agricultural Machinery

Worm reducer gearboxes are applied in agricultural equipment like seeders, harvesters, and irrigation systems. Their robust construction and versatile power range (0.18kW to 15kW) ensure dependable performance in harsh outdoor environments, enhancing efficiency and reducing maintenance needs for farming operations.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Textile Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Packaging Industry |

WPDS Worm Gear Reducer Troubleshooting

- Overheating During Operation

Overheating can occur due to insufficient lubrication, excessive load, or prolonged operation. Ensure the gearbox is filled with the correct lubricant type and quantity. Check the load requirements to confirm they are within the gearbox’s rated capacity. Regularly inspect and clean the ventilation areas to prevent heat buildup. - Abnormal Noise or Vibrations

Unusual noise or excessive vibration may indicate misalignment, worn-out bearings, or damaged gears. Inspect the installation to verify proper alignment between the motor and gearbox. Examine the internal components for wear or damage and replace faulty parts to restore smooth operation. - Oil Leakage from the Gearbox

Oil leakage can result from damaged seals, overfilled lubrication, or excessive wear on the housing. Check for damaged or improperly installed seals and replace them as needed. Ensure the lubricant level is appropriate and inspect the housing for cracks or defects. - Reduced Torque or Power Transmission

A drop in torque or power may be caused by worn gears, insufficient lubrication, or excessive loading. Inspect the gears for wear or damage and replace them if necessary. Maintain proper lubrication levels and ensure the load does not exceed the gearbox’s rating. - Motor Not Operating Smoothly with the Gearbox

If the motor struggles or operates inconsistently, it could be due to improper mounting or misalignment. Verify that the motor is securely and correctly mounted to the gearbox flange. Check for alignment issues and correct them to avoid unnecessary strain on the motor and gearbox. - Shortened Service Life of Components

Premature wear of gearbox components can occur due to incorrect usage, lack of maintenance, or poor-quality lubrication. Follow the manufacturer’s maintenance schedule for regular inspections and servicing. Use the recommended lubricant and ensure the gearbox operates within its specified load and speed limits.

Additional information

| Edited by | Yjx |

|---|