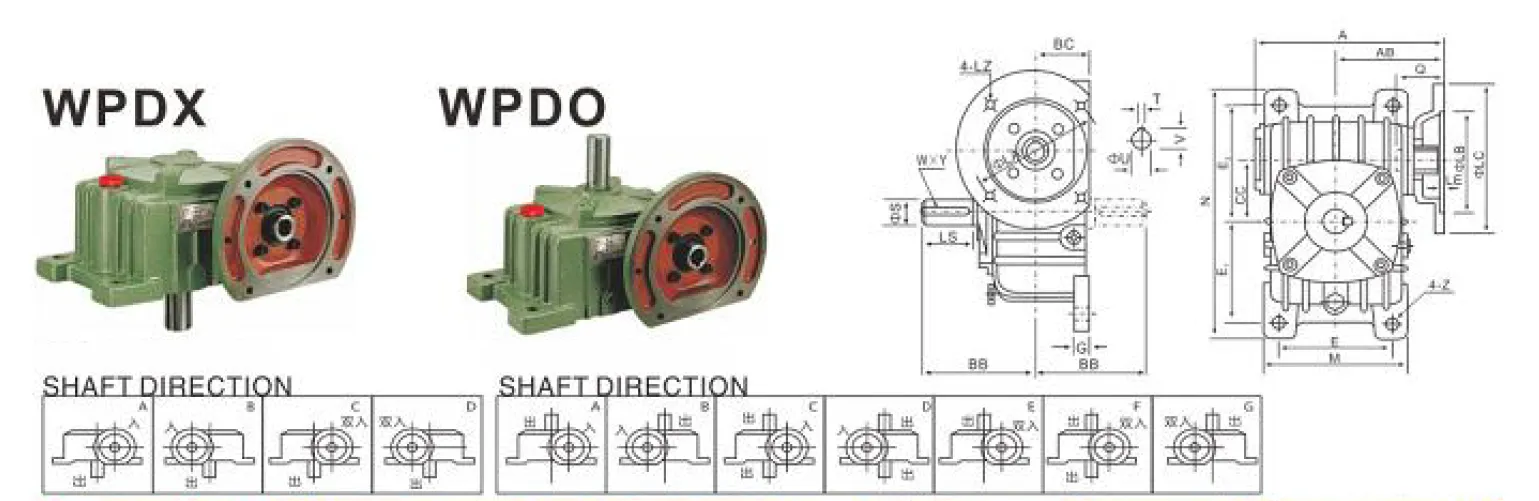

WPDO Worm Gear Reducers/Worm Gearbox

WPDO worm gear reducers are flange-mounted worm gearboxes with an upward-oriented output shaft, designed for efficient power transmission in compact spaces. They feature a worm (a screw-like gear) and a worm wheel, enabling high torque output and significant speed reduction, typically with gear ratios ranging from 10:1 to 60:1. A key characteristic is their self-locking function under specific conditions, where a small worm helix angle prevents reverse rotation due to friction, ensuring the worm gear cannot back-drive the worm. This makes WPDO worm gearboxes ideal for applications requiring stability, such as in metallurgy, mining, and lifting equipment.

WPDO worm gear reducers are flange-mounted worm gearboxes with an upward-oriented output shaft, designed for efficient power transmission in compact spaces. They feature a worm (a screw-like gear) and a worm wheel, enabling high torque output and significant speed reduction, typically with gear ratios ranging from 10:1 to 60:1. A key characteristic is their self-locking function under specific conditions, where a small worm helix angle prevents reverse rotation due to friction, ensuring the worm gear cannot back-drive the worm. This makes WPDO worm gearboxes ideal for applications requiring stability, such as in metallurgy, mining, and lifting equipment. Constructed with durable materials like tin bronze worm gears and heat-treated steel worms, they offer wear resistance and reliability. Input power ranges from 0.18kW to 15kW, and they support flange or foot installation for versatility.

WPDO Worm Gear Reducer Specifications

| Product Name: | WPDO Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPDO |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.18kW~15kW |

| IEC Flange: | 63B5,71B5,80B5,90B5,100/112B5,132B5,160B5 |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

WPDO Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | A | AB | BB | BC | CC | M | N | E | E₁ | E₂ | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 74 | 45 | 40 | 94 | 104 | 70 | 74 | 86 | 10 | 10 |

| 50 | 0.18 | 151 | 83 | 97 | 50 | 50 | 116 | 220 | 90 | 93 | 102 | 15 | 12 | |

| 60 | 0.37 | 167 | 91 | 112 | 55 | 60 | 126 | 260 | 100 | 105 | 120 | 20 | 12 | |

| 70 | 0.37 | 200 | 109 | 131 | 65 | 70 | 156 | 295 | 120 | 120 | 135 | 20 | 15 | |

| 80 | 0.75 | 202 | 111 | 142 | 70 | 80 | 175 | 320 | 140 | 130 | 150 | 20 | 15 | |

| 80 | 1.5 | 225 | 125 | 142 | 70 | 80 | 175 | 320 | 140 | 130 | 150 | 20 | 15 | |

| 100 | 1.5 | 280 | 148 | 169 | 90 | 100 | 224 | 375 | 190 | 155 | 180 | 25 | 15 | |

| 120 | 2.2 | 333 | 181 | 190 | 100 | 120 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 120 | 3.0 | 333 | 181 | 190 | 100 | 120 | 266 | 450 | 220 | 185 | 215 | 30 | 18 | |

| 135 | 3.0 | 375 | 202 | 210 | 110 | 135 | 306 | 495 | 260 | 210 | 235 | 30 | 18 | |

| 135 | 4.0 | 375 | 202 | 210 | 110 | 135 | 306 | 495 | 260 | 210 | 235 | 30 | 18 | |

| 147 | 3.0 | 415 | 235 | 210 | 114 | 147 | 302 | 558 | 250 | 254 | 254 | 32 | 18 | |

| 147 | 4.0 | 415 | 235 | 210 | 114 | 147 | 302 | 558 | 250 | 254 | 254 | 32 | 18 | |

| 155 | 5.5 | 448 | 247 | 252 | 140 | 155 | 350 | 590 | 290 | 245 | 295 | 35 | 21 | |

| 175 | 5.5 | 481 | 262 | 255 | 150 | 175 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 175 | 7.5 | 481 | 262 | 255 | 150 | 175 | 394 | 640 | 320 | 267 | 323 | 40 | 21 | |

| 200 | 11.0 | 543 | 285 | 319 | 175 | 200 | 440 | 710 | 370 | 290 | 360 | 40 | 24 | |

| 250 | 11.0 | 615 | 330 | 385 | 200 | 250 | 510 | 860 | 440 | 350 | 440 | 45 | 28 | |

| 250 | 15.0 | 615 | 330 | 385 | 200 | 250 | 510 | 860 | 440 | 350 | 440 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | LS | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 28 | 14 | 5×3 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 40 | 17 | 5×3 | 8 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 50 | 22 | 7×4 | 11 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 60 | 28 | 7×4 | 17 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 60 | 28 | 7×4 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 65 | 32 | 10×4.5 | 22 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 75 | 38 | 10×4.5 | 38 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 85 | 45 | 12×4.5 | 64 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 85 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 95 | 55 | 16×6 | 105 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 60 | 18×7 | 118 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 110 | 65 | 18×7 | 165 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 125 | 70 | 20×7.5 | 236 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 155 | 90 | 25×9 | 396 |

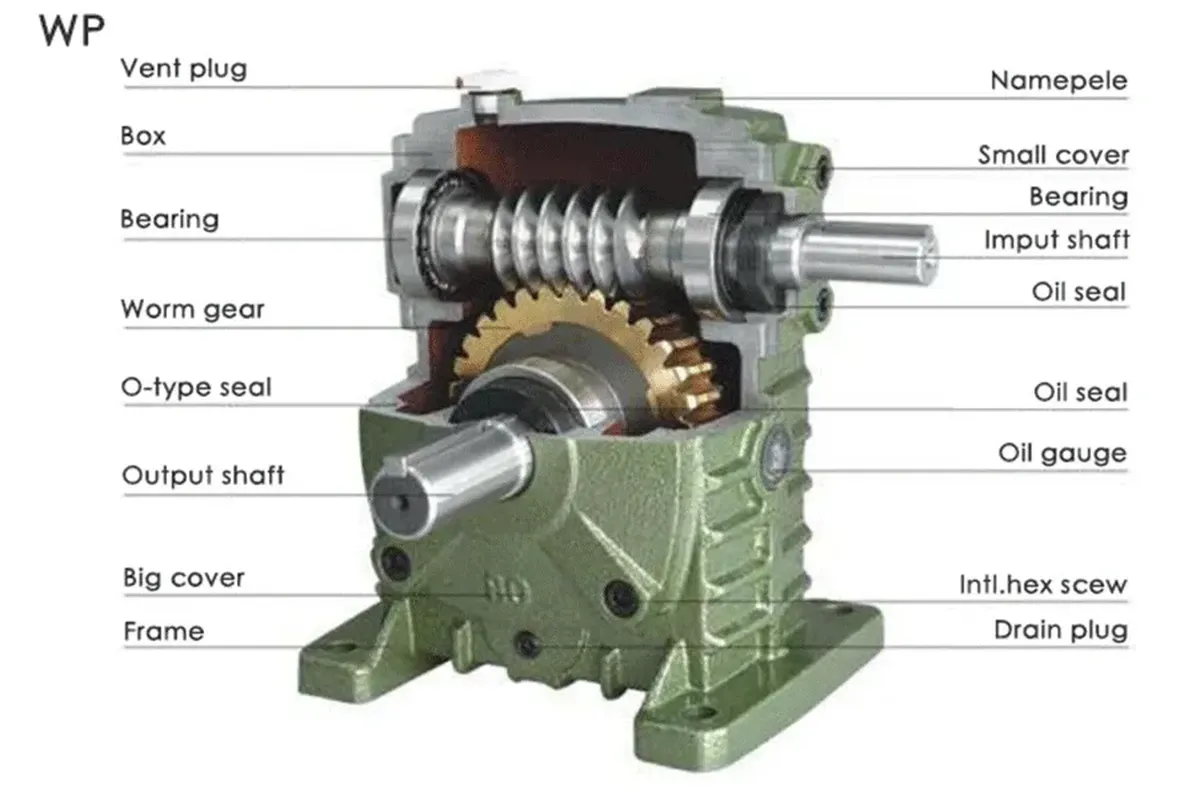

WPDO Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPDO Worm Drive Gearbox Benefits

- High Torque Output and Compact Design

WPDO worm drive gearboxes deliver exceptional torque for heavy-duty applications while maintaining a compact, space-saving design. Their flange-mounted configuration with an upward output shaft ensures efficient power transmission, making them ideal for constrained spaces in industries like metallurgy and mining. - Self-Locking Capability for Safety

Under specific conditions, the small worm helix angle enables self-locking, preventing reverse rotation of the worm. This feature enhances safety and stability in applications such as lifting equipment, where unintended movement could be hazardous, ensuring reliable operation without additional braking mechanisms. - Versatile Installation Options

The WPDO worm gearbox supports both flange and foot mounting, offering flexibility for various setups. This adaptability simplifies integration into diverse machinery, such as conveyors or cranes, allowing engineers to optimize system design without compromising performance or structural integrity. - Durable and Wear-Resistant Materials

Constructed with tin bronze worm gears and heat-treated steel worms, worm gear speed reducers resist wear and corrosion. This durability extends service life, reducing maintenance costs and ensuring consistent performance in demanding environments like chemical plants or textile machinery. - Wide Range of Gear Ratios

Offering gear ratios from 10:1 to 60:1, WPDO worm reducer gearboxes provide precise speed reduction and torque multiplication. This versatility suits applications requiring varied speed control, such as in automation systems, ensuring optimal performance across different operational requirements. - Energy Efficiency and Low Noise

Worm drive gearboxes are designed for smooth operation, minimizing energy loss and reducing noise levels. Their precision-engineered components ensure quiet performance, making them suitable for noise-sensitive environments like food processing or indoor industrial settings, enhancing workplace comfort.

WPDO Worm Gear Reducer Applications

- Metallurgy Industry

WPDO worm gear reducers are used in metallurgical equipment like rolling mills and furnaces. Their high torque output and self-locking feature ensure precise control and stability under heavy loads, enhancing efficiency in metal processing and shaping operations. - Mining Industry

In mining, WPDO gearboxes drive conveyors and hoists. Their compact design and durable tin bronze worm gears withstand harsh environments, providing reliable power transmission and preventing reverse motion, which is critical for safe material handling in rugged conditions. - Lifting Equipment

WPDO reducers are ideal for cranes and elevators due to their self-locking capability. This prevents unintended load descent, ensuring safety. The upward output shaft and flange mounting allow seamless integration into lifting systems for consistent performance. - Textile Machinery

WPDO gearboxes power textile equipment like spinning and weaving machines. Their wide gear ratios enable precise speed control, while low-noise operation suits indoor settings. The robust construction ensures longevity despite continuous operation in high-demand production lines. - Chemical Processing

In chemical plants, WPDO reducers drive mixers and pumps. Their corrosion-resistant materials and self-locking function maintain operational stability in aggressive environments, ensuring safe and efficient processing of chemicals with minimal maintenance requirements. - Automation Systems

WPDO gearboxes are used in automated assembly lines and robotic systems. Their compact size and versatile mounting options facilitate integration, while high torque and precise speed reduction support smooth, controlled movements in automated manufacturing processes.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Metallurgy Industry |

|  |

| Worm Gearbox for Textile Industry | Worm Gearbox for Chemical Industry |

WPDO Worm Gearbox Parts

- Worm Shaft

The worm shaft is a screw-like component that engages with the worm gear to transfer motion and torque. It is typically made of hardened steel to ensure durability and efficient performance under high loads and continuous operation. - Worm Gear

The worm gear is a toothed wheel that meshes with the worm shaft. Made from materials like bronze or cast iron, it is designed to handle friction effectively while providing smooth torque transmission and speed reduction in the gearbox. - Housing

The housing encases and protects the internal components of the gearbox. It is made of cast iron or aluminum alloy for strength and heat dissipation, ensuring the gearbox remains durable and operational in demanding environments with minimal maintenance. - Flange Mount

The flange mount is a key feature of worm drive gearboxes, allowing for secure and easy installation. Its design ensures the gearbox can be mounted in various orientations, making it adaptable to different machinery setups and operational requirements. - Input Shaft

The input shaft connects the gearbox to the motor or power source. It transmits rotational energy to the worm shaft, initiating the gear reduction process. The input shaft is designed for precision alignment to ensure smooth operation and minimal wear. - Output Shaft

The output shaft, positioned upward in the WPDO worm reduction gearbox, delivers the reduced speed and amplified torque to the connected machinery. It is constructed for strength and stability, capable of handling heavy loads and ensuring reliable performance over extended periods. - Bearings

Bearings support the rotation of the worm shaft and worm gear, reducing friction and ensuring smooth operation. High-quality bearings improve efficiency, minimize heat generation, and extend the service life of the gearbox even under continuous or heavy-duty use. - Seals and Gaskets

Seals and gaskets prevent the leakage of lubricants and protect internal components from dust and contaminants. These parts are vital for maintaining the gearbox's efficiency and longevity, ensuring it operates smoothly in challenging industrial environments.

Additional information

| Edited by | Yjx |

|---|