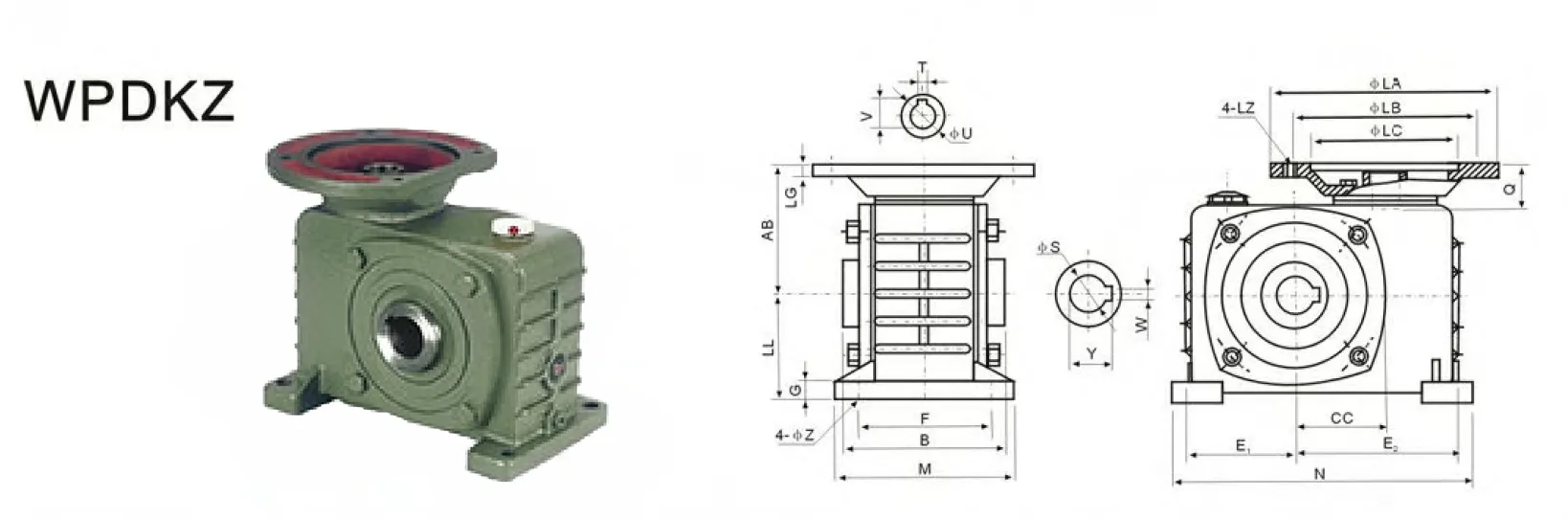

WPDKZ Worm Gear Reducers/Worm Gearbox

The WPDKZ worm gear reducers, commonly referred to as worm gearboxes, are specialized speed reducers designed for compact, high-torque applications requiring efficient power transmission. They feature a worm (a screw-like gear) and a worm wheel (a spur-like gear) with shafts positioned at a 90-degree angle. This unique arrangement allows for significant speed reduction and torque multiplication while maintaining a compact size. The WPDKZ series worm gearbox is built with a durable cast iron housing and offers various mounting options, including horizontal and vertical setups for input and output shafts.

The WPDKZ worm gear reducers, commonly referred to as worm gearboxes, are specialized speed reducers designed for compact, high-torque applications requiring efficient power transmission. They feature a worm (a screw-like gear) and a worm wheel (a spur-like gear) with shafts positioned at a 90-degree angle. This unique arrangement allows for significant speed reduction and torque multiplication while maintaining a compact size. The WPDKZ series worm gearbox is built with a durable cast iron housing and offers various mounting options, including horizontal and vertical setups for input and output shafts.

Available configurations include solid or hollow output shafts and motor flanges compatible with IEC B5/B14 standards. Gear ratios range from 7.5:1 to 100:1, with double reduction models achieving up to 10,000:1. These worm gear speed reducers are valued for their quiet operation, compactness, and self-locking capabilities (at ratios above 50:1). High-quality components ensure exceptional durability, low noise, and reliable performance over a long lifespan. Ideal for conveyors, elevators, and various industrial machinery, WPDKZ worm gear reducers deliver efficient and dependable power transmission solutions.

WPDKZ Worm Gear Reducer Specifications

| Product Name: | WPDKZ Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPDKZ |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.12kW~15kW |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

WPDKZ Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | AB | LL | BB | CC | E₁ | E₂ | F | G | M | N | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 0.18 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 88 | 105 | 50 | 53 | 77 | 100 | 15 | 77 | 160 | 125 | 11 |

| 60 | 0.18 0.37 | 80 | 110 | 60 | 68 | 92 | 100 | 15 | 82 | 190 | 130 | 11 | |

| 70 | 0.37 0.75 | 100 | 130 | 70 | 75 | 115 | 120 | 20 | 95 | 230 | 155 | 15 | |

| 100 | 1.5 | 120 | 150 | 80 | 96 | 144 | 125 | 20 | 100 | 265 | 160 | 15 | |

| 135 | 3.0 4.0 | 150 | 160 | 100 | 100 | 150 | 155 | 22 | 135 | 310 | 195 | 15 | |

| 165 | 175 | 120 | 120 | 180 | 180 | 28 | 160 | 360 | 230 | 18 | |||

| 185 | 210 | 135 | 130 | 200 | 200 | 30 | 170 | 390 | 250 | 18 |

| Flange | Input hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LB | LC | LA | LG | LZ | Q | U | T×V | S | W×Y | (kg) |

| 115 | 95 | 140 | 10 | M8 | 26 | 11 | 4×12.8 | 20 | 6×22.8 | 8 |

| 115 | 95 | 140 | 10 | M8 | 27 | 11 | 4×12.8 | 25 | 8×28.3 | 12.5 |

| 130 | 110 | 160 | 10 | M8 | 37 | 14 | 5×16.3 | 25 | 8×28.3 | 12.5 |

| 130 | 110 | 160 | 10 | M8 | 32 | 14 | 5×16.3 | 30 | 8×33.3 | 16 |

| 165 | 130 | 200 | 10 | M10 | 42 | 19 | 6×21.8 | 30 | 8×33.3 | 16 |

| 165 | 130 | 200 | 12 | M10 | 45 | 19 | 6×21.8 | 35 | 10×38.3 | 23 |

| 165 | 130 | 200 | 12 | M10 | 57 | 24 | 8×27.3 | 35 | 10×38.3 | 23 |

| 165 | 130 | 200 | 15 | M10 | 60 | 24 | 8×27.3 | 40 | 12×43.3 | 38 |

| 215 | 180 | 250 | 15 | M12 | 70 | 28 | 8×31.3 | 40 | 12×43.3 | 38 |

| 215 | 180 | 250 | 18 | M12 | 70 | 28 | 8×31.3 | 45 | 14×48.8 | 60 |

| 215 | 180 | 250 | 18 | M12 | 70 | 28 | 8×31.3 | 45 | 14×48.8 | 60 |

| 215 | 180 | 250 | 20 | M12 | 68 | 28 | 8×31.3 | 60 | 18×64.4 | 80 |

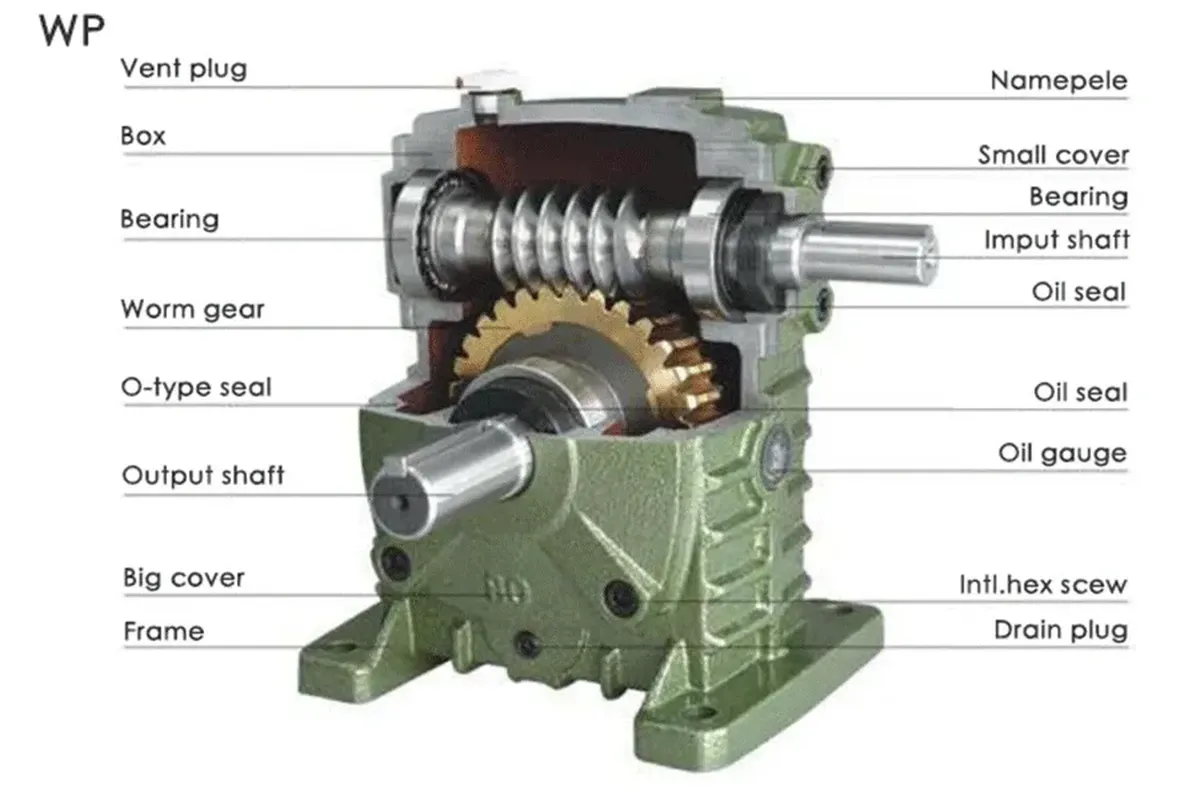

WPDKZ Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPDKZ Worm Gear Reducer Components

- Worm Gear

The worm gear is a helical gear that meshes with the worm to transmit power. It is typically made of high-strength bronze or similar materials for durability, wear resistance, and smooth operation. Its design allows for efficient torque transfer and speed reduction. - Worm Shaft

The worm shaft is a screw-like component made from hardened steel to provide strength and resistance to deformation. It engages with the worm gear to produce rotational motion and torque multiplication, ensuring efficient power transmission between the input and output shafts. - Housing

The housing is usually made from cast iron or aluminum for durability and vibration damping. It encloses the worm gear and worm shaft, protecting them from contaminants such as dust and moisture while also providing necessary structural support. - Bearings

High-quality bearings, such as NSK or equivalent brands, are used to support the worm shaft and worm gear. These bearings reduce friction, enhance efficiency, and ensure smooth operation under high loads, contributing to the reducer's long service life. - Oil Seals

Premium oil seals, like Simrit seals, are used to prevent lubrication leakage and to keep contaminants out of the gearbox. These seals ensure proper lubrication of internal components, minimizing wear and tear while maintaining optimal performance over time. - Input Shaft

The input shaft is connected to the power source, such as an electric motor. It transfers rotational motion to the worm shaft. Designed for high-speed operation, it ensures smooth power transfer without vibration or misalignment issues. - Output Shaft

The output shaft delivers the reduced speed and amplified torque to the connected machine or application. Depending on the configuration, it can be solid or hollow, offering flexibility for various mounting and coupling requirements.

WPDKZ Worm Drive Gearbox Applications

- Conveyor Systems

WPDKZ worm drive gearboxes are widely used in conveyor systems for material handling in industries such as manufacturing, logistics, and mining. Their compact design and high torque output make them ideal for driving conveyor belts, ensuring smooth and efficient load movement under varying operational conditions. - Elevators and Lifting Equipment

These worm drive reduction gearboxes are essential in elevators, hoists, and other lifting machinery where precise control and high torque are required. Their self-locking capability at higher gear ratios ensures safety by preventing back-driving, making them highly reliable for vertical lifting applications in construction and industrial settings. - Industrial Machinery

WPDKZ right angle worm gearboxes play a critical role in various industrial machines, such as mixers, crushers, and extruders, where torque multiplication is necessary. Their durability and ability to handle heavy loads make them suitable for continuous operation in harsh environments with minimal maintenance requirements. - Agricultural Equipment

In the agricultural sector, these worm gear reducerss are used in machines like grain augers, irrigation systems, and tractors. Their ability to operate efficiently under high loads and variable speeds ensures reliable performance in demanding agricultural applications, enhancing productivity and reducing downtime. - Packaging and Printing Machines

WPDKZ worm gear speed reducers are commonly used in packaging and printing equipment, where precision and quiet operation are essential. Their compact design and ability to deliver consistent torque at reduced speeds make them ideal for driving rollers, cutters, and other components in these machines. - Renewable Energy Systems

These worm reducer gearboxes are increasingly used in renewable energy applications, such as solar trackers and small wind turbines. Their high efficiency, compact size, and ability to handle varying loads make them suitable for optimizing energy generation and ensuring reliable operation in sustainable energy systems.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Textile Industry |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Food and Beverage Industry |

WPDKZ Worm Gear Speed Reducer Lubrication Steps

- Initial Inspection and Cleaning

Before applying lubricant, inspect the gearbox to ensure all internal components are clean and free of debris. Remove any contaminants, old grease, or oil residue to prevent mixing incompatible lubricants, which could reduce the gearbox's efficiency and accelerate component wear. - Choosing the Correct Lubricant

Select a high-quality lubricant recommended by the manufacturer, typically a synthetic or mineral-based oil with high viscosity. The oil should be appropriate for the operating temperature and load conditions to ensure proper lubrication, reduce friction, and minimize heat generation in the gearbox. - Filling the Gearbox with Lubricant

Locate the oil filling port and pour the lubricant into the gearbox until it reaches the recommended level, often indicated by a sight glass or dipstick. Avoid overfilling, as excess oil can lead to leakage, increased pressure, and reduced gearbox efficiency during operation. - Sealing and Testing for Leaks

After filling, securely close the oil filling port and inspect the gearbox for leaks around the seals, gaskets, and housing joints. Allow the gearbox to run for a short period to ensure the lubricant circulates properly and no leakage occurs during operation. - Regular Lubricant Monitoring

Periodically check the lubricant level and condition during routine maintenance. Use the dipstick or sight glass to verify levels and inspect the oil for contamination or degradation. Replace the lubricant if it appears dark, thick, or contains debris that could impair gearbox performance. - Scheduled Oil Replacement

Replace the lubricant according to the manual's recommendations or after a specific number of operational hours. Fully drain the old oil from the gearbox before refilling with fresh lubricant to maintain optimal performance, reduce wear, and extend the lifespan of the worm gear speed reducer.

Additional information

| Edited by | Yjx |

|---|