WPDKS Worm Gear Reducers/Worm Gearbox

The WPDKS worm gear reducer, commonly known as a worm gearbox, is a high-efficiency mechanical device specifically designed for industrial power transmission. It operates using a worm (a screw-like gear) meshing with a worm wheel, enabling exceptional torque multiplication and compactness. With reduction ratios ranging from 7.5:1 to 100:1 in single-stage setups and up to 10,000:1 in double-reduction configurations, it is ideal for applications requiring precise speed control and high torque output.

The WPDKS worm gear reducer, commonly known as a worm gearbox, is a high-efficiency mechanical device specifically designed for industrial power transmission. It operates using a worm (a screw-like gear) meshing with a worm wheel, enabling exceptional torque multiplication and compactness. With reduction ratios ranging from 7.5:1 to 100:1 in single-stage setups and up to 10,000:1 in double-reduction configurations, it is ideal for applications requiring precise speed control and high torque output.

The WPDKS worm gearbox is available in sizes from 50 to 250, offering flexibility for various industrial needs. Its structure features a durable cast iron housing and precision-machined components, ensuring long service life and low noise operation. It supports multiple mounting options (horizontal and vertical) and configurations such as solid or hollow output shafts, making it adaptable to diverse setups. Additionally, its self-locking capability under certain conditions enhances safety in applications like conveyors, elevators, and packaging machines.

WPDKS Worm Gear Reducer Specifications

| Product Name: | WPDKS Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPDKS |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.18kW~15kW |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

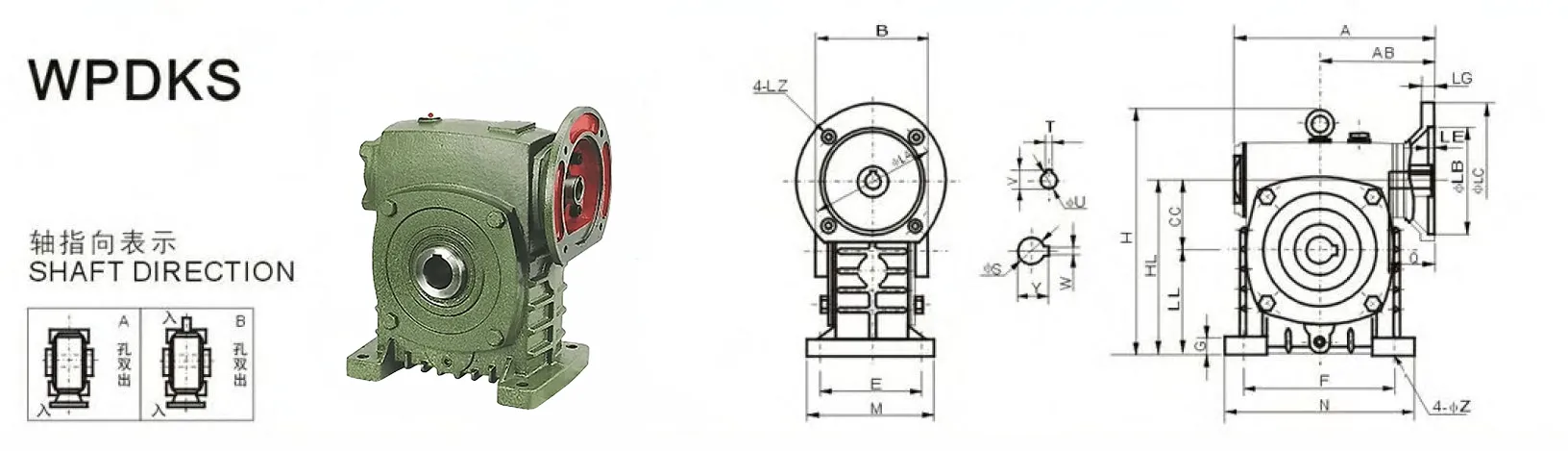

WPDKS Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | A | AB | B | CC | H | LL | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 135 | 75 | 85 | 40 | 138 | 60 | 90 | 100 | 70 | 80 | 13 | 10 |

| 50 | 0.18 | 151 | 83 | 105 | 50 | 180 | 80 | 120 | 140 | 95 | 110 | 15 | 11 | |

| 60 | 0.37 | 167 | 91 | 110 | 60 | 207 | 90 | 130 | 150 | 105 | 120 | 20 | 11 | |

| 70 | 0.37 | 200 | 109 | 130 | 70 | 238 | 105 | 150 | 190 | 115 | 150 | 20 | 15 | |

| 70 | 0.75 | 202 | 111 | 130 | 70 | 238 | 105 | 150 | 190 | 115 | 150 | 20 | 15 | |

| 80 | 0.75 | 225 | 125 | 150 | 80 | 273 | 120 | 170 | 220 | 135 | 180 | 20 | 15 | |

| 100 | 1.5 | 280 | 148 | 160 | 100 | 334 | 150 | 190 | 260 | 155 | 220 | 25 | 15 | |

| 120 | 2.2 | 333 | 181 | 175 | 120 | 423 | 180 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 120 | 3.0 | 333 | 181 | 175 | 120 | 423 | 180 | 230 | 320 | 180 | 260 | 30 | 18 | |

| 135 | 3.0 | 375 | 202 | 210 | 135 | 482 | 215 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 135 | 4.0 | 375 | 202 | 210 | 135 | 482 | 215 | 250 | 350 | 200 | 290 | 30 | 18 | |

| 155 | 4.0 | 448 | 247 | 252 | 155 | 541 | 235 | 280 | 390 | 220 | 320 | 35 | 20 | |

| 155 | 5.5 | 448 | 247 | 252 | 155 | 541 | 235 | 280 | 390 | 220 | 320 | 35 | 20 | |

| 175 | 5.5 | 481 | 262 | 255 | 175 | 600 | 260 | 310 | 430 | 250 | 350 | 40 | 20 | |

| 175 | 7.5 | 481 | 262 | 255 | 175 | 600 | 260 | 310 | 430 | 250 | 350 | 40 | 20 | |

| 200 | 11.0 | 543 | 285 | 319 | 200 | 677 | 290 | 360 | 480 | 290 | 390 | 40 | 22 | |

| 250 | 11.0 | 615 | 330 | 385 | 250 | 824 | 350 | 460 | 560 | 380 | 480 | 45 | 27 | |

| 250 | 15.0 | 615 | 330 | 385 | 250 | 824 | 350 | 460 | 560 | 380 | 480 | 45 | 27 |

| Flange | Input hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 16 | 6×18.8 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 20 | 6×22.8 | 8 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 25 | 8×28.3 | 10.5 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 35 | 10×38.3 | 25 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 40 | 12×43.3 | 38 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 45 | 14×48.8 | 60 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 60 | 18×64.4 | 85 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 70 | 20×74.9 | 120 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 80 | 22×85.4 | 150 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 85 | 22×90.4 | 218 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 110 | 28×116.4 | 350 |

WPDKS Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPDKS Worm Gear Speed Reducer Advantages

- High Torque Output

The WPDKS worm gear speed reducer delivers exceptional torque multiplication due to its worm and wheel design. This allows it to handle heavy loads efficiently, making it ideal for demanding industrial applications such as conveyors, mixers, and material handling equipment, ensuring reliable performance under stress. - Compact and Space-Saving Design

Its compact structure maximizes space efficiency without compromising power. The worm gear gearbox integrates high reduction ratios within a small footprint, making it suitable for installations in confined spaces, such as automated machinery or compact production lines, while maintaining robust functionality. - Self-Locking Capability

The WPDKS worm drive gearbox offers self-locking under specific conditions, preventing back-driving and enhancing safety. This feature is critical in applications like hoists or elevators, where unintended reverse motion could be hazardous, providing operational stability and reducing the need for additional braking systems. - Low Noise and Smooth Operation

Precision-engineered components and high-quality lubrication minimize noise and vibration. The worm reducer gearbox ensures smooth, quiet performance, which is essential in environments like food processing or packaging, where reduced noise levels improve working conditions and meet strict industry standards. - Durable and Low Maintenance

Constructed with a robust cast iron housing and high-quality alloy steel gears, the WPDKS worm gear reducers are built for longevity. Its design reduces wear and tear, requiring minimal maintenance, which lowers operational costs and downtime in industries like manufacturing or logistics. - Versatile Mounting and Configuration

The worm gear reducer gearbox supports multiple mounting options (horizontal, vertical, or flange-mounted) and configurations like solid or hollow output shafts. This versatility allows seamless integration into diverse systems, such as textile machinery or automation lines, enhancing adaptability across various industrial applications.

WPDKS Worm Drive Gearbox Application Fields

- Conveyor Systems

WPDKS Worm Drive Gearboxes are widely used in conveyor systems for material handling in industries like mining and logistics. Their high torque output and compact design ensure efficient movement of heavy loads, enhancing productivity in automated transport lines. - Packaging Machinery

In packaging industries, WPDKS gearboxes drive equipment like filling, sealing, and labeling machines. Their smooth operation and precise speed control ensure accurate performance, while the compact size fits seamlessly into space-constrained setups, improving efficiency in high-speed production environments. - Elevators and Hoists

The self-locking feature of WPDKS gearboxes makes them ideal for elevators and hoists in construction and warehousing. This capability prevents unintended reverse motion, ensuring safety and reliability when lifting heavy loads or personnel in demanding operational conditions. - Textile Machinery

WPDKS gearboxes power textile machines such as spinning and weaving equipment. Their ability to provide consistent torque and low-noise operation supports precise control in fabric production, contributing to high-quality output and reduced maintenance in textile manufacturing processes. - Food Processing Equipment

In food processing, WPDKS gearboxes drive mixers, grinders, and slicers. Their durable, low-maintenance design and quiet operation meet hygiene and noise standards, ensuring reliable performance in sensitive environments while handling variable loads with precision and efficiency. - Automation and Robotics

WPDKS gearboxes are integral to automation systems and robotic arms in manufacturing. Their versatile mounting options and high reduction ratios enable precise motion control, supporting complex tasks in assembly lines and improving accuracy in automated industrial applications.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Textile Industry |

|  |

| Worm Gearbox for Chemical Industry | Worm Gearbox for Food and Beverage Industry |

WPDKS Worm Gearbox Repairs

- Inspection and Fault Diagnosis

The first step in repairing a worm gearbox is a thorough inspection to identify faults. Technicians check for wear, cracks, or damage in the worm, worm wheel, bearings, and housing. Accurate fault diagnosis ensures the correct repair process is applied, minimizing downtime. - Replacement of Worn Components

Key components like the worm gear, worm wheel, and bearings may need replacement if excessive wear or damage is detected. Using precision-engineered replacement parts ensures the gearbox regains its original performance while maintaining efficiency and torque transmission capabilities. - Lubrication System Maintenance

Proper lubrication is essential for the smooth operation of the gearbox. During repairs, old or degraded lubricant is drained, and the system is cleaned. Fresh, high-quality lubricant is added to reduce friction, prevent overheating, and extend the lifespan of the gearbox. - Alignment and Assembly Adjustments

Misalignment of internal components can cause noise, vibration, and reduced efficiency. During repairs, technicians realign the worm and worm wheel to ensure proper meshing. Adjustments are made with precision tools to restore optimal performance and prevent premature wear or further damage. - Seal and Gasket Replacement

Damaged seals and gaskets can lead to lubricant leakage, resulting in inefficient operation and potential damage. As part of the repair process, all seals and gaskets are inspected and replaced if necessary. This ensures the gearbox remains properly sealed and protected against contaminants. - Performance Testing and Quality Assurance

After repairs, the worm reduction gearbox undergoes rigorous performance testing to ensure all issues have been resolved. Technicians check for noise, vibration, and proper torque output. Quality assurance measures confirm the gearbox meets operational standards before it is reinstalled or returned to service.

Additional information

| Edited by | Yjx |

|---|