WPDKA Worm Gear Reducers/Worm Gearbox

WPDKA worm gear reducers, part of the WP series worm gearbox, are mechanical power transmission devices designed for efficient speed reduction and torque multiplication in compact, industrial applications. These gearboxes feature a worm (a screw-like gear) and a worm wheel, oriented at a 90-degree angle, enabling high gear ratios. The WPDKA worm gearbox, with a lower input flange and vertical downward output shaft, uses a cast iron housing and single-stage worm gears for durability. Key features include solid or hollow output shaft options, quiet operation, and self-locking capabilities at higher ratios (50:1 to 60:1).

WPDKA worm gear reducers, part of the WP series worm gearbox, are mechanical power transmission devices designed for efficient speed reduction and torque multiplication in compact, industrial applications. These gearboxes feature a worm (a screw-like gear) and a worm wheel, oriented at a 90-degree angle, enabling high gear ratios (typically 7.5:1 to 100:1, or up to 10,000:1 with double reduction). The WPDKA worm gearbox, with a lower input flange and vertical downward output shaft, uses a cast iron housing and single-stage worm gears for durability. Key features include solid or hollow output shaft options, quiet operation, and self-locking capabilities at higher ratios (50:1 to 60:1). They are ideal for space-constrained applications like conveyors, elevators, and packaging equipment, offering low maintenance, corrosion resistance, and compatibility with IEC motor flanges.

WPDKA Worm Gear Reducer Specifications

| Product Name: | WPDKA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPDKA |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.06KW~15KW |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

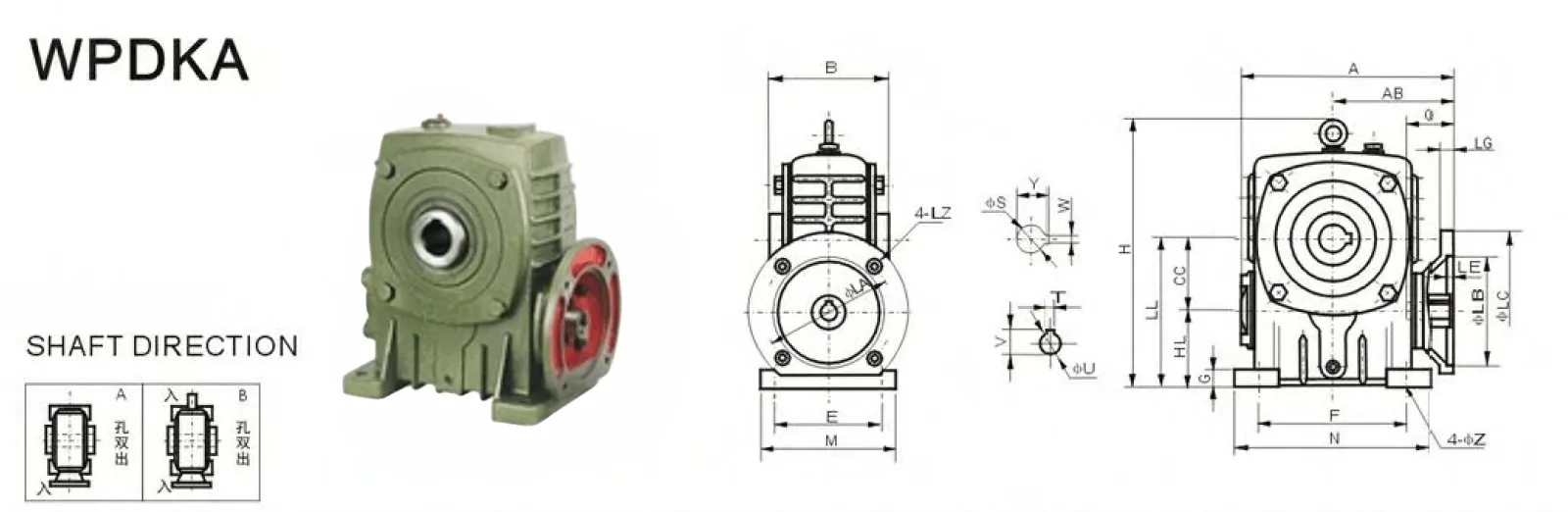

WPDKA Worm Gearbox Dimensions

| Model | Input Power (kW) | Ratio | A | AB | B | CC | H | HL | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 0.12 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 75 | 85 | 40 | 138 | 40 | 9C | 100 | 70 | 80 | 13 | 10 |

| 50 | 0.18 | 151 | 83 | 105 | 50 | 176 | 50 | 12D | 140 | 95 | 110 | 15 | 11 | |

| 60 | 0.37 | 167 | 91 | 110 | 60 | 204 | 60 | 13D | 150 | 105 | 120 | 20 | 11 | |

| 70 | 0.37 | 200 | 109 | 130 | 70 | 236 | 70 | 15D | 190 | 115 | 150 | 20 | 15 | |

| 70 | 0.75 | 202 | 111 | 130 | 70 | 238 | 105 | 15D | 190 | 115 | 150 | 20 | 15 | |

| 80 | 0.75 | 225 | 125 | 150 | 80 | 268 | 80 | 17D | 220 | 135 | 180 | 20 | 15 | |

| 100 | 1.5 | 280 | 148 | 160 | 100 | 334 | 100 | 19D | 270 | 155 | 220 | 25 | 15 | |

| 120 | 2.2 | 333 | 181 | 175 | 120 | 430 | 120 | 23D | 320 | 180 | 260 | 30 | 18 | |

| 120 | 3.0 | 333 | 181 | 175 | 120 | 430 | 120 | 23D | 320 | 180 | 260 | 30 | 18 | |

| 135 | 3.0 | 375 | 202 | 210 | 135 | 480 | 135 | 25D | 350 | 200 | 290 | 30 | 18 | |

| 135 | 4.0 | 375 | 202 | 210 | 135 | 482 | 215 | 25D | 350 | 200 | 290 | 30 | 18 | |

| 155 | 4.0 | 425 | 224 | 256 | 155 | 531 | 135 | 27.5D | 390 | 220 | 320 | 35 | 20 | |

| 155 | 5.5 | 448 | 247 | 256 | 155 | 541 | 235 | 27.5D | 390 | 220 | 320 | 35 | 20 | |

| 175 | 5.5 | 481 | 262 | 282 | 175 | 600 | 160 | 31D | 430 | 250 | 350 | 40 | 20 | |

| 175 | 7.5 | 481 | 262 | 282 | 175 | 600 | 260 | 31D | 430 | 250 | 350 | 40 | 20 | |

| 200 | 7.5 | 543 | 285 | 320 | 200 | 666 | 175 | 36D | 480 | 290 | 390 | 40 | 22 | |

| 200 | 11.0 | 543 | 285 | 320 | 200 | 677 | 290 | 36D | 480 | 290 | 390 | 40 | 22 | |

| 250 | 11.0 | 615 | 330 | 400 | 250 | 800 | 200 | 46D | 560 | 380 | 480 | 45 | 27 | |

| 250 | 15.0 | 615 | 330 | 400 | 250 | 824 | 350 | 46D | 560 | 380 | 480 | 45 | 28 |

| Flange | Input hole | Output shaft | Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | LC | LE | LZ | Q | U | T×V | S | W×Y | (kg) |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 16 | 6×18.8 | 5 |

| 115 | 95 | 140 | 4 | M8 | 31 | 11 | 4×12.8 | 20 | 6×22.8 | 8 |

| 130 | 110 | 160 | 4 | M8 | 33 | 14 | 5×16.3 | 25 | 8×28.3 | 10.5 |

| 130 | 110 | 160 | 4 | M8 | 40 | 14 | 5×16.3 | 30 | 8×33.3 | 17 |

| 165 | 130 | 200 | 4 | M10 | 42 | 19 | 6×21.8 | 35 | 10×38.3 | 25 |

| 165 | 130 | 200 | 4.5 | M10 | 48 | 19 | 6×21.8 | 40 | 12×43.3 | 38 |

| 165 | 130 | 200 | 4.5 | M10 | 52 | 24 | 8×27.3 | 45 | 14×48.8 | 60 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 60 | 18×64.4 | 85 |

| 215 | 180 | 250 | 5 | M12 | 63 | 28 | 8×31.3 | 70 | 20×74.9 | 120 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 80 | 22×85.4 | 150 |

| 265 | 230 | 300 | 5 | M12 | 83 | 38 | 10×41.3 | 85 | 22×90.4 | 218 |

| 300 | 250 | 350 | 6 | M16 | 114 | 42 | 12×45.3 | 110 | 28×116.4 | 350 |

WPDKA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPDKA Worm Gear Reducer Advantages

1. High Torque Output

WPDKA worm gear reducers deliver exceptional torque multiplication due to their worm and wheel design. This allows them to handle heavy loads efficiently, making them ideal for demanding applications like conveyors, mixers, and industrial machinery requiring robust power transmission in compact setups.

2. Compact and Space-Saving Design

The 90-degree angle between the worm and wheel enables a compact footprint. This makes worm reducer gearboxes perfect for applications with limited space, such as packaging equipment or small-scale automation systems, without compromising performance or efficiency in tight installations.

3. Self-Locking Capability

At higher gear ratios (typically 50:1 to 60:1), WPDKA worm gear speed reducers offer self-locking, preventing back-driving. This enhances safety and stability in applications like hoists or elevators, where maintaining position under load is critical, reducing the need for additional braking mechanisms.

4. Quiet and Smooth Operation

The sliding contact between the worm and wheel results in low-noise performance. This makes worm drive gearboxes suitable for environments requiring minimal noise, such as food processing or indoor automation systems, ensuring a quieter and more comfortable workspace.

5. Durable and Low Maintenance

Constructed with cast iron housing and high-quality materials, WPDKA right angle worm gearboxes resist wear and corrosion. Their robust design minimizes maintenance needs, ensuring long-term reliability in harsh industrial settings, reducing downtime, and lowering overall operational costs for businesses.

6. Versatile Motor Compatibility

Worm gear reducers feature IEC-standard motor flanges, allowing easy integration with various electric motors. This flexibility simplifies installation and upgrades in diverse applications, from material handling to robotics, enabling seamless adaptation to different power sources and system requirements.

WPDKA Worm Reducer Gearbox Applications

1. Conveyor Systems

Worm gear reducers are widely used in conveyor systems for material handling in industries like manufacturing and logistics. Their high torque and compact design ensure efficient movement of heavy loads, providing reliable speed control in automated production lines and warehouses.

2. Packaging Machinery

In packaging equipment, WPDKA worm gear gearboxes drive precise and consistent motion for tasks like filling, sealing, and labeling. Their quiet operation and self-locking feature at high ratios ensure stable performance, making them ideal for high-speed, space-constrained packaging lines in food and beverage industries.

3. Elevators and Hoists

WPDKA worm gear speed reducers are employed in elevators and hoisting systems due to their self-locking capability, which prevents back-driving under load. This ensures safety and stability in vertical lifting applications, such as construction hoists or warehouse cargo lifts, with minimal maintenance requirements.

4. Agricultural Equipment

In agricultural machinery like seeders, harvesters, or irrigation systems, worm reducer gearboxes provide robust torque for heavy-duty tasks. Their durable cast iron housing withstands harsh outdoor conditions, ensuring reliable operation in rugged environments while maintaining efficiency and low maintenance costs.

5. Robotics and Automation

WPDKA worm drive gearboxes support precise motion control in robotic arms and automated systems. Their compact size and compatibility with IEC motor flanges make them suitable for space-limited automation setups, enabling smooth, high-torque performance in assembly lines or robotic workstations.

6. Mixing and Agitation Equipment

In chemical, pharmaceutical, or food processing industries, worm gear reducer gearboxes power mixers and agitators. Their ability to handle high torque and maintain consistent speeds ensures thorough mixing of viscous materials, while their quiet operation suits sensitive production environments.

|  |

| Worm Gearbox for Conveyor Equipment | Worm Gearbox for Construction Industry |

|  |

| Worm Gearbox for Food and Beverage Industry | Worm Gearbox for Chemical Industry |

Helical Gearbox Vs Worm Gearbox

Helical gearboxes and worm gearboxes are two widely used types of mechanical gear systems, but they differ significantly in design, operation, and applications.

Design and Construction

Helical gearboxes feature cylindrical gears with angled teeth, allowing smooth, continuous meshing. This design distributes load across multiple teeth, enhancing durability. Worm gearboxes, like the WPDKA, use a worm (screw-like gear) meshing with a worm wheel at a 90-degree angle, creating a compact, right-angle output. This makes worm gearboxes ideal for space-constrained setups.

Efficiency

Helical gearboxes are highly efficient, typically achieving 95-98% efficiency due to rolling contact between teeth, minimizing energy loss. Worm gearboxes, however, have lower efficiency (50-90%, depending on the ratio) due to sliding contact, which generates more friction and heat, especially at higher ratios.

Torque and Speed

Helical gearboxes offer moderate to high torque and are suitable for high-speed applications, as their design supports a wide range of ratios (1:1 to 10:1 typically). Worm gearboxes excel in high-torque, low-speed applications, with ratios often ranging from 7.5:1 to 100:1, or higher with double reduction, making them ideal for heavy loads.

Self-Locking and Noise

Worm gearboxes often provide self-locking at higher ratios (50:1 to 60:1), preventing back-driving, which is advantageous for applications like hoists. They operate quietly due to sliding action. Helical gearboxes lack self-locking but produce less noise at high speeds due to smoother meshing.

Applications and Maintenance

Helical gearboxes suit high-speed, high-power applications like industrial machinery or automotive systems, requiring regular lubrication. Worm gearboxes, with lower maintenance needs, are used in conveyors, elevators, or packaging equipment. Their durability suits harsh environments, but efficiency losses may increase operating costs.

|  |

| Helical Gearbox | Worm Gearbox |

Additional information

| Edited by | Yjx |

|---|