WPA Worm Gear Reducers/Worm Gearbox

A WPA worm gear reducer, also known as a worm gearbox, is a compact mechanical power transmission device designed to reduce rotational speed while increasing torque. It consists of a worm (a screw-like gear) meshing with a worm wheel (a toothed gear) at a 90-degree angle, enabling efficient power transfer between non-intersecting shafts. WPA worm gearboxes are widely used in industries like metallurgy, mining, and packaging for applications such as conveyor drives and lifting systems.

A WPA worm gear reducer, also known as a worm gearbox, is a compact mechanical power transmission device designed to reduce rotational speed while increasing torque. It consists of a worm (a screw-like gear) meshing with a worm wheel (a toothed gear) at a 90-degree angle, enabling efficient power transfer between non-intersecting shafts. The WPA series worm gear speed reducer, typically made with a cast iron housing and a bronze worm gear, offers a high reduction ratio (10:1 to 60:1), self-locking capabilities under certain conditions, and smooth, quiet operation. Its robust design, featuring a lower input shaft and upper output shaft, ensures durability and low maintenance. WPA worm gearboxes are widely used in industries like metallurgy, mining, and packaging for applications such as conveyor drives and lifting systems.

WPA Worm Gear Reducer Specifications

| Product Name: | WPA Worm Gearbox/ Worm Gear Speed Reducer |

| Model: | WPA |

| Size: | 40,50,60,70,80,100,120,135,155,175,200,250 |

| Ratio: | 1:10,15,20,25,30,40,50,60,200,300,400,500,600,800,900 |

| Color: | Blue/Green/Black/Customized |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear: Copper9-4 | |

| Shaft: chromium steel 45# | |

| Packing: | Carton and Plywood Case |

| Bearing: | C&U/SKF/HRB, or on customer request |

| Seal: | NAK/SKF/KSK, or on customer request |

| Warranty: | one year |

| Input Power: | 0.06KW~15KW |

| IEC Flange: | 56B14, 63B14, 63B5, 63B5, 71B14,80B14, etc. |

| Lubricant: | Synthetic & Mineral |

| Usage: | Plastics, metallurgy, beverages, mining, lifting and transportation, chemical construction, and so on. |

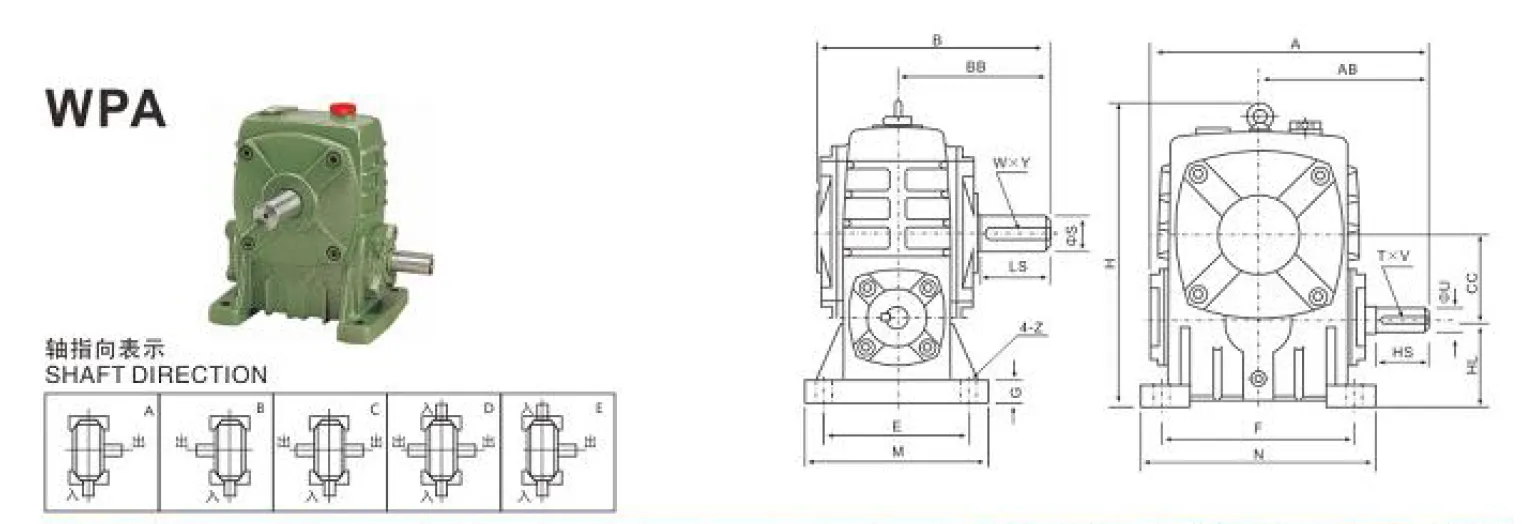

WPA Worm Gearbox Dimensions

| Model | Ratio | A | AB | B | BB | CC | H | HL | M | N | E | F | G | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 143 | 87 | 114 | 74 | 40 | 138 | 40 | 9C | 100 | 70 | 80 | 13 | 10 |

| 50 | 175 | 108 | 150 | 97 | 50 | 176 | 50 | 12D | 140 | 95 | 110 | 15 | 12 | |

| 60 | 198 | 120 | 168 | 112 | 60 | 204 | 60 | 13D | 150 | 105 | 120 | 20 | 12 | |

| 70 | 231 | 140 | 194 | 131 | 70 | 236 | 70 | 15D | 190 | 115 | 150 | 20 | 15 | |

| 80 | 261 | 160 | 214 | 142 | 80 | 268 | 80 | 17D | 220 | 135 | 180 | 20 | 15 | |

| 100 | 322 | 190 | 254 | 169 | 100 | 336 | 100 | 19D | 270 | 155 | 220 | 25 | 15 | |

| 120 | 371 | 219 | 282 | 190 | 120 | 430 | 120 | 23D | 320 | 180 | 260 | 30 | 18 | |

| 135 | 422 | 249 | 317 | 210 | 135 | 480 | 135 | 25D | 350 | 200 | 290 | 30 | 18 | |

| 147 | 432 | 256 | 320 | 210 | 147 | 460 | 123 | 25D | 350 | 200 | 280 | 32 | 18 | |

| 155 | 497 | 295 | 382 | 252 | 155 | 531 | 135 | 27.5D | 390 | 220 | 320 | 35 | 21 | |

| 175 | 534 | 314 | 388 | 255 | 175 | 600 | 160 | 31D | 430 | 250 | 350 | 40 | 21 | |

| 200 | 580 | 342 | 456 | 319 | 200 | 666 | 175 | 36D | 480 | 290 | 390 | 40 | 24 | |

| 250 | 703 | 420 | 552 | 385 | 250 | 800 | 200 | 46D | 560 | 380 | 480 | 45 | 28 |

| Size | Ratio | input shaft | output shaft | Weight (kg) | Oil quantity (L) | ||||

| HS | U | TXV | LS | S | WXY | ||||

| 40 | 1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 | 25 | 12 | 4x2.5 | 28 | 14 | 5X3 | 4 | 0.13 |

| 60 | 30 | 12 | 4x2.5 | 40 | 17 | 5x3 | 7 | 0.17 | |

| 70 | 40 | 15 | 5x3 | 50 | 22 | 7x4 | 10 | 0.22 | |

| 80 | 40 | 18 | 5x3 | 60 | 28 | 7x4 | 15 | 0.60 | |

| 100 | 50 | 22 | 7x4 | 65 | 32 | 10x4.5 | 20 | 0.85 | |

| 120 | 50 | 25 | 7x4 | 75 | 38 | 10x4.5 | 35 | 1.50 | |

| 135 | 65 | 30 | 7x4 | 85 | 45 | 12x4.5 | 60 | 3.20 | |

| 147 | 75 | 35 | 10x4.5 | 95 | 55 | 16X6 | 80 | 3.60 | |

| 155 | 75 | 35 | 10x4.5 | 95 | 55 | 16x6 | 98 | 3.70 | |

| 175 | 85 | 40 | 12x5 | 110 | 60 | 18X7 | 110 | 3.80 | |

| 200 | 85 | 45 | 14x5.5 | 110 | 65 | 18X7 | 150 | 4.60 | |

| 250 | 95 | 50 | 14x5.5 | 125 | 70 | 20x7.5 | 215 | 6.50 | |

| 110 | 60 | 18x7 | 155 | 90 | 25x9 | 360 | 9.00 | ||

WPA Worm Reducer Gearbox Part Structure

| 1 | Frame | 13 | O Ring |

| 2 | Worm Wheel | 14 | O Ring |

| 3 | Worm Shaft | 15 | Oil Hole Cover |

| 4 | Output Shaft | 16 | Pin |

| 5 | Output Shaft Cover | 17 | Oil Guage |

| 6 | Output Shaft Cover | 18 | Oil Plug |

| 7 | Input Shaft Cover | 19 | Key |

| 8 | Input Shaft Cover | 20 | Key |

| 9 | Bearing | 21 | Key |

| 10 | Bearing | 22 | Intl.hex Screw |

| 11 | Oil Seal | 23 | Intl.hex Screw |

| 12 | Oil Seal | 24 | Shim |

WPA Worm Gear Reducer Design Features

- High Reduction Ratio

The WPA worm gear reducer achieves high reduction ratios, typically ranging from 10:1 to 60:1, allowing significant speed reduction and torque amplification. This makes it ideal for applications requiring precise control and high output torque, such as conveyor systems and heavy machinery, ensuring efficient power transmission. - Compact and Robust Housing

Constructed with a cast iron housing, the WPA worm drive gearbox offers exceptional durability and resistance to wear. Its compact design optimizes space in industrial setups, providing structural integrity under heavy loads while maintaining a lightweight profile for easy installation and maintenance in various applications. - Self-Locking Capability

The worm and worm wheel configuration enables self-locking under specific conditions, preventing back-driving. This feature ensures safety and stability in applications like lifting equipment, where maintaining position without external braking is critical, enhancing operational reliability in demanding industrial environments. - Smooth and Quiet Operation

The WPA worm gear speed reducer’s worm gear meshing produces minimal noise and vibration due to its precise engineering. This ensures smooth operation, making it suitable for noise-sensitive environments like packaging or food processing, where consistent performance and low acoustic interference are essential. - Efficient Heat Dissipation

Designed with integrated cooling fins and high-quality materials, the WPA worm gear drive gearbox effectively dissipates heat generated during operation. This thermal management extends the lifespan of internal components, ensuring reliable performance in continuous-duty applications like mining or metallurgy under high-temperature conditions. - Low Maintenance Design

The WPA worm gear reducer incorporates high-quality bronze worm gears and sealed bearings, reducing wear and maintenance needs. Its robust construction minimizes downtime, making it cost-effective for industries requiring long-term, reliable operation, such as material handling and automation systems.

WPA Worm Drive Gearbox Applications

- Metallurgy Industry

WPA worm drive gearboxes are extensively used in metallurgy for driving rolling mills and conveyor systems. Their high torque output and self-locking feature ensure precise control and safety in heavy-duty operations, handling molten metal and heavy loads with reliable performance. - Mining Industry

In mining, WPA worm gear reducers power equipment like crushers and belt conveyors. Their robust cast iron housing withstands harsh environments, while high reduction ratios provide the torque needed for moving heavy materials, ensuring efficient and durable operation in demanding conditions. - Packaging Industry

WPA worm gearboxes drive packaging machinery, such as fillers and sealers. Their smooth, quiet operation minimizes disruptions in noise-sensitive environments, and compact design allows integration into space-constrained setups, ensuring precise and reliable performance for high-speed packaging processes. - Material Handling Industry

Used in cranes and hoists, WPA worm drive reduction gearboxes offer self-locking capabilities to secure heavy loads. Their high torque and low maintenance design make them ideal for continuous material handling, improving efficiency and safety in warehouses and logistics operations. - Food Processing Industry

WPA worm drive gearboxes are employed in food processing equipment like mixers and conveyors. Their sealed design prevents contamination, and quiet operation suits cleanroom environments. The durable construction ensures reliable performance, meeting stringent hygiene and efficiency standards in food production. - Construction Industry

In construction, WPA worm reducer gearboxes drive machinery like concrete mixers and lifting systems. Their ability to handle high torque and resist environmental stress makes them suitable for rugged sites, providing consistent power transmission and durability for heavy-duty construction tasks.

|  |

| Worm Gearbox for Mining and Quarrying Industry | Worm Gearbox for Metallurgy Industry |

|  |

| Worm Gearbox for Construction Industry | Worm Gearbox for Food and Beverage Industry |

Additional information

| Edited by | Yjx |

|---|