Tilt Hydraulic Cylinder for Small Tonnage Forklift

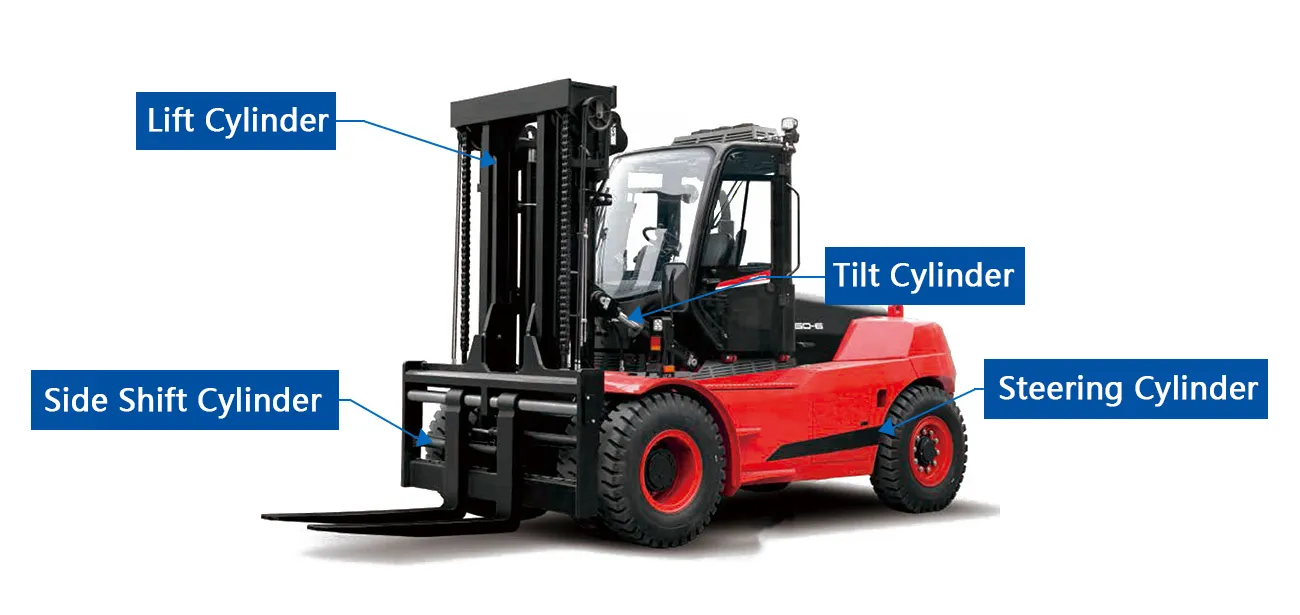

A tilt hydraulic cylinder for a small tonnage forklift is a double-acting hydraulic component that controls the forward and backward tilting of the forklift’s mast, typically on models with a lifting capacity of 1 to 3 tons. It uses pressurized hydraulic fluid to move a piston within a sealed cylinder, enabling precise mast angle adjustments to secure and stabilize loads during lifting or placement. Usually, two tilt cylinders are mounted, connecting the mast’s stationary rails to the forklift frame, ensuring uniform tilting and preventing lateral flexing.

A tilt hydraulic cylinder for a small tonnage forklift is a double-acting hydraulic component that controls the forward and backward tilting of the forklift’s mast, typically on models with a lifting capacity of 1 to 3 tons. It uses pressurized hydraulic fluid to move a piston within a sealed cylinder, enabling precise mast angle adjustments to secure and stabilize loads during lifting or placement. Usually, two tilt cylinders are mounted, connecting the mast’s stationary rails to the forklift frame, ensuring uniform tilting and preventing lateral flexing.

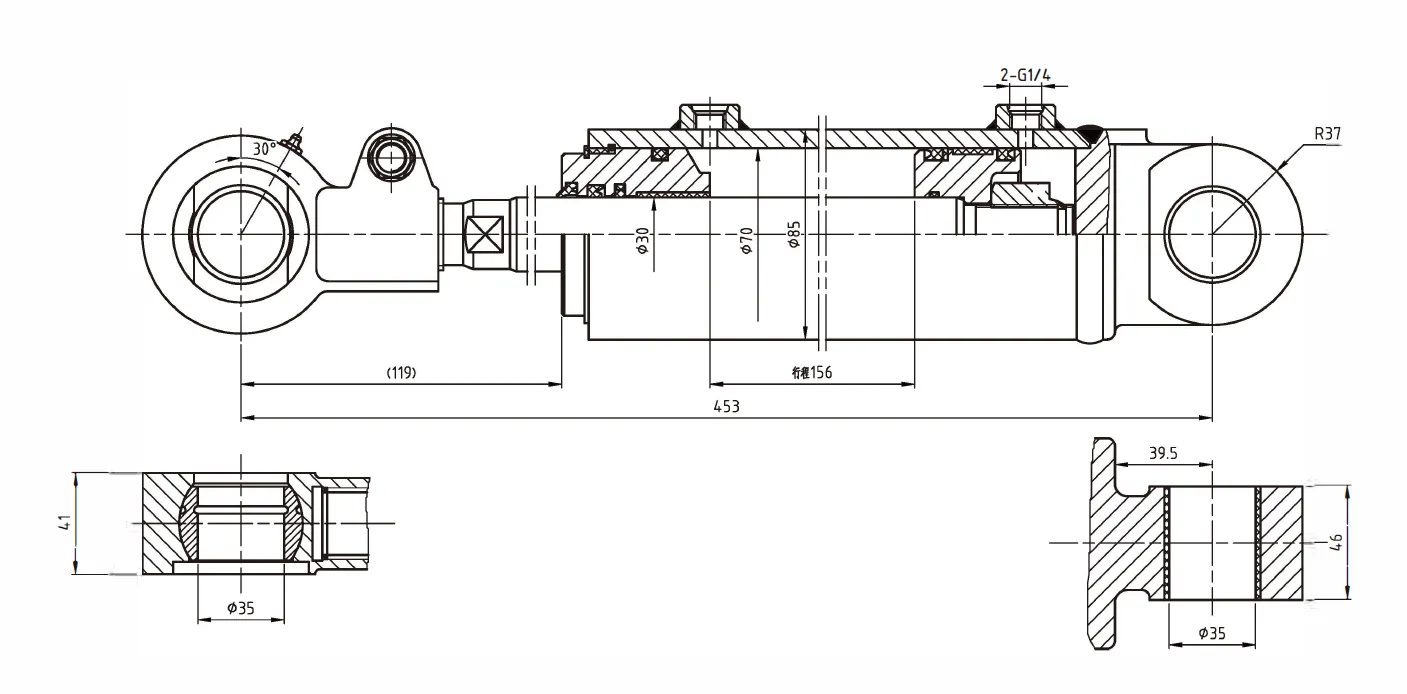

Forklift Tilt Hydraulic Cylinder Dimensions

|

|

|

|

| Forklift Tilt Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance |

Weight |

| CMN11112001 | Φ70xΦ30x156 | 18.1MPa | 27MPa | 156 | 453 | 12kg |

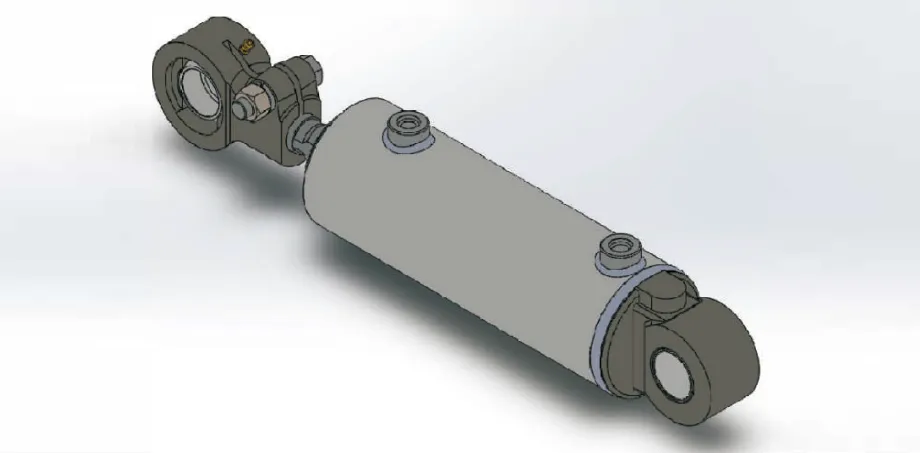

| Product Name: | Tilt Hydraulic Cylinder |

| Function: | Implement the forward and backward tilting action of the forklift gantry |

| Cylinder diameter: | 50mm-85mm |

| Rod diameter: | 25mm-35mm |

| Travel: | 37mm-156mm |

| Maximum pressure: | 18.1MPa |

| Maximum thrust: | 103KN |

Small Tonnage Forklift Hydraulic Cylinder Types

Forklift Tilt Cylinder vs Forklift Lifting Cylinder

| Aspect | Forklift Tilt Cylinder | Forklift Lifting Cylinder |

|---|---|---|

| Primary Function | Controls the forward and backward tilting of the forklift mast to stabilize loads. | Raises and lowers the forklift mast to lift or lower loads. |

| Location on Forklift | Connects the stationary mast rails to the forklift frame, typically on both sides. | Mounted within or alongside the mast assembly, often centrally or in pairs. |

| Number of Cylinders | Usually two cylinders, one on each side of the mast for balanced tilting. | Typically one or two, depending on the forklift design and lifting capacity. |

| Hydraulic Action | Double-acting, allowing controlled movement in both tilt directions (forward/backward). | Single-acting or double-acting, primarily for upward force, with gravity aiding descent. |

| Operating Pressure | Operates at around 2,500–3,000 psi, suited for precise tilting. | Higher pressure, often 3,000–4,000 psi, to handle heavy lifting loads. |

| Cylinder Size | Smaller and more compact to fit the tilting mechanism in small tonnage forklifts. | Larger and longer to accommodate the extended stroke needed for lifting heights. |

| Stroke Length | Shorter stroke, typically 4–8 inches, for limited angular movement. | Longer stroke, often 20–60 inches, to achieve full mast extension. |

| Mounting Orientation | Angled or diagonal to facilitate mast tilting motion. | Vertical or near-vertical to align with the mast’s lifting path. |

| Load Capacity Influence | Does not directly affect lifting capacity; focuses on load stability during tilting. | Directly determines the forklift’s maximum lifting capacity. |

| Material Construction | Steel with high-strength seals (e.g., polyurethane, PTFE) to withstand tilt stresses. | Heavy-duty steel with robust seals to handle higher loads and pressures. |

| Maintenance Frequency | Regular checks for leaks and seal wear due to frequent tilting cycles. | Requires maintenance for seals and hydraulic fluid, with focus on load-bearing components. |

| Impact on Maneuverability | Enhances maneuverability by allowing precise load positioning in tight spaces. | Less impact on maneuverability; primarily affects vertical load handling. |

| Failure Consequences | Failure may cause unstable load tilting, risking load spillage or tipping. | Failure can prevent lifting or cause sudden load drops, posing significant safety risks. |

| Typical Application | Used in small tonnage forklifts (1–3 tons) for tasks like pallet stacking in warehouses. | Essential for all forklifts, especially for high-lift tasks in storage or loading docks. |

|

|

| Forklift Tilt Cylinder | Forklift Lifting Cylinder |

|---|

Choose the Right Tilt Hydraulic Cylinder for Forklift

- Load Capacity Compatibility

Ensure the tilt hydraulic cylinder matches the forklift's load capacity. A cylinder with insufficient capacity can cause instability, while an oversized one may lead to unnecessary costs and reduced operational efficiency. Accurate load rating is essential. - Stroke Length and Tilt Angle

Choose a cylinder with the appropriate stroke length to achieve the desired tilt angle for your forklift mast. The right tilt angle ensures optimal load handling, stability, and maneuverability in various operational settings. - Material and Durability

The cylinder material should be durable and resistant to wear, corrosion, and extreme conditions. High-quality steel or alloy construction ensures longevity and reduces downtime caused by frequent repairs or replacements in demanding environments. - Hydraulic Pressure Rating

Check the cylinder’s hydraulic pressure rating to ensure compatibility with the forklift’s hydraulic system. A mismatch in pressure rating can lead to performance issues, leaks, or damage to both the cylinder and the forklift. - Mounting Configuration

Select a cylinder with the correct mounting configuration to fit your forklift model. Proper mounting ensures secure installation, smooth operation, and prevents misalignment that could impair the cylinder’s performance or damage other components.

Additional information

| Edited by | Yjx |

|---|