Tilt Hydraulic Cylinder for Large Tonnage Forklift

A tilt hydraulic cylinder for a large tonnage forklift is a double-acting hydraulic component designed to control the forward and backward tilting of the forklift’s mast, enabling precise load handling for heavy-duty applications. Typically used in forklifts with capacities exceeding 10 tons, these hydraulic tilt cylinders are robust, constructed from high-strength steel to withstand high pressures and heavy loads.

A tilt hydraulic cylinder for a large tonnage forklift is a double-acting hydraulic component designed to control the forward and backward tilting of the forklift’s mast, enabling precise load handling for heavy-duty applications. Typically used in forklifts with capacities exceeding 10 tons, these hydraulic tilt cylinders are robust, constructed from high-strength steel to withstand high pressures and heavy loads.

They feature a piston rod, cylinder barrel, seals, and ports for hydraulic fluid, which is pressurized to move the piston, tilting the mast to stabilize loads during lifting or placement. Two hydraulic tilt cylinders are often mounted on the forklift’s frame, connecting to the mast’s stationary rails, ensuring uniform control and preventing lateral flexing.

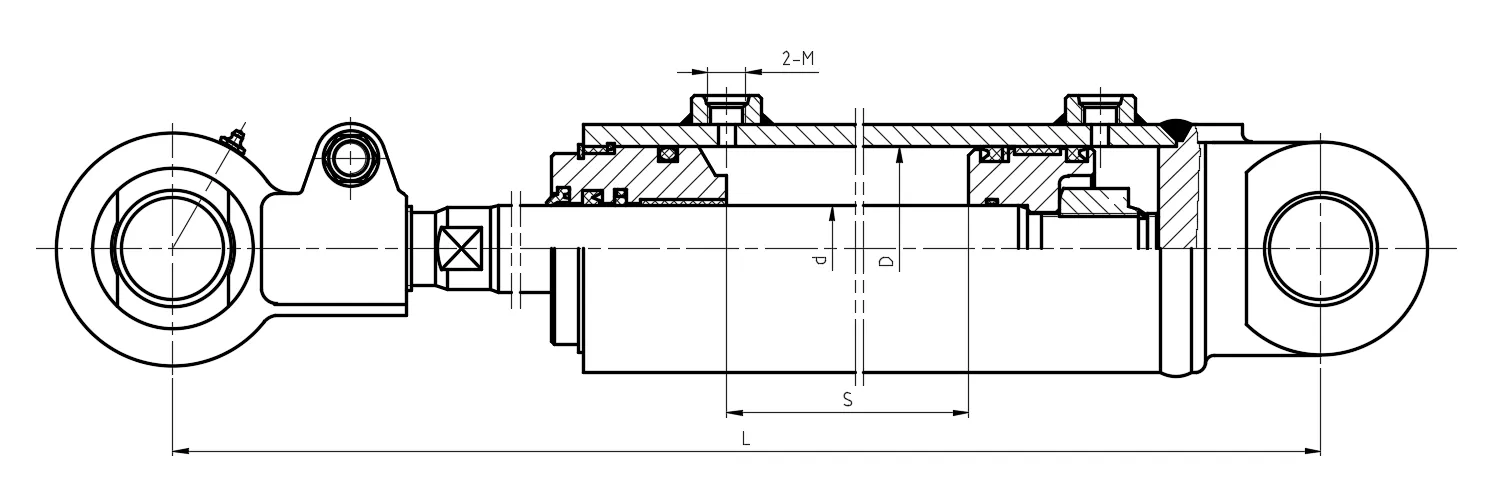

Forklift Tilt Hydraulic Cylinder Dimensions

| drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| A30M300-600000-000B | Φ70 | Φ30 | 156 | 453 | 18.1MPa | 2-G1/4 | 12kg |

| A35M300-600000-000C | Φ80 | Φ30 | 156 | 456.5 | 18.1MPa | 2-G1/4 | 13kg |

| A45M300-600000Z | Φ100 | Φ40 | 193 | 498 | 18.1MPa | 2-M16*1.5 | 22kg |

| Product Name: | Tilt Hydraulic Cylinder |

| Function: | Implement the forward and backward tilting action of the forklift gantry. |

| Cylinder diameter: | 90mm-220mm |

| Rod diameter: | 45mm-100mm |

| Travel: | 37mm-363mm |

| Maximum pressure: | 27MPa |

| Maximum thrust: | 1026KN |

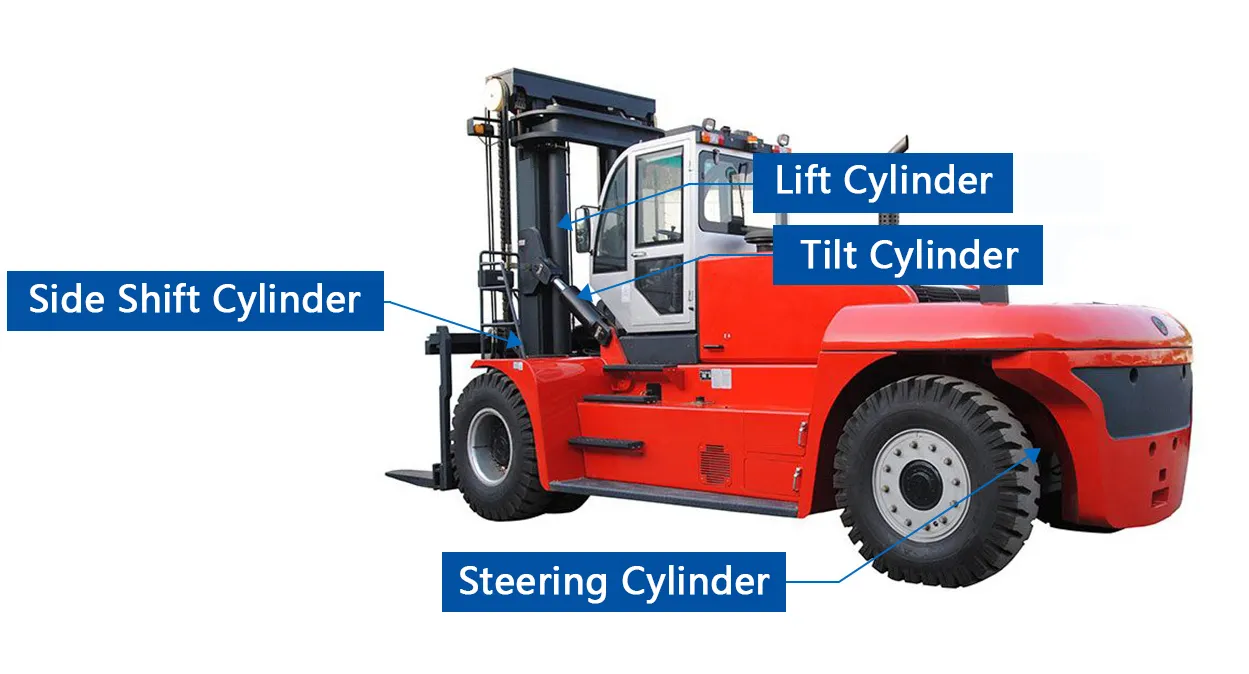

Large Tonnage Forklift Hydraulic Cylinder Types

- Tilt Hydraulic Cylinders

Tilt hydraulic cylinders are responsible for controlling the forward and backward tilting motion of the forklift mast. These cylinders ensure the secure handling of heavy loads by adjusting the mast angle. They are built with robust materials to handle high-pressure hydraulic operations while maintaining precision, stability, and safety during the lifting and depositing processes. - Lift Hydraulic Cylinders

Lift hydraulic cylinders provide the vertical lifting force required to raise and lower the forklift’s forks or platforms. These cylinders are designed to handle heavy weights and ensure smooth vertical movement. They operate using hydraulic pressure to move the piston, which lifts the load safely and efficiently in industrial and heavy-duty applications. - Steering Hydraulic Cylinders

Steering hydraulic cylinders aid in precise control of the forklift’s directional movement by adjusting the turning angle of the vehicle’s wheels. This type of cylinder ensures smooth and responsive steering, even under heavy load conditions. They are crucial for maneuvering the forklift in tight spaces or complex working environments. - Side Shift Hydraulic Cylinders

Side shift hydraulic cylinders enable lateral movement of the forklift forks, allowing loads to be shifted left or right without moving the entire forklift. This improves load positioning accuracy and operational efficiency. These cylinders are especially useful in confined spaces where repositioning the forklift would be challenging or time-consuming.

Forklift Hydraulic Tilt Cylinder Design Features

- High-Strength Materials

Forklift hydraulic tilt cylinders are constructed using high-strength materials such as alloy steel to ensure durability and resistance to wear and tear. These materials allow the cylinder to withstand high pressures and the heavy loads typically encountered in industrial applications, ensuring long-term reliability. - Heavy-Duty Seals

These forklift hydraulic cylinders use advanced heavy-duty seals that prevent hydraulic fluid leakage and maintain consistent performance. The seals are designed to endure extreme temperatures, high pressures, and prolonged usage, ensuring efficient operation and reduced maintenance requirements over time. - Precision Machining

The internal components of hydraulic tilt cylinders, such as pistons and rods, are manufactured with precision machining. This ensures smooth operation, reduces friction, and enhances the cylinder's overall efficiency and responsiveness, which is crucial for handling heavy loads. - Corrosion-Resistant Coating

To withstand harsh working conditions, these hydraulic cylinders are coated with corrosion-resistant materials, such as chrome plating or specialized paints. This design feature protects the cylinder from environmental factors like moisture, chemicals, and rust, extending its operational lifespan. - Adjustable Stroke Length

Forklift hydraulic tilt cylinders often feature an adjustable stroke length to accommodate varying mast tilt angles. This flexibility allows operators to handle different load types and adjust the mast position precisely for improved operational efficiency. - High-Pressure Tolerance

These tilt hydraulic cylinders are designed to handle high-pressure hydraulic systems, ensuring reliable performance under challenging conditions. The internal components are reinforced to prevent deformation or failure, maintaining safety and stability during heavy-duty operations.

Large Forklift Tilt Cylinder Application Scenarios

- Heavy Material Handling

Large forklift tilt cylinders enable precise mast tilting in large tonnage forklifts, facilitating safe transport and placement of heavy materials like steel coils or concrete blocks in industrial settings, ensuring stability during lifting and lowering operations. - Warehouse Stacking

In high-capacity warehouses, tilt hydraulic cylinders adjust the mast angle to align heavy pallets accurately, optimizing space utilization and enabling efficient stacking of oversized goods like lumber or industrial equipment on tall racks. - Construction Sites

Tilt cylinders support forklifts in construction environments by tilting the mast to handle uneven terrain, allowing stable positioning of heavy loads like precast concrete panels or large machinery components during installation. - Port and Shipping Operations

At ports, forklift hydraulic cylinders aid in handling large cargo, such as shipping containers or bulk goods, by tilting the mast to maintain load balance during loading and unloading from ships or trucks. - Manufacturing Facilities

In manufacturing plants, hydraulic tilt cylinders facilitate the movement of heavy raw materials or finished products, enabling forklifts to tilt loads for precise placement on assembly lines or storage areas with limited space. - Mining Operations

Forklift tilt cylinders are critical in mining, where forklifts handle heavy ore containers or equipment, tilting the mast to navigate rough surfaces and position loads securely in underground or open-pit environments.

|

|

|

|

Additional information

| Edited by | Yjx |

|---|