Telescopic Hydraulic Cylinder for Hook Arm Lift Garbage Truck

A telescopic hydraulic cylinder for a hook arm lift garbage truck is a specialized multi-stage hydraulic actuator designed to provide the extended stroke and high force needed for lifting and maneuvering heavy waste containers in compact spaces. It consists of nested steel tubes, or stages, that decrease in diameter, allowing the cylinder to extend significantly while collapsing to a fraction of its extended length (typically 20-40% of the fully extended length).

A telescopic hydraulic cylinder for a hook arm lift garbage truck is a specialized multi-stage hydraulic actuator designed to provide the extended stroke and high force needed for lifting and maneuvering heavy waste containers in compact spaces. It consists of nested steel tubes, or stages, that decrease in diameter, allowing the cylinder to extend significantly while collapsing to a fraction of its extended length (typically 20-40% of the fully extended length).

In hook arm lift garbage trucks, these hydraulic telescopic cylinders power the hook arm’s lifting and lowering functions, engaging and securing containers via hydraulic pressure. Single-acting versions extend hydraulically and retract using gravity or the container’s weight, while double-acting cylinders use hydraulic pressure for both extension and retraction, ideal for horizontal applications. Built for durability, they withstand harsh waste management conditions, handling heavy loads with precision and reliability.

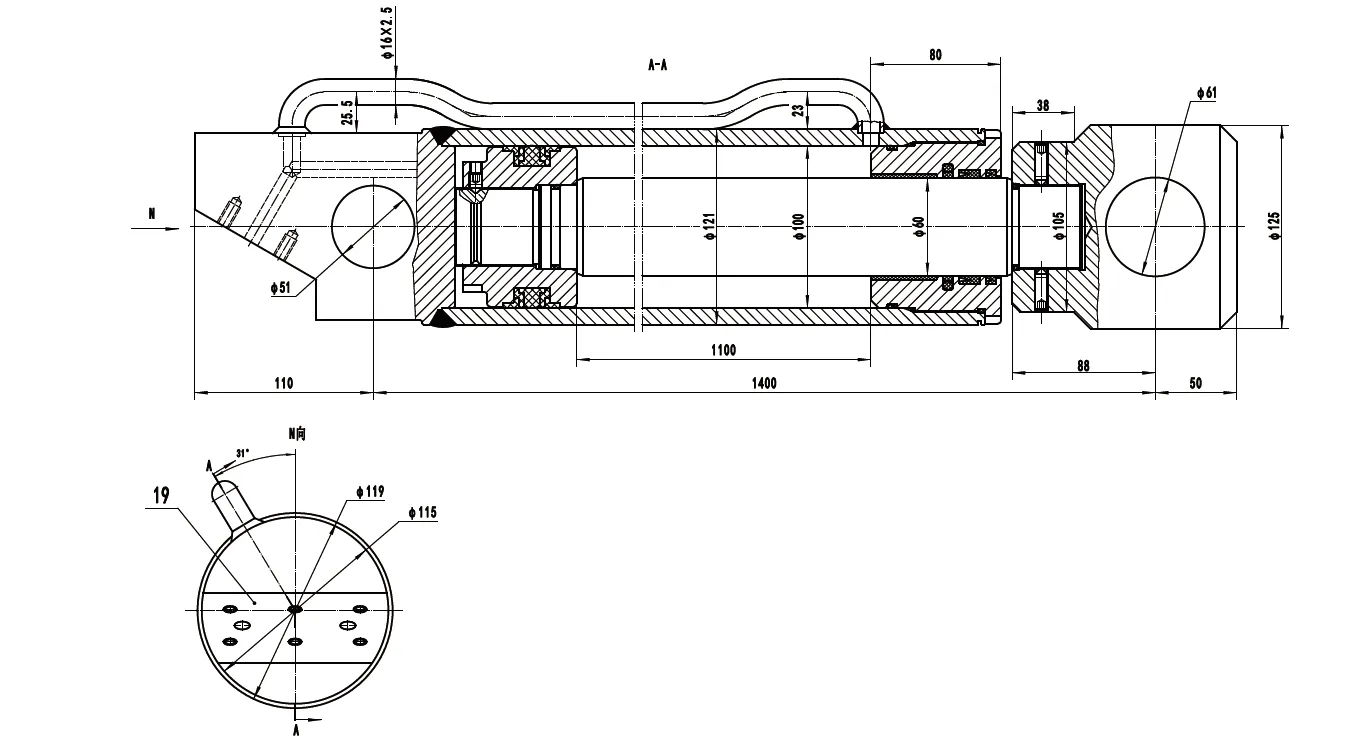

Telescopic Hydraulic Cylinder Dimensions

|

|

|

|

| Hydraulic Telescopic Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112015 | Φ100xΦ60x1100 | 30MPa | 35MPa | 1100 | 1400 | 90kg |

| Product Name: | Sliding Hydraulic Cylinder |

| Function: | Control the forward and backward movement of the arm hook. |

| Cylinder diameter: | 63mm-100mm |

| Rod diameter: | 40mm-60mm |

| Travel: | 200mm-1500mm |

| Maximum pressure: | 30MPa |

| Maximum thrust: | 236KN |

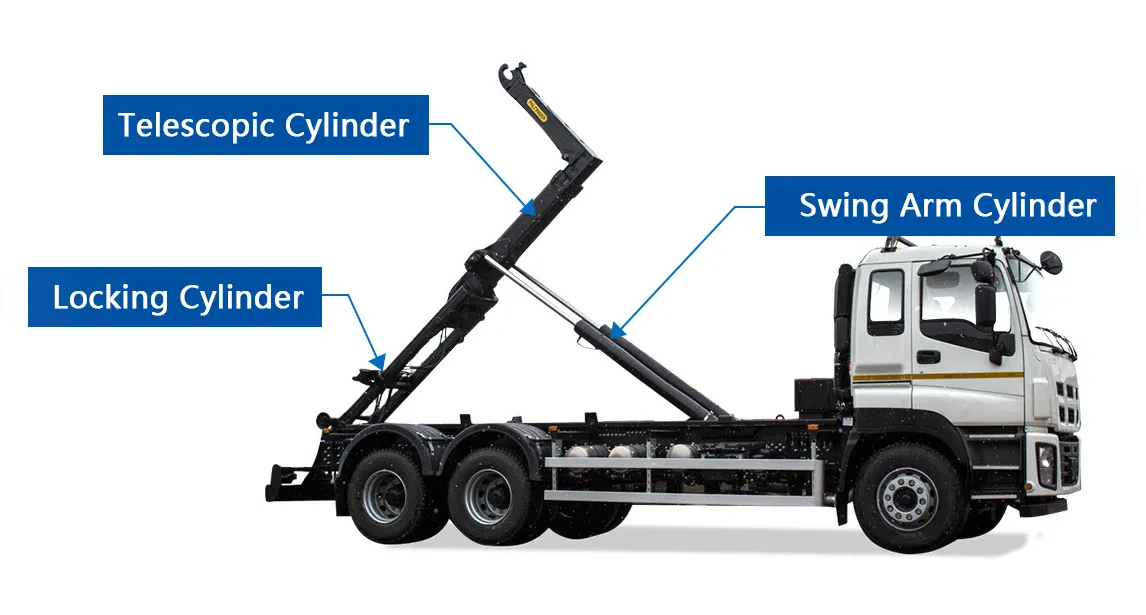

Hook Arm Lift Garbage Truck Hydraulic Cylinder Types

1. Hydraulic Locking Cylinders

Hydraulic locking cylinders are designed to securely hold the load in place during lifting or transportation. These cylinders incorporate locking mechanisms that maintain stability even if hydraulic pressure drops. They are essential for ensuring safety, especially when handling heavy garbage containers on uneven terrains. The locking feature prevents accidental movement, reducing the risk of damage or injury. These cylinders are built for reliability and operate with precision in high-load scenarios.

2. Hydraulic Swing Arm Cylinders

Hydraulic swing arm cylinders are used to provide rotational or angular motion to the arm system of the garbage truck. These cylinders enable controlled and smooth swinging of the arm, allowing the truck to position and lift bins effectively. They are engineered to handle continuous rotational loads and harsh working conditions. Their robust design ensures consistent performance and reduces wear and tear, making them ideal for frequent operations in waste management.

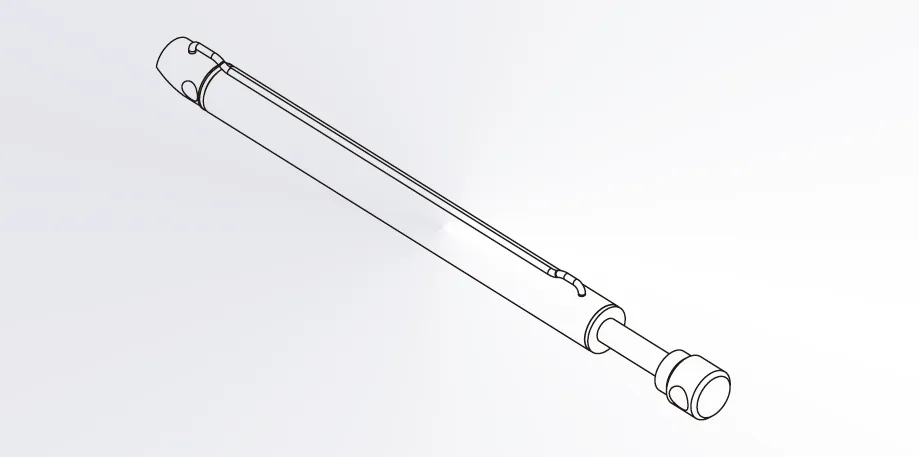

3. Hydraulic Telescopic Cylinders

Hydraulic telescopic cylinders are multi-stage cylinders that provide extended reach while maintaining a compact retracted size. These cylinders are crucial for lifting heavy containers from varying distances and heights. They operate by extending in multiple stages for increased versatility without compromising power. Due to their compact design, they save space while offering excellent lifting capacity. Their durability and smooth operation make them indispensable for hook arm lift garbage trucks.

Hook Lift Garbage Truck Telescopic Hydraulic Cylinder Parts

1. Cylinder Barrel

The hydraulic cylinder barrel is the main body of the telescopic hydraulic cylinder, housing the piston and hydraulic fluid. It is constructed from high-strength materials like hardened steel to resist pressure, wear, and environmental factors. The barrel's precision engineering ensures smooth piston movement and prevents hydraulic fluid leakage. Its durability is critical for handling the heavy loads and frequent operations of garbage trucks.

2. Telescopic Stages

Telescopic stages consist of multiple nested tubes that extend and retract to provide variable reach. Each stage is engineered for seamless operation under high loads and pressure. These stages allow the cylinder to achieve long strokes while maintaining a compact retracted size. Their construction must be robust to withstand the repeated stress of lifting and positioning heavy garbage bins.

3. Piston

The hydraulic cylinder piston is a movable component inside the cylinder that separates the hydraulic chambers. It translates hydraulic pressure into linear motion, enabling the lifting and lowering actions. The piston is equipped with seals to prevent fluid leakage and ensure efficient performance. For telescopic cylinders, the piston must endure immense pressure while maintaining precise movement.

4. Hydraulic Seals

Hydraulic cylinder seals are critical components that prevent fluid leakage and contamination inside the cylinder. They are located around the piston and telescopic stages, ensuring a tight seal under high pressure. These seals are made from durable materials like polyurethane or rubber, capable of withstanding extreme temperatures, pressure fluctuations, and debris commonly encountered in waste management operations.

5. End Cap

The hydraulic cylinder end cap is located at the base of the cylinder and serves as a structural support for the hydraulic system. It houses fittings for hydraulic fluid input and output, ensuring proper flow and pressure. Additionally, the end cap connects the cylinder to the mounting structure, providing stability during operation. Its strength and precision are essential for reliable performance.

Hook Lift Garbage Truck Hydraulic Cylinder Maintenance

1. Regular Inspection for Leaks

Inspect the hydraulic cylinder for fluid leaks around the seals, hoses, and connections. Leaks can indicate worn-out seals or damaged components, which could lead to performance issues. Frequent checks ensure the system operates efficiently and prevents further damage to the cylinder or associated parts.

2. Lubrication of Moving Parts

Ensure all moving parts, such as the piston rod and mounting points, are adequately lubricated to reduce friction and wear. Proper lubrication extends the lifespan of the cylinder and minimizes the risk of operational failure due to excessive heat or friction.

3. Cleaning the Cylinder Surface

Clean the cylinder’s outer surface regularly to remove dirt, debris, and contaminants that can damage seals or scratch the piston rod. A clean cylinder prevents foreign particles from entering the hydraulic system, which could lead to internal wear or blockages.

4. Inspection of Hydraulic Fluid

Check the hydraulic fluid for contamination, proper levels, and viscosity. Contaminated or degraded fluid can damage internal components and reduce performance. Replace old hydraulic fluid as needed to ensure smooth operation and to avoid corrosion or blockages within the system.

5. Seal and Rod Maintenance

Inspect the seals and piston rod for wear, cracks, or damage. Damaged seals can cause fluid leakage and reduce the cylinder’s ability to hold pressure. A scratched or bent piston rod can lead to misalignment and seal failure, requiring immediate repair or replacement.

6. Testing Cylinder Functionality

Periodically test the hydraulic cylinder’s performance under load to ensure it operates smoothly and without abnormal noises or jerky movements. This helps identify internal problems, such as piston wear or insufficient hydraulic pressure, before they lead to complete failure.

|

|

Additional information

| Edited by | Yjx |

|---|