Swing Hydraulic Cylinder for Mini Excavator

The swing hydraulic cylinder, also known as a slew cylinder, is a critical component in mini excavators, enabling the rotation of the machine’s upper structure (house) around its vertical axis. This double-acting hydraulic cylinder, powered by pressurized hydraulic fluid, facilitates precise side-to-side swinging of the boom and bucket, essential for maneuvering in tight spaces or digging in multiple directions. Typically located at the base of the upper structure, it converts fluid energy into linear motion, driving the rotational movement of the excavator’s cabin, boom, and attachments.

The swing hydraulic cylinder, also known as a slew cylinder, is a critical component in mini excavators, enabling the rotation of the machine’s upper structure (house) around its vertical axis. This double-acting hydraulic cylinder, powered by pressurized hydraulic fluid, facilitates precise side-to-side swinging of the boom and bucket, essential for maneuvering in tight spaces or digging in multiple directions. Typically located at the base of the upper structure, it converts fluid energy into linear motion, driving the rotational movement of the excavator’s cabin, boom, and attachments.

Constructed with durable materials like chrome-plated rods and high-strength steel, hydraulic swing cylinders are designed to withstand high pressures and heavy loads. Proper maintenance, including regular checks for fluid leaks and seal wear, ensures optimal performance and longevity, minimizing downtime in demanding construction tasks.

Mini Excavator Swing Hydraulic Cylinder Specifications

| Product Name: | Mini Excavator Swing Hydraulic Cylinder |

| Function: | Deflection of the big arm. |

| Bore Diameter: | 50mm-120mm |

| Rod diameter: | 25mm-75mm |

| Stroke: | ≤1000 mm |

| Maximum pressure MPa: | 29.4MPa |

| Thrust Force: | 333KN |

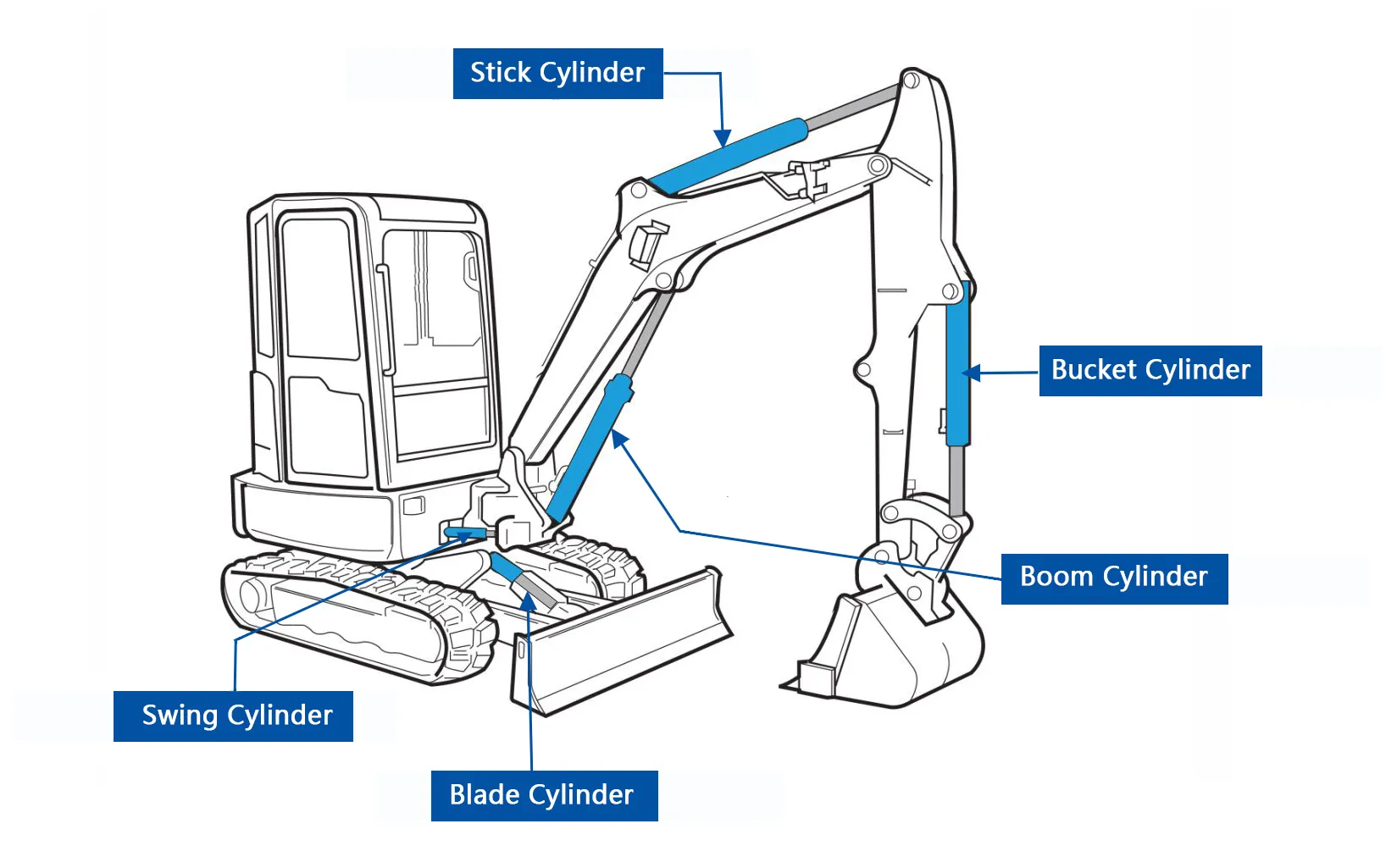

Mini Excavator Hydraulic Cylinder Types

Mini Excavator Swing Hydraulic Cylinder Components

- Cylinder Barrel

The hydraulic cylinder barrel is a robust, seamless steel tube housing the piston and hydraulic fluid. It withstands high internal pressures during operation, ensuring structural integrity. Precision machining ensures smooth piston movement, preventing leaks and maintaining efficient hydraulic performance in demanding excavation tasks. - Piston

The hydraulic cylinder piston is a precision-engineered component that moves within the cylinder barrel, driven by hydraulic fluid pressure. It converts fluid energy into linear motion, enabling the swing mechanism. High-strength materials ensure durability, while seals prevent fluid bypass, maintaining consistent force output. - Piston Rod

The hydraulic cylinder piston rod, typically chrome-plated steel, connects the piston to the excavator’s swing mechanism. It transmits linear motion to rotate the upper structure. Its polished surface resists corrosion and wear, ensuring smooth operation and longevity under heavy loads and repetitive movements. - Seals

Hydraulic cylinder seals, including O-rings and wiper seals, prevent hydraulic fluid leaks and contamination. Made from durable rubber or polyurethane, they ensure a tight fit between moving parts. Regular inspection and replacement of worn seals are crucial for maintaining pressure and preventing performance issues. - End Caps

Hydraulic cylinder end caps, or cylinder heads, seal the barrel’s ends, guiding the piston rod and containing hydraulic fluid. Constructed from high-strength steel, they house seals and ports for fluid entry. Their robust design ensures pressure containment and alignment during the cylinder’s operation. - Hydraulic Ports

Hydraulic ports are precision-machined openings on the cylinder for fluid inlet and outlet. They connect to the excavator’s hydraulic system, enabling fluid flow to drive the piston. Proper port maintenance prevents blockages, ensuring consistent pressure and smooth swing motion.

Custom Hydraulic Swing Cylinder for Mini Excavator

- Bore Diameter

The bore diameter is the internal width of the cylinder barrel, determining the volume of hydraulic fluid the cylinder can hold. A larger bore diameter increases the force generated by the cylinder, making it suitable for heavy-duty applications. For a custom hydraulic swing cylinder, the bore diameter must match the mini excavator’s pressure capacity and workload requirements. - Rod Diameter

The rod diameter refers to the thickness of the piston rod, which influences the cylinder's ability to handle mechanical stress. A thicker rod diameter provides better resistance to bending and extends the cylinder’s lifespan. Customizing the rod diameter ensures the cylinder can withstand the specific forces encountered during swing movements. - Working Pressure

The working pressure indicates the maximum hydraulic pressure the cylinder can safely handle during operation. Custom mini excavator hydraulic cylinders are designed to match the pressure output of the mini excavator’s hydraulic system. Higher working pressures allow for more powerful and precise swing movements. - Installation Distance

The installation distance is the length between the cylinder’s mounting points when fully retracted. This measurement ensures the cylinder fits perfectly into the mini excavator’s swing mechanism. Customizing the installation distance allows compatibility with the excavator’s design while ensuring efficient swing functionality. - Stroke Length

The stroke length is the distance the piston rod can extend or retract within the mini excavator hydraulic cylinder, determining the range of motion for the swing mechanism. A longer stroke length provides greater rotational movement, enhancing the excavator’s versatility. Customizing the stroke length ensures the hydraulic swing cylinder meets specific application requirements, such as confined space operations or extended reach tasks. - Thrust Force

The thrust force is the amount of force the swing hydraulic cylinder generates to move the excavator’s swing mechanism. It is calculated based on the bore diameter, hydraulic pressure, and efficiency of the system. Customizing the thrust force ensures the cylinder can handle the excavator’s operational demands, such as heavy loads or rapid movements.

Additional information

| Edited by | Yjx |

|---|