Support Hydraulic Cylinder for Truss Arm Crawler Crane

The support hydraulic cylinder for a truss arm crawler crane is a critical component designed to enhance the stability and functionality of the crane during heavy lifting operations. This hydraulic cylinder serves as a structural support mechanism, specifically engineered to sustain and adjust the angle or position of the truss arm. It operates through hydraulic pressure, converting fluid power into linear motion to provide precise control and alignment of the crane’s arm or boom.

The support hydraulic cylinder for a truss arm crawler crane is a critical component designed to enhance the stability and functionality of the crane during heavy lifting operations. This hydraulic cylinder serves as a structural support mechanism, specifically engineered to sustain and adjust the angle or position of the truss arm. It operates through hydraulic pressure, converting fluid power into linear motion to provide precise control and alignment of the crane’s arm or boom.

Typically constructed from high-strength materials such as alloy steel to endure heavy loads and harsh conditions, this hydraulic support cylinder ensures that the truss arm remains stable while maintaining flexibility for various tasks. It is equipped with seals and pistons to prevent fluid leakage, ensuring smooth and reliable operation. The support hydraulic cylinder is essential in distributing stress evenly across the crane’s framework, reducing the risk of mechanical failure and improving operational safety. This component is particularly vital in applications requiring heavy lifting, such as construction, shipbuilding, and infrastructure development, where precision and stability are paramount.

Support Hydraulic Cylinder Dimensions

|

|

|

|

| Hydraulic Support Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112020 | Φ170xΦ150x800 | 30MPa | 40MPa | 800 | 1140 | 262kg |

| Product Name: | Support Hydraulic Cylinder |

| Function: | Supporting function |

| Cylinder diameter: | 100mm-300mm |

| Rod diameter: | 80mm-220mm |

| Travel: | 700mm-800mm |

| Maximum pressure: | 31.5MPa |

| Maximum thrust: | 2226KN |

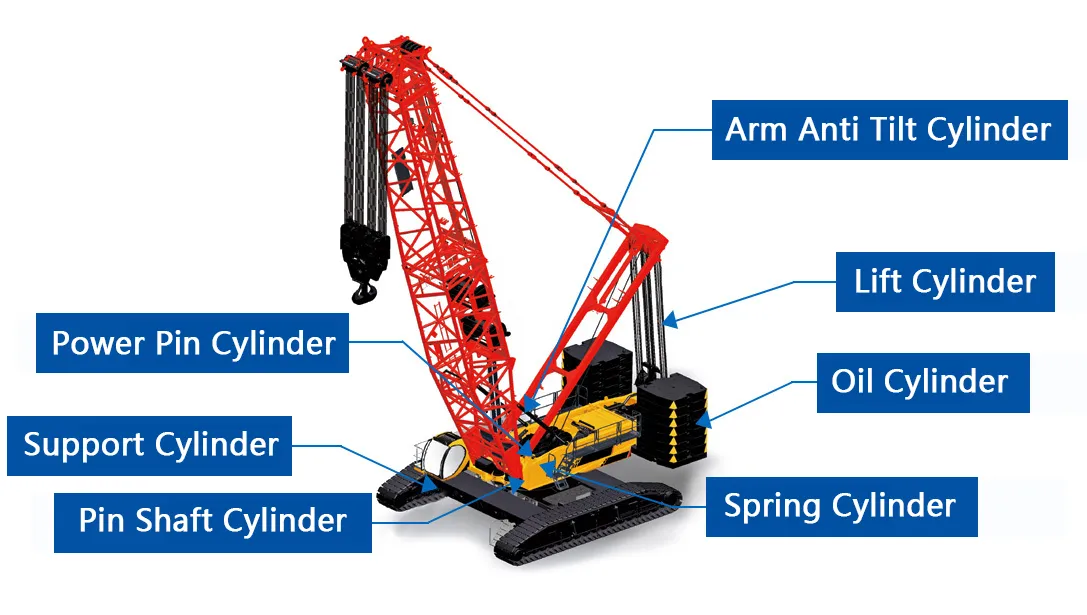

Truss Arm Crawler Crane Hydraulic Cylinder Types

- Hydraulic Pin Shaft Cylinders

Hydraulic Pin Shaft Cylinders are used to control the movement and locking of key pivot points in a truss arm crawler crane. These cylinders provide precise motion and stability by securely managing the rotation of shafts. They are crucial for ensuring the crane’s structural alignment during operation, especially under heavy loads. - Hydraulic Spring Cylinders

Hydraulic Spring Cylinders incorporate a spring mechanism to assist in retracting or extending the cylinder under varying load conditions. These are typically used to absorb shock and maintain consistent pressure in the crane’s arm, ensuring smooth operation in challenging environments or during sudden movements. - Hydraulic Power Pin Cylinders

Hydraulic Power Pin Cylinders deliver controlled force to securely lock or unlock the crane’s components, such as joints or arm extensions. These cylinders provide high precision and are vital for safety, especially during setup or dismantling processes in large-scale operations. - Hydraulic Arm Anti-Tilt Cylinders

Hydraulic Arm Anti-Tilt Cylinders are specialized to prevent the truss arm from tilting or misaligning during lifting operations. By maintaining the arm’s horizontal stability, they ensure safe and effective movement of heavy loads, even in uneven working conditions. - Hydraulic Support Cylinders

Hydraulic Support Cylinders provide additional stability to the crane by acting as load-bearing supports. These are commonly used to stabilize the truss arm during static operations, preventing unwanted rocking or shifting caused by uneven ground or external forces. - Hydraulic Lift Cylinders

Hydraulic Lift Cylinders are responsible for raising and lowering the truss arm, offering smooth and controlled vertical movement. These cylinders ensure precise positioning of loads, which is critical for construction tasks that demand high accuracy and reliability in lifting operations.

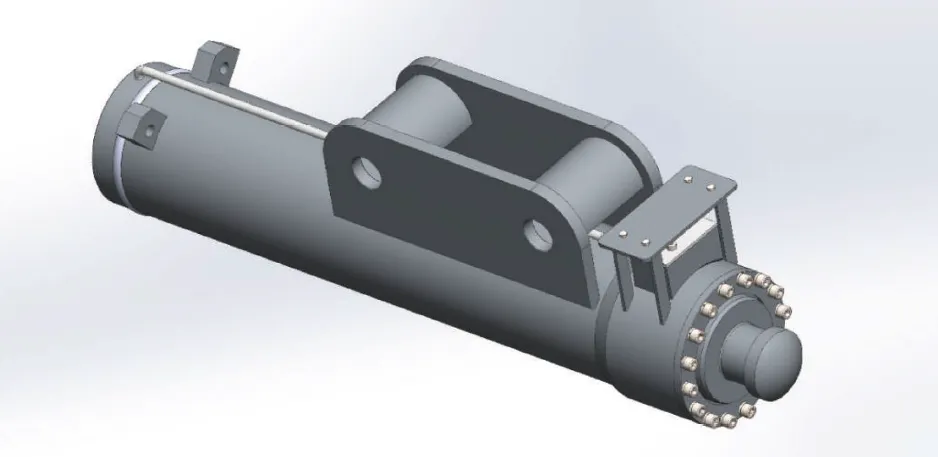

Truss Arm Crawler Crane Support Hydraulic Cylinder Parts

- Cylinder Barrel

The hydraulic cylinder barrel is the main body of the support hydraulic cylinder, housing the piston and hydraulic fluid. It is typically made from high-strength materials like alloy steel to withstand immense pressure and ensure durability during heavy-duty operations. - Piston and Piston Rod

The hydraulic cylinder piston and piston rod are critical for converting hydraulic pressure into mechanical force. The piston moves within the cylinder barrel, while the rod extends or retracts to provide linear motion, enabling precise control of the truss arm’s position. - Hydraulic Seals

Hydraulic cylinder seals are designed to prevent fluid leakage within the cylinder. They ensure efficient operation by maintaining pressure and separating hydraulic fluid and air, thereby reducing wear and enhancing the cylinder's lifespan under intense workloads. - End Caps

Hydraulic cylinder end caps are positioned at both ends of the cylinder barrel to secure internal components and provide mounting points. These parts also help maintain the hydraulic pressure and ensure the cylinder operates efficiently under heavy loads. - Mounting Brackets

Mounting brackets are used to attach the hydraulic cylinder to the truss arm and crane structure. They provide stability and flexibility, allowing the cylinder to pivot and align with the crane’s movements during operation. - Hydraulic Ports

Hydraulic cylinder ports are the entry and exit points for hydraulic fluid within the cylinder. These ports ensure proper fluid flow, enabling smooth operation and precise control of the truss arm’s movement during lifting and positioning tasks.

Hydraulic Support Cylinder for Truss Arm Crawler Crane

A hydraulic support cylinder for a truss arm crawler crane is a specialized component designed to provide controlled stability and support to the crane's structure during operation. It functions by converting hydraulic energy into linear mechanical force, ensuring precise positioning and maintaining balance during heavy lifting tasks.

The cylinder operates through the controlled flow of hydraulic fluid, typically oil, under high pressure. This fluid is pumped into the cylinder through hydraulic ports connected to the crane's hydraulic system. Inside the cylinder, the pressurized fluid pushes against a piston, which is connected to a piston rod. The movement of the piston generates linear motion, either extending or retracting the rod depending on the direction of the fluid flow. This motion is used to stabilize or adjust the position of the truss arm.

When the crane is in use, the hydraulic support cylinder helps distribute the load evenly across the crane's structure, preventing excessive strain on any single component. For example, during lifting operations, the cylinder can extend to provide additional support to the arm, counteracting the weight of the load and reducing the risk of tipping or instability.

The cylinder is equipped with seals to prevent fluid leakage and ensure consistent pressure. Additionally, mounting brackets allow it to pivot and adapt to the crane's movements. This adaptability is critical for maintaining stability, especially on uneven terrain or during sudden directional changes, making it an essential component for safe and efficient crane operation.

Additional information

| Edited by | Yjx |

|---|