Stick Hydraulic Cylinder for Mini Excavator

The stick hydraulic cylinder, also known as the dipper or arm hydraulic cylinder, is a critical component in a mini excavator’s hydraulic system, responsible for powering the movement of the stick arm, which connects the boom to the bucket. This double-acting hydraulic cylinder uses pressurized hydraulic fluid to extend and retract, controlling the stick arm’s reach and depth during excavation. Typically located along the stick arm, it enables precise digging motions by pulling the bucket toward or pushing it away from the machine’s cab.

The stick hydraulic cylinder, also known as the dipper or arm hydraulic cylinder, is a critical component in a mini excavator’s hydraulic system, responsible for powering the movement of the stick arm, which connects the boom to the bucket. This double-acting hydraulic cylinder uses pressurized hydraulic fluid to extend and retract, controlling the stick arm’s reach and depth during excavation. Typically located along the stick arm, it enables precise digging motions by pulling the bucket toward or pushing it away from the machine’s cab. Designed for durability, it withstands harsh conditions like dust and heavy loads. Its size and force output are smaller than the boom cylinder but optimized for precise control, ensuring efficient digging and material handling.

Mini Excavator Stick Hydraulic Cylinder Specifications

| Product Name: | Mini Excavator Stick Hydraulic Cylinder |

| Function: | Control the movement of the forearm. |

| Bore Diameter: | 50mm-115mm |

| Rod diameter: | 25mm-70mm |

| Stroke: | ≤1000 mm |

| Maximum pressure MPa: | 29.4MPa |

| Thrust Force: | 305KN |

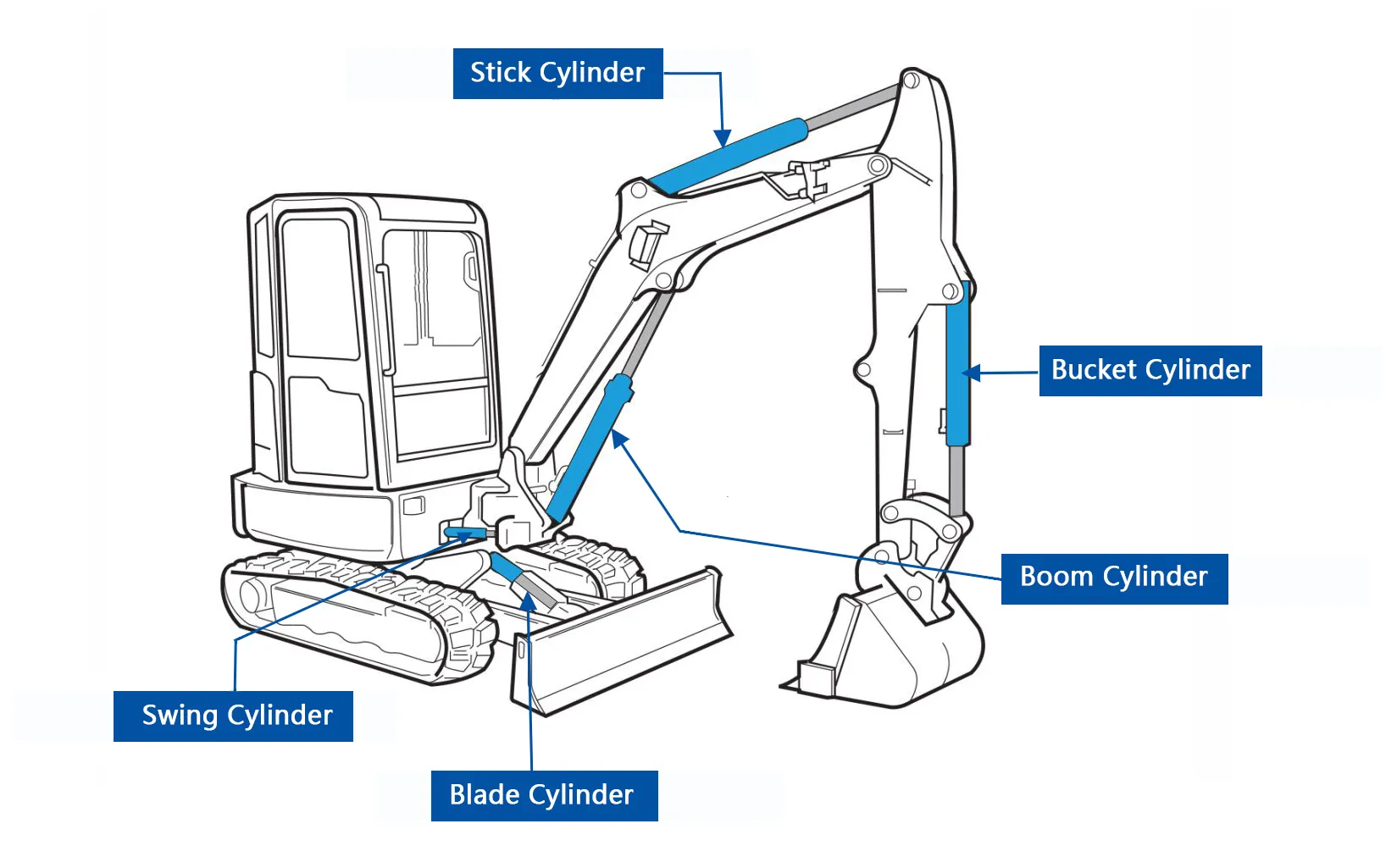

Mini Excavator Hydraulic Cylinder Types

- Boom Hydraulic Cylinders

The boom hydraulic cylinders are responsible for raising and lowering the boom, which is the main arm of the excavator. These cylinders provide the strength required to lift heavy loads and to position the boom for digging or lifting tasks. Designed for durability, they withstand significant stress and pressure during operation, ensuring smooth and precise vertical movement of the excavator's primary arm. - Bucket Hydraulic Cylinders

Bucket hydraulic cylinders are tasked with controlling the movement of the excavator’s bucket. They allow the bucket to tilt, scoop, and dump materials efficiently. These cylinders are highly durable, as they endure constant contact with soil, rocks, and debris. Their precise motion ensures accurate digging, trenching, and material handling, making them essential for tasks requiring forceful or delicate operations. - Stick Hydraulic Cylinders

Stick hydraulic cylinders control the stick or dipper arm, which connects the boom to the bucket. These cylinders enable the controlled extension and retraction of the stick, allowing the excavator to dig deeper or reach farther. Built to handle heavy loads and high hydraulic pressure, they provide versatility and accuracy in positioning the bucket during operations like trenching or grading. - Swing Hydraulic Cylinders

Swing hydraulic cylinders manage the rotational movement of the excavator’s upper structure, allowing it to pivot left or right. This rotation is critical for maneuvering the excavator in confined spaces and positioning the arm for digging or loading. These cylinders are engineered for smooth and fluid movement, ensuring consistent performance and efficient operation in challenging environments. - Blade Hydraulic Cylinders

Blade hydraulic cylinders control the up-and-down motion of the dozer blade, which is often attached to mini excavators. The blade is used for leveling, backfilling, or stabilizing the machine on uneven terrain. These cylinders are designed to provide precise adjustments to the blade's angle and height, ensuring stability and efficiency during grading or pushing materials. They are built to withstand high pressure and abrasive conditions.

Mini Excavator Stick Hydraulic Cylinder Benefits

- Enhanced Precision and Control

The stick hydraulic cylinder provides precise control over the stick's movement, allowing the operator to perform accurate digging, trenching, and material handling. This precision increases efficiency and reduces the risk of over-digging or material wastage. - High Strength and Durability

Constructed from high-strength materials like hardened steel, the hydraulic cylinder can endure extreme forces and harsh working conditions. Its robust design ensures long-term reliability, even in demanding excavation environments with heavy loads and constant use. - Smooth and Efficient Operation

The mini excavator hydraulic cylinder delivers smooth and consistent movement during extension and retraction. This ensures seamless operation of the excavator arm, improving productivity and minimizing wear and tear on the machine's components. - Versatility in Applications

With the help of the hydraulic stick cylinder, mini excavators can perform a wide range of tasks, including digging, grading, and trenching. Its flexibility makes it essential for construction, landscaping, and utility work. - Compact and Space-Saving Design

The stick hydraulic cylinder is specifically designed for mini excavators, where space is limited. Its compact design ensures it fits perfectly into the machine's structure without compromising performance or maneuverability in tight work areas. - Reduced Maintenance Requirements

Equipped with advanced sealing systems and corrosion-resistant materials, the mini excavator hydraulic cylinder requires minimal maintenance. These features help prevent hydraulic fluid leaks, reduce downtime, and lower overall maintenance costs for the operator.

Mini Excavator Hydraulic Stick Cylinder Maintenance

- Regular Inspection for Leaks

Routinely check the stick hydraulic cylinder for hydraulic fluid leaks around seals, fittings, and hoses. Leaks can reduce performance and lead to contamination. Early detection prevents costly repairs and maintains consistent operation during digging tasks in demanding environments. - Lubrication of Moving Parts

Apply appropriate grease to the cylinder’s pivot points and rod ends to reduce friction and wear. Proper lubrication ensures smooth extension and retraction, prolonging the cylinder’s lifespan and maintaining precise control during excavation or material handling tasks. - Seal and Gasket Maintenance

Inspect and replace worn or damaged seals and gaskets to prevent fluid leaks and contamination. Regular seal checks ensure the mini excavator hydraulic cylinder maintains hydraulic pressure, supporting efficient stick arm movements and preventing performance issues during intensive operations. - Cleaning to Prevent Contamination

Regularly clean the cylinder rod and surrounding areas to remove dirt, debris, and abrasive materials. Preventing contamination of hydraulic fluid maintains system efficiency, reduces wear on internal components, and ensures reliable operation in harsh construction or landscaping conditions. - Checking Hydraulic Fluid Levels

Monitor and maintain proper hydraulic fluid levels in the excavator’s system. Low or contaminated fluid can impair the hydraulic cylinder for excavator performance, leading to sluggish or erratic stick arm movements. Use the manual-recommended fluid to ensure optimal function and longevity. - Rod Surface Inspection

Examine the stick cylinder rod for scratches, dents, or corrosion, which can damage seals and cause leaks. Promptly address any surface imperfections by polishing or replacing the rod to ensure smooth operation and prevent costly downtime during excavation tasks.

Additional information

| Edited by | Yjx |

|---|