Steering Hydraulic Cylinder for Large Tonnage Forklift

A steering hydraulic cylinder for a large tonnage forklift is a critical component in the power steering system, enabling precise and efficient control of the vehicle’s direction, especially under heavy loads. Typically a double-acting, double-ended cylinder, it exerts equal force in both directions to swing the wheels side-to-side for left and right turns. The hydraulic steering cylinder contains a piston rod extending through both ends of the tube, with the piston centered, allowing hydraulic fluid to move the rod back and forth via ports at each end. This design ensures high maneuverability in demanding environments like warehouses or construction sites.

A steering hydraulic cylinder for a large tonnage forklift is a critical component in the power steering system, enabling precise and efficient control of the vehicle’s direction, especially under heavy loads. Typically a double-acting, double-ended cylinder, it exerts equal force in both directions to swing the wheels side-to-side for left and right turns. The hydraulic steering cylinder contains a piston rod extending through both ends of the tube, with the piston centered, allowing hydraulic fluid to move the rod back and forth via ports at each end. This design ensures high maneuverability in demanding environments like warehouses or construction sites. Built with robust materials and seals to withstand high pressures, it enhances safety and reduces operator effort, making it ideal for large-tonnage forklifts handling substantial weights.

Forklift Steering Hydraulic Cylinder Dimensions

| drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| R960-224000-001 | Φ65 | Φ40 | 2*98 | 672 | 10.5MPa | 2-G1/4 | 15kg |

| Product Name: | Steering Hydraulic Cylinder |

| Function: | Implement forklift steering axle action and enable forklift tire steering. |

| Cylinder diameter: | 80mm-160mm |

| Rod diameter: | 50mm-110mm |

| Travel: | 71mm * 2-235mm * 2 |

| Maximum pressure: | 18MPa |

| Maximum thrust: | 362KN |

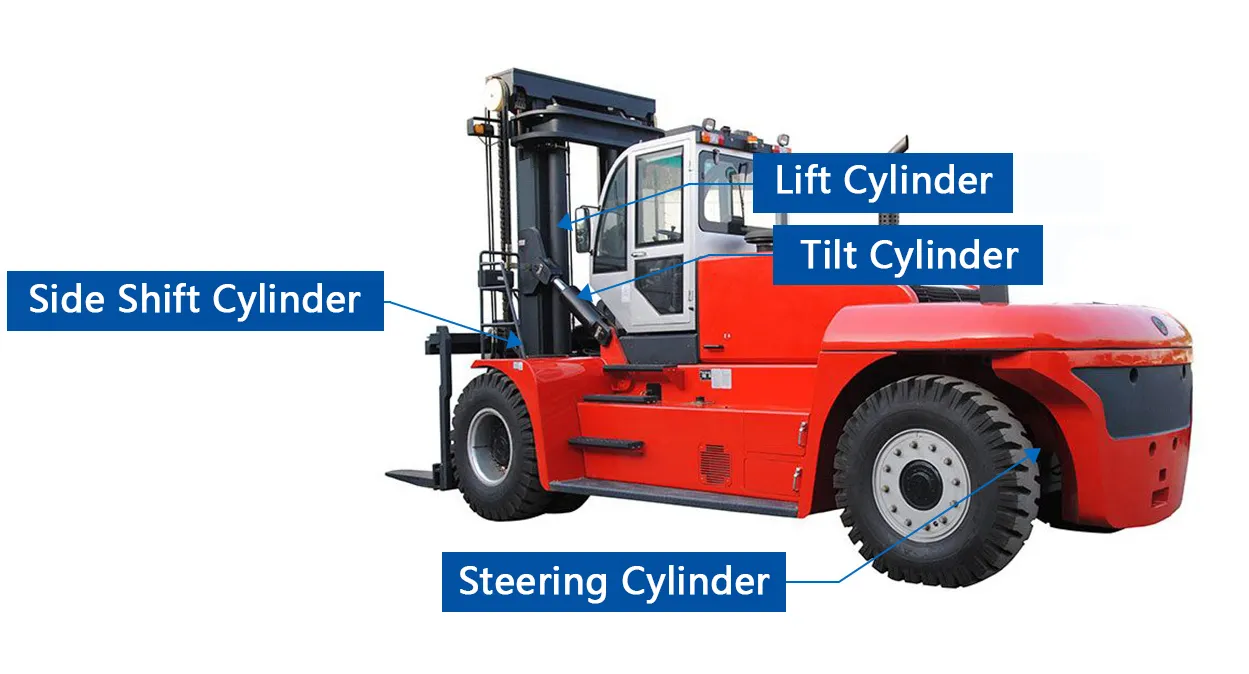

Large Tonnage Forklift Hydraulic Cylinder Types

- Tilt Hydraulic Cylinders

Tilt hydraulic cylinders are used to adjust the angle of the forklift's mast, allowing it to tilt forward or backward. These cylinders provide stability during load handling by ensuring the mast can adapt to different operational needs. Constructed with heavy-duty materials, they handle the immense forces required to tilt the mast while the forklift carries large loads. - Lift Hydraulic Cylinders

Lift hydraulic cylinders are essential for raising and lowering the forklift’s forks and loads. These cylinders operate by converting hydraulic pressure into vertical motion, enabling the forklift to handle heavy items efficiently. Their robust construction allows them to withstand extreme weight and repetitive operations in demanding environments. - Steering Hydraulic Cylinders

Steering hydraulic cylinders control the wheels of the forklift, enabling smooth and precise maneuvering. These cylinders allow the forklift to navigate tight spaces and heavy loads with ease, even on uneven surfaces. Designed for durability, they withstand high-pressure hydraulic flow and constant use in industrial settings. - Side Shift Hydraulic Cylinders

Side shift hydraulic cylinders allow the forklift’s forks to move laterally, enabling precise positioning of loads without moving the entire vehicle. This feature enhances productivity by reducing the need for additional adjustments. These cylinders are designed to handle lateral forces while maintaining stability under heavy loads.

Large Forklift Hydraulic Steering Cylinder Features

- Double-Acting Design

The steering cylinder functions as a double-acting system, utilizing hydraulic fluid to drive the piston rod in both directions, delivering precise and balanced control for left and right turns, enhancing efficiency in heavy-duty forklifts. - Double-Ended Rod

Incorporating a piston rod extending through both cylinder ends, this design ensures equal force distribution, improving steering responsiveness and stability, crucial for maneuvering large tonnage forklifts in confined or challenging spaces effectively. - High-Pressure Capacity

Engineered to endure extreme hydraulic pressures, the forklift hydraulic steering cylinder maintains reliable performance under heavy loads, ensuring consistent steering control in demanding environments such as warehouses, ports, or construction sites with large forklifts. - Robust Material Construction

Made from high-grade steel with reinforced seals, the steering hydraulic cylinder resists wear, corrosion, and physical damage, providing exceptional durability and long-term reliability in harsh industrial conditions for large tonnage forklift operations. - Precision Steering Control

The forklift hydraulic cylinder delivers smooth and accurate wheel alignment, minimizing operator effort while enhancing maneuverability, which is essential for safely navigating large tonnage forklifts in tight, crowded, or complex industrial environments. - Leak-Resistant Seals

Equipped with advanced sealing technology, the forklift hydraulic steering cylinder prevents hydraulic fluid leaks, ensuring system efficiency and reducing maintenance requirements, supporting continuous and reliable operation of large forklifts in high-throughput industrial settings.

Forklift Steering Hydraulic Cylinder Troubleshooting

- Steering Difficulty or Stiffness

Hard steering may stem from low hydraulic fluid levels or contaminated oil, reducing system efficiency. Inspect the hydraulic pump and cylinder for wear, blockages, or internal damage restricting fluid flow, and replace or repair components to restore smooth steering control. - Hydraulic Fluid Leaks

Leaks around the forklift hydraulic steering cylinder suggest damaged seals, worn piston rods, or cracked steering hydraulic cylinder walls, leading to pressure loss. Regularly inspect these parts, replacing faulty components promptly to maintain system integrity and ensure efficient steering performance in large tonnage forklifts. - Unresponsive Steering

Unresponsive steering often results from air trapped in the hydraulic system, disrupting fluid flow. Bleed the system to eliminate air, and inspect for loose connections or defective valves, repairing them to restore precise and reliable steering functionality. - Uneven or Jerky Steering Movements

Jerky steering can be caused by contaminated hydraulic fluid, worn seals, or internal forklift hydraulic cylinder damage, leading to irregular motion. Replace the fluid, inspect internal components for wear or misalignment, and repair to ensure smooth and consistent steering operation. - Excessive Noise During Steering

Whining or hissing noises may indicate a failing hydraulic pump, air in the system, or damaged cylinder parts, affecting performance. Inspect and repair the pump, bleed the system, and replace worn components to eliminate noise and ensure reliable steering. - Cylinder Overheating

Overheating occurs when the hydraulic system is overworked or fluid is degraded, impacting hydraulic steering cylinder efficiency. Check for blockages, ensure proper cooling mechanisms, and replace old fluid to maintain optimal performance and prevent damage to the steering cylinder.

Additional information

| Edited by | Yjx |

|---|