Steering Hydraulic Cylinder for Arm Type Aerial Work Platform

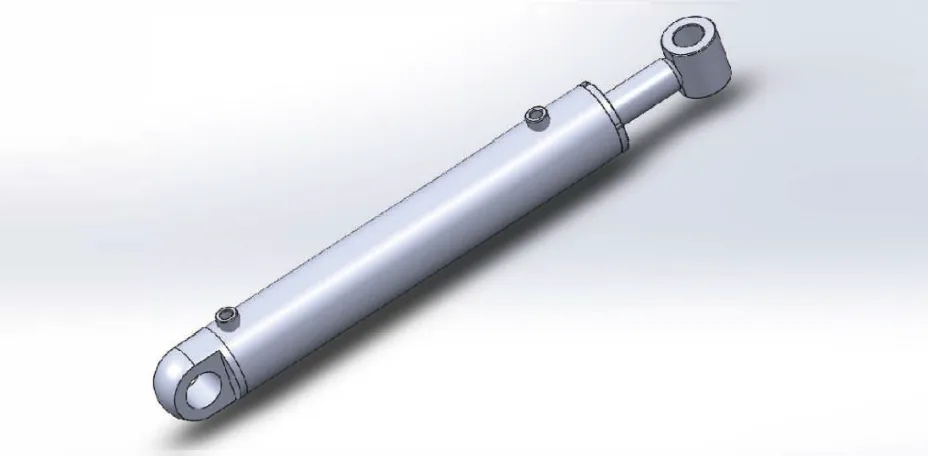

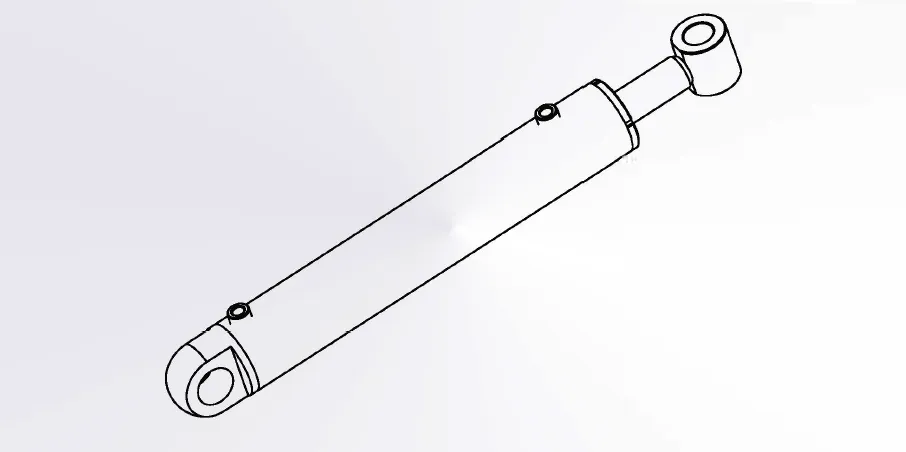

The steering hydraulic cylinder for arm-type aerial work platforms is a critical component designed to facilitate precise steering and maneuverability in these specialized lifting machines. It is a hydraulic actuator that converts hydraulic energy into mechanical force, enabling controlled steering of the platform’s wheels or axles. Composed of a robust cylindrical body, a piston, and a rod, the cylinder uses hydraulic fluid under pressure to extend or retract the piston, thereby steering the platform in the desired direction.

The steering hydraulic cylinder for arm-type aerial work platforms is a critical component designed to facilitate precise steering and maneuverability in these specialized lifting machines. It is a hydraulic actuator that converts hydraulic energy into mechanical force, enabling controlled steering of the platform's wheels or axles. Composed of a robust cylindrical body, a piston, and a rod, the cylinder uses hydraulic fluid under pressure to extend or retract the piston, thereby steering the platform in the desired direction.

This component is critical for the safe and efficient operation of arm-type aerial work platforms, which are commonly used in construction, maintenance, and industrial tasks. It ensures smooth, responsive, and reliable wheel movement, even under heavy loads or in challenging terrains. Durable seals and high-quality materials are used to prevent leaks and ensure long-term performance. Additionally, the hydraulic cylinder is engineered to withstand harsh environmental conditions and dynamic forces, making it a vital part of the platform's mobility system, enhancing both safety and operational efficiency.

Steering Hydraulic Cylinder Dimensions

|

|

|

|

| Steering Hydraulic Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112012 | Φ63xΦ35x320 | 21 MPa | 32MPa | 320 | 540 | 13kg |

| Product Name: | Steering Hydraulic Cylinder |

| Function: | Implement steering axle action and enable arm-type tire steering. |

| Cylinder diameter: | 40mm-80mm |

| Rod diameter: | 20mm-50mm |

| Travel: | 110mm-300mm |

| Maximum pressure: | 20MPa |

| Maximum thrust: | 100KN |

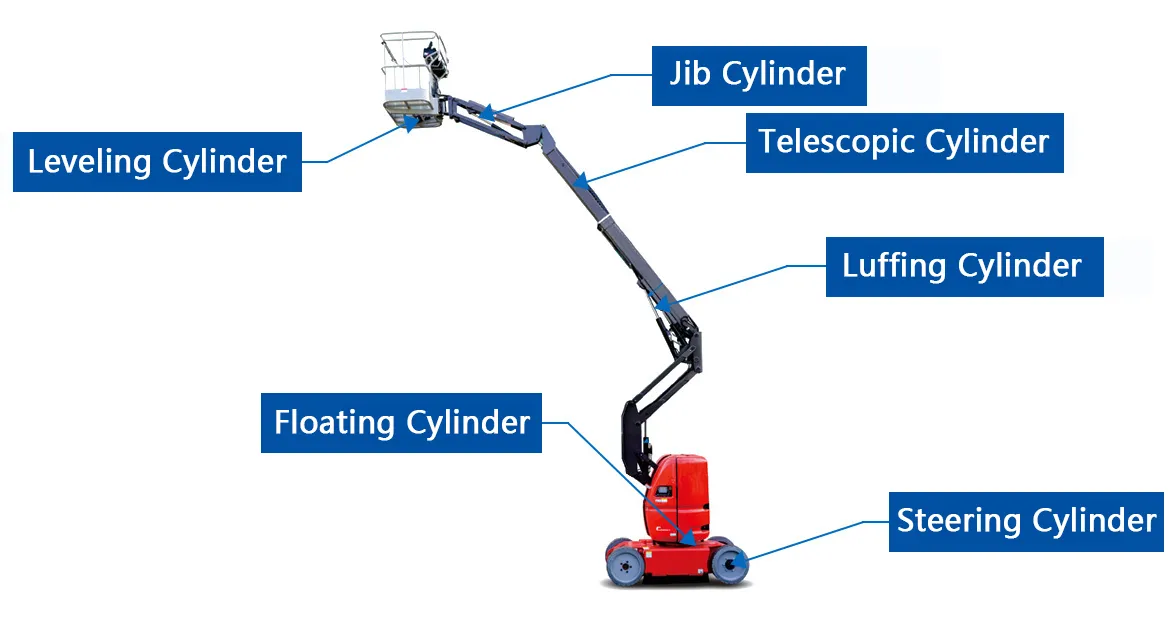

Arm Type Aerial Work Platform Hydraulic Cylinder Types

- Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders enable the extension and retraction of the arm in arm-type aerial work platforms. Comprising multiple nested stages, they provide significant reach while maintaining a compact retracted length. These cylinders use hydraulic fluid to drive sequential extension, ensuring smooth, controlled movement for accessing high or distant work areas. Their robust design handles heavy loads and maintains stability during operation. - Leveling Hydraulic Cylinders

Leveling hydraulic cylinders maintain the platform’s horizontal position regardless of the arm’s angle or terrain. They adjust the basket’s tilt by extending or retracting, ensuring operator safety and comfort. These cylinders are engineered for precision, with durable seals and high-pressure tolerance to support consistent leveling under varying loads and environmental conditions. - Floating Hydraulic Cylinders

Floating hydraulic cylinders allow limited free movement in specific directions to absorb shocks and vibrations. They enhance stability by compensating for uneven terrain or dynamic loads during platform operation. These cylinders feature flexible mounting and hydraulic damping, ensuring smooth performance and reducing wear on the platform’s structural components in rugged environments. - Luffing Hydraulic Cylinders

Luffing hydraulic cylinders control the vertical pivoting motion of the arm, enabling the platform to raise or lower its working height. They provide powerful, precise articulation for positioning the basket accurately. Built with high-strength materials, these cylinders ensure reliable operation under heavy loads and maintain structural integrity during repetitive movements. - Jib Hydraulic Cylinders

Jib hydraulic cylinders manage the articulation of the jib arm, allowing fine-tuned positioning of the platform. They enable lateral and vertical adjustments, enhancing access to confined or complex work areas. These cylinders are designed for precision and durability, with advanced seals to prevent leaks and ensure consistent performance in demanding conditions. - Steering Hydraulic Cylinders

Steering hydraulic cylinders facilitate directional control of the platform’s wheels or chassis. Double-acting and robust, they convert hydraulic pressure into mechanical force for smooth, precise steering. Featuring corrosion-resistant components and reliable seals, they ensure maneuverability in tight spaces, enhancing operational efficiency and safety in diverse work environments.

Arm Type Aerial Work Platform Steering Hydraulic Cylinder Components

- Cylinder Barrel

The hydraulic cylinder barrel is a heavy-duty steel tube that houses the piston and hydraulic fluid in the steering hydraulic cylinder. Engineered to withstand extreme pressure and external forces, it ensures structural stability. Precision-machined for seamless piston movement, it features corrosion-resistant coatings to deliver reliable, long-term performance in harsh environments typical of aerial work platforms. - Piston

The hydraulic cylinder piston is a vital component that slides within the cylinder barrel, powered by hydraulic fluid pressure. It transfers force to the piston rod, facilitating precise steering motion. Constructed from high-strength alloys, it resists wear and deformation, ensuring consistent performance and durability under heavy loads in demanding operational conditions. - Piston Rod

The hydraulic cylinder piston rod extends from the piston to connect with the steering mechanism of the aerial work platform. Made from hardened chrome-plated steel, it resists corrosion and abrasion. Its polished surface reduces seal friction, enabling efficient force transfer and smooth, reliable steering in challenging work environments. - Seals

Hydraulic cylinder seals are essential for preventing hydraulic fluid leaks and blocking contaminants from entering the cylinder. Crafted from durable materials like polyurethane or high-grade rubber, they maintain integrity under high pressure. Their advanced design ensures long-lasting performance and reliability, protecting the cylinder in rugged conditions encountered during aerial platform operations. - End Caps

Hydraulic cylinder end caps close off both ends of the cylinder barrel, guiding the piston rod and containing hydraulic fluid. Built from robust materials, they incorporate fluid ports and ensure precise alignment. Their engineered design supports high-pressure operations, maintaining structural integrity and enabling consistent steering performance in aerial work platforms. - Hydraulic Fluid Ports

Hydraulic fluid ports are integrated into the end caps to facilitate the flow of hydraulic fluid in and out of the cylinder. They ensure precise control of piston movement for responsive steering. Designed for high-pressure efficiency, they enable smooth operation and accurate directional control in arm-type aerial work platforms.

Arm Type Aerial Work Platform Steering Hydraulic Cylinder Repair

- Safety Precautions

Before repairing the steering hydraulic cylinder, ensure the aerial work platform is powered off and secured on stable ground. Depressurize the hydraulic system to prevent fluid spray injuries. Wear protective gear, including gloves and safety glasses, to handle components safely and avoid hazards during disassembly. - Disassembly and Inspection

Remove the cylinder from the platform by disconnecting hydraulic lines and mounting bolts. Disassemble the cylinder by removing end caps and extracting the piston and rod. Inspect all components for wear cracks or corrosion noting any damaged seals or scored surfaces that may affect performance. - Seal Replacement

Replace worn or damaged seals to prevent leaks and ensure proper cylinder function. Use high-quality seals compatible with the hydraulic fluid such as polyurethane or rubber. Clean the seal grooves thoroughly and install new seals carefully to avoid damage ensuring a tight fit for reliable operation. - Piston and Rod Repair

Examine the piston and rod for scratches, dents, or corrosion. Polish minor surface imperfections with fine emery cloth or replace severely damaged components. Ensure the rod’s chrome plating is intact to minimize friction and maintain smooth movement for effective steering control in the platform. - Cylinder Barrel Maintenance

Inspect the cylinder barrel for internal scoring or corrosion that could impair piston movement. Hone the inner surface if minor damage is present, or replace the barrel if damage is extensive. Clean thoroughly to remove debris, ensuring smooth operation and longevity of the repaired cylinder. - Reassembly and Testing

Reassemble the cylinder with new seals, lubricated components, and properly aligned parts. Reinstall it onto the platform and reconnect the hydraulic lines. Test the system under low pressure to check for leaks and verify smooth steering operation before returning the platform to full service.

Additional information

| Edited by | Yjx |

|---|