Steel Straight Bevel Gears Ratio 2:1 Straight Tooth System

A steel straight bevel gear with a 2:1 ratio refers to a mechanical component designed for transmitting motion and power between intersecting shafts at a 90-degree angle. These gears feature straight teeth that are cut radially along the surface of the conical gear face, ensuring direct and efficient engagement with the mating gear. The 2:1 ratio indicates that for every two revolutions of the driving gear, the driven gear completes one revolution, effectively doubling the torque while reducing the speed.

A steel straight bevel gear with a 2:1 ratio refers to a mechanical component designed for transmitting motion and power between intersecting shafts at a 90-degree angle. These gears feature straight teeth that are cut radially along the surface of the conical gear face, ensuring direct and efficient engagement with the mating gear. The 2:1 ratio indicates that for every two revolutions of the driving gear, the driven gear completes one revolution, effectively doubling the torque while reducing the speed.

Made of durable steel, these steel bevel gears are commonly used in high-strength applications requiring precision and reliability, such as automotive systems, industrial machinery, and robotics. Their straight-tooth system provides simplicity in design and manufacturing, although it may generate more noise and less smooth operation compared to spiral bevel gears.

Steel Straight Bevel Gear Ratio 2:1

|  |

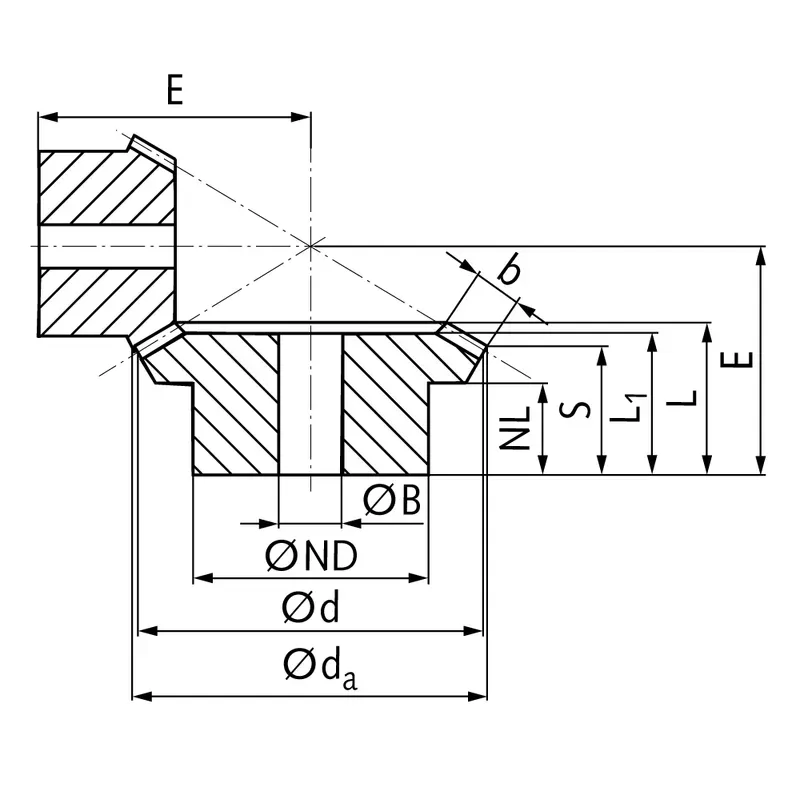

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 20 | 11,2 | 10 | 8 | 4,0 | 7,0 | 7,5 | 5,0 | 3 | 4 | 14,65 | 0,017 | 2 |

| 0,5 | 40 | 20,3 | 20 | 12 | 5,0 | 7,5 | 8,4 | 7,1 | 3 | 4 | 11,83 | 0,034 | 8 |

| 1 | 15 | 17,4 | 15 | 13 | 6,5 | 11 | 11,9 | 7,6 | 5 | 5 | 22 | 0,063 | 10 |

| 1 | 30 | 30,6 | 30 | 20 | 9,0 | 13 | 15,1 | 13,1 | 5 | 5 | 20 | 0,126 | 40 |

| 1,5 | 15 | 26,1 | 22,5 | 18 | 6,5 | 13 | 14,8 | 8,4 | 7,6 | 8 | 30 | 0,22 | 26 |

| 1,5 | 30 | 45,9 | 45 | 30 | 12,0 | 18 | 20,7 | 17,6 | 7,6 | 10 | 28 | 0,44 | 124 |

| 1,5 | 20 | 33,6 | 30 | 20 | 9,5 | 19 | 21,6 | 12,9 | 10,1 | 8 | 42 | 0,54 | 59 |

| 1,5 | 40 | 60,9 | 60 | 40 | 12,0 | 19 | 22,0 | 17,9 | 10,1 | 15 | 32 | 1,08 | 234 |

| 2 | 15 | 33,7 | 30 | 20 | 7,5 | 22 | 23,0 | 10,9 | 14 | 10 | 40 | 0,59 | 58 |

| 2 | 30 | 61,8 | 60 | 40 | 12,0 | 24 | 27,2 | 21,9 | 14 | 15 | 35 | 1,18 | 312 |

| 2 | 20 | 43,7 | 40 | 30 | 7,5 | 22 | 24,0 | 10,9 | 15 | 10 | 50 | 1,4 | 132 |

| 2 | 40 | 81,8 | 80 | 50 | 18,0 | 29 | 32,8 | 26,9 | 15 | 20 | 45 | 2,8 | 593 |

| 2,5 | 15 | 42,2 | 37,5 | 30 | 15,6 | 31 | 33,3 | 18,6 | 17 | 10 | 55 | 3,4 | 160 |

| 2,5 | 30 | 77,3 | 75 | 50 | 10,0 | 24 | 28,1 | 21,6 | 17 | 15 | 38 | 6,8 | 530 |

| 2,5 | 20 | 54,6 | 50 | 30 | 14,0 | 34 | 36,6 | 19,2 | 20 | 10 | 68 | 4,3 | 280 |

| 2,5 | 40 | 102,3 | 100 | 60 | 15,0 | 29 | 33,3 | 25,3 | 20 | 25 | 48 | 8,6 | 970 |

| 3 | 15 | 50,6 | 45 | 30 | 11,5 | 33 | 35,4 | 16,4 | 22 | 10 | 60 | 6,1 | 270 |

| 3 | 30 | 92,8 | 90 | 50 | 10 | 26 | 30,7 | 22,3 | 22 | 20 | 42 | 12,2 | 750 |

| 3 | 20 | 65,6 | 60 | 40 | 10 | 33 | 36,1 | 14,4 | 25 | 15 | 73 | 15,2 | 450 |

| 3 | 40 | 122,8 | 120 | 60 | 18 | 34 | 38,7 | 28,8 | 25 | 25 | 56 | 30,4 | 1400 |

| 4 | 15 | 67,5 | 60 | 40 | 10 | 38 | 41,0 | 16,9 | 28 | 20 | 75 | 14,6 | 410 |

| 4 | 30 | 123,8 | 120 | 60 | 15 | 33 | 39,4 | 28,8 | 28 | 25 | 55 | 29,2 | 1600 |

| 4 | 20 | 87,4 | 80 | 50 | 13 | 45 | 48,0 | 21,9 | 30 | 20 | 100 | 35,0 | 970 |

| 4 | 40 | 163,7 | 160 | 80 | 20 | 40 | 45,7 | 33,7 | 30 | 30 | 70 | 70,0 | 3300 |

| 5 | 15 | 84,4 | 75 | 60 | 15 | 50 | 54,1 | 21,4 | 38 | 20 | 94 | 30,2 | 980 |

| 5 | 30 | 154,7 | 150 | 70 | 15 | 40 | 46,7 | 32,2 | 38 | 30 | 65 | 60,4 | 3030 |

| 5 | 20 | 109,3 | 100 | 60 | 18 | 58 | 62,1 | 27,3 | 40 | 25 | 125 | 72,4 | 1890 |

| 5 | 40 | 204,7 | 200 | 90 | 20 | 48 | 55,6 | 39,7 | 40 | 35 | 85 | 144,8 | 6480 |

| 6 | 20 | 130,7 | 120 | 70 | 15 | 58 | 67 | 23,6 | 50 | 30 | 139,9 | 130,0 | 2960 |

| 6 | 40 | 245,3 | 240 | 100 | 20 | 50 | 58 | 37,7 | 50 | 40 | 92,3 | 260,0 | 9610 |

Advantages of Steel Straight Bevel Gears

1. High Strength and Durability

Steel straight bevel gears, made from robust materials like carbon or alloy steel, offer exceptional strength and wear resistance. Their heat-treated construction ensures longevity, making them ideal for heavy-duty applications requiring reliable power transmission under significant loads.

2. Cost-Effective Manufacturing

The straight tooth design simplifies the production process compared to spiral bevel gears. This straightforward geometry allows for easier machining and lower manufacturing costs, making steel straight bevel gears an economical choice for many industrial applications without sacrificing performance.

3. Efficient Power Transmission

These steel bevel gears provide effective torque transfer between intersecting shafts, typically at 90 degrees. The 2:1 ratio ensures precise speed reduction and torque increase, making them suitable for machinery requiring consistent power delivery in compact, right-angle configurations.

4. Versatility in Applications

Steel straight bevel gears are adaptable to various industries, including automotive, aerospace, and heavy machinery. Their ability to handle moderate loads and speeds makes them suitable for applications like differential systems, where reliable power transfer is critical.

5. Ease of Maintenance

The simple design of steel bevel gears facilitates easier inspection and maintenance. Their straightforward tooth geometry allows for quick identification of wear or damage, reducing downtime and maintenance costs in industrial settings where reliability is paramount.

6. Compact Design

These gears enable efficient power transmission in space-constrained systems. Their conical shape and straight teeth allow for a compact footprint, making them ideal for machinery where space is limited, while still delivering robust performance and torque.

Miter Gear Vs Bevel Gear

Miter Gears: Miter gears are a type of bevel gear with teeth that intersect at a 90-degree angle. They are designed to transmit motion and power between two shafts that are perpendicular to each other. Miter gears are commonly used in a wide range of mechanical applications, including industrial machinery, automotive systems, and precision instruments.

The teeth of miter gears are cut at a 45-degree angle to the axis of rotation, allowing them to mesh together smoothly and efficiently. This unique tooth geometry enables miter gears to change the direction of rotation while maintaining a constant velocity ratio between the input and output shafts.

Bevel Gears: Bevel gears are a type of mechanical gear that features conically-shaped teeth, allowing them to transmit power between intersecting shafts at various angles. Unlike miter gears, which are limited to 90-degree angles, bevel gears offer greater flexibility in shaft orientation. These gears find extensive use in a wide range of machinery and applications where power transmission between non-parallel shafts is required.

Bevel gears come in different configurations, including straight bevel gears, spiral bevel gears, and hypoid bevel gears.

- Straight bevel gears have teeth that are cut straight across the cone surface, while spiral bevel gears feature curved teeth for smoother and quieter operation.

- Hypoid bevel gears, a variation of spiral bevel gears, have an offset pinion axis for increased torque capacity and reduced noise.

Key Differences Between Miter Gears and Bevel Gears

While both miter gears and bevel gears are used to transmit power between intersecting shafts, they have distinct differences in design, functionality, and mechanical advantage.

1. Design

Miter gears are a specific type of bevel gear designed to operate with shafts at a 90-degree angle.

In contrast, bevel gears can be designed for any angle between 0 and 180 degrees, providing greater flexibility in shaft positioning.

2. Functional

Miter gears are typically used in applications requiring a 90-degree change in direction of motion or power transmission. They are commonly found in hand tools, automotive differentials, and industrial machinery.

Bevel gears, on the other hand, offer more versatility in terms of shaft angles and are used in a wider range of applications, such as automotive drivetrains, aircraft control systems, and power transmission in various machines.

3. Mechanical Advantage

Miter gears generally have a 1:1 gear ratio, meaning they do not provide any mechanical advantage in terms of speed or torque.

Bevel gears, however, can be designed with different gear ratios, allowing for speed reduction or torque multiplication, depending on the application requirements.

4. Load Requirements

The load capacity of miter gears and bevel gears varies based on factors such as material, surface hardness, and tooth profile. Generally, bevel gears can handle higher loads compared to miter gears due to their ability to distribute stress more evenly along the tooth surface.

5. Space Constraints

Miter gears are more compact and require less space for their installation, making them suitable for applications with limited space. Bevel gears, while more versatile in terms of shaft angles, may require more space to accommodate their larger size and angular positioning.

|  |

| Miter Gear | Bevel Gear |

Steel Straight Bevel Gear Applications

- Automotive Differentials

Steel straight bevel gears are widely used in automotive differentials to transfer torque between the drive shaft and the wheels. Their ability to handle high loads and provide efficient torque transmission ensures smooth operation under varying driving conditions, including sharp turns. - Industrial Machinery

In heavy industrial machinery, such as conveyors, mixers, and crushers, these steel bevel gears play a critical role in transmitting power between intersecting shafts. Their durable steel construction ensures reliability and efficiency, even in environments with high stress and continuous operation. - Power Tools and Equipment

Many power tools, such as drills, saws, and grinders, rely on straight bevel gears for motion transfer. Their compact design and precise motion control make them ideal for small, portable devices requiring efficient speed reduction or torque multiplication. - Robotics and Automation Systems

Steel bevel gears are used in robotics and automated systems for precise movement and power transfer at right angles. Their high precision and reliability allow them to function seamlessly in robotic arms, conveyor systems, and other automated machinery requiring accuracy and durability. - Marine Equipment

In marine applications, such as winches, rudder systems, and propulsion mechanisms, these gears handle the challenging conditions of high humidity and heavy loads. Their robust steel construction ensures resistance to wear and corrosion, providing long-lasting performance in harsh marine environments. - Aerospace Industry

Steel straight bevel gears are used in aerospace systems for power transmission in landing gears, flight control systems, and auxiliary equipment. Their ability to function reliably under extreme temperatures and stresses makes them indispensable in aviation and space exploration technology.

|  |

| Bevel Gear for Automotive Differentials | Bevel Gear for Robotics |

|  |

| Bevel Gear for Industrial Machinery | Bevel Gear for Marine Industry |

Additional information

| Edited by | Yjx |

|---|