Steel Straight Bevel Gears Ratio 1:1 – 4:1 Straight Tooth System

Steel straight bevel gears with ratios from 1:1 to 4:1 are conical gears designed to transmit power between intersecting shafts, typically at a 90-degree angle. The straight tooth system features teeth cut parallel to the cone’s generators, resembling spur gears but conical in shape. The gear ratio, ranging from 1:1 (equal teeth on both gears, as in miter gears) to 4:1 (driven gear has four times the teeth of the pinion), determines speed and torque changes.

Steel straight bevel gears with ratios from 1:1 to 4:1 are conical gears designed to transmit power between intersecting shafts, typically at a 90-degree angle. The straight tooth system features teeth cut parallel to the cone’s generators, resembling spur gears but conical in shape. The gear ratio, ranging from 1:1 (equal teeth on both gears, as in miter gears) to 4:1 (driven gear has four times the teeth of the pinion), determines speed and torque changes.

For example, a 4:1 ratio reduces speed but increases torque fourfold. Made from materials like carbon or alloy steel (e.g., C45), these straight bevel gears are heat-treated for durability. They’re cost-effective, simple to manufacture, and ideal for low-speed, low-load applications like differential drives, but abrupt tooth engagement increases noise and limits high-speed use.

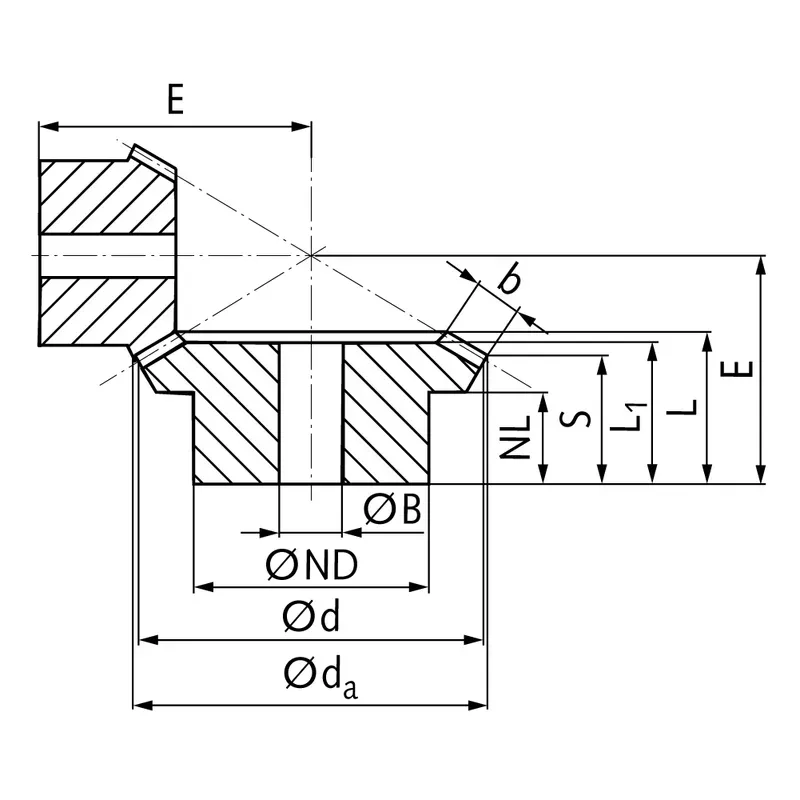

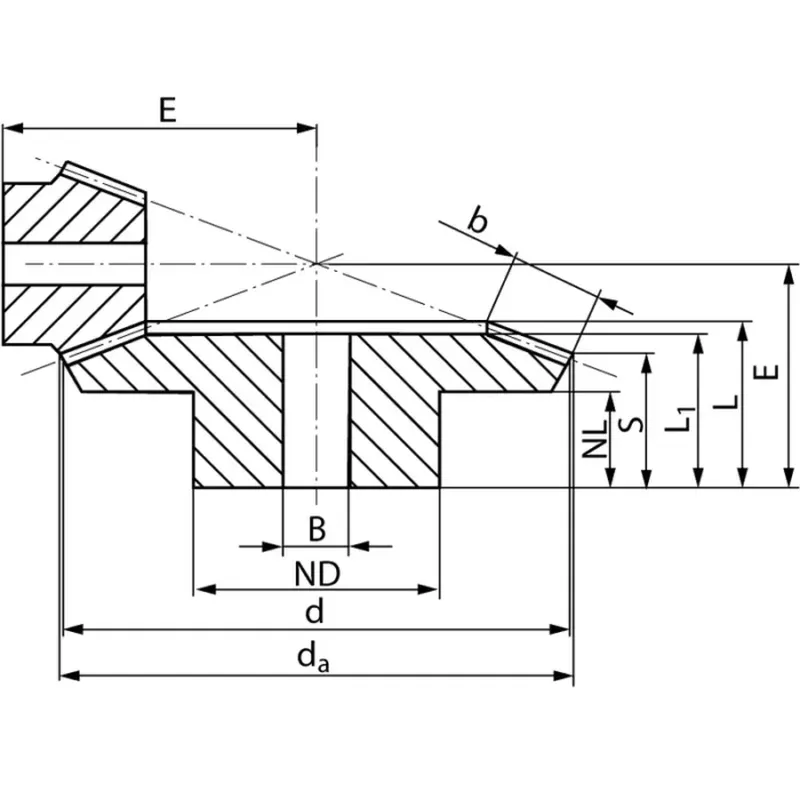

Steel Straight Bevel Gear Ratio 1.25:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 3 | 16 | 52,9 | 48 | 40 | 11,7 | 27 | 29,2 | 16,9 | 17 | 15 | 45 | 5,2 | 220 |

| 3 | 20 | 63,9 | 60 | 40 | 10,0 | 25 | 27,8 | 18,4 | 17 | 15 | 40 | 6,5 | 300 |

| 4 | 16 | 70,6 | 64 | 50 | 12,5 | 32 | 36,5 | 20,6 | 22 | 20 | 58 | 12,7 | 470 |

| 4 | 20 | 85,2 | 80 | 50 | 15,0 | 33 | 38,4 | 26,3 | 22 | 20 | 55 | 15,9 | 700 |

| 5 | 16 | 88,2 | 80 | 60 | 12,0 | 40 | 44,2 | 23,3 | 29 | 20 | 70 | 25,4 | 910 |

| 5 | 20 | 106,6 | 100 | 60 | 15,0 | 39 | 45,0 | 29,1 | 29 | 25 | 65 | 31,8 | 1300 |

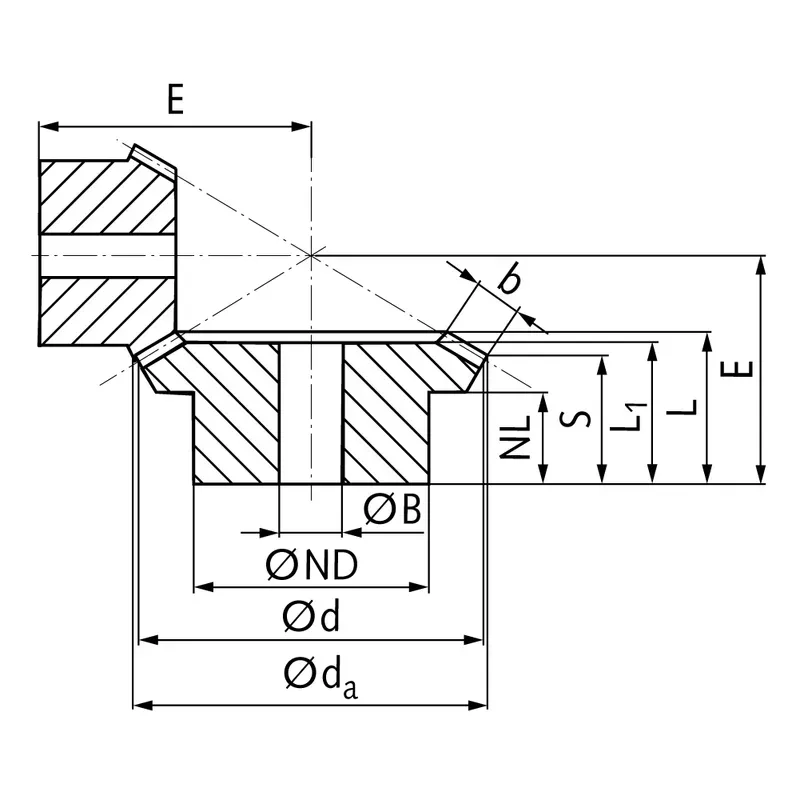

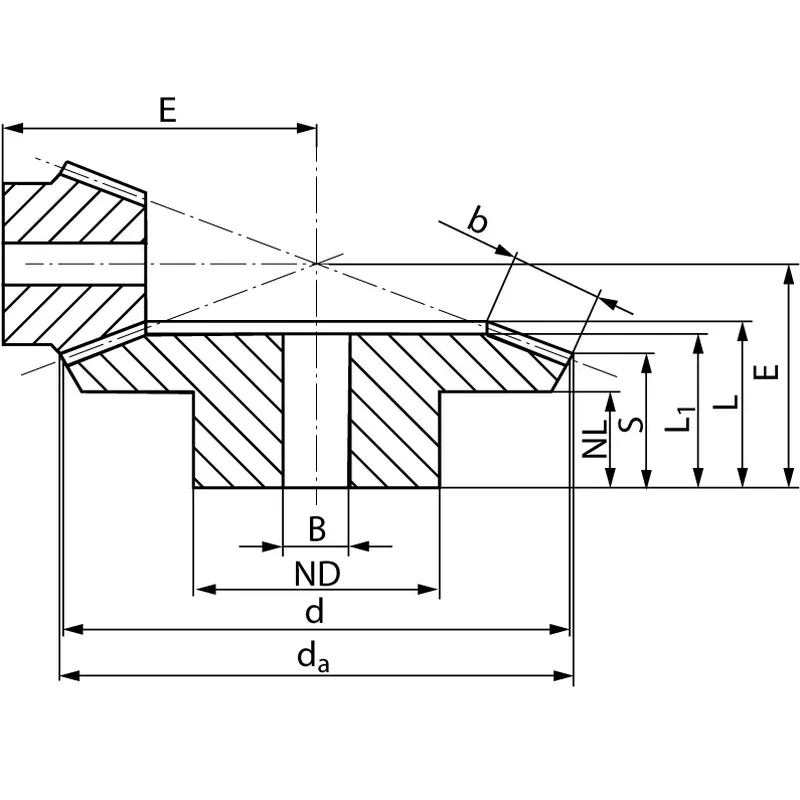

Steel Straight Bevel Gear Ratio 1.5:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 20 | 11,0 | 10 | 8 | 3,5 | 6,5 | 7,1 | 4,7 | 3 | 4 | 11,9 | 0,014 | 2 |

| 0,5 | 30 | 15,4 | 15 | 10 | 4,0 | 6,0 | 7,0 | 5,4 | 3 | 4 | 10,1 | 0,021 | 4 |

| 1 | 16 | 18,1 | 16 | 13 | 6,9 | 11 | 12,0 | 8,7 | 4,3 | 5 | 20 | 0,066 | 10 |

| 1 | 24 | 24,8 | 24 | 20 | 8,8 | 13 | 14,8 | 12,6 | 4,3 | 5 | 20 | 0,099 | 32 |

| 1,5 | 16 | 27,1 | 24 | 20 | 8,7 | 14 | 16,1 | 11,0 | 6,5 | 8 | 28 | 0,023 | 34 |

| 1,5 | 24 | 37,2 | 36 | 20 | 12,0 | 17 | 20,2 | 16,9 | 6,5 | 10 | 28 | 0,035 | 55 |

| 1,5 | 20 | 33,1 | 30 | 20 | 9,0 | 17 | 18,9 | 12,5 | 8,1 | 8 | 34 | 0,43 | 52 |

| 1,5 | 30 | 46,2 | 45 | 30 | 12,0 | 20 | 22,1 | 17,9 | 8,1 | 10 | 32 | 0,65 | 133 |

| 2 | 16 | 35,5 | 32 | 20 | 8,0 | 21 | 22,6 | 13,1 | 12 | 10 | 36 | 0,57 | 60 |

| 2 | 24 | 50,3 | 48 | 30 | 8,0 | 18 | 21,5 | 15,7 | 12 | 10 | 30 | 0,86 | 151 |

| 2 | 20 | 43,5 | 40 | 30 | 7,5 | 20 | 22,3 | 11,2 | 14 | 10 | 40 | 1,15 | 119 |

| 2 | 30 | 62,3 | 60 | 40 | 15,0 | 25 | 28,7 | 21,7 | 14 | 15 | 40 | 1,73 | 301 |

| 2,5 | 16 | 44,3 | 40 | 30 | 11,7 | 26 | 28,2 | 16,4 | 14 | 10 | 45 | 3,3 | 150 |

| 2,5 | 24 | 62,9 | 60 | 30 | 12,0 | 26 | 29,4 | 22,1 | 14 | 10 | 40 | 5,0 | 300 |

| 2,5 | 20 | 54,3 | 50 | 30 | 10,0 | 27 | 30,2 | 16,0 | 18 | 10 | 52 | 6,8 | 230 |

| 2,5 | 30 | 77,9 | 75 | 50 | 14,0 | 27 | 31,1 | 22,2 | 18 | 15 | 45 | 10,2 | 550 |

| 3 | 16 | 53,2 | 48 | 40 | 13,2 | 30 | 32,7 | 17,7 | 19 | 15 | 52 | 5,9 | 250 |

| 3 | 24 | 75,5 | 72 | 50 | 8,0 | 24 | 27,8 | 18,6 | 19 | 15 | 40 | 8,9 | 490 |

| 3 | 20 | 65,2 | 60 | 40 | 10,0 | 33 | 35,8 | 16,8 | 24 | 15 | 60 | 12,4 | 390 |

| 3 | 30 | 93,5 | 90 | 50 | 15,0 | 33 | 37,6 | 25,7 | 24 | 20 | 53 | 18,6 | 860 |

| 4 | 16 | 71,0 | 64 | 50 | 12,5 | 36 | 38,9 | 19,3 | 25 | 20 | 65 | 14,3 | 500 |

| 4 | 24 | 100,7 | 96 | 60 | 12,0 | 31 | 35,6 | 23,5 | 25 | 20 | 52 | 21,5 | 1010 |

| 4 | 20 | 87,0 | 80 | 50 | 18,0 | 48 | 51,1 | 27,3 | 30 | 20 | 85 | 29,5 | 950 |

| 4 | 30 | 124,6 | 120 | 60 | 18,0 | 40 | 46,4 | 31,5 | 30 | 25 | 68 | 44,3 | 1900 |

| 5 | 20 | 108,7 | 100 | 60 | 12,0 | 50 | 54,7 | 22,9 | 40 | 25 | 95 | 60,6 | 1630 |

| 5 | 30 | 155,8 | 150 | 70 | 12,0 | 40 | 46,3 | 26,4 | 40 | 30 | 72 | 90,9 | 3070 |

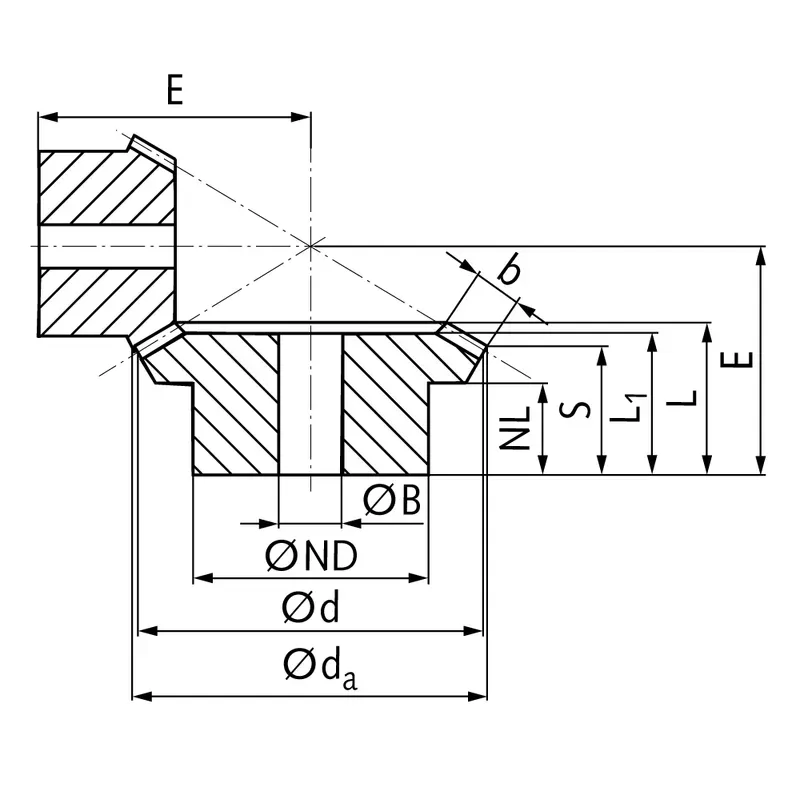

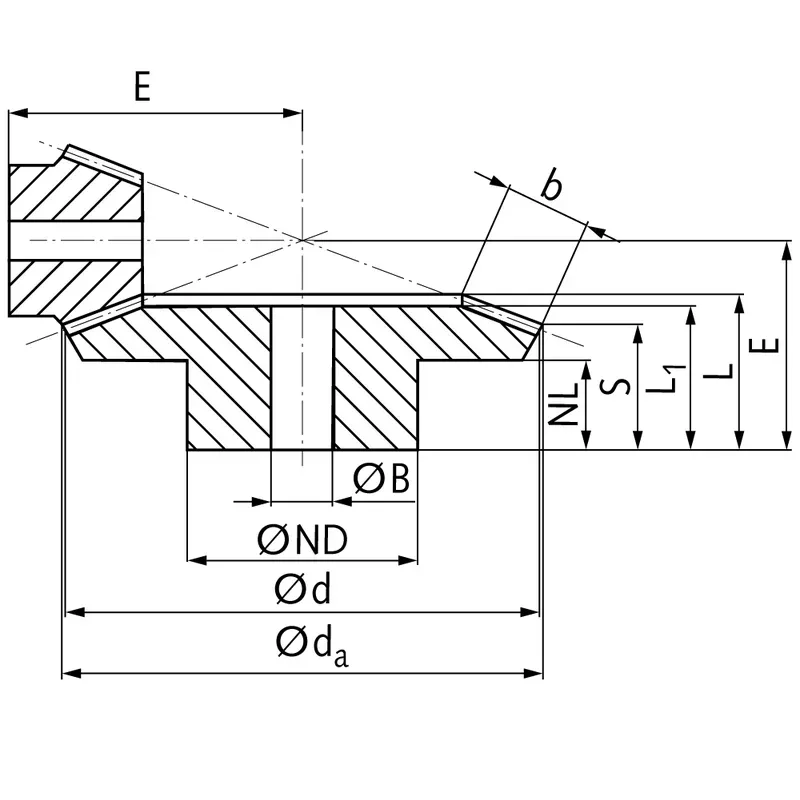

Steel Straight Bevel Gear Ratio 2:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 20 | 11,2 | 10 | 8 | 4,0 | 7,0 | 7,5 | 5,0 | 3 | 4 | 14,65 | 0,017 | 2 |

| 0,5 | 40 | 20,3 | 20 | 12 | 5,0 | 7,5 | 8,4 | 7,1 | 3 | 4 | 11,83 | 0,034 | 8 |

| 1 | 15 | 17,4 | 15 | 13 | 6,5 | 11 | 11,9 | 7,6 | 5 | 5 | 22 | 0,063 | 10 |

| 1 | 30 | 30,6 | 30 | 20 | 9,0 | 13 | 15,1 | 13,1 | 5 | 5 | 20 | 0,126 | 40 |

| 1,5 | 15 | 26,1 | 22,5 | 18 | 6,5 | 13 | 14,8 | 8,4 | 7,6 | 8 | 30 | 0,22 | 26 |

| 1,5 | 30 | 45,9 | 45 | 30 | 12,0 | 18 | 20,7 | 17,6 | 7,6 | 10 | 28 | 0,44 | 124 |

| 1,5 | 20 | 33,6 | 30 | 20 | 9,5 | 19 | 21,6 | 12,9 | 10,1 | 8 | 42 | 0,54 | 59 |

| 1,5 | 40 | 60,9 | 60 | 40 | 12,0 | 19 | 22,0 | 17,9 | 10,1 | 15 | 32 | 1,08 | 234 |

| 2 | 15 | 33,7 | 30 | 20 | 7,5 | 22 | 23,0 | 10,9 | 14 | 10 | 40 | 0,59 | 58 |

| 2 | 30 | 61,8 | 60 | 40 | 12,0 | 24 | 27,2 | 21,9 | 14 | 15 | 35 | 1,18 | 312 |

| 2 | 20 | 43,7 | 40 | 30 | 7,5 | 22 | 24,0 | 10,9 | 15 | 10 | 50 | 1,4 | 132 |

| 2 | 40 | 81,8 | 80 | 50 | 18,0 | 29 | 32,8 | 26,9 | 15 | 20 | 45 | 2,8 | 593 |

| 2,5 | 15 | 42,2 | 37,5 | 30 | 15,6 | 31 | 33,3 | 18,6 | 17 | 10 | 55 | 3,4 | 160 |

| 2,5 | 30 | 77,3 | 75 | 50 | 10,0 | 24 | 28,1 | 21,6 | 17 | 15 | 38 | 6,8 | 530 |

| 2,5 | 20 | 54,6 | 50 | 30 | 14,0 | 34 | 36,6 | 19,2 | 20 | 10 | 68 | 4,3 | 280 |

| 2,5 | 40 | 102,3 | 100 | 60 | 15,0 | 29 | 33,3 | 25,3 | 20 | 25 | 48 | 8,6 | 970 |

| 3 | 15 | 50,6 | 45 | 30 | 11,5 | 33 | 35,4 | 16,4 | 22 | 10 | 60 | 6,1 | 270 |

| 3 | 30 | 92,8 | 90 | 50 | 10 | 26 | 30,7 | 22,3 | 22 | 20 | 42 | 12,2 | 750 |

| 3 | 20 | 65,6 | 60 | 40 | 10 | 33 | 36,1 | 14,4 | 25 | 15 | 73 | 15,2 | 450 |

| 3 | 40 | 122,8 | 120 | 60 | 18 | 34 | 38,7 | 28,8 | 25 | 25 | 56 | 30,4 | 1400 |

| 4 | 15 | 67,5 | 60 | 40 | 10 | 38 | 41,0 | 16,9 | 28 | 20 | 75 | 14,6 | 410 |

| 4 | 30 | 123,8 | 120 | 60 | 15 | 33 | 39,4 | 28,8 | 28 | 25 | 55 | 29,2 | 1600 |

| 4 | 20 | 87,4 | 80 | 50 | 13 | 45 | 48,0 | 21,9 | 30 | 20 | 100 | 35,0 | 970 |

| 4 | 40 | 163,7 | 160 | 80 | 20 | 40 | 45,7 | 33,7 | 30 | 30 | 70 | 70,0 | 3300 |

| 5 | 15 | 84,4 | 75 | 60 | 15 | 50 | 54,1 | 21,4 | 38 | 20 | 94 | 30,2 | 980 |

| 5 | 30 | 154,7 | 150 | 70 | 15 | 40 | 46,7 | 32,2 | 38 | 30 | 65 | 60,4 | 3030 |

| 5 | 20 | 109,3 | 100 | 60 | 18 | 58 | 62,1 | 27,3 | 40 | 25 | 125 | 72,4 | 1890 |

| 5 | 40 | 204,7 | 200 | 90 | 20 | 48 | 55,6 | 39,7 | 40 | 35 | 85 | 144,8 | 6480 |

| 6 | 20 | 130,7 | 120 | 70 | 15 | 58 | 67 | 23,6 | 50 | 30 | 139,9 | 130,0 | 2960 |

| 6 | 40 | 245,3 | 240 | 100 | 20 | 50 | 58 | 37,7 | 50 | 40 | 92,3 | 260,0 | 9610 |

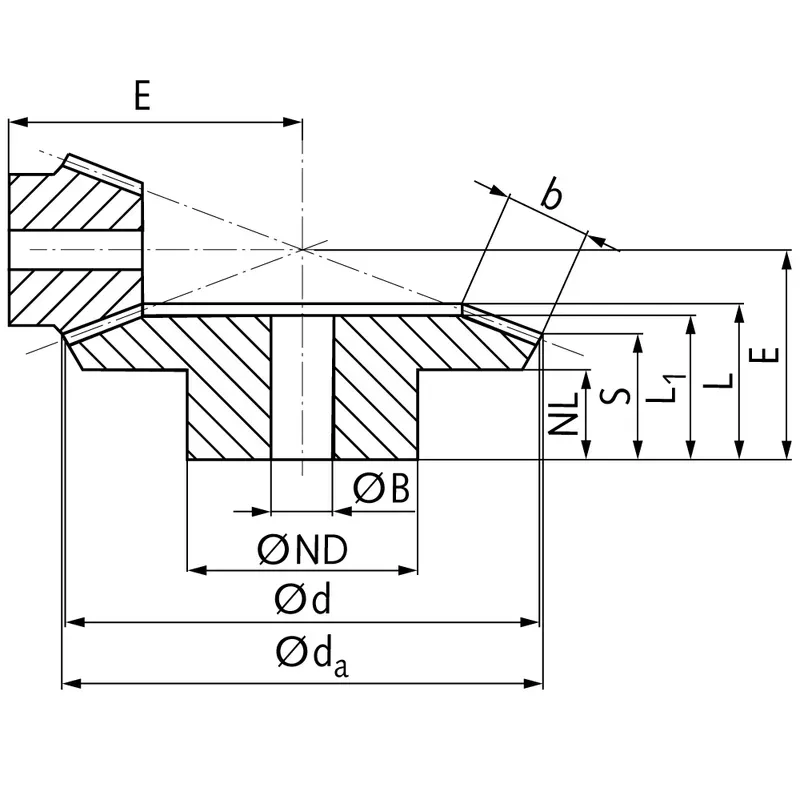

Steel Straight Bevel Gear Ratio 2.5:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 20 | 11,3 | 10 | 8 | 4,0 | 7 | 7,6 | 4,9 | 3 | 4 | 17,1 | 0,018 | 3 |

| 0,5 | 50 | 25,2 | 25 | 14 | 5,0 | 7 | 7,8 | 6,8 | 3 | 4 | 11,5 | 0,045 | 10 |

| 1 | 16 | 18,6 | 16 | 13 | 7,4 | 13 | 14,4 | 8,5 | 6,5 | 5 | 28 | 0,090 | 13 |

| 1 | 40 | 40,5 | 40 | 25 | 9,0 | 13 | 14,8 | 12,6 | 6,5 | 8 | 20 | 0,225 | 65 |

| 1,5 | 16 | 27,9 | 24 | 18 | 8,8 | 18 | 19,5 | 10,8 | 9,7 | 8 | 40 | 0,32 | 36 |

| 1,5 | 40 | 60,7 | 60 | 40 | 10,0 | 17 | 20,1 | 16,9 | 9,7 | 15 | 28 | 0,80 | 220 |

| 1,5 | 18 | 30,9 | 27 | 20 | 10,8 | 21 | 22,9 | 13,0 | 10,9 | 8 | 46 | 0,47 | 54 |

| 1,5 | 45 | 68,2 | 67,5 | 50 | 12,0 | 20 | 24,1 | 20,4 | 10,9 | 15 | 33 | 1,18 | 370 |

| 2 | 16 | 35,9 | 32 | 20 | 9,0 | 25 | 26,4 | 12,7 | 15 | 10 | 52 | 0,84 | 76 |

| 2 | 40 | 81,5 | 80 | 50 | 15,0 | 29 | 32,7 | 27,9 | 15 | 20 | 42 | 2,10 | 650 |

| 2 | 18 | 39,8 | 36 | 30 | 11,8 | 26 | 27,4 | 13,8 | 15 | 10 | 58 | 1,18 | 133 |

| 2 | 45 | 91,5 | 90 | 60 | 18,0 | 30 | 33,8 | 28,9 | 15 | 25 | 45 | 2,95 | 830 |

| 2,5 | 16 | 44,8 | 40 | 30 | 13,0 | 32 | 34,1 | 15,9 | 20 | 10 | 65 | 5,0 | 180 |

| 2,5 | 40 | 101,9 | 100 | 60 | 15,0 | 29 | 33,8 | 27,4 | 20 | 25 | 45 | 12,5 | 1000 |

| 2,5 | 18 | 49,8 | 45 | 30 | 15,75 | 36 | 37,9 | 19,7 | 20 | 10 | 75 | 7,1 | 240 |

| 2,5 | 45 | 114,4 | 112,5 | 70 | 15,0 | 28 | 33,4 | 26,9 | 20 | 25 | 47 | 17,8 | 1200 |

| 3 | 16 | 53,8 | 48 | 40 | 13,6 | 37 | 38,8 | 16,1 | 25 | 15 | 75 | 9,0 | 310 |

| 3 | 40 | 122,3 | 120 | 60 | 16,0 | 32 | 36,8 | 28,9 | 25 | 25 | 50 | 22,5 | 1400 |

| 3 | 18 | 59,8 | 54 | 40 | 11,7 | 36 | 38,4 | 15,7 | 25 | 15 | 82 | 12,8 | 380 |

| 3 | 45 | 137,3 | 135 | 70 | 18,0 | 34 | 39,0 | 30,9 | 25 | 30 | 55 | 32,0 | 1900 |

| 4 | 16 | 71,8 | 64 | 50 | 12,0 | 41 | 43,8 | 16,5 | 30 | 20 | 95 | 20,9 | 600 |

| 4 | 40 | 163,1 | 160 | 80 | 20,0 | 40 | 46,4 | 36,9 | 30 | 30 | 65 | 52,3 | 3400 |

| 4 | 18 | 79,7 | 72 | 50 | 13,8 | 44 | 46,8 | 19,5 | 30 | 20 | 108 | 29,3 | 800 |

| 4 | 45 | 183,0 | 180 | 90 | 20,0 | 43 | 49,6 | 39,9 | 30 | 30 | 72 | 73,3 | 4900 |

| 5 | 18 | 99,6 | 90 | 60 | 16,5 | 57 | 60,8 | 24,4 | 40 | 25 | 135 | 61,0 | 1560 |

| 5 | 45 | 228,8 | 225 | 100 | 20,0 | 50 | 57,8 | 44,8 | 40 | 40 | 85 | 152,5 | 9080 |

Steel Straight Bevel Gear Ratio 3:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 15 | 8,0 | 7,5 | 6 | 3,7 | 6,5 | 7,0 | 4,3 | 3 | 3 | 15,3 | 0,009 | 1 |

| 0,5 | 45 | 22,7 | 22,5 | 12 | 5,0 | 7,5 | 8,4 | 7,5 | 3 | 4 | 11,0 | 0,027 | 10 |

| 1 | 15 | 17,7 | 15 | 13 | 9,2 | 16 | 16,5 | 10,0 | 7,1 | 5 | 32 | 0,086 | 14 |

| 1 | 45 | 45,4 | 45 | 25 | 10 | 15 | 17,0 | 15,1 | 7,1 | 8 | 22 | 0,258 | 92 |

| 1,5 | 16 | 28 | 24 | 18 | 11 | 22 | 23,2 | 12,7 | 11,4 | 8 | 48 | 0,38 | 42 |

| 1,5 | 48 | 72,6 | 72 | 50 | 12 | 20 | 24,1 | 20,8 | 11,4 | 15 | 32 | 1,14 | 405 |

| 2 | 16 | 35,9 | 32 | 20 | 10 | 25 | 26,6 | 12,6 | 15 | 10 | 60 | 0,92 | 80 |

| 2 | 48 | 97,3 | 96 | 60 | 18 | 30 | 35,0 | 31,0 | 15 | 25 | 45 | 2,76 | 950 |

| 2,5 | 16 | 44,9 | 40 | 30 | 15,35 | 34 | 36,5 | 17,8 | 20 | 10 | 77 | 5,6 | 200 |

| 2,5 | 48 | 121,6 | 120 | 80 | 15 | 29 | 33,9 | 28,5 | 20 | 25 | 46 | 16,8 | 1600 |

| 3 | 16 | 53,9 | 48 | 40 | 12,5 | 36 | 38,3 | 15,0 | 25 | 15 | 86 | 10,0 | 310 |

| 3 | 48 | 145,9 | 144 | 70 | 18 | 34 | 38,7 | 32,0 | 25 | 30 | 53 | 30,0 | 2300 |

| 4 | 16 | 71,8 | 64 | 50 | 17 | 46 | 48,3 | 20,3 | 30 | 20 | 115 | 22,9 | 680 |

| 4 | 48 | 194,6 | 192 | 90 | 20 | 43 | 50,0 | 41,9 | 30 | 30 | 70 | 68,7 | 5700 |

| 5 | 15 | 84,9 | 75 | 60 | 15 | 53 | 56,4 | 19,1 | 40 | 20 | 130 | 39,3 | 1110 |

| 5 | 45 | 228,3 | 225 | 100 | 20 | 45 | 53,1 | 42,4 | 40 | 40 | 75 | 117,9 | 7920 |

| 5 | 16 | 89,8 | 80 | 60 | 16,5 | 55 | 59,0 | 21,6 | 40 | 20 | 140 | 47,7 | 1310 |

| 5 | 48 | 243,2 | 240 | 100 | 20 | 47 | 55,7 | 44,9 | 40 | 40 | 80 | 143,1 | 9640 |

| 6 | 15 | 101,4 | 90 | 70 | 20 | 67 | 73 | 26,2 | 50 | 30 | 159,2 | 70,7 | 1880 |

| 6 | 45 | 273,8 | 270 | 100 | 30 | 60 | 69 | 55,0 | 50 | 45 | 94,3 | 212,1 | 13170 |

Steel Straight Bevel Gear Ratio 3.5:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 16 | 18,7 | 16 | 13 | 7,6 | 16 | 16,6 | 8,4 | 8,7 | 5 | 36 | 0,127 | 16 |

| 1 | 56 | 56,3 | 56 | 30 | 10,0 | 14 | 16,7 | 14,6 | 8,7 | 8 | 22 | 0,445 | 130 |

| 1,5 | 16 | 28,1 | 24 | 18 | 12,2 | 24 | 26 | 13,6 | 13,1 | 8 | 55 | 0,45 | 48 |

| 1,5 | 56 | 84,5 | 84 | 50 | 12 | 24 | 27,1 | 23,8 | 13,1 | 15 | 35 | 1,58 | 634 |

| 2 | 16 | 35,9 | 32 | 20 | 10 | 25 | 26,8 | 12,5 | 15 | 10 | 68 | 0,99 | 82 |

| 2 | 56 | 113,1 | 112 | 60 | 18 | 31 | 35,5 | 31,9 | 15 | 25 | 46 | 3,47 | 1200 |

| 2,5 | 16 | 44,9 | 40 | 30 | 16,5 | 36 | 37,7 | 18,7 | 20 | 10 | 88 | 6,0 | 220 |

| 2,5 | 56 | 141,4 | 140 | 80 | 18 | 32 | 37,2 | 32,4 | 20 | 25 | 50 | 21,0 | 2300 |

| 3 | 16 | 53,9 | 48 | 40 | 15 | 39 | 40,6 | 16,8 | 25 | 15 | 100 | 10,9 | 340 |

| 3 | 56 | 169,7 | 168 | 80 | 18 | 33 | 39,8 | 34,0 | 25 | 30 | 55 | 38,2 | 3100 |

| 4 | 16 | 71,9 | 64 | 50 | 13 | 42 | 44,6 | 16,1 | 30 | 20 | 127 | 24,7 | 660 |

| 4 | 56 | 226,3 | 224 | 90 | 20 | 40 | 49,0 | 42,0 | 30 | 30 | 70 | 86,5 | 6900 |

Steel Straight Bevel Gear Ratio 4:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 15 | 17,8 | 15 | 13 | 7,7 | 17,3 | 17,3 | 8,4 | 9,3 | 5 | 38 | 0,117 | 15 |

| 1 | 60 | 60,3 | 60 | 30 | 10,0 | 15 | 17,1 | 15,1 | 9,3 | 8 | 22 | 0,468 | 160 |

| 1,5 | 15 | 26,7 | 22,5 | 18 | 14,45 | 28 | 28,9 | 15,5 | 13,9 | 8 | 60 | 0,41 | 42 |

| 1,5 | 60 | 90,4 | 90 | 50 | 12,0 | 25 | 27,6 | 24,6 | 13,9 | 15 | 35 | 1,64 | 745 |

| 2 | 15 | 34,0 | 30 | 20 | 13,5 | 29 | 29,9 | 15,5 | 15 | 10 | 75 | 1,02 | 80 |

| 2 | 60 | 120,9 | 120 | 60 | 20,0 | 35 | 40,1 | 37,0 | 15 | 25 | 50 | 4,08 | 1600 |

| 2,5 | 15 | 42,5 | 37,5 | 30 | 16,1 | 35 | 36,8 | 17,6 | 20 | 10 | 92 | 5,3 | 190 |

| 2,5 | 60 | 151,2 | 150 | 80 | 18,0 | 33 | 37,8 | 33,8 | 20 | 25 | 50 | 21,2 | 2600 |

| 3 | 15 | 51,0 | 45 | 30 | 13,15 | 38 | 39,7 | 15,7 | 25 | 10 | 105 | 9,6 | 270 |

| 3 | 60 | 181,5 | 180 | 80 | 18,0 | 35 | 40,6 | 35,5 | 25 | 30 | 55 | 38,4 | 3800 |

| 4 | 15 | 68,0 | 60 | 40 | 12,5 | 43 | 44,8 | 16,0 | 30 | 20 | 135 | 21,7 | 520 |

| 4 | 60 | 242,0 | 240 | 90 | 20,0 | 41 | 50,1 | 44,0 | 30 | 30 | 70 | 86,8 | 8300 |

Steel Straight Bevel Gear Design Features

- Conical Geometry

Steel straight bevel gears have a conical shape, allowing power transmission between intersecting shafts, typically at 90 degrees. The geometry ensures efficient torque transfer, with teeth cut straight along the cone’s surface, resembling spur gears but adapted for angular motion. - Straight Tooth Configuration

The teeth are cut parallel to the cone’s generators, creating a straightforward, cost-effective design. This configuration simplifies manufacturing and maintenance but results in abrupt tooth engagement, leading to higher noise levels compared to spiral bevel gears, especially in high-speed applications. - Material Strength

Typically made from high-strength carbon or alloy steels like C45 or 4140, these straight bevel gears undergo heat treatment (e.g., quenching or case hardening) to enhance durability. This ensures resistance to wear and fatigue, making them suitable for demanding industrial applications. - Gear Ratios (1:1 to 4:1)

The steel bevel gears support ratios from 1:1 (equal teeth, as in miter gears) to 4:1 (driven gear has four times the teeth). This range allows flexibility in adjusting speed and torque, critical for applications like differential systems or machinery drives. - Load Distribution

Straight teeth engage fully across their width, distributing loads evenly during operation. While this ensures reliable power transmission in low-speed settings, it can cause stress concentration at contact points, necessitating precise alignment to prevent premature wear or failure. - Compact Design

The compact conical structure allows integration into space-constrained systems, such as automotive differentials or small machinery. Their design balances strength and size, providing efficient power transfer while maintaining a robust profile suitable for moderate-load industrial environments.

Straight Bevel Gears vs. Spiral Bevel Gears

| Feature | Straight Bevel Gear | Spiral Bevel Gear |

|---|---|---|

| Teeth Profile | Teeth are straight and cut along the gear axis on a cone. | Teeth have a spiral curve profile cut on the pitch cone. |

| Contact Between Teeth | Two teeth come into sudden contact, and the contact is a line equal to the face width of the teeth. | Teeth come into contact gradually, starting with a point and progressing to a line. |

| Loading | Teeth are subjected to sudden impact or shock loading. | Teeth experience gradual loading, minimizing impact. |

| Operational Noise | Sudden contact causes significant noise during operation. | Gradual engagement results in quieter operation. |

| Vibration | Shock loading induces noticeable vibration, making operation less smooth. | Vibration is minimal due to gradual load application, ensuring smoother operation. |

| Ease of Manufacturing | Easier to design and manufacture, leading to lower costs. | Complex design and manufacturing process make it more expensive. |

| Thrust Force on Bearings | Exerts less thrust force on bearings compared to spiral bevel gears. | Exerts higher thrust force on bearings due to the spiral tooth profile. |

| Cost | More affordable due to simpler manufacturing and design. | Higher cost due to complex manufacturing and finishing requirements. |

| Speed and Power Transmission | Limited speed and power capacity due to vibration and noise constraints. | Capable of handling higher speeds and power loads due to smoother operation. |

| Applications | Suitable for applications requiring simplicity and lower costs. | Ideal for high-performance applications where smoothness and quiet operation are critical. |

|  |

| Straight Bevel Gears | Spiral Bevel Gears |

Steel Straight Bevel Gear Examples and Applications

1. Automotive Industry

Straight bevel gears are integral to the automotive industry, enhancing performance and efficiency. In differential systems, they distribute torque smoothly for stable cornering. In steering systems, they provide precise motion for better control. For transmissions, they enable seamless gear shifts with reduced noise and vibration. Additionally, in electric and hybrid vehicles, they minimize drivetrain noise, ensuring quiet, efficient operation. Their durability and adaptability make them essential in modern automotive designs.

2. Industrial Machinery

Steel bevel gears are essential in industrial machinery, providing smooth, efficient power transmission with reduced noise and vibration. They are widely used in gearboxes for heavy-duty equipment, ensuring reliable torque transfer under high loads. Additionally, straight bevel gears enhance performance in conveyors and material handling systems, ensuring durability and consistent operation in demanding industrial environments. Their adaptability supports various machinery designs.

3. Power Tools

Straight bevel gears are crucial in power tools, offering efficient torque transfer with minimal noise and vibration. In cordless drills and angle grinders, they ensure smooth power delivery for precise and reliable performance. Their durability and ability to handle high torque make them ideal for heavy-duty tools, extending tool life. Additionally, their compact design supports ergonomic and space-efficient tool configurations, enhancing functionality and user comfort in a wide range of applications.

4. Robotics

Bevel gears are vital in robotics, enabling precise motion control and efficient power transmission. They are widely used in robotic arms and joints, ensuring smooth and accurate movements with minimal noise and vibration. Their compact, durable design supports space-constrained robotic systems, making them ideal for advanced automation in manufacturing, healthcare, and logistics, where precision and reliability are critical.

5. Agricultural Machinery

Steel bevel gears play a key role in agricultural machinery by providing reliable, efficient power transmission under heavy loads. In tractors and harvesters, they ensure smooth torque transfer to drive systems, improving performance. For rotary tillers and mowers, they enable precise, durable operation, enhancing cutting and tilling efficiency. Their robust design and noise-reducing capabilities make them ideal for grain conveyors and fertilizer spreaders, ensuring consistent performance in demanding agricultural applications.

|  |

| Straight Bevel Gear for Automotive Industry | Straight Bevel Gear for Industrial Machinery |

|  |

| Straight Bevel Gear for Robotics | Straight Bevel Gear for Agricultural Machinery |

Additional information

| Edited by | Yjx |

|---|