Steel Straight Bevel Gears Ratio 1.5:1 Straight Tooth System

The steel straight bevel gears ratio 1.5:1 straight tooth system refers to a mechanical component used to transmit power and motion between intersecting shafts at a specific angle, typically 90 degrees. These gears feature straight teeth, which are cut along the surface of a cone, allowing for smooth engagement and power transfer. The 1.5:1 gear ratio means that for every 1.5 revolutions of the driving gear (input gear), the driven gear (output gear) completes one full revolution. This setup is ideal for applications requiring moderate speed reduction or torque increase.

The steel straight bevel gears ratio 1.5:1 straight tooth system refers to a mechanical component used to transmit power and motion between intersecting shafts at a specific angle, typically 90 degrees. These gears feature straight teeth, which are cut along the surface of a cone, allowing for smooth engagement and power transfer. The 1.5:1 gear ratio means that for every 1.5 revolutions of the driving gear (input gear), the driven gear (output gear) completes one full revolution. This setup is ideal for applications requiring moderate speed reduction or torque increase.

Made from durable steel, these steel bevel gears can handle high loads and operate efficiently in demanding environments, such as machinery, automotive systems, and industrial equipment. Their simple design ensures easier manufacturing and maintenance compared to helical or spiral bevel gears.

Steel Straight Bevel Gear Ratio 1.5:1

|  |

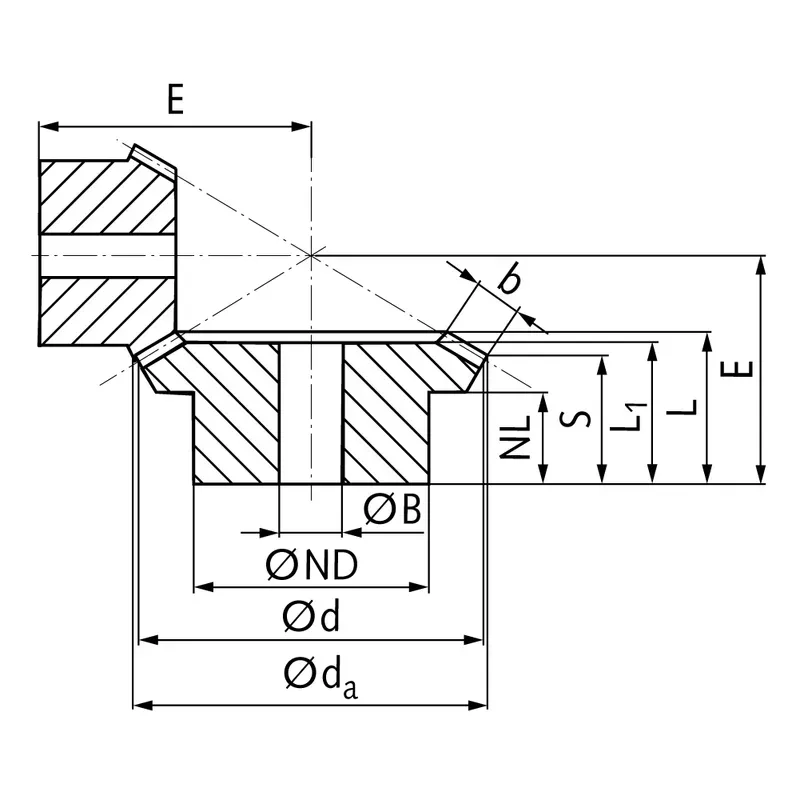

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 20 | 11,0 | 10 | 8 | 3,5 | 6,5 | 7,1 | 4,7 | 3 | 4 | 11,9 | 0,014 | 2 |

| 0,5 | 30 | 15,4 | 15 | 10 | 4,0 | 6,0 | 7,0 | 5,4 | 3 | 4 | 10,1 | 0,021 | 4 |

| 1 | 16 | 18,1 | 16 | 13 | 6,9 | 11 | 12,0 | 8,7 | 4,3 | 5 | 20 | 0,066 | 10 |

| 1 | 24 | 24,8 | 24 | 20 | 8,8 | 13 | 14,8 | 12,6 | 4,3 | 5 | 20 | 0,099 | 32 |

| 1,5 | 16 | 27,1 | 24 | 20 | 8,7 | 14 | 16,1 | 11,0 | 6,5 | 8 | 28 | 0,023 | 34 |

| 1,5 | 24 | 37,2 | 36 | 20 | 12,0 | 17 | 20,2 | 16,9 | 6,5 | 10 | 28 | 0,035 | 55 |

| 1,5 | 20 | 33,1 | 30 | 20 | 9,0 | 17 | 18,9 | 12,5 | 8,1 | 8 | 34 | 0,43 | 52 |

| 1,5 | 30 | 46,2 | 45 | 30 | 12,0 | 20 | 22,1 | 17,9 | 8,1 | 10 | 32 | 0,65 | 133 |

| 2 | 16 | 35,5 | 32 | 20 | 8,0 | 21 | 22,6 | 13,1 | 12 | 10 | 36 | 0,57 | 60 |

| 2 | 24 | 50,3 | 48 | 30 | 8,0 | 18 | 21,5 | 15,7 | 12 | 10 | 30 | 0,86 | 151 |

| 2 | 20 | 43,5 | 40 | 30 | 7,5 | 20 | 22,3 | 11,2 | 14 | 10 | 40 | 1,15 | 119 |

| 2 | 30 | 62,3 | 60 | 40 | 15,0 | 25 | 28,7 | 21,7 | 14 | 15 | 40 | 1,73 | 301 |

| 2,5 | 16 | 44,3 | 40 | 30 | 11,7 | 26 | 28,2 | 16,4 | 14 | 10 | 45 | 3,3 | 150 |

| 2,5 | 24 | 62,9 | 60 | 30 | 12,0 | 26 | 29,4 | 22,1 | 14 | 10 | 40 | 5,0 | 300 |

| 2,5 | 20 | 54,3 | 50 | 30 | 10,0 | 27 | 30,2 | 16,0 | 18 | 10 | 52 | 6,8 | 230 |

| 2,5 | 30 | 77,9 | 75 | 50 | 14,0 | 27 | 31,1 | 22,2 | 18 | 15 | 45 | 10,2 | 550 |

| 3 | 16 | 53,2 | 48 | 40 | 13,2 | 30 | 32,7 | 17,7 | 19 | 15 | 52 | 5,9 | 250 |

| 3 | 24 | 75,5 | 72 | 50 | 8,0 | 24 | 27,8 | 18,6 | 19 | 15 | 40 | 8,9 | 490 |

| 3 | 20 | 65,2 | 60 | 40 | 10,0 | 33 | 35,8 | 16,8 | 24 | 15 | 60 | 12,4 | 390 |

| 3 | 30 | 93,5 | 90 | 50 | 15,0 | 33 | 37,6 | 25,7 | 24 | 20 | 53 | 18,6 | 860 |

| 4 | 16 | 71,0 | 64 | 50 | 12,5 | 36 | 38,9 | 19,3 | 25 | 20 | 65 | 14,3 | 500 |

| 4 | 24 | 100,7 | 96 | 60 | 12,0 | 31 | 35,6 | 23,5 | 25 | 20 | 52 | 21,5 | 1010 |

| 4 | 20 | 87,0 | 80 | 50 | 18,0 | 48 | 51,1 | 27,3 | 30 | 20 | 85 | 29,5 | 950 |

| 4 | 30 | 124,6 | 120 | 60 | 18,0 | 40 | 46,4 | 31,5 | 30 | 25 | 68 | 44,3 | 1900 |

| 5 | 20 | 108,7 | 100 | 60 | 12,0 | 50 | 54,7 | 22,9 | 40 | 25 | 95 | 60,6 | 1630 |

| 5 | 30 | 155,8 | 150 | 70 | 12,0 | 40 | 46,3 | 26,4 | 40 | 30 | 72 | 90,9 | 3070 |

Steel Straight Bevel Gear Benefits

- High Strength and Durability

Steel straight bevel gears are made from robust steel, which provides excellent strength and durability. This ensures they can handle heavy loads, resist wear, and maintain performance even under extreme conditions, such as high torque and temperature variations. - Efficient Power Transmission

The straight tooth design allows for efficient and straightforward power transmission between shafts at intersecting angles, typically 90 degrees. This efficiency minimizes energy losses, making them ideal for applications requiring consistent and reliable mechanical performance. - Cost-Effective Manufacturing

Due to their simple geometry, straight bevel gears are easier and less expensive to manufacture compared to alternatives like spiral bevel gears. This makes them a cost-effective choice for industries seeking high efficiency without overly complex designs. - Low Maintenance Requirements

The straightforward design of steel bevel gears makes them easy to inspect, clean, and maintain. This reduces downtime and maintenance costs, benefiting industries where operational efficiency and reliability are critical for long-term performance. - Versatility in Applications

Steel bevel gears are versatile and can be used in various industries, including automotive, industrial machinery, and aerospace. Their ability to transmit motion and torque reliably in intersecting shaft systems makes them suitable for diverse mechanical setups. - Precise Motion Control

The straight tooth configuration ensures smooth engagement and precise motion control. This is particularly beneficial in applications requiring accurate and predictable movement, such as robotics, gearboxes, and other precision-based mechanical systems.

Steel Straight Bevel Gear Uses

- Automotive Industry

Steel straight bevel gears are heavily used in the automotive sector for components like differential systems and transmissions. Their ability to transfer power efficiently between intersecting shafts ensures smooth torque delivery, critical for vehicle performance and fuel efficiency. - Industrial Machinery

In industrial machinery, these gears are employed to drive conveyor systems, pumps, and heavy-duty equipment. Their robust design and ability to handle high loads make them indispensable in manufacturing plants, mining operations, and other heavy industrial environments. - Aerospace Industry

The aerospace sector relies on steel bevel gears in systems such as landing gear mechanisms and flight control systems. Their precision, durability, and ability to handle high stress are critical for ensuring safety and reliability in aviation applications. - Agricultural Equipment

Agricultural machinery, such as tractors, harvesters, and plows, frequently utilizes straight bevel gears. Their strength and efficiency are ideal for transmitting power in rugged environments, ensuring the reliability and productivity of equipment used in farming operations. - Marine and Offshore Equipment

Steel bevel gears are used in marine applications like ship steering systems, propulsion units, and winches. Their corrosion-resistant properties and capability to handle heavy loads make them suitable for harsh offshore environments and demanding maritime operations. - Robotics and Automation

In robotics and automated systems, straight bevel gears are used for precise motion control and power transmission. Their accuracy and reliability are crucial in applications like robotic arms, automated assembly lines, and precision machinery in advanced manufacturing.

|  |

| Bevel Gear for Automotive Differentials | Bevel Gear for Robotics |

|  |

| Bevel Gear for Agricultural Machinery | Bevel Gear for Marine Industry |

Different Types of Bevel Gears

Straight Bevel Gears

Straight bevel gears are the simplest type of bevel gears, featuring straight teeth that are parallel to the generatrix of the pitch cone. They are used in applications where high speeds and low to medium loads are present. However, straight bevel gears may generate more noise compared to other types of bevel gears due to the sudden engagement of the teeth.

Spiral Bevel Gears

Spiral bevel gears have curved teeth that are oblique to the generatrix of the pitch cone. The spiral angle of the teeth provides a gradual and smooth engagement, resulting in quieter operation and higher load capacity compared to straight bevel gears. Spiral bevel gears are commonly used in automotive differentials and industrial applications that require high speeds and heavy loads.

Hypoid Bevel Gears

Hypoid bevel gears are similar to spiral bevel gears but with a notable difference: the pitch cones of the gears do not intersect. Instead, the axes of the gears are offset, allowing for larger pinion diameters and improved tooth contact. This offset configuration provides several advantages, such as higher torque capacity, reduced noise, and more compact designs. Hypoid gears are frequently used in automotive rear axles and industrial gearboxes.

Zerol Bevel Gears

Zerol bevel gears are a special case of spiral bevel gears, where the spiral angle is zero. This means that the teeth are parallel to the axis of rotation, similar to straight bevel gears. However, unlike straight bevel gears, Zerol bevel gears have a curved tooth profile that allows for smooth and gradual engagement. Zerol bevel gears offer a balance between the benefits of straight and spiral bevel gears, providing improved load capacity and quieter operation compared to straight bevel gears.

Miter Bevel Gears

Miter bevel gears are a specific type of bevel gear where the number of teeth on both gears is equal, and the shaft angle is 90°. This configuration results in a 1:1 gear ratio, making miter gears ideal for applications that require a change in the direction of rotation without altering the speed or torque. Miter gears can have straight, spiral, or Zerol teeth.

|  |

| Hypoid Bevel Gears | Miter Bevel Gears |

Additional information

| Edited by | Yjx |

|---|