Steel Miter Bevel Gears Ratio 1:1 Straight Tooth System

Steel miter bevel gears with a 1:1 ratio and straight tooth system are a specialized type of bevel gear designed to transmit rotational motion between two intersecting shafts, typically at a 90-degree angle, without altering speed or torque. The 1:1 ratio indicates that both gears have an equal number of teeth, ensuring identical rotational speeds for the input and output shafts. The straight tooth design, characterized by teeth cut parallel to the gear’s cone generators, resembles a conical spur gear and is simpler to manufacture than spiral or zerol bevel gears.

Steel miter bevel gears with a 1:1 ratio and straight tooth system are a specialized type of bevel gear designed to transmit rotational motion between two intersecting shafts, typically at a 90-degree angle, without altering speed or torque. The 1:1 ratio indicates that both gears have an equal number of teeth, ensuring identical rotational speeds for the input and output shafts. The straight tooth design, characterized by teeth cut parallel to the gear’s cone generators, resembles a conical spur gear and is simpler to manufacture than spiral or zerol bevel gears.

However, this design results in abrupt tooth engagement, leading to higher noise and stress, limiting their use to lower-speed applications (typically under 1000 feet/min or 1000 rpm for small gears). Made from steel (e.g., C45 or stainless steel), these gears offer durability and strength, suitable for applications like robotics, conveyor systems, and printing presses, where precise directional changes are needed. Their octoidal tooth profile ensures proper meshing, and they are often produced as matched pairs to maintain alignment and efficiency.

Steel Miter Bevel Gear Ratio 1:1

|  |

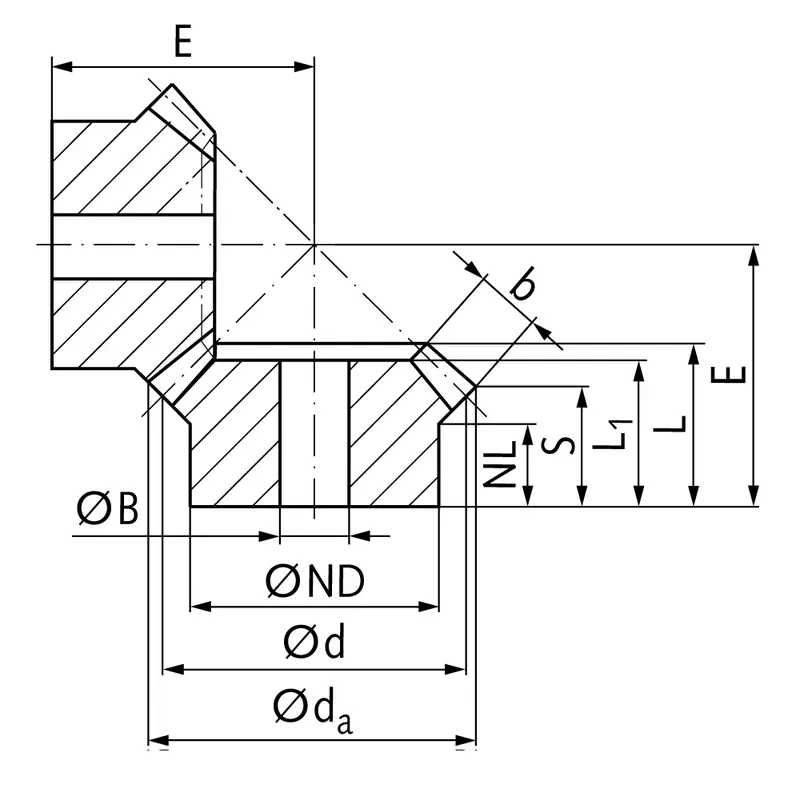

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 20 | 10,7 | 10 | 8 | 4 | 7,0 | 7,0 | 5,0 | 3 | 4 | 9,7 | 0,011 | 1 |

| 0,5 | 24 | 12,7 | 12 | 8 | 4 | 6,4 | 7,0 | 5,0 | 3 | 4 | 10,7 | 0,018 | 3 |

| 0,5 | 30 | 15,7 | 15 | 10 | 4 | 7,5 | 8,5 | 6,6 | 3 | 4 | 13,7 | 0,032 | 4 |

| 0,5 | 36 | 18,7 | 18 | 12 | 5 | 9,0 | 10,1 | 8,0 | 3 | 4 | 16,7 | 0,050 | 10 |

| 0,5 | 40 | 20,7 | 20 | 12 | 5 | 8,5 | 9,5 | 7,5 | 3 | 4 | 17,1 | 0,064 | 10 |

| 0,5 | 50 | 25,7 | 25 | 14 | 5 | 8,5 | 9,5 | 7,5 | 3 | 4 | 19,6 | 0,108 | 16 |

| 1 | 12 | 13,0 | 12 | 10 | 6,2 | 7,95 | 9,6 | 7,7 | 3 | 5 | 13,2 | 0,035 | 3 |

| 1 | 16 | 17,4 | 16 | 14 | 7 | 10 | 11,2 | 8,7 | 4 | 5 | 16 | 0,052 | 9 |

| 1 | 19 | 20,4 | 19 | 15 | 6,5 | 10 | 11,8 | 9,2 | 4 | 5 | 18 | 0,085 | 14 |

| 1 | 20 | 21,4 | 20 | 16 | 6,1 | 10 | 11,4 | 8,8 | 4 | 5 | 18,1 | 0,138 | 15 |

| 1 | 22 | 23,4 | 22 | 18 | 7 | 11 | 12,8 | 9,7 | 4,7 | 5 | 20 | 0,158 | 22 |

| 1 | 26 | 27,4 | 26 | 22 | 7 | 12 | 13,4 | 9,7 | 5,5 | 5 | 22 | 0,193 | 35 |

| 1 | 30 | 31,4 | 30 | 22 | 7 | 14 | 16,0 | 11,7 | 6,4 | 5 | 26 | 0,29 | 50 |

| 1 | 40 | 41,4 | 40 | 30 | 10 | 18 | 19,8 | 15,7 | 6,0 | 8 | 35 | 0,55 | 111 |

| 1,5 | 16 | 26,1 | 24 | 20 | 11 | 15 | 17,3 | 14,1 | 5,1 | 8 | 25 | 0,18 | 32 |

| 1,5 | 20 | 32,1 | 30 | 22 | 9 | 15 | 17,2 | 13,1 | 6,4 | 8 | 27 | 0,34 | 47 |

| 1,5 | 22 | 35,1 | 33 | 20 | 8 | 15 | 17,1 | 12,6 | 7,0 | 8 | 28 | 0,44 | 50 |

| 1,5 | 25 | 39,6 | 37,5 | 25 | 8 | 15 | 17,6 | 12,3 | 8,0 | 10 | 30 | 0,62 | 70 |

| 1,5 | 30 | 47,1 | 45 | 30 | 12 | 20 | 21,9 | 15,6 | 9,6 | 10 | 37 | 1,01 | 135 |

| 1,5 | 40 | 62,1 | 60 | 40 | 12 | 25 | 27,7 | 19,1 | 12,7 | 15 | 48 | 2,46 | 310 |

| 2 | 16 | 34,8 | 32 | 25 | 11,5 | 18 | 20,7 | 16,4 | 6,8 | 10 | 31 | 0,45 | 66 |

| 2 | 20 | 42,8 | 40 | 30 | 10 | 17 | 19,9 | 14,4 | 8,5 | 10 | 33 | 0,84 | 104 |

| 2 | 22 | 46,8 | 44 | 30 | 10 | 19 | 21,0 | 15,4 | 9,3 | 10 | 36 | 1,08 | 130 |

| 2 | 25 | 52,8 | 50 | 35 | 8 | 19 | 21,4 | 14,4 | 10,6 | 10 | 38 | 1,50 | 182 |

| 2 | 30 | 62,8 | 60 | 40 | 12 | 25 | 26,9 | 18,4 | 12,7 | 15 | 47 | 2,45 | 306 |

| 2 | 40 | 82,8 | 80 | 50 | 15 | 31 | 33,7 | 23,4 | 15,2 | 20 | 62 | 16,3 | 660 |

| 2,5 | 16 | 43,7 | 40 | 30 | 10 | 21 | 23,8 | 16,8 | 11 | 10 | 35 | 2,6 | 120 |

| 2,5 | 18 | 48,7 | 45 | 30 | 10 | 22 | 25,0 | 17,4 | 12 | 10 | 38 | 3,6 | 150 |

| 2,5 | 20 | 53,7 | 50 | 35 | 10 | 22 | 25,9 | 16,9 | 14 | 10 | 40 | 4,9 | 210 |

| 2,5 | 22 | 58,7 | 55 | 30 | 10 | 24 | 27,1 | 17,3 | 15 | 10 | 43 | 6,3 | 240 |

| 2,5 | 25 | 66,2 | 62,5 | 45 | 10 | 25 | 28,8 | 17,6 | 17 | 15 | 47 | 9,3 | 370 |

| 2,5 | 30 | 78,7 | 75 | 50 | 12 | 29 | 32,7 | 19,3 | 20 | 15 | 55 | 16,3 | 560 |

| 2,5 | 40 | 103,6 | 100 | 60 | 14 | 31 | 35,4 | 21,8 | 20 | 25 | 70 | 33,6 | 1100 |

| 3 | 16 | 52,4 | 48 | 40 | 12 | 24 | 27,7 | 18,2 | 15 | 10 | 40 | 4,6 | 240 |

| 3 | 18 | 58,4 | 54 | 40 | 10 | 25 | 28,1 | 17,2 | 17 | 10 | 42 | 6,4 | 280 |

| 3 | 20 | 64,4 | 60 | 40 | 10 | 26 | 29,5 | 17,2 | 19 | 15 | 45 | 8,7 | 320 |

| 3 | 22 | 70,4 | 66 | 40 | 8 | 27 | 30,2 | 17,2 | 20 | 15 | 48 | 11,6 | 410 |

| 3 | 25 | 79,4 | 75 | 50 | 10 | 28 | 31,9 | 16,7 | 23 | 15 | 52 | 17,3 | 490 |

| 3 | 30 | 94,4 | 90 | 50 | 12 | 35 | 38,8 | 22,2 | 25 | 20 | 65 | 29,2 | 950 |

| 3 | 40 | 124,4 | 120 | 60 | 15 | 35 | 39,1 | 22,2 | 25 | 25 | 80 | 60,7 | 1600 |

| 4 | 16 | 70,0 | 64 | 50 | 11 | 29 | 32,9 | 21,0 | 19 | 20 | 50 | 11,1 | 420 |

| 4 | 18 | 78,0 | 72 | 50 | 16 | 36 | 41,0 | 27,0 | 22 | 20 | 60 | 15,6 | 640 |

| 4 | 20 | 85,9 | 80 | 50 | 16 | 39 | 43,5 | 28,0 | 24 | 20 | 65 | 20,8 | 810 |

| 4 | 22 | 93,9 | 88 | 50 | 12 | 37 | 40,9 | 24,0 | 26 | 20 | 65 | 27,9 | 940 |

| 4 | 25 | 105,9 | 100 | 60 | 12 | 38 | 42,7 | 23,0 | 30 | 20 | 70 | 41,9 | 1400 |

| 4 | 30 | 125,9 | 120 | 60 | 18 | 42 | 47,9 | 27,9 | 30 | 25 | 85 | 67,5 | 2000 |

| 4 | 40 | 165,8 | 160 | 80 | 20 | 48 | 53,2 | 32,9 | 30 | 30 | 110 | 138,0 | 4200 |

| 5 | 16 | 87,4 | 80 | 60 | 12 | 36 | 41,5 | 25,7 | 25 | 20 | 62 | 22,2 | 860 |

| 5 | 18 | 97,4 | 90 | 60 | 12 | 37 | 42,2 | 23,7 | 29 | 20 | 65 | 30,7 | 1050 |

| 5 | 20 | 107,4 | 100 | 60 | 12 | 39 | 44,4 | 23,7 | 32 | 25 | 70 | 42,7 | 1300 |

| 5 | 22 | 117,5 | 110 | 70 | 12 | 43 | 48,5 | 25,7 | 35 | 25 | 77 | 57,5 | 1840 |

| 5 | 25 | 132,4 | 125 | 70 | 12 | 42 | 47,5 | 21,2 | 40 | 30 | 80 | 85,8 | 2140 |

| 5 | 30 | 157,4 | 150 | 70 | 12 | 44 | 51,3 | 24,7 | 40 | 30 | 96 | 139,5 | 3520 |

| 5 | 40 | 207,3 | 200 | 90 | 20 | 52 | 60 | 32,9 | 40 | 35 | 128,1 | 288,0 | 7060 |

| 6 | 18 | 116,5 | 108 | 60 | 15 | 44 | 53,6 | 31,3 | 35 | 25 | 81,0 | 54,8 | 1770 |

| 6 | 20 | 128,5 | 120 | 70 | 15 | 44 | 53,5 | 27,8 | 40 | 30 | 83,4 | 76,3 | 2190 |

| 6 | 25 | 158,5 | 150 | 75 | 15 | 51 | 60 | 26,7 | 50 | 30 | 97,3 | 153,4 | 3790 |

| 6 | 30 | 188,5 | 180 | 90 | 15 | 51 | 60 | 26,4 | 50 | 35 | 112,1 | 250,6 | 5810 |

| 6 | 40 | 248,5 | 240 | 100 | 20 | 58 | 67 | 32,9 | 50 | 40 | 148,6 | 555,0 | 11600 |

| 8 | 20 | 171,3 | 160 | 90 | 15 | 52 | 62 | 29,20 | 50 | 40 | 103,3 | 181,6 | 4560 |

Different Types of Bevel Gears

Straight Bevel Gears

Straight bevel gears are the simplest type of bevel gears, featuring straight teeth that are parallel to the generatrix of the pitch cone. They are used in applications where high speeds and low to medium loads are present. However, straight bevel gears may generate more noise compared to other types of bevel gears due to the sudden engagement of the teeth.

Spiral Bevel Gears

Spiral bevel gears have curved teeth that are oblique to the generatrix of the pitch cone. The spiral angle of the teeth provides a gradual and smooth engagement, resulting in quieter operation and higher load capacity compared to straight bevel gears. Spiral bevel gears are commonly used in automotive differentials and industrial applications that require high speeds and heavy loads.

Hypoid Bevel Gears

Hypoid bevel gears are similar to spiral bevel gears but with a notable difference: the pitch cones of the gears do not intersect. Instead, the axes of the gears are offset, allowing for larger pinion diameters and improved tooth contact. This offset configuration provides several advantages, such as higher torque capacity, reduced noise, and more compact designs. Hypoid gears are frequently used in automotive rear axles and industrial gearboxes.

Zerol Bevel Gears

Zerol bevel gears are a special case of spiral bevel gears, where the spiral angle is zero. This means that the teeth are parallel to the axis of rotation, similar to straight bevel gears. However, unlike straight bevel gears, Zerol bevel gears have a curved tooth profile that allows for smooth and gradual engagement. Zerol bevel gears offer a balance between the benefits of straight and spiral bevel gears, providing improved load capacity and quieter operation compared to straight bevel gears.

Miter Gears

Miter gears are a specific type of bevel gear where the number of teeth on both gears is equal, and the shaft angle is 90°. This configuration results in a 1:1 gear ratio, making miter gears ideal for applications that require a change in the direction of rotation without altering the speed or torque. Miter gears can have straight, spiral, or Zerol teeth.

|  |

| Straight Bevel Gears | Spiral Bevel Gears |

|  |

| Zerol Bevel Gears | Hypoid Bevel Gears |

Steel Miter Bevel Gear Design Features

- 1:1 Gear Ratio

The steel miter bevel gears are specifically designed with a 1:1 gear ratio. This ensures that the input and output shafts rotate at the same speed, making them ideal for applications requiring equal torque and consistent angular velocity transmission. - Straight Tooth Configuration

These gears feature straight, radially aligned teeth that allow smooth engagement and efficient power transfer. The simplicity of the straight tooth design reduces manufacturing complexity while providing reliable performance in applications with moderate speed and load requirements. - Durable Steel Construction

Made from high-strength steel, these gears are designed to withstand heavy loads, high torque, and wear over time. The material's durability and resistance to deformation ensure long operational life even in demanding industrial or mechanical environments. - 90-Degree Shaft Orientation

Steel miter bevel gears are engineered to transmit motion between intersecting shafts at a 90-degree angle. This specific design feature enables compact mechanical setups and efficient power transfer in systems where angular motion is required. - Compact and Lightweight Design

Despite their robust construction, the gears are designed to be compact and lightweight, making them suitable for space-constrained applications. This feature enhances their versatility, allowing them to fit seamlessly into both large industrial machines and smaller devices. - Precision Machining for Accuracy

The design incorporates precision machining to achieve high accuracy in tooth alignment and surface finish. This ensures minimal backlash, smooth operation, and consistent power transmission, which is critical for applications requiring precise motion control and reliability.

Steel Miter Bevel Gear Applications

- Industrial Machinery

Steel miter bevel gears are used in industrial machines such as conveyors, mixers, and printing presses. They efficiently transmit power at right angles, ensuring smooth operation in applications requiring constant speed and torque consistency in compact mechanical layouts. - Automotive Systems

These gears are essential in automotive differentials, enabling wheels to rotate at different speeds during cornering. Their ability to handle high torque and operate at 90-degree angles makes them a key component in drivetrain systems for improved vehicle handling and performance. - Robotics and Automation

In robotics, steel miter bevel gears provide precise motion transfer between axes, crucial for robotic arms and automated systems. Their high durability and accuracy help maintain consistent functionality in repetitive operations, even under heavy loads or continuous use. - Aerospace Engineering

Aerospace systems use steel miter bevel gears in control mechanisms, landing gear systems, and actuators. Their reliability and ability to function in extreme conditions make them ideal for transmitting power in critical systems where performance and safety are paramount. - Marine Equipment

In marine applications, these gears are found in steering mechanisms, winches, and propulsion systems. Their corrosion-resistant steel construction ensures longevity in harsh environments while maintaining precise power transmission between intersecting shafts under heavy loads. - Power Tools and Equipment

Steel miter bevel gears are integral to power tools like drills, grinders, and saws, where angular motion transfer is needed. Their compact size, strength, and efficiency allow power tools to operate reliably, even under high-speed or high-torque conditions.

|  |

| Bevel Gear for Automotive Industry | Bevel Gear for Marine Industry |

|  |

| Bevel Gear for Aerospace Industry | Bevel Gear for Robotics Industry |

Additional information

| Edited by | Yjx |

|---|